Issue 04/2016

bioplasticsMAGAZINE_1604

bioplasticsMAGAZINE_1604

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Toys<br />

By:<br />

Nikola Kocić, Martin Bastian, Bernhard Ulmer,<br />

Marieluise Lang, Peter Heidemeyer<br />

German Plastics Center SKZ<br />

Dirk Schawaller, Michael Schweizer, Helmut Nägele<br />

Tecnaro GmbH<br />

A slightly lower tensile strength of the biobased materials<br />

can be compensated through adaptation of the part<br />

design. The amount of renewable raw materials (without<br />

filler) in the developed compounds is approx. 64 wt.%. The<br />

materials exhibit good processability regarding injection<br />

moulding with the processing temperature being 50 °C<br />

lower than that of PVC-p. This considerably reduces the<br />

energy consumption and the related production costs.<br />

Additionally, toys made of biobased materials showed<br />

good results regarding coloring. The first demonstrator<br />

toy, the horse “Falabella”, was produced by Schleich<br />

GmbH and directly coloured under serial conditions. The<br />

result is presented in figure 4.<br />

Based on the results obtained by SKZ, the upscaling trials<br />

were performed by Tecnaro GmbH. In scope of these trials,<br />

further biobased materials (special grades of Arboblend)<br />

with special consideration of the economic aspects were<br />

developed. The mechanical and thermal properties of the<br />

biobased materials obtained by Tecnaro are equal to that<br />

of the commercial PVC-p materials. Furthermore, the new<br />

biobased materials show better thermal resistance than<br />

PVC-p. The paintability as well as the paint adherence of<br />

the injection moulded toys made of Tecnaro’s biobased<br />

materials were examined and confirmed. As example, the<br />

demonstrator toy „Tigerjunges“ produced and painted by<br />

Schleich GmbH are shown in figure 5.<br />

The project is conducted in the framework of the<br />

program “Biobased Polymers and Biobased Natural Fibre<br />

Reinforced Plastics” of the German Federal Ministry of<br />

Food and Agriculture and financially supported via the<br />

Agency of Renewable Resources (FNR)..<br />

www.skz.de<br />

Bernd Kugler<br />

Schleich GmbH<br />

Frank Waiblinger<br />

Konrad Hornschuch AG<br />

Figure 3: Elongation at break and tensile strength of biobased<br />

materials developed by SKZ compared to standard PVC-p,<br />

used for the toys production.<br />

Elongation at break (%)<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Bio<br />

alternative 1<br />

Bio<br />

alternative 2<br />

PVC-p<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Tensile strength (MPa)<br />

Figure 4: Horse „Falabella“ made by Schleich GmbH using<br />

the biobased materials developed at SKZ<br />

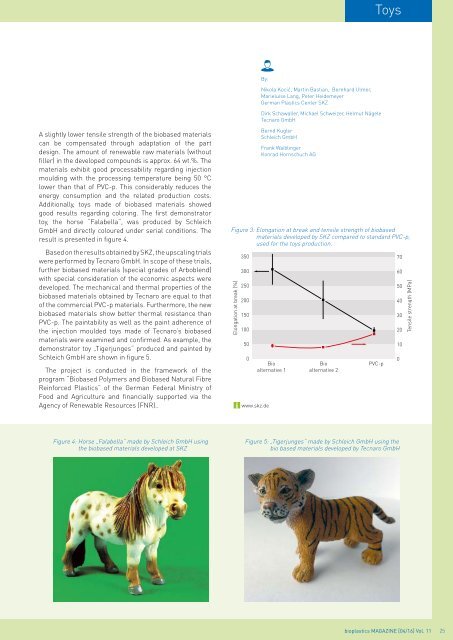

Figure 5: „Tigerjunges“ made by Schleich GmbH using the<br />

bio based materials developed by Tecnaro GmbH<br />

bioplastics MAGAZINE [<strong>04</strong>/16] Vol. 11 25