Issue 03/2016

bioplasticsMAGAZINE_1603

bioplasticsMAGAZINE_1603

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cover story<br />

on which all the fingers were missing. “Of course” Ivan<br />

agreed and, together with Richard the carpenter, created<br />

a prototype hand for Liam. It worked, but it was “metal,<br />

clunky and ugly”, as Jen described it. They nicknamed it<br />

the “Frankenhand”. Yet soon, a far more serious realization<br />

dawned: children grow, and therefore Liam would quickly<br />

outgrow the hand. How to solve this problem?<br />

To make a much longer story short, they decided to try<br />

3D-printing. With the help of two 3D-printers donated by<br />

MakerBot, Ivan taught himself how to code and design.<br />

They created the first PLA plastic hand, which Richard the<br />

carpenter then 3D-printed for Liam. And soon they<br />

realized, that if there was one child like Liam –<br />

there must be thousands in the world… .<br />

Now, instead of patenting the<br />

design – he felt it was too big<br />

to keep for himself – Ivan put<br />

the files online, open source,<br />

in the public domain, so<br />

that anyone, anywhere could<br />

print a hand for somebody<br />

who needed one. And from<br />

there, the project just took off.<br />

A Google+ group and an online<br />

map was created on which people<br />

willing to volunteer the use of their printer<br />

could show their location, so that people who<br />

needed hands would know who they could turn<br />

to. Thus the enable-the-future community was<br />

born.<br />

The group of volunteers quickly grew to<br />

more than 8,000 worldwide today and more<br />

than 2,000 hands have since been printed and<br />

distributed to children around the globe. The<br />

hands, made from PLA, can be scaled to fit any<br />

child’s size. The parts snap together easily. If a<br />

finger breaks, a new one can be printed to fit<br />

the hand.<br />

Then, in the course of the project, “they started<br />

getting creative”, said Jen. “There are LED light<br />

fingertips, there are laser pointers to terrify the cat,<br />

superhero hands, Star Wars hands – you name it,<br />

it’s out there,” said Jen. “The superhero hands are<br />

probably the most popular.”<br />

“These designs are basic hands. They have just a basic<br />

grasping motion. They’re nowhere near as robust as<br />

a traditional prosthetic, but for children who were born<br />

with no fingers and a palm, there was nothing available<br />

for them in the general prosthetic world. And these can<br />

be made for USD 30 to 50, versus USD 3,000 to 5,000<br />

traditional prosthetics would cost their families.” Plus,<br />

they would need a new size every 6 to 12 months.<br />

As time has gone by, families have learned to make (and<br />

repair) hands for their own kids. Children have started to<br />

make hands for other children. Schools, boy scout and girl<br />

scout troops have launched projects to make hands and<br />

ship them to clinics along the Syrian border and to Africa.<br />

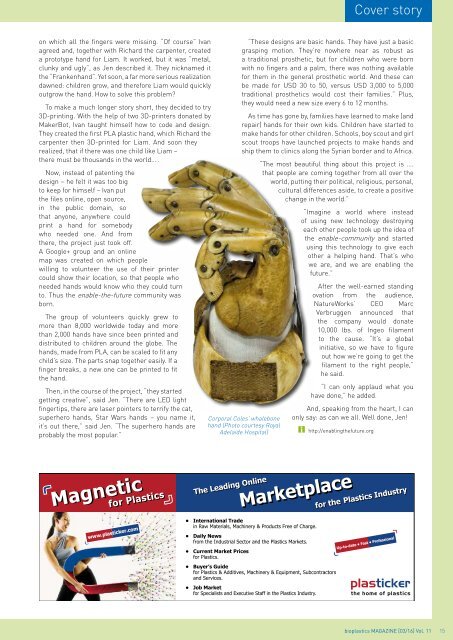

Corporal Coles’ whalebone<br />

hand (Photo courtesy Royal<br />

Adelaide Hospital)<br />

“The most beautiful thing about this project is ….<br />

that people are coming together from all over the<br />

world, putting their political, religious, personal,<br />

cultural differences aside, to create a positive<br />

change in the world.”<br />

“Imagine a world where instead<br />

of using new technology destroying<br />

each other people took up the idea of<br />

the enable-community and started<br />

using this technology to give each<br />

other a helping hand. That’s who<br />

we are, and we are enabling the<br />

future.”<br />

After the well-earned standing<br />

ovation from the audience,<br />

NatureWorks’ CEO Marc<br />

Verbruggen announced that<br />

the company would donate<br />

10,000 lbs. of Ingeo filament<br />

to the cause. “It’s a global<br />

initiative, so we have to figure<br />

out how we’re going to get the<br />

filament to the right people,”<br />

he said.<br />

“I can only applaud what you<br />

have done,” he added.<br />

And, speaking from the heart, I can<br />

only say: as can we all. Well done, Jen!<br />

http://enablingthefuture.org<br />

Magnetic<br />

for Plastics<br />

www.plasticker.com<br />

• International Trade<br />

in Raw Materials, Machinery & Products Free of Charge.<br />

• Daily News<br />

from the Industrial Sector and the Plastics Markets.<br />

• Current Market Prices<br />

for Plastics.<br />

• Buyer’s Guide<br />

for Plastics & Additives, Machinery & Equipment, Subcontractors<br />

and Services.<br />

• Job Market<br />

for Specialists and Executive Staff in the Plastics Industry.<br />

Up-to-date • Fast • Professional<br />

bioplastics MAGAZINE [<strong>03</strong>/16] Vol. 11 15