Issue 06/2018

bioplasticsMAGAZINE_1806

bioplasticsMAGAZINE_1806

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

From Science & Research<br />

To obtain land use data from production capacities in this<br />

bottom-up approach (see Table 1), it needs producer-specific<br />

production capacities of a type of bioplastics to be multiplied by<br />

the output data of the corresponding process routes. If producerspecific<br />

feedstock was known, it was taken into consideration.<br />

In other cases, where these data were missing, only the most<br />

common used crop per material was taken into consideration (e.g.<br />

corn starch for PLA).<br />

For the basic assumptions referring to PLA, previous estimates<br />

of IfBB resulted in a need of 0.37 hectares land for feedstock<br />

cultivation per tonne of material. This is a corn-based, PLAspecific<br />

global average land use factor, for which the following<br />

calculation impact factors (CIF) are assumed.<br />

One obvious impact factor on land use of bioplastics might be<br />

the production capacity itself. According to own research, total<br />

annual installed capacity for PLA worldwide in 2017 was roughly<br />

240,000 tonnes, which gives 88,300 hectares according to the<br />

basic assumptions. However, is relying on the installed capacity<br />

correct? Very few industrial plants run at full degree of capacity<br />

continuously, so an optimistic sensitivity would be 85 % degree of<br />

capacity.<br />

Another impact factor is the region specific yield of a feedstock<br />

in different countries. While for the basic estimation for PLA made<br />

out of corn, a global average yield of 6.5 tonnes of corn per hectare<br />

over the past decade (weighted by production amount) (FAO <strong>2018</strong>),<br />

corn being grown in the United States in the same period would<br />

yield in 9.5 tonnes per hectare and the same acreage in China<br />

delivered 40 % less of corn (5.5 t / ha). This is even more important,<br />

as corn from USA makes up to 37 % of world’s corn production,<br />

but China, with its significantly lower yield per hectare still ranks at<br />

an important one fifth (20 %) of global corn production. Therefore it<br />

has a decreasing effect on the global average corn yield (6.5 t / ha).<br />

Further impacts derive from natural harvesting fluctuation.<br />

Using single year data leads to tremendous deviation in calculating<br />

PLA land use. Comparing available corn yields between 2002<br />

and 2013 for e.g. corn in the USA shows, that there is a deviation<br />

between minimum and maximum of 3.2 tonnes per hectare<br />

(Average yield: 9.1 t / ha). By using either minimum or maximum<br />

yield data of a given period for calculation will result in this case in<br />

a fluctuation of land use of +43 % or -30 %.<br />

But even when looking at a global average yield for corn, the<br />

choice of a certain decade leads to different results. Using a global<br />

average yield over a mid-term period (10 years) helps to minimize<br />

natural harvesting fluctuation while at the same time provides<br />

data, which are not influenced by single local yield deviations.<br />

When comparing two different time periods (2002 – 2011 and 2003<br />

– 2014), the worldwide general increase in harvesting yields of<br />

corn raised by 2.5 %. For other (food) crops relevant in bioplastics<br />

production, the increase is at the same level or even higher, e.g.<br />

sugar beet (+ 5.9 %), sugar cane (+ 1.9 %) and castor oil (+ 17.1 %).<br />

Advances in crop growing techniques and better feedstock yields<br />

result in a lower land use, which decreases to the same extent<br />

for each bioplastic material. Even without changes in bioplastics<br />

technology (1st, 2nd, 3rd generation), future land use per tonne of<br />

bioplastic material will de facto decrease.<br />

Additional impact factors could arise from the source of<br />

feedstock (e.g. PLA made from sugar cane versus corn starch)<br />

and allocation assumptions. Allocation is in detail also a very<br />

complex topic and would go beyond the scope of this comparison<br />

as there are different factors itself, which can be used. In general,<br />

this would be mass-balanced, energy-balanced or economicbalanced<br />

allocation. In this case, if using residues is being taken<br />

into account, the bioplastic material will only be burdened with<br />

parts of the full impact of its land use. To make a proposal, the<br />

results will cover 30 % use of residues.<br />

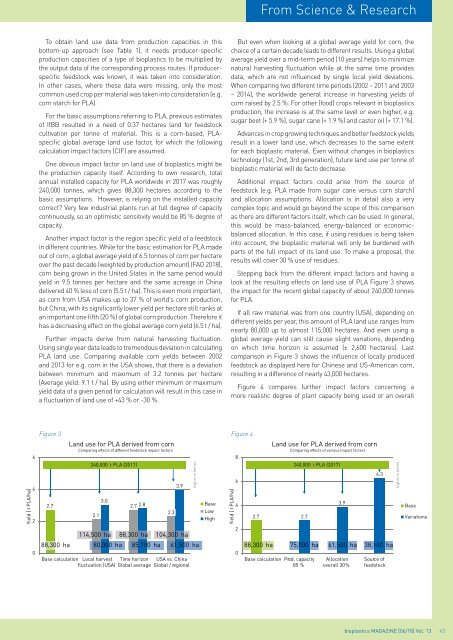

Stepping back from the different impact factors and having a<br />

look at the resulting effects on land use of PLA Figure 3 shows<br />

the impact for the recent global capacity of about 240,000 tonnes<br />

for PLA.<br />

If all raw material was from one country (USA), depending on<br />

different yields per year, this amount of PLA land use ranges from<br />

nearly 80,000 up to almost 115,000 hectares. And even using a<br />

global average yield can still cause slight variations, depending<br />

on which time horizon is assumed (± 2,600 hectares). Last<br />

comparison in Figure 3 shows the influence of locally produced<br />

feedstock as displayed here for Chinese and US-American corn,<br />

resulting in a difference of nearly 43,000 hectares.<br />

Figure 4 compares further impact factors concerning a<br />

more realistic degree of plant capacity being used or an overall<br />

Yield [ t PLA/ha]<br />

6<br />

4<br />

2<br />

0<br />

Figure 3 Figure 4<br />

2.7<br />

Land use for PLA derived from corn<br />

Comparing effects of different feedstock impact factors<br />

240,000 t PLA (2017)<br />

2.1<br />

3.0<br />

114,500 ha<br />

88,300 ha 80,000 ha<br />

Base calculation Local harvest<br />

fluctuation (USA)<br />

2.7 2.8<br />

88,300 ha<br />

Time horizon<br />

Global average<br />

2.3<br />

3.9<br />

104,300 ha<br />

USA vs. China<br />

Global / regional<br />

higher is better<br />

85,700 ha 61,500 ha<br />

Base<br />

Low<br />

High<br />

Yield [ t PLA/ha]<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Land use for PLA derived from corn<br />

Comparing effects of various impact factors<br />

2.7 2.7<br />

Base calculation Prod. capacity<br />

85 %<br />

240,000 t PLA (2017)<br />

88,300 ha 75,000 ha 61,500 ha 38,100 ha<br />

3.9<br />

Allocation<br />

overall 30 %<br />

6.3<br />

Source of<br />

feedstock<br />

higher is better<br />

Base<br />

Variations<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 43