You still Can't Beat The System when it's all Frick India

You still Can't Beat The System when it's all Frick India

You still Can't Beat The System when it's all Frick India

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

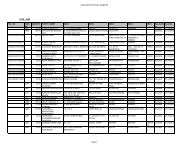

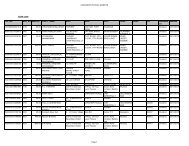

SHA Series Frigid Coil for Moderate Temperature Applications (R-717)<br />

Sl. ACU Model FPI Capacity Total CFM Fan No. of Dimensions Weight<br />

No. Capacity Size Fans<br />

BTU/Hr/DegF/TD AT 10 DEG F L x W x H (mm) (Kgs.)<br />

1 SHA-120808-2 4 8300 8.3 11200 24”X1HP 2 2909 x 1012 x 1002 550<br />

2 SHA-120810-2 4 10300 10.3 13500 24”X1.5HP 2 3510 x 1012 x 1002 630<br />

3 SHA-140812-3 4 14400 14.4 18800 24”X1.5HP 3 4110 x 1012 x 1117 960<br />

4 SHA-160816-4 4 20200 20.2 27200 24”X1.5HP 4 5310 x 1012 x 1232 1275<br />

SFA Series Frigid Coil for Low Temperature Applications (R-717)<br />

Sl. ACU Model FPI Capacity Total CFM Fan No. of Dimensions Weight<br />

No. Capacity Size Fans<br />

BTU/Hr/DegF/TD AT 10 DEG F L x W x H (mm) (Kgs.)<br />

1 SFA-120608-2 3 6840 5.7 13000 24”X1.5HP 2 2909 x 910 x 1002 450<br />

2 SFA-120610-3 3 9960 8.3 19500 24”X1.5HP 3 3510x 910 x 1002 550<br />

3 SFA-160610-2 3 11670 9.8 24000 30”X2HP 2 3510 x 910 x 1232 625<br />

4 SFA-160810-2 3 14040 11.7 23600 30”X2HP 2 3510 x 1012 x 1232 790<br />

SFA Series Frigid Coil for Blast freezer Applications (R-717)<br />

Sl. ACU Model FPI Capacity Total CFM Fan No. of Dimensions Weight<br />

No. Capacity Size Fans<br />

BTU/Hr/DegF/TD AT 10 DEG F L x W x H (mm) (Kgs.)<br />

1 SFA-180810-2 3 16920 14.1 25000 30”X3HP 2 3510 X 1012 X 1347 940<br />

2 SFA-180812-3 3 22800 19.0 37500 30”X3HP 3 4110 X 1012 X 1347 1175<br />

3 SFA-180816-4 3 30000 25.0 50000 30”X3HP 4 5310 X 1012 X 1347 1560<br />

4 SFA-200816-4 3 32640 27.2 50000 30”X3HP 4 5310 X 1012 X 1462 1635<br />

STR Series Frigid Coil for Moderate Temperature Applications (R-717)<br />

Sl. ACU Model No. of Total Air Flow W (HP) Capacity Dimensions Weight<br />

No. Fans Cu.M/Hr. Per Fan BTU/Hr/DegF/TD L x W x H (mm) (Kgs.)<br />

1 STR-36 3 20390 370 (0.5) 6600 3200x990x1400 400<br />

2 STR-66 6 40780 370 (0.5) 13300 5640x990x1400 750<br />

We can customize the coils as per your size & Capacity requirements.<br />

All Specifications are subject to change without prior notice.<br />

<strong>The</strong> coil is made of 7/8” OD seamless Steel Tubes and Aluminum Fins. Ratings for other gases please contact Factory.<br />

SHA Series Frigid Coil SFA Series Frigid Coil<br />

SFA Series Frigid CoilS for Blast STR Series Frigid Coil<br />

<strong>You</strong> <strong>still</strong> Can’t <strong>Beat</strong> <strong>The</strong> <strong>System</strong> <strong>when</strong> it’s <strong>all</strong> <strong>Frick</strong> <strong>India</strong><br />

FACTORY :<br />

21.5 KM, Main Mathura Road,<br />

Faridabad - 121003<br />

Ph. 0129 -2275691/94, 2270546/47<br />

Fax- 0129-2275695<br />

email: fbd@frick.co.in<br />

Customer Care Numbers :<br />

0129 – 2254103 / 104<br />

Website :<br />

www.frickweb.com<br />

Branch offices:<br />

T-1, Swastik Manandi Arcade 401/2,<br />

Sheshadri Puram,<br />

Bangalore - 560 020<br />

Ph : 22196021, 23469693 Fax :<br />

23469693 email : bng@frick.co.in<br />

243, Anna Salai, Post Box. No. 1077,<br />

Chennai - 600 006<br />

Ph : 28524010, 28524003<br />

Fax : 28524003<br />

email : mad@frick.co.in<br />

41/3273-D, Golden Castle Bldg.,Old<br />

Railway Rd., Cochin - 682018.<br />

Ph : 2394173<br />

email : cochin@frick.co.in<br />

809, Surya Kiran, 19 K. G. Marg,<br />

New Delhi 110 001.<br />

Ph : 23322381/384/391<br />

Fax : 23322396.<br />

email: delhi@frick.co.in<br />

Poonam Building, 5/2 Russel Street,<br />

Kolkata - 700 071. Ph : 22261179,<br />

22267834 Fax : 22266231<br />

Email : cal@frick.co.in<br />

Ion House, 3rd Floor, Dr. E. Mosses<br />

Road, Mumbai - 400 011. Ph :<br />

24924687 Fax : 24935552<br />

email : bom@frick.co.in<br />

807, Jagat Trade Centre, Krishna<br />

Bhawan Compound, Frazer Road,<br />

Patna -800001 Ph : 09431477402<br />

email : patna@frickmail.com<br />

608,VI Floor, Swapnalok, 92/93, S.D.<br />

Road, Secunderabad -500 003 Ph :<br />

27813044, 27813897 Fax : 27813897<br />

email : hyd@frick.co.in<br />

401, 4th Floor, Eswar Homes, 1st Lane,<br />

Dwarka Nagar, Vizag-530016.<br />

Ph: 2553232 email: vizag@frick.co.in<br />

COMPACT<br />

HYGIENIC<br />

RELIABLE<br />

ENERGY SAVING<br />

LIGHT WEIGHT<br />

FISFC-03/0612

Introduction<br />

<strong>Frick</strong> <strong>India</strong> Limited, established in 1962, has an<br />

extensive experience in cold and chilled storage, blast<br />

freezer and <strong>all</strong> aspects of heat transfer technology in<br />

food processing. Now the company is offering the<br />

coils manufactured with latest technology for <strong>all</strong> your<br />

storage and food processing requirements. <strong>The</strong><br />

company pioneered the use of plate fin hot dip<br />

galvanized coils as well as “S Series” coils having<br />

Stainless Steel Tubes and Aluminum Fins.<br />

Applications<br />

�Chilled<br />

Warehouse<br />

�Chillers<br />

�Deep<br />

/ blast freezers<br />

�Pre<br />

Coolers<br />

�High<br />

humidity cold storage<br />

�Ante<br />

rooms<br />

�Processing<br />

H<strong>all</strong>s.<br />

Standard Air cooling Units<br />

<strong>Frick</strong> <strong>India</strong> energy saving air-cooling units are available in<br />

various capacities ranging from 5400 CFM to 50000 CFM.<br />

Coil capacity is based on sensible heat removal, medium<br />

frosted coil condition. Temperature difference is the<br />

temperature of the air entering the coil and the coil<br />

evaporating temperature.<br />

Importance of Fins<br />

6 & 4 FPI is margin<strong>all</strong>y more efficient and cost effective. 4 FPI<br />

is acceptable where moisture load is moderate.<br />

2/3 Fins offers not only wider fin spacing but also greater frost<br />

carrying capacity in the form of enhanced secondary surface<br />

area. This combination offers the best option where low<br />

temperature and heavy moisture loads are anticipated.<br />

FANS<br />

�<strong>Frick</strong><br />

<strong>India</strong> “S Series” used<br />

Marathon USA designed<br />

Axial Flow fans.<br />

STANDARD FEATURES<br />

�Axial<br />

Flow Fans are made up<br />

of heavy duty cast aluminum<br />

with adjustable blades.<br />

�<strong>The</strong>se<br />

dynamic<strong>all</strong>y balanced Aerofoil design fans are<br />

selected for maximum performance to match exact<br />

pressure requirements.<br />

�<strong>The</strong>se<br />

fans have a huge range and can be selected for any<br />

type of static, noise, airflow and Horsepower.<br />

�<br />

�<br />

WATER DEFROST<br />

A Spray tray with full coverage nonclogging<br />

perforations and an<br />

oversized drain pan connection are<br />

provided. Spray tray and<br />

perforations are easily accessible.<br />

HOT GAS DEFROST<br />

A multi-circulated pan coil is welded to the inner pan. <strong>The</strong><br />

coil design reduces pressure drop, increases hot gas flow<br />

and shortens over<strong>all</strong> defrost times.<br />

INSULATED DRAIN PAN(Optional)<br />

<strong>The</strong>rmal Insulated Drain pan is placed between the inner<br />

drain pan and outer cover. Both the inner drain pan and<br />

outer cover are fabricated from galvanized sheet.<br />

Importance & Selection of Fin Spacing<br />

6 Fins per Inch Coils are the best for processing rooms/<br />

packing rooms. <strong>The</strong>se coils gives more airflow with low<br />

pressure drop.<br />

4 Fins per Inch coils are the best option because this spacing<br />

permits air passage with moderate frost. <strong>The</strong>se coils are widely<br />

O<br />

used for cold storage having O C temperature and above.<br />

4/3 Fins per Inch(Variable Fins) coils are best suitable for cold<br />

storage applications which reduces the frosting of coils.<br />

3 Fins per Inch coils are used for low temperature storage<br />

where moisture loads are high or where defrosting is<br />

necessary.<br />

1<br />

3/2 / 2 Fins per Inch (Variable Fins) coils<br />

temperature applications.<br />

Axial Flow fan with Adjustable Blade<br />

are used for low<br />

1<br />

2 / 2 Fins per Inch coils are used for low temperature where<br />

moisture load is heavy and defrosting is very frequent.<br />

Why Stainless Steel/ Aluminum<br />

Evaporators<br />

Today largely Stainless Steel air-cooling<br />

evaporators are used in Ammonia (R717)<br />

refrigeration systems.<br />

Stainless Steel / Aluminum - an ideal metal to be<br />

used in ammonia evaporators because of :<br />

�Low<br />

Cost<br />

�Light<br />

Weight<br />

�High<br />

<strong>The</strong>rmal Conductivity<br />

�Easy<br />

Cleanability<br />

�High<br />

Reliability<br />

�Resistance<br />

to Corrosion<br />

Advantages of “S Series” Frigid Coils<br />

�<strong>Frick</strong><br />

<strong>India</strong> Traditional Design always gives a generous<br />

surface area for equivalent capacity making the users<br />

plant more ENERGY EFFICIENT.<br />

�We<br />

are using State-of–the-Art software to design<br />

sizes and capacity.<br />

�Our<br />

coils will always give the buyer his “Money’s<br />

Worth”<br />

�<strong>The</strong><br />

surface area of <strong>Frick</strong> <strong>India</strong> Frigid Coils is 90% more<br />

than what HTRI recommends.<br />

�<strong>Frick</strong><br />

<strong>India</strong> can design inst<strong>all</strong> and manufacture the rest<br />

of the refrigeration equipment ensuring a matching<br />

design that is energy efficient, reliable and has a long<br />

life.<br />

Fin Press machine<br />

Features of “S Series” Frigid Coils<br />

�Constructed<br />

with seamless stainless steel tubes as per<br />

ASTM A213<br />

�Die-formed,<br />

Aluminum plate fins are a continuous design<br />

with a clean full collar to optimize performance,<br />

resistance to airflow and easy clean-ability.<br />

�Fin<br />

pattern is optimized to produce highly energy efficient<br />

operation.<br />

�<strong>The</strong><br />

7/8” diameter tubes keep the pressure drop to<br />

minimum and eliminates blockages. This increases the<br />

operating efficiency of the entire system.<br />

�<strong>The</strong><br />

coil is available with 2 ½ to 6 fins per inch<br />

�Coils<br />

are tested with 350 psig air pressure<br />

Arial View of New Coil Section<br />

Amada Turrent Punch Press<br />

�Each<br />

coil is circulated for the operating conditions to<br />

which it will be exposed. This assures proper gas velocities<br />

through the tubes and that refrigerant pressure drops will<br />

be kept to minimum.<br />

�All<br />

coils can be circulated for Liquid Circulation, Flooded<br />

system, Brine circulation & Chilled Water.