English - Groz-Beckert

English - Groz-Beckert

English - Groz-Beckert

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

experience<br />

an eventful history<br />

1852 - today

2 | INTRODUCTION<br />

Past experience determines the future – and, throughout its event -<br />

ful history since 1852, <strong>Groz</strong>-<strong>Beckert</strong> has experienced a great deal.<br />

During that time the company has developed with consistence and<br />

intelligence, overcoming periods of political as well as economic<br />

hardship by treating them as opportunities for new potential and<br />

new beginnings. The march of time never ends, and <strong>Groz</strong>-<strong>Beckert</strong><br />

continues to provide its own impetus on a sustainable basis.<br />

Find out all about the company's exciting history in this brochure.<br />

Discover how, over the past century and a half, <strong>Groz</strong>-<strong>Beckert</strong> has<br />

developed into an important partner for the entire textile industry.<br />

Look forward to numerous insights, prognoses, historic milestones<br />

and authentic tales from the past.<br />

>><br />

METICULOUS FROM<br />

THE VERY START:<br />

THEODOR GROZ'S<br />

NOTEBOOK (CA. 1883)<br />

THE BASIS:<br />

THE BUILDING ON BAHNHOFSTRASSE (CA. 1884)<br />

GROWTH:<br />

COMPANY HEADQUARTERS (CA. 1950)<br />

INNOVATIVE:<br />

TECHNOLOGY AND DEVELOPMENT CENTRE (2010)

BASED ON TRADITION:<br />

THE COATS OF ARMS OF<br />

THE GROZ AND BECKERT<br />

FAMILIES<br />

The depictions provided of our products are not to scale and are<br />

intended for illustrative purposes only. Consequently they make<br />

no claim to be an accurate representation of the original.<br />

® = Registered trademark of the <strong>Groz</strong>-<strong>Beckert</strong> company group.<br />

© = This publication is copyrighted. All rights reserved, in particular<br />

the right of duplication, distribution and translation. This<br />

publication or any parts thereof may not be reproduced or stored,<br />

processed, duplicated or distributed using electronic systems in<br />

any form or by any means whatsoever without the express written<br />

consent of <strong>Groz</strong>-<strong>Beckert</strong>.<br />

Introduction and contents 2 | 3<br />

In words<br />

Beginnings 4<br />

Development 6<br />

Continuation 8<br />

In brief<br />

1852 - 1969 14<br />

1970 - 1995 16<br />

1996 - 2002 18<br />

2003 - 2007 20<br />

2008 - 2010 22<br />

CONTENTS | 3<br />

>>

4 | BEGINNINGS<br />

The Swabian Alb, in the first half of the 19th century: a rough moun-<br />

tain plateau, sloping away at its south-eastern edge towards the upper<br />

reaches of the River Danube. This is the location of Ebingen, today<br />

known as Albstadt. The small Swabian town has only one thing to offer<br />

its inhabitants: a life of hardship. The people here are just only able to<br />

feed themselves from the fruits of their labour. Their primary source of<br />

income is hosiery knitting. It will be a long time before the incipient<br />

industrial revolution finally reaches Ebingen. One of those who will<br />

bring it here is Theodor <strong>Groz</strong>.<br />

>><br />

Theodor <strong>Groz</strong>, the son of Daniel <strong>Groz</strong>, a<br />

dispensing chemist, leaves his home town<br />

after his father’s early death and enters into<br />

an apprenticeship with a needle-master in<br />

Ludwigsburg. Then he travels further; his<br />

goal is Vienna. In this metropolis on the<br />

Danube he accumulates more experience<br />

in the art of needle manufacture. In 1852<br />

he returns to Ebingen and marries Rosina<br />

Rieber. He also opens a shop selling toys<br />

and fashion accessories, with its own needle<br />

workshop. His slogan, “Better needles”,<br />

is still valid today. At the same time Ernst<br />

<strong>Beckert</strong> is spending his childhood in the<br />

Saxon town of Eibenberg, near Chemnitz.<br />

Here, too, many people live primarily from<br />

hosiery knitting. Like his father before him,<br />

the 12-year-old Ernst <strong>Beckert</strong>'s father often<br />

has to work the hand wheel of the knitting<br />

loom. The young boy is not in the least<br />

interested in knitting, trains as a mechanic,<br />

and works in mining until he breaks both<br />

legs in an accident. He is confined to bed<br />

for months. More out of boredom than<br />

anything else, he occupies himself with<br />

his father’s needles and thinks about<br />

needle manufacture. He spends the last<br />

of his money on high-grade barbed wire,<br />

and tests out various production and<br />

hardening processes. At Christmas in<br />

1860, he makes his breakthrough. Thus,<br />

while Theodor <strong>Groz</strong> is celebrating his first<br />

successes in needle production and is<br />

already employing 25 people, Ernst <strong>Beckert</strong><br />

is also finding his way into the craft of<br />

needle-making. He grows increasingly<br />

ambitious and, in 1871, the year in which<br />

Bismarck declares the new German Reich,<br />

Ernst <strong>Beckert</strong> starts his own needle production<br />

in his home town of Eibenberg.<br />

From now on there are two needle factories<br />

in Germany, both heading in the same<br />

direction along a path that will ultimately<br />

bring them together.<br />

Non-stop series of inventions<br />

The road to worldwide success is a long<br />

one. The first requirement is economic<br />

survival. This is because needle production<br />

is a difficult trade, in which all the<br />

work is done by hand. At the same time it<br />

has to keep step with rapid innovation. In<br />

the early years Theodor <strong>Groz</strong> was only<br />

producing sharp-pointed iron needles, but<br />

soon a new material entered the market<br />

from France: steel. Good steel is expensive,<br />

however, and has to be hardened by<br />

means of a special process. Over the next<br />

few years it was the search for adequate<br />

material and a special hardening process<br />

that determined the working day and success<br />

at the end of it. In 1864, for instance,<br />

while Ernst <strong>Beckert</strong> in Saxony is perfecting<br />

his knowledge of needle-making, the<br />

Swabian Theodor <strong>Groz</strong> is threatened with<br />

the loss of his entire clientele. The reason:<br />

low-quality wire. Four hundred thousand<br />

circular warp loom needles have been<br />

produced but cannot be used – all part of<br />

the fate of a needle-maker. In the early<br />

1860s, the advance of steel is joined by<br />

that of a new type of needle – the latch

needle, invented by Matthew Townsend,<br />

an <strong>English</strong> textile engineer. The first person<br />

to produce these needles in Germany is<br />

Theodor <strong>Groz</strong>, starting in 1863. Eleven<br />

years later his son Daniel, together with<br />

his friend Daniel Beck, makes a decisive<br />

improvement to them. In future, the slot<br />

in which the latch is fastened is no longer<br />

stamped but machined. Daniel <strong>Groz</strong><br />

brought this idea with him from Saxony,<br />

where he had worked for two years for<br />

the biggest needle producers. He may<br />

even have made the acquaintance of an<br />

ingenious young entrepreneur named<br />

Ernst <strong>Beckert</strong>, who by then had opened<br />

his own factory and, in a few years' time,<br />

would be one of the biggest names in the<br />

business. On the Swabian Alb, these<br />

developments are accompanied by the<br />

transition from a workshop to a needle<br />

factory. Production is increased and everlarger<br />

hardening furnaces and more efficient<br />

steam engines are brought into use.<br />

One invention follows hard on the heels<br />

THE COMPANY'S OWN SPECIAL<br />

MACHINERY PRODUCTION AT<br />

THE BITZ FACTORY IN 1902<br />

of another: the pointed-needle press, for<br />

instance, or the “spoon” machine for producing<br />

latches, both of which were developed<br />

by a technical employee, Ferdinand<br />

Binder. By the mid-1880s needle production<br />

had already surpassed the million<br />

mark. Nowadays, however, far more than<br />

that quantity is produced in a single day.<br />

All in the family<br />

Economic growth is accompanied by<br />

expan sion of the premises. After 23 years<br />

the workshop in the street called Am<br />

Unteren Tor has outlived its usefulness.<br />

In 1875 Theodor <strong>Groz</strong> moves into new<br />

business premises in the Pfarrstrasse in<br />

Ebingen. In the same year Carl Theodor<br />

Beck starts to work for him in Bitz. The<br />

next few years bring various removals<br />

and extensions, and the head office of the<br />

firm does not reach its final home in the<br />

Wiesenstrasse until 1902. Today the street<br />

is named after the founder of the firm.<br />

Building work also begins in Chemnitz,<br />

BEGINNINGS | 5<br />

TOOL OF THE TIME:<br />

MANUAL SETTING DEVICE (CA. 1900)<br />

POINTED-NEEDLE PRESS >><br />

at Beckerstrasse 27-29. Within a quarter<br />

of a century Ernst <strong>Beckert</strong>'s business has<br />

grown to a considerable size. In 1895 a<br />

branch is opened in Stollberg, in the Erz<br />

Mountains, and over the following 10 years<br />

evolves into a complete factory. By 1898<br />

the company is already employing more<br />

than 200 people. The first Chemnitz factory<br />

is bursting at the seams. Building an extension<br />

on one side only brings short-term<br />

relief, however, and so an imposing new<br />

building is erected in the Metzer strasse<br />

in 1905. The move is no longer supervised<br />

by the founder himself, however, but by<br />

his son-in-law and successor Julius<br />

Seelmann-Eggebert. Ernst <strong>Beckert</strong> dies in<br />

Radebeul on October 4, 1909. Far away on<br />

the Swabian Alb, the generational change<br />

has taken place long since. Back in 1879<br />

Theodor <strong>Groz</strong> had made his two eldest<br />

sons, Theodor and Daniel, active partners<br />

in the firm, as reflected in the name of the<br />

company: Theodor <strong>Groz</strong> & Sons. It is not<br />

the older brother who succeeds the

6 | DEVELOPMENT<br />

father, however, for a sad reason: in April<br />

1892 both Theodor <strong>Groz</strong> Senior and Junior<br />

die within three days of one another. For<br />

a short time the inventive Daniel <strong>Groz</strong><br />

runs the company, but leaves it for health<br />

reasons in 1897. Management passes to<br />

his younger brother, Oskar, and to his<br />

brother-in-law Heinrich Cless who, however,<br />

leaves a few years later to set up his<br />

own business. Finally, in 1901, Adolf <strong>Groz</strong>,<br />

the youngest son of the founder, becomes<br />

an active partner. It is this generation of<br />

sons and sons-in-law, Oskar and Adolf<br />

<strong>Groz</strong> on the one side and Julius Seelmann-<br />

Eggebert on the other, which ultimately<br />

leads the two companies towards a merger.<br />

The first collaboration starts in 1918:<br />

the two companies have long since made<br />

names for themselves on the world market,<br />

and once World War I is over they<br />

decide to reactivate their international<br />

activities and establish a joint sales office<br />

in New York. A first step on the way to<br />

>><br />

joining forces? Certainly: They go on to<br />

prepare the second step, while the merg-<br />

er itself is ultimately carried out by their<br />

grand children's generation.<br />

Unravelling and rejoining<br />

The year 1923 brings hyperinflation – a loaf<br />

of bread costs several billion Marks. These<br />

consequences of the world war also leave<br />

traces on the needle industry. Everybody<br />

needs needles. Production cannot keep up<br />

with demand, and a lively but illusory<br />

econ omy develops. New needle factories<br />

appear. But then the economy collapses,<br />

money loses its value, and prices fall.<br />

Renowned needle factories con sider a<br />

merg er in 1924 in order to ensure their<br />

sur vival; the nine leading ones in Saxony,<br />

headed by Ernst <strong>Beckert</strong>, and the Swabian<br />

firm of Theodor <strong>Groz</strong> & Sons negotiate<br />

with one another. However, the economy<br />

now starts improving again and these<br />

negotiations peter out. Nevertheless the<br />

interest is there, the contacts have been<br />

made, and the idea continues to mature<br />

silently. Four years later merger plans<br />

col lapse again, this time because opinions<br />

differ about automatic production methods –<br />

in which the Swabians are a step ahead<br />

of the Saxons. However, Julius Seel mann-<br />

Eggebert is the only one of the Saxon<br />

manufacturers to recognize and respect<br />

this fact. From then on it is only the two<br />

biggest needle manufacturers, Theodor<br />

<strong>Groz</strong> & Sons and Ernst <strong>Beckert</strong>, who consider<br />

a merger. Many years are still to<br />

pass before one can come about, however.<br />

In 1937, the day finally comes: the new<br />

firm takes the name of 'Theodor <strong>Groz</strong> und<br />

Söhne & Ernst <strong>Beckert</strong> Nadel fabriken<br />

Commandit-Gesellschaft Ebingen und<br />

Chemnitz' – which, being rather long, is<br />

usually shortened to <strong>Groz</strong>-<strong>Beckert</strong>. It is<br />

managed by Hans and Walther <strong>Groz</strong>, the<br />

sons of Alfred <strong>Groz</strong>, and by Fritz Seelmann-<br />

Eggebert who took over from his father<br />

NEEDLE PATTERN BOOK CA. 1930<br />

WORKERS CA. 1935

Julius. The company represents two-thirds<br />

of the entire German knitting needle indus-<br />

try, which puts it in an excellent posi tion<br />

against competition. But then comes the<br />

war, and destruction.<br />

Heavy setbacks<br />

Chemnitz is heavily bombed in the night<br />

of 5th March 1945, and one of the buildings<br />

to be hit is the <strong>Beckert</strong> factory. Part of<br />

it is burned down, another part collapses.<br />

The finished-goods warehouse and all<br />

the needles and sinkers are destroyed.<br />

Everything is lost, even the company’s<br />

official rubber stamp. Nevertheless, most<br />

of the machines have only suffered minor<br />

damage and will soon be ready for use<br />

again. Friedrich Ernst <strong>Beckert</strong>, the son of<br />

the founder, and Dora Steude, a granddaughter,<br />

lose their lives. Fritz Seelmann-<br />

Eggebert is hit by a heavy air-raid shelter<br />

door and suffers bruises on his back.<br />

The <strong>Groz</strong> works in Ebingen and Bitz come<br />

off relatively lightly, Bitz remaining completely<br />

unscathed. However, on 17th April<br />

1945 low-flying aircraft open fire on the<br />

nearby Ebingen railroad station and set<br />

an ammu nition train on fire. The explosions<br />

continue all day, shattering doors<br />

and win dows. The roofs are damaged. The<br />

devastation is enormous, but the basic<br />

structure is unharmed. Then comes the<br />

fate ful moment – the end of the Third<br />

Reich, the start of the post-war era. The<br />

Allies demand reparations and start dismantling<br />

German industrial plants. <strong>Groz</strong>-<br />

<strong>Beckert</strong> is also affected. Everything that is<br />

left in the Chemnitz factory is dismantled<br />

and taken away to Russia. Fritz Seelmann-<br />

Eggebert is arrested and spends four<br />

years in Russian custody. More than 500<br />

machines are dismantled in Ebingen as<br />

well, and transported to France. But then<br />

something amazing occurs: the dismantling<br />

work is stopped. It is not possible to<br />

make proper use of the machines at their<br />

DEVELOPMENT | 7<br />

HUGE CHALLENGES:<br />

AFTER THE EXPLOSION OF<br />

THE AMMUNITION TRAIN IN<br />

EBINGEN ON 19.04.1945<br />

new destinations. At the same time there<br />

is a huge demand for needles in France.<br />

It is thus the French knitwear industry, of<br />

all things, which urges that <strong>Groz</strong>-<strong>Beckert</strong><br />

should be retained.<br />

>><br />

Social network<br />

What about the employees? How have<br />

they survived the war? What does restarting<br />

operations mean to them? Many have<br />

not yet returned from the war. Many are<br />

helping with the work of clearing up. And<br />

while the first customers come to<br />

Ebingen and enquire about needles, people<br />

have one major problem – hunger. The<br />

manage ment solves the problem by selling<br />

needles for food, which they distribute,<br />

because people who work also need<br />

to eat. This ingenious plan leads on to<br />

greater things; a works canteen is set up,<br />

and is a sign to the employees of social<br />

commitment. It is not the first in the company’s<br />

history; a works health fund had

8 | CONTINUATION<br />

EXEMPLARY:<br />

THE WORKS HEALTH FUND, DATING BACK TO 1888<br />

>><br />

been set up as long ago as 1888, a pre cursor<br />

of the works health funds now found<br />

in many big firms. Later, in 1929, it was<br />

joined by a pension and welfare fund.<br />

However, a year after the end of the war<br />

the French military government puts an<br />

end to these social security elements and<br />

the works health fund does not re-open<br />

until 1949, at the unanimous request of<br />

the workforce and in the face of opposition<br />

from representatives of a purely state-run<br />

social insurance plan. That is not all. The<br />

construction of several hundred workers’<br />

apartments helps to relieve the urgent<br />

housing shortage. Older employees are<br />

given the facility of relaxing once every<br />

two years in the company leisure centre<br />

in the Black Forest in addition to the<br />

annual holiday to which they are entitled.<br />

The company thus sets new standards in<br />

showing a sense of responsibility towards<br />

its employees by providing benefits far<br />

beyond the usual level.<br />

Successful connections<br />

Production starts up again. Under the<br />

pressure of circumstances, with materials,<br />

machines, and workers all in short supply,<br />

new technical designs and ever more<br />

highly automated production methods<br />

become established. International business<br />

contacts are also taken up again. People<br />

abroad remember the reliable <strong>Groz</strong>-<strong>Beckert</strong><br />

needles, and they need them. Urgently.<br />

Even before the war the company had<br />

been the world leader in the field of knitting<br />

and warp-knitting machine needles.<br />

Now, in a world divided into two power<br />

blocks, nothing is possible without the<br />

top-quality needles from the Swabian Alb.<br />

The Saxon needle factories are now stateowned<br />

enterprises and their output is all<br />

going to Russia. Although the needle<br />

industries in the Western countries have<br />

gained ground during the war years, their<br />

quality has still not caught up with that of<br />

<strong>Groz</strong>-<strong>Beckert</strong>. So the old contacts can be<br />

taken up again quickly. The testimonials of<br />

friendship are deeply moving; one customer<br />

from Crete reports that his father<br />

had wept with joy over the first consignment<br />

of needles, and had kissed each<br />

indi vidual box. Anyone who realizes that a<br />

textile manufacturer who has all the yarn,<br />

machinery, and workers that he needs but<br />

is condemned to idleness if he has no<br />

needles will understand this reaction. By<br />

1948 <strong>Groz</strong>-<strong>Beckert</strong> is already delivering to<br />

39 different countries, and exports account<br />

for 63 percent of the total output. In 1950<br />

as much is produced on the Swabian Alb<br />

as both factories together had been producing<br />

before the war, and twice as much<br />

in 1952. At this point in time the company<br />

employs 2,150 people – a figure that is set<br />

to grow constantly over the coming years.<br />

Far greater effect<br />

The company has been international right<br />

from its earliest days, and was already<br />

doing its first business in the USA back in<br />

the early 1860s. Regular overseas busi-

ness has been running since about 1880,<br />

although it has been interrupted many<br />

times, mainly by wars. But now, from 1952<br />

onwards, more and more production and<br />

affiliated sales companies are founded in<br />

Germany and abroad. For instance, in 1960<br />

<strong>Groz</strong>-<strong>Beckert</strong> starts to open up the growing<br />

Asian market by working out of the<br />

Indian city of Chandigarh. This is followed<br />

in 1969 by <strong>Groz</strong>-<strong>Beckert</strong> Portuguesa Lda,<br />

near Porto, and 10 years later anoth er<br />

Portuguese factory, Euronadel, is acquired.<br />

MADE TO MEASURE:<br />

NEEDLE PRODUCTION IN ALBSTADT-EBINGEN, CA. 1950<br />

THE ORIGINAL:<br />

FIRST EDITION OF<br />

"DER NADLER" IN 1953<br />

As a result of the political re-opening of<br />

Eastern Europe, <strong>Groz</strong>-<strong>Beckert</strong> takes over<br />

the Czech needle factory of AKRA and in<br />

2001 renames it <strong>Groz</strong>-<strong>Beckert</strong> Czech s.r.o.<br />

<strong>Groz</strong>-<strong>Beckert</strong> also opens a factory in China<br />

in the mid-1990s: Yantex. All these are just<br />

examples of the way the company has<br />

developed in the last 50 years. This development<br />

has been accompanied by an<br />

expansion of its fields of business.<br />

Up to 1980 <strong>Groz</strong>-<strong>Beckert</strong> was only engaged<br />

in the field of needles for knitting and<br />

warp-knitting machines, but now the range<br />

has been expanded to include needles<br />

for sewing and shoe machines and also<br />

felting and structuring needles. Finally<br />

the acquisition of the “Eisbär” brand in<br />

1998 and the Swiss firm of Grob Horgen<br />

AG in 2000 brought tufting and weaving<br />

machine accessories into the range as<br />

well. <strong>Groz</strong>-<strong>Beckert</strong> is thus showing proof<br />

of its technical competence in everything<br />

that requires precision, beyond the limits<br />

of needle production.<br />

CONTINUATION | 9<br />

Technology and Development Centre (TEZ)<br />

Develop, research and improve. What<br />

made Theodor <strong>Groz</strong> and Ernst <strong>Beckert</strong> successful<br />

entrepreneurs – and ultimately<br />

brought the company international<br />

success – remains a timeless maxim. In<br />

accordance with it, the Technology and<br />

Development Centre (TEZ) was built at<br />

the company's headquarters in Albstadt.<br />

It was officially opened in July, 2010.<br />

The TEZ is a platform for research and<br />

development, for intensification of the<br />

system concept, for innovations and for<br />

synergies. Here, in close cooperation with<br />

machine builders, users and partners,<br />

<strong>Groz</strong>-<strong>Beckert</strong> is shaping the textile future.<br />

Five Technical Centres for the most diverse<br />

textile production methods form the central<br />

focus: they are the Technical Centre<br />

Knitting, the Technical Centre Weaving, the<br />

Technical Centre Felting, the Technical<br />

Centre Tufting and the Technical Centre<br />

Sewing. Machines and production lines<br />

are also integral components of these<br />

IMPRESSIVE AND SETTING NEW STANDARDS:<br />

THE TECHNOLOGY AND DEVELOPMENT CENTRE<br />

>>

10 | CONTINUATION<br />

Technical Centres: They enable application<br />

experiments, the production of short and<br />

special runs as a service to partners, and<br />

also the testing of <strong>Groz</strong>-<strong>Beckert</strong> products<br />

under real production conditions.<br />

Furthermore, training options are available<br />

to customers and employees for everything<br />

relating to the <strong>Groz</strong>-<strong>Beckert</strong> core<br />

competencies. The broad and varied product<br />

range is being constantly enhanced<br />

by the addition of systems solutions and<br />

services. Initial examples of systems<br />

solutions here include knitting heads for<br />

circular knitting machines, the Board<br />

Master System (BMS) – an efficient semiautomatic<br />

machine for needleboard<br />

handling – and the entirely new needleholder<br />

GEBESWITCH ®. Moreover, in the<br />

service sector and as a complement to its<br />

laboratory services <strong>Groz</strong>-<strong>Beckert</strong> offers the<br />

"Card Clothing“ service in the Nonwovens<br />

division, plus a sewing-machine-needle<br />

consulting service. Integration of further<br />

>><br />

LABORATORIES AND TECHNICAL CENTRES – THE MOST<br />

IMPORTANT COMPONENTS OF THE TEZ<br />

training and qualification also plays an<br />

important role at the TEZ. At its headquarters<br />

in Albstadt, <strong>Groz</strong>-<strong>Beckert</strong> employs a<br />

full-time staff of roughly 30 commercial<br />

and 145 technical apprentices. In addition<br />

to development offices and various recrea<br />

tion rooms and conference rooms,<br />

the TEZ also contains a generously-sized<br />

training workshop for this purpose.<br />

Furthermore, together with the University<br />

of Albstadt-Sigmaringen, <strong>Groz</strong>-<strong>Beckert</strong><br />

is offering the course "Textile Product<br />

Technology – Technical Textiles“, and has<br />

made rooms and facilities at the TEZ<br />

available for this. A further key component<br />

of the Technology and Development<br />

Centre is the <strong>Groz</strong>-<strong>Beckert</strong> Laboratory,<br />

offering lab services for the most diverse<br />

sectors, ranging from textile technology<br />

and mechanical engineering to the aerospace<br />

industry. Chemical and failure analyses<br />

are carried out, along with materials<br />

consulting and development. A particular<br />

highlight is the auditorium: Equipped with<br />

state-of-the-art multimedia technology<br />

and simultaneous interpreting booths, it<br />

can accommodate up to 275 people.<br />

A connection to the future<br />

The Technology and Development Centre<br />

is not the only milestone where construction<br />

projects are concerned. In April 2007<br />

a pedestrian bridge made from reinforced<br />

concrete in the Albstadt district of Laut -<br />

lingen had to be dismantled because of<br />

corrosion and the resulting safety problems.<br />

Textiles are rust-free, of course – and<br />

this was reason enough for <strong>Groz</strong>-<strong>Beckert</strong><br />

to propose a textile solution for the<br />

reconstruction of the bridge. The plan was<br />

to use a special textile reinforcement in<br />

place of the ferroconcrete, in order to<br />

enable longer service life by means of<br />

comparatively better material properties<br />

as well<br />

as a positive eco-balance. The town of

THE TEZ AUDITORIUM ACCOMODATES<br />

UP TO 275 PEOPLE<br />

Albstadt decided in favour of these plans,<br />

and in March 2008 the contract was signed<br />

for the construction project. <strong>Groz</strong>-<strong>Beckert</strong><br />

acted as general contractor and also participated<br />

in the costs. Building work began<br />

on the substructure and other sections<br />

in November 2009. Just one year later,<br />

<strong>Groz</strong>-<strong>Beckert</strong> was able to officially hand<br />

over a 100-metre-long bridge to the town<br />

of Albstadt. This project is a prime example<br />

of what textile production can do, and is<br />

also a calling-card for Albstadt and the<br />

CONTINUATION | 11<br />

TEXTILES AT ITS CORE:<br />

THE TEXTILE REINFORCED CONCRETE BRIDGE<br />

IN ALBSTADT-LAUTLINGEN IS ROUGHLY<br />

100 METRES LONG<br />

>><br />

entire region.<br />

Parallel to these milestones, the company<br />

also successfully acquired further subsidiaries<br />

and distribution channels worldwide.<br />

With far more than 6,000 employees<br />

and around 70,000 prototypes, <strong>Groz</strong>-<strong>Beckert</strong><br />

is active internationally in over 150 markets.<br />

That is diversity – diversity with a<br />

past and a future.

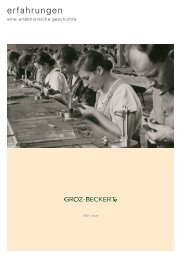

Meßstetten, 1902

Workers at the Meßstetten branch in 1902. However much work materials and techniques have<br />

changed until the present day, it is the company's employees that have always been crucial to its<br />

success. The commitment, expertise and precision of each individual greatly define the superior<br />

quality of the products.<br />

>>

14 | 1852 - 1969<br />

THEODOR GROZ,<br />

COMPANY LETTERHEAD<br />

>> 1852 | 1863 | 1871 | 1884 | 1888 1905 | 1918 | 1922 | 1927 | 1929<br />

The founders<br />

ERNST BECKERT,<br />

COMPANY LETTERHEAD<br />

WARP KNITTING NEEDLE SOLID STAMPED NEEDLE<br />

1852_Theodor <strong>Groz</strong> opens a toys and fashion<br />

accessories store and also a needle-making<br />

workshop in Ebingen.<br />

1871_Ernst <strong>Beckert</strong> establishes a needle factory<br />

in Eibenberg in the Erz Mountains.<br />

Innovation<br />

1852_Theodor <strong>Groz</strong> produces warp-knitting<br />

needles used in seamless production for the<br />

very first time.<br />

1863_The first latch needle comes from<br />

Ebingen.<br />

New head office<br />

1884_Theodor <strong>Groz</strong> & Söhne move into<br />

the factory building on Bahnhofstrasse<br />

in Ebingen.<br />

Social commitment<br />

1888_Foundation of a works health fund.<br />

New building<br />

1905_New headquarters of the Ernst<br />

<strong>Beckert</strong> Needle Factory in Metzerstrasse,<br />

Chemnitz.<br />

Internationality<br />

1918_First joint foreign sales office<br />

of the <strong>Groz</strong> and <strong>Beckert</strong> companies<br />

established in New York, USA.<br />

1927_Foundation of a distribution<br />

company in Paris, France.<br />

Innovation<br />

1922_Introduction of solid<br />

stamped needles.<br />

Social commitment<br />

1929_Foundation of a company pension<br />

fund at Theodor <strong>Groz</strong> & Söhne.

SALES OUTLET IN NEW YORK<br />

1937 | 1945 | 1952 | 1960 | 1965 | 1969<br />

New start<br />

COMPANY MERGER<br />

EMPLOYEES AT CHANDIGARH<br />

HOFA-SPEC HOSIERY KNITTING NEEDLE<br />

1937_Theodor <strong>Groz</strong> & Söhne and Ernst<br />

<strong>Beckert</strong> merge to form one company.<br />

1945_The Chemnitz factory is destroyed<br />

in the war, and the machines are dismantled<br />

and taken to Russia.<br />

1945_The dismantling process is stopped<br />

in Ebingen at the request of the French<br />

textile industry, and production is restarted.<br />

Innovation<br />

1952_<strong>Groz</strong>-<strong>Beckert</strong> presents the<br />

Hofa-Spec hosiery knitting needle.<br />

It is a mere 0.34 millimetres thick.<br />

Jubilee<br />

1952_<strong>Groz</strong>-<strong>Beckert</strong> celebrates its 100th<br />

anniversary. The company employs<br />

2,150 people. A partnership agreement<br />

is concluded between the owners and<br />

the employees.<br />

Internationality<br />

1960_Foundation of a <strong>Groz</strong>-<strong>Beckert</strong><br />

production plant in Chandigarh, India.<br />

1965_Distribution company in<br />

Barcelona, Spain.<br />

1969_Foundation of the production<br />

company <strong>Groz</strong>-<strong>Beckert</strong> Portuguesa Lda.<br />

in Valadares near Porto, Portugal.<br />

1852 - 1969 | 15<br />

PRODUCTION PLANT<br />

IN PORTO<br />

>>

16 | 1970 - 1995<br />

MEANDER NEEDLE<br />

LOW-PROFILE MEANDER SHAPE NEEDLE<br />

>> 1971 | 1978 | 1980 1983 | 1987 | 1989 | 1991 | 1992<br />

Innovation<br />

1971_Introduction of the "meander" needle.<br />

1978_Further development of the meander<br />

shape to create the low-profile needle.<br />

Internationality<br />

1980_Acquisition of the company<br />

Torrington Portuguesa near Lisbon,<br />

Portugal; name changed to Euronadel<br />

Industrias de Agulhas Lda.<br />

Range expansion<br />

1980_<strong>Groz</strong>-<strong>Beckert</strong> now produces and<br />

distributes sewing- and shoe-machine<br />

needles as well as felting and structuring<br />

needles.<br />

HIGH PERFORMANCE STEEL/PLASTIC<br />

COMPOSITE NEEDLE, SPRING LATCH NEEDLE<br />

AND TRANSFER FLAT-KNITTING NEEDLE<br />

Innovation<br />

1983_Patent granted on the high performance<br />

steel/plastic composite needle. It<br />

combines the advantages of the full-shank<br />

with those of the low-profile meander<br />

shape needle.<br />

1987_Introduction of the spring latch<br />

needle for modern flat knitting machines.<br />

1989_Presentation of the compound needle<br />

for flat knitting with a transfer device.<br />

1989_Market rollout of the rectangular<br />

blind-stitch needle.<br />

1991_Introduction of the special application<br />

needle SAN ® for jeans and fine knitwear.<br />

1992_Presentation of the transfer flatknitting<br />

needle with integrated selector.<br />

Internationality<br />

1987_Foundation of a distribution company<br />

in Leicester, England.<br />

1991_Further distribution companies<br />

founded in Milan, Italy and Osaka, Japan.

SPECIAL APPLICATION NEEDLES<br />

SAN ® 10 AND SAN ® 6 GEBEDUR ®<br />

1993 | 1994 | 1995<br />

Innovation<br />

1993_Market rollout of the titanium<br />

nitride-coated GEBEDUR ® sewing-machine<br />

needle.<br />

1993_ Introduction of the Tri STAR ®, a<br />

felting needle with concave triangular<br />

surfaces.<br />

1994_Introduction of the felting needle<br />

GEBEDUR ® I. It is especially suitable for<br />

needling man-made fibres.<br />

Internationality<br />

1993_<strong>Groz</strong>-<strong>Beckert</strong> acquires the Akra-<br />

Werke in Budweis, Lužice and Klobouky,<br />

known collectively from 2000 onwards<br />

as <strong>Groz</strong>-<strong>Beckert</strong> Czech s.r.o.<br />

1993_Acquisition of Exeltor in Bedford,<br />

Canada.<br />

1994_Foundation of the distribution<br />

subsidiary <strong>Groz</strong>-<strong>Beckert</strong> de México S.A. de<br />

C.V. in Naucalpan, Mexico.<br />

1995_Foundation of the production<br />

company Yantex (Yantai) Precision Textile<br />

Accessories Co. Ltd. in Yantai, China.<br />

1970 - 1995 | 17<br />

Tri STAR ® NEEDLE GEBEDUR ® FELTING NEEDLE<br />

>>

18 | 1996 - 2002<br />

SELECTOR<br />

COMPONENT<br />

>> 1996 | 1997 | 1998 | 1999<br />

Innovation<br />

CIRCULAR KNITTING<br />

NEEDLE – JUST ONE OF<br />

COUNTLESS PATENTS<br />

1996_Selector for electronically<br />

controlled knitting machines.<br />

1996_Fine-gauge fork needle with<br />

gauge 38 gg.<br />

1997_Introduction of the felting needle<br />

GEBEDUR ® II. It is used for needling<br />

natural fibres as well as insulation and<br />

fireproof materials.<br />

1998_Introduction of the Cross STAR ®<br />

felting needle for production of the most<br />

uniform fabric.<br />

GAUGE PARTS TUFTING<br />

Range expansion<br />

1998_Acquisition of the "Eisbär" trademark<br />

and the tufting needle business<br />

of Jos. Zimmermann, Aachen.<br />

1999_Acquisition of the Singer Factory<br />

in Würselen.<br />

Internationality<br />

1998_Foundation of distribution subsidiary<br />

Sinotech Asia Ltd., Hong Kong.<br />

Cross STAR ®

2000 | 2001 | 2002<br />

Range expansion<br />

2000_<strong>Groz</strong>-<strong>Beckert</strong> acquires the Swiss<br />

company GROB HORGEN AG and is now<br />

active in the weaving-machine accessories<br />

market segment.<br />

New building<br />

2000_<strong>Groz</strong>-<strong>Beckert</strong> expands its production<br />

facilities in Albstadt.<br />

HEADQUARTERS IN<br />

ALBSTADT, GERMANY<br />

DISTRIBUTION SUBSIDIARY,<br />

HONG KONG<br />

Internationality<br />

2001_Foundation of two further distribution<br />

subsidiaries in Seoul, South Korea<br />

and Singapore.<br />

Range expansion<br />

2001_<strong>Groz</strong>-<strong>Beckert</strong> acquires the company<br />

of SCHMEING, Raesfeld, Germany, thereby<br />

expanding its weaving-machine accessories<br />

segment.<br />

Innovation<br />

2001_Special application needle SAN ® 11<br />

for multidirectional automatic and difficult<br />

quilt-stitching applications.<br />

2002_ALforfix ® heald frame.<br />

2002_The company has 40 active patents<br />

in the knitting sector alone.<br />

Jubilee<br />

2002_<strong>Groz</strong>-<strong>Beckert</strong> celebrates its 150th<br />

anniversary.<br />

1996 - 2002 | 19<br />

>>

20 | 2003 - 2007<br />

litespeed ® HyTec ®<br />

>> 2003 | 2004 | 2005<br />

Range expansion<br />

2003_Further expansion in the sewingmachine-needle<br />

sector.<br />

2004_<strong>Groz</strong>-<strong>Beckert</strong> enters the system<br />

components sector<br />

GEBECON ® SYSTEM COMPONENTS<br />

JETSTRIP<br />

TRANSFER<br />

WING NEEDLE<br />

Innovation<br />

2003_The litespeed ® needle is presented<br />

at the ITMA in Birmingham.<br />

2003_The GEBECON ® needle is patented.<br />

2004_<strong>Groz</strong>-<strong>Beckert</strong> discontinues the first<br />

HyTec ® jetstrips for waterjet hydroentanglement<br />

systems and taps new markets.<br />

2004_New fine-gauge fork needle with<br />

gauge 43 gg.<br />

2005_Introduction of the transfer<br />

wing needle and the TWIN C Power ® heald<br />

frame.<br />

Internationality<br />

2004_Foundation of P.T. <strong>Groz</strong>-<strong>Beckert</strong><br />

Indonesia in Bandung, as a new distribution<br />

subsidiary.<br />

TWIN C Power ® HEALD FRAME

TWINTEC ® TWIN FLAT STEEL HEALD<br />

2006 | 2007<br />

Range expansion<br />

NEEDLEHOLDER<br />

GEBESWITCH ®<br />

2006_Takeover of SMC GmbH and<br />

expansion of the range with cylinders,<br />

dials and sinker rings for circular knitting<br />

machines.<br />

2007_Acquisition of the Bräcker company's<br />

heald eye business.<br />

Innovation<br />

2007_Numerous different products<br />

and systems are presented at the ITMA<br />

in Munich:<br />

- OPTILOOP ® coating for knitting-machine<br />

needles.<br />

- Innovative packaging solutions for<br />

sinkers in knitting cylinders.<br />

- Circular knitting head for gauge E66.<br />

- Segmented cylinders for circular<br />

knitting machines to reduce energy<br />

consumption.<br />

- Cylinder with cooling ducts for active<br />

cooling systems.<br />

- Needle Oil Test Kit – neutral oil consulting<br />

and analysis in the knitting sector.<br />

KNITTING HEAD FOR CIRCULAR<br />

KNITTING MACHINES<br />

- TWINtec ® twin flat steel healds, new<br />

leno healds and ALtop ® heald frame.<br />

- Shedding system for weaving.<br />

- Board Master System (BMS) for all-round<br />

effective needleboard handling.<br />

- Developments in all-steel sets for the<br />

production of nonwoven and velour.<br />

- New generation Level Cut Looper (LCL),<br />

Nickel-Free Finish (NFF) and Cut Pile<br />

Looper Tungsten Insert (CPL-TI) for<br />

tufting.<br />

- Needleholder GEBESWITCH ® for mediumheavy<br />

lockstitching machines.<br />

New building<br />

2006_Preparations begin for the<br />

Technology and Development Centre at<br />

the company headquarters in Albstadt.<br />

2003 - 2007 | 21<br />

THE PLANNING PHASE:<br />

THE TECHNOLOGY AND DEVELOPMENT CENTRE<br />

AS A 3D MODEL<br />

SHEDDING SYSTEM FOR<br />

WEAVING MACHINES<br />

>>

22 | 2008- 2010<br />

TEXTILE REINFORCED<br />

CONCRETE BRIDGE IN<br />

ALBSTADT-LAUTLINGEN<br />

PosiLeno ® FRAME<br />

>> 2008 | 2009 | 2010<br />

Range expansion<br />

2008_Acquisition of the mechanical<br />

engineering companies Oskar Fischer<br />

GmbH and Knotex GmbH & Co. KG in<br />

the weaving sector.<br />

Innovation<br />

2008_Conversion kit for rotary knitting<br />

machines from gauges E28 to E44.<br />

2008_Positively driven leno device<br />

PosiLeno ® for far higher processing speeds.<br />

2008_ALbasic ® heald frame for looper<br />

weaving machines.<br />

2008_LPC lockstitch (Loop Position<br />

Control).<br />

2010_LPC chainstitch (Loop Position<br />

Control)<br />

Internationality<br />

2008_The distribution subsidiary<br />

<strong>Groz</strong>-<strong>Beckert</strong> Taiwan Ltd. begins operations<br />

in Taipei.<br />

2008_Foundation of <strong>Groz</strong>-<strong>Beckert</strong> Vietnam<br />

in Ai Nghia, Vietnam.<br />

Social<br />

2008_Construction work for a pathbreaking<br />

textile concrete bridge in<br />

Albstadt is given the go-ahead – a project<br />

comprehensively accompanied and<br />

supported by <strong>Groz</strong>-<strong>Beckert</strong>.<br />

2009_Short-time work and qualification<br />

measures as a consequence of the global<br />

recession.<br />

2010_Completion of the textile reinforced<br />

concrete bridge in Albstadt-Lautlingen<br />

and handover to the town of Albstadt.<br />

2010_Awarded the KYOCERA<br />

Environment Prize in the former German<br />

Bundestag, Bonn.<br />

New building<br />

2008_Construction work commences<br />

on the Technology and Development<br />

Centre at the company headquarters in<br />

Albstadt, Germany.<br />

2010_Official opening of the Technology<br />

and Development Centre (TEZ).<br />

FREE FOR USE FROM 2010:<br />

THE TECHNOLOGY AND DEVELOPMENT CENTRE

KNITTING I WEAVING I FELTING I TUFTING I SEWING<br />

www.groz-beckert.com<br />

EN | 06.2011