You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

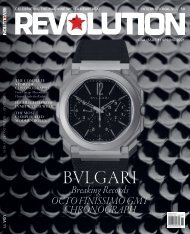

2014: OCTO FINISSIMO<br />

MECHANICAL HAND-WOUND<br />

Buonamassa, Bvlgari’s design director, explains, “The<br />

objective of thinness was not arrived at in isolation. After all,<br />

there are many brands that have been associated with ultrathin<br />

watches, especially in the 20th century. The objective<br />

was to enhance this dynamic tension, this unique proposition<br />

between having a watch that was, when viewed straight on,<br />

very muscular and even aggressive, yet when you turned it on<br />

its side, it was really surprising in how thin it was. I wanted, as<br />

Jean-Christophe expressed, to bring something to watches<br />

that the world had never seen in terms of this proposition.”<br />

But this objective of dynamic tension between bold and<br />

thin necessitated Bvlgari to push the technical envelope in<br />

every component of the Octo Finissimo. Says Babin, “The<br />

Octo Finissimo was only possible because we own our<br />

movement maker, dial maker, casemaker [and] bracelet<br />

maker, as it would be impossible to convince outside<br />

suppliers to make the effort we needed.”<br />

What kind of effort are we talking about? For example,<br />

the entire dial of the Octo Finissimo is 0.2mm (0.3mm if<br />

a coat of lacquer is applied) which makes it thinner than<br />

a single index on the majority of other watches. In order<br />

for this to be achieved, the indexes and even the “Bvlgari”<br />

signature have to be galvanically grown and transferred over<br />

to the dial, almost as if they were stickers. In the instance of<br />

the Octo Finissimo, it is just the seconds track in the subdial<br />

that is printed. The very first Octo Finissimo was a manual<br />

wind (now replaced by a micro-rotor, automatic-winding<br />

model) with a BVL 128 movement that was 2.23mm and a<br />

final watch that was 5.15mm in total thickness. In order to<br />

achieve this, even the way in which the watch was assembled<br />

had to be completely rethought.<br />

Says Buonamassa, “Of course we wanted a sapphire<br />

back to showcase the beauty of our in-house caliber with its<br />

beautiful ‘full bridge’ architecture. However, to conserve<br />

space, the sapphire back is integrated into the case, basically<br />

pre-fitted into the monobloc case. Next, the movement is<br />

placed into the case, [then] the dial and hands are added<br />

and finally the bezel and sapphire are placed on top. It is the<br />

bezel that seals the watch.” Each bezel features eight hollow<br />

threaded posts that are inserted through the case and fixed<br />

at the back of the watch with special fasteners that look like<br />

five-sided nuts. I particularly like that because they are not<br />

slotted, they are never out of alignment as you see on other<br />

watches that are fastened in the back in this way.<br />

Above, clockwise<br />

from left<br />

Antoine Pin,<br />

managing director<br />

of Bvlgari’s<br />

Watch Division.<br />

The dial of the Octo<br />

Finissimo measures<br />

a mere 0.2mm thin.<br />

Each dial is<br />

finished by hand.<br />

Opposite<br />

The escapement<br />

is supported with<br />

a balance bridge<br />

that’s screwed<br />

down on both<br />

sides, rather than a<br />

balance cock, which<br />

improves the ultrathin<br />

movement’s<br />

shock resistance.<br />

The barrel bridge<br />

doubles as a power<br />

reserve display.<br />

The Octo Finissimo<br />

Petite Seconds in<br />

rose gold, with hour<br />

markers that are<br />

galvanically grown<br />

and then transferred<br />

to the dial.<br />

30 COVER STORY