2009 Momentum - Glashütte Original

2009 Momentum - Glashütte Original

2009 Momentum - Glashütte Original

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

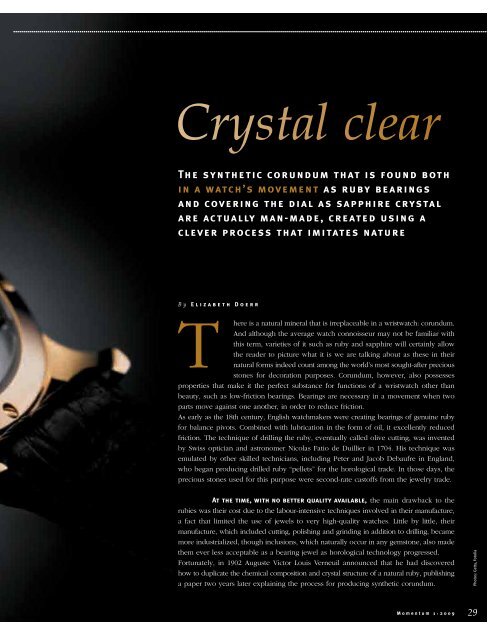

Crystal clear<br />

The synthetic corundum that is found both<br />

in a watch’s movement as ruby bearings<br />

and covering the dial as sapphire crystal<br />

are actually man-made, created using a<br />

clever process that imitates nature<br />

By Elizabeth Doerr<br />

T<br />

here is a natural mineral that is irreplaceable in a wristwatch: corundum.<br />

And although the average watch connoisseur may not be familiar with<br />

this term, varieties of it such as ruby and sapphire will certainly allow<br />

the reader to picture what it is we are talking about as these in their<br />

natural forms indeed count among the world’s most sought-after precious<br />

stones for decoration purposes. Corundum, however, also possesses<br />

properties that make it the perfect substance for functions of a wristwatch other than<br />

beauty, such as low-friction bearings. Bearings are necessary in a movement when two<br />

parts move against one another, in order to reduce friction.<br />

As early as the 18th century, English watchmakers were creating bearings of genuine ruby<br />

for balance pivots. Combined with lubrication in the form of oil, it excellently reduced<br />

friction. The technique of drilling the ruby, eventually called olive cutting, was invented<br />

by Swiss optician and astronomer Nicolas Fatio de Duillier in 1704. His technique was<br />

emulated by other skilled technicians, including Peter and Jacob Debaufre in England,<br />

who began producing drilled ruby “pellets” for the horological trade. In those days, the<br />

precious stones used for this purpose were second-rate castoffs from the jewelry trade.<br />

At the time, with no better quality available, the main drawback to the<br />

rubies was their cost due to the labour-intensive techniques involved in their manufacture,<br />

a fact that limited the use of jewels to very high-quality watches. Little by little, their<br />

manufacture, which included cutting, polishing and grinding in addition to drilling, became<br />

more industrialized, though inclusions, which naturally occur in any gemstone, also made<br />

them ever less acceptable as a bearing jewel as horological technology progressed.<br />

Fortunately, in 1902 Auguste Victor Louis Verneuil announced that he had discovered<br />

how to duplicate the chemical composition and crystal structure of a natural ruby, publishing<br />

a paper two years later explaining the process for producing synthetic corundum.<br />

<strong>Momentum</strong> 1· <strong>2009</strong><br />

Photos: Getty, Fotolia<br />

29