Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HOW LASER WELDING WORKS<br />

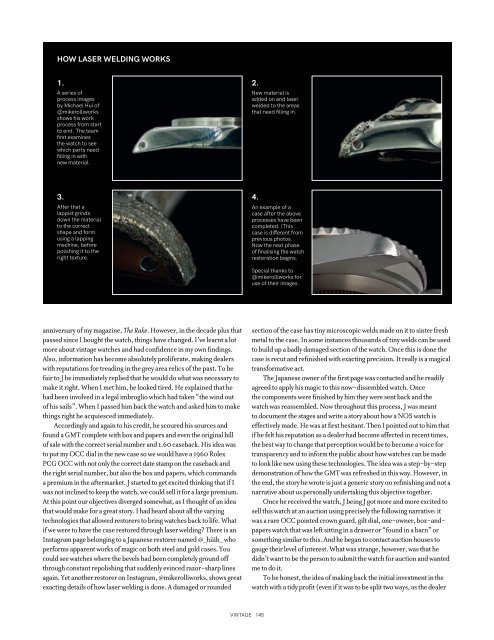

1.<br />

A series of<br />

process images<br />

by Michael Hui of<br />

@mikerolliworks<br />

shows his work<br />

process from start<br />

to end. The team<br />

first examines<br />

the watch to see<br />

which parts need<br />

filling in with<br />

new material.<br />

2.<br />

New material is<br />

added on and laser<br />

welded to the areas<br />

that need filling in.<br />

3.<br />

Afterthata<br />

lappist grinds<br />

down the material<br />

to the correct<br />

shape and form<br />

using a lapping<br />

machine, before<br />

polishing it to the<br />

right texture.<br />

4.<br />

An example of a<br />

case after the above<br />

processes have been<br />

completed. (This<br />

case is different from<br />

previous photos.<br />

Now the next phase<br />

of finalising the watch<br />

restoration begins.<br />

Special thanks to<br />

@mikerolliworks for<br />

useoftheirimages.<br />

anniversary of my magazine, The Rake. However, in the decade plus that<br />

passed since I bought the watch, things have changed. I’ve learnt a lot<br />

more about vintage watches and had confidence in my own findings.<br />

Also, information has become absolutely proliferate, making dealers<br />

with reputations for treading in the grey area relics of the past. To be<br />

fair to J he immediately replied that he would do what was necessary to<br />

make it right. When I met him, he looked tired. He explained that he<br />

had been involved in a legal imbroglio which had taken “the wind out<br />

of his sails”. When I passed him back the watch and asked him to make<br />

things right he acquiesced immediately.<br />

Accordingly and again to his credit, he scoured his sources and<br />

found a GMT complete with box and papers and even the original bill<br />

of sale with the correct serial number and 1.60 caseback. His idea was<br />

to put my OCC dial in the new case so we would have a 1960 Rolex<br />

PCG OCC with not only the correct date stamp on the caseback and<br />

the right serial number, but also the box and papers, which commands<br />

a premium in the aftermarket. J started to get excited thinking that if I<br />

was not inclined to keep the watch, we could sell it for a large premium.<br />

At this point our objectives diverged somewhat, as I thought of an idea<br />

that would make for a great story. I had heard about all the varying<br />

technologies that allowed restorers to bring watches back to life. What<br />

if we were to have the case restored through laser welding? There is an<br />

Instagram page belonging to a Japanese restorer named @_hiiih_ who<br />

performs apparent works of magic on both steel and gold cases. You<br />

could see watches where the bevels had been completely ground off<br />

through constant repolishing that suddenly evinced razor-sharp lines<br />

again. Yet another restorer on Instagram, @mikerolliworks, shows great<br />

exacting details of how laser welding is done. A damaged or rounded<br />

section of the case has tiny microscopic welds made on it to sinter fresh<br />

metal to the case. In some instances thousands of tiny welds can be used<br />

to build up a badly damaged section of the watch. Once this is done the<br />

case is recut and refinished with exacting precision. It really is a magical<br />

transformative act.<br />

The Japanese owner of the first page was contacted and he readily<br />

agreed to apply his magic to this now-dissembled watch. Once<br />

the components were finished by him they were sent back and the<br />

watch was reassembled. Now throughout this process, J was meant<br />

to document the stages and write a story about how a NOS watch is<br />

effectively made. He was at first hesitant. Then I pointed out to him that<br />

if he felt his reputation as a dealer had become affected in recent times,<br />

the best way to change that perception would be to become a voice for<br />

transparency and to inform the public about how watches can be made<br />

to look like new using these technologies. The idea was a step-by-step<br />

demonstration of how the GMT was refreshed in this way. However, in<br />

the end, the story he wrote is just a generic story on refinishing and not a<br />

narrative about us personally undertaking this objective together.<br />

Once he received the watch, J being J got more and more excited to<br />

sell this watch at an auction using precisely the following narrative: it<br />

was a rare OCC pointed crown guard, gilt dial, one-owner, box-andpapers<br />

watch that was left sitting in a drawer or “found in a barn” or<br />

something similar to this. And he began to contact auction houses to<br />

gauge their level of interest. What was strange, however, was that he<br />

didn’t want to be the person to submit the watch for auction and wanted<br />

me to do it.<br />

To be honest, the idea of making back the initial investment in the<br />

watch with a tidy profit (even if it was to be split two ways, as the dealer<br />

VINTAGE 145