Issue 04/2016

bioplasticsMAGAZINE_1604

bioplasticsMAGAZINE_1604

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Blow Moulding<br />

By:<br />

Pilar Diego, Chelo Escrig<br />

Extrusion Department<br />

AIMPLAS (Plastics Technology Center)<br />

Valencia, Spain<br />

Partners<br />

Seven companies and technological centers have<br />

worked with AIMPLAS, who has coordinated this project;<br />

VLB (Germany), OWS (Belgium), CNR (Italy), VIZELPAS,<br />

ESPAÇOPLAS (Portugal) and ALMUPLAS, ALJUAN (Spain).<br />

About AIMPLAS<br />

AIMPLAS is a Plastics Technology Center located in<br />

Valencia, Spain. It is a non-profit research association<br />

which has the objective of acting as a technological<br />

partner with companies in all sectors related to plastics,<br />

customizing integral and personalized solutions through<br />

the coordination of R&D&I projects and technological<br />

services.<br />

Mode of operation<br />

The 2-year project was finished in May <strong>2016</strong>. The first<br />

period of the project was mainly focused on the studies at<br />

lab and pilot plant scale while the second period mostly<br />

concentrated on the industrial scale-up, product validation<br />

and environmental and economic studies, i. e.:<br />

• Definition of requirements, material selection based on<br />

the biodegradable materials and additives and study of<br />

chemical modifications<br />

• Evaluation of bio-compounds’ processability at pilot<br />

plant level considering the different manufacturing<br />

processes: Blown film extrusion and form-sealing<br />

packaging machine to obtain pouches, extrusion blow<br />

moulding for bottles and injection moulding for caps.<br />

• The scaling-up industrial processes according to<br />

the optimized parameters at pilot plant level and the<br />

optimization state to achieve the desired output (see<br />

figures)<br />

• Full characterization and validation of the final industrial<br />

products to be used in the dairy applications defined<br />

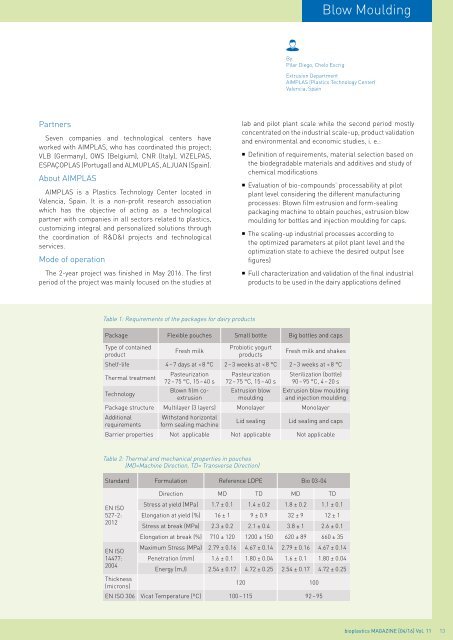

Table 1: Requirements of the packages for dairy products<br />

Package Flexible pouches Small bottle Big bottles and caps<br />

Type of contained<br />

product<br />

Fresh milk<br />

Probiotic yogurt<br />

products<br />

Fresh milk and shakes<br />

Shelf-life 4 – 7 days at < 8 °C 2 – 3 weeks at < 8 °C 2 – 3 weeks at < 8 °C<br />

Thermal treatment<br />

Technology<br />

Pasteurization<br />

72 – 75 °C, 15 – 40 s<br />

Blown film coextrusion<br />

Pasteurization<br />

72 – 75 °C, 15 – 40 s<br />

Extrusion blow<br />

moulding<br />

Sterilization (bottle)<br />

90 – 95 °C, 4 – 20 s<br />

Extrusion blow moulding<br />

and injection moulding<br />

Package structure Multilayer (3 layers) Monolayer Monolayer<br />

Additional<br />

requirements<br />

Withstand horizontal<br />

form sealing machine<br />

Lid sealing<br />

Lid sealing and caps<br />

Barrier properties Not applicable Not applicable Not applicable<br />

Table 2: Thermal and mechanical properties in pouches<br />

(MD=Machine Direction, TD= Transverse Direction)<br />

Standard Formulation Reference LDPE Bio 03-<strong>04</strong><br />

EN ISO<br />

527-2:<br />

2012<br />

EN ISO<br />

14477:<br />

20<strong>04</strong><br />

Direction MD TD MD TD<br />

Stress at yield (MPa) 1.7 ± 0.1 1.4 ± 0.2 1.8 ± 0.2 1.1 ± 0.1<br />

Elongation at yield (%) 16 ± 1 9 ± 0.9 32 ± 9 12 ± 1<br />

Stress at break (MPa) 2.3 ± 0.2 2.1 ± 0.4 3.8 ± 1 2.6 ± 0.1<br />

Elongation at break (%) 710 ± 120 1200 ± 150 620 ± 89 660 ± 35<br />

Maximum Stress (MPa) 2.79 ± 0.16 4.67 ± 0.14 2.79 ± 0.16 4.67 ± 0.14<br />

Penetration (mm) 1.6 ± 0.1 1.80 ± 0.<strong>04</strong> 1.6 ± 0.1 1.80 ± 0.<strong>04</strong><br />

Energy (mJ) 2.54 ± 0.17 4.72 ± 0.25 2.54 ± 0.17 4.72 ± 0.25<br />

Thickness<br />

(microns)<br />

120 100<br />

EN ISO 306 Vicat Temperature (ºC) 100 – 115 92 – 95<br />

bioplastics MAGAZINE [<strong>04</strong>/16] Vol. 11 13