Hypertherm Automation Edge II Software Main Features - Genstar ...

Hypertherm Automation Edge II Software Main Features - Genstar ...

Hypertherm Automation Edge II Software Main Features - Genstar ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

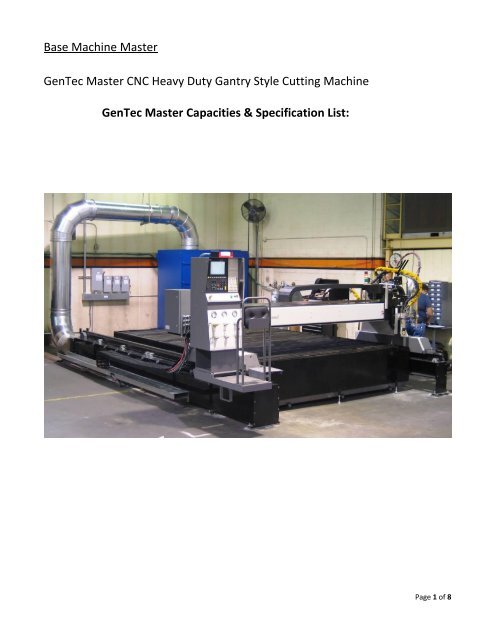

Base Machine Master<br />

GenTec Master CNC Heavy Duty Gantry Style Cutting Machine<br />

GenTec Master Capacities & Specification List:<br />

Page 1 of 8

GenTec Master Series <strong>Main</strong> <strong>Features</strong>:<br />

Super Duty Structural Rigid Box Frame<br />

Dual Drives AC Servos on X Axis<br />

Single Drive AC Servo on Y Axis<br />

Square Way Linear Bearings Throughout for Rigid Accurate<br />

Drives<br />

Self Compensating Pinion On Dual Drive<br />

German Made Low Back Lash Gear Box Accurate<br />

To Less than 2 Arc Minutes<br />

Self Lubricating <strong>Main</strong> Rail<br />

Rack And Pinion Drives On All Axis<br />

Ground Square Way Rails Throughout<br />

Dual Cable Tracks Sealed Construction<br />

Transverse Anti-Dust Device<br />

Page 2 of 8

GenTec Linear Rail Package:<br />

o Ground Linear Rail 3 X 3 Meter Sections<br />

o Unique two Directional Rail Adjusting Mounts<br />

Track extension, 3M (dual drive/ include cable chain) 82 lb<br />

Page 3 of 8

Sequential Zoned Downdraft Table For Above System<br />

Table Grid Can Be Removed For Easy Clean Up<br />

The cutting table could be lifting for residue, scrap…cleaning.<br />

Page 4 of 8

<strong>Hypertherm</strong> <strong>Automation</strong> <strong>Edge</strong> Pro Included <strong>Edge</strong> <strong>II</strong> With Included The With Gentec the Master GenTec Series<br />

Master Series<br />

<strong>Hypertherm</strong> <strong>Automation</strong> <strong>Edge</strong> <strong>II</strong><br />

Hardware <strong>Main</strong> Feature<br />

Air Cooled Dust Proof Cabinet<br />

Sentry Temperature Monitor<br />

<strong>Hypertherm</strong> <strong>Automation</strong> <strong>Edge</strong> <strong>II</strong><br />

<strong>Hypertherm</strong> <strong>Automation</strong> <strong>Edge</strong> Pro <strong>Hypertherm</strong> <strong>Automation</strong> <strong>Edge</strong> Pro<br />

<strong>Software</strong> <strong>Main</strong> <strong>Features</strong>:<br />

<strong>Edge</strong> Pro Hardware <strong>Features</strong> <strong>Edge</strong> Pro <strong>Software</strong> <strong>Features</strong><br />

Built-in Extensive Standard Shape Library<br />

15" Durable Glass 15" Touch Glass Screen Touch Screen<br />

Windows Operating XPe System Operating Windows SystemXPe<br />

Tactile<br />

Intel Tactile Surface<br />

2.4 Surface Wave<br />

GHZ or Wave Technology<br />

Greater Technology Processor<br />

Full Remote Cut Pro<br />

Shape User Wizard<br />

Editor HelpWith<br />

User Prompts<br />

Designed For Ease of<br />

SATA Air Cooled Hard Dust Drive Proof Cabinet<br />

Cut Part Pro Wizard Program For Support Ease Of For Operation Easy<br />

Process Dual SATA Scan Hard Color DriveScreen<br />

Use PPS Part Program Support Controlling<br />

Two<br />

256<br />

One On<br />

Megabyte<br />

GB Board Of Memory USB Ports<br />

of Ram<br />

Standard Plasma Control THC DXF From And Input Within Table for Customer The Parameters Program Files<br />

Universal Input Power Power Input<br />

FromKey<br />

Process Parameter Watch<br />

Windows 40 24 Or GB 48 hard User Drive IO Points Capacity<br />

Actual Within Part The Display Program. in Cut Mode with<br />

One Back GB Door Of User Memory Input Board<br />

Cutting Watch Customizing Line Window High Real Of Light Cut Time Charts Monitoring With The<br />

Progr Universal Input Power<br />

Designed For Extreme Enviroments<br />

Watch Window process Monitoring<br />

24 On Board Nesting with Shape Repeat<br />

1.44 Intuitive Or MB 48 Hardware User Floppy IO Drive Service Kit<br />

Creation And Storage Of Custom Cut<br />

Back Two On Door Board User USB Input Ports Board<br />

Dynamic Charts. Kef Compensation<br />

Network 24 Lines Linked IO for To User <strong>Hypertherm</strong> Signals<br />

Network Capable Ethernet CardService<br />

Fast Cutting To Marking Support<br />

On Process Information with User Defined<br />

USB Hi Frequency Board Port Ethernet for Program Protected CardStorage<br />

On Board Service Help<br />

CE,CSA Two Station Compliant Opcon<br />

Watch Built In Windows Help Screens For Table<br />

Two External Tactile Station Operator Mouse/Keyboard Opcon Joystick Compatible<br />

Windows Performance XP Operating And Cutting System Optimization<br />

Tactile On CE,CSA Board Joystick Compliant Ethernet Card Network<br />

Visual Display Of Consumables For<br />

Two Year Warranty<br />

Manual Operation and Full Test Modes<br />

Compatible<br />

Standard 2 Year Warranty<br />

Rapid Process Change.<br />

Dust Proof Air Cooled Cabinet<br />

DXF File Compatable<br />

Hi Frequency Protected<br />

Designed And Tested For Extreme Conditions<br />

Parameter Viewing Window<br />

Full <strong>Main</strong>tenance Screen with Status<br />

Meters<br />

Page 5 of 8

Oxy-Fuel Package<br />

Oxy Fuel Torch & Lifter Assembly<br />

A Rack & Pinion Motorized Torch Lifter<br />

B Adjustable Torch Bracket & Holder<br />

C GenTec Or Similar Torch<br />

D Individual Torch Solenoid<br />

E Full Cutting Hose Package<br />

Page 6 of 8

Master Oxy Fuel Gas Console Package<br />

A Hi-Low Pre Heat<br />

B Status Gauges<br />

C Gas Manifold<br />

D Dual Stage Piercing<br />

E Cabinet Mounted At Control<br />

For Ease of Access & Viewing<br />

Page 7 of 8

Machine Options<br />

Laser Alignment Assembly<br />

Removes the need to accurately locate plate to machine by aligning laser to<br />

two (2) corners and teaching the skew.<br />

Off Line Nesting <strong>Software</strong> Option<br />

MTC ProNest Off Line <strong>Software</strong> Package:<br />

Warranties<br />

� True Shape Nesting<br />

� Automatically Places Part Contours Together<br />

� Places Part Within Parts<br />

� Tooling Path Automatically Generated<br />

� Automatic Machine G Code Creation<br />

� Report Generation For Cutting Times Sheet & Sheet Utilization<br />

� Standard DXF File Input<br />

� Easy To Use<br />

Gentec Products 12 Months Warranty Parts & Labor<br />

<strong>Edge</strong> CNC Control 12 Months Warranty Parts & Labor<br />

<strong>Hypertherm</strong> Torch & Lifter 12 Months Warranty Parts & Labor **<br />

<strong>Hypertherm</strong> Power Source 24 Months Warranty Parts & Labor<br />

Kaliburn Torch & Lifter 12 Months Warranty Parts & Labor **<br />

Kaliburn Power Source 36 Months Warranty Parts & Labor<br />

** Excludes Torch Peripherals<br />

Terms & Conditions<br />

<strong>Genstar</strong> Technologies Conditions of Sale – Addendum A – Attached & Incorporated<br />

Page 8 of 8