fluid_mechanics

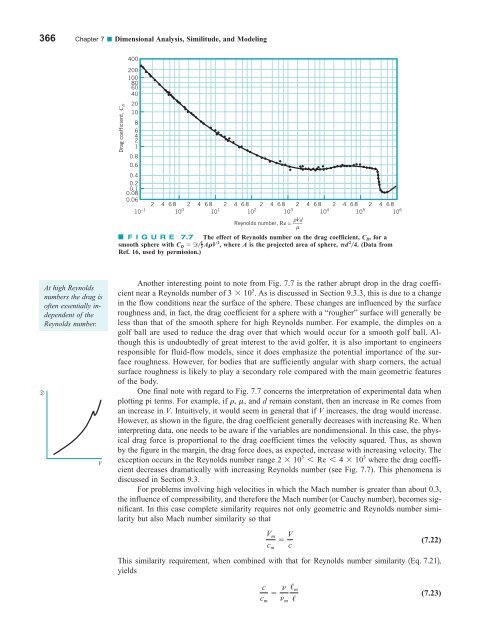

366 Chapter 7 ■ Dimensional Analysis, Similitude, and Modeling 400 Drag coefficient, C D 200 100 80 60 40 20 10 8 6 4 2 1 0.8 0.6 0.4 0.2 0.1 0.08 0.06 2 4 68 2 4 68 2 4 68 2 4 68 2 4 68 2 4 68 2 4 68 10 –1 10 0 10 1 10 2 10 3 10 4 10 5 10 6 Reynolds number, Re = ____ ρ Vd μ F I G U R E 7.7 The effect of Reynolds number on the drag coefficient, C D , for a smooth sphere with C where A is the projected area of sphere, Pd 2 D d 1 2 ARV 2 , 4. (Data from Ref. 16, used by permission.) At high Reynolds numbers the drag is often essentially independent of the Reynolds number. V Another interesting point to note from Fig. 7.7 is the rather abrupt drop in the drag coefficient near a Reynolds number of 3 10 5 . As is discussed in Section 9.3.3, this is due to a change in the flow conditions near the surface of the sphere. These changes are influenced by the surface roughness and, in fact, the drag coefficient for a sphere with a “rougher” surface will generally be less than that of the smooth sphere for high Reynolds number. For example, the dimples on a golf ball are used to reduce the drag over that which would occur for a smooth golf ball. Although this is undoubtedly of great interest to the avid golfer, it is also important to engineers responsible for fluid-flow models, since it does emphasize the potential importance of the surface roughness. However, for bodies that are sufficiently angular with sharp corners, the actual surface roughness is likely to play a secondary role compared with the main geometric features of the body. One final note with regard to Fig. 7.7 concerns the interpretation of experimental data when plotting pi terms. For example, if r, m, and d remain constant, then an increase in Re comes from an increase in V. Intuitively, it would seem in general that if V increases, the drag would increase. However, as shown in the figure, the drag coefficient generally decreases with increasing Re. When interpreting data, one needs to be aware if the variables are nondimensional. In this case, the physical drag force is proportional to the drag coefficient times the velocity squared. Thus, as shown by the figure in the margin, the drag force does, as expected, increase with increasing velocity. The exception occurs in the Reynolds number range 2 10 5 6 Re 6 4 10 5 where the drag coefficient decreases dramatically with increasing Reynolds number (see Fig. 7.7). This phenomena is discussed in Section 9.3. For problems involving high velocities in which the Mach number is greater than about 0.3, the influence of compressibility, and therefore the Mach number 1or Cauchy number2, becomes significant. In this case complete similarity requires not only geometric and Reynolds number similarity but also Mach number similarity so that V m c m V c (7.22) This similarity requirement, when combined with that for Reynolds number similarity 1Eq. 7.212, yields c c m n n m / m / (7.23)

7.9 Some Typical Model Studies 367 Clearly the same fluid with c c m and n n m cannot be used in model and prototype unless the length scale is unity 1which means that we are running tests on the prototype2. In high-speed aerodynamics the prototype fluid is usually air, and it is difficult to satisfy Eq. 7.23 for reasonable length scales. Thus, models involving high-speed flows are often distorted with respect to Reynolds number similarity, but Mach number similarity is maintained. Froude number similarity is usually required for models involving freesurface flows. V7.17 River flow model 7.9.3 Flow with a Free Surface Flows in canals, rivers, spillways, and stilling basins, as well as flow around ships, are all examples of flow phenomena involving a free surface. For this class of problems, both gravitational and inertial forces are important and, therefore, the Froude number becomes an important similarity parameter. Also, since there is a free surface with a liquid–air interface, forces due to surface tension may be significant, and the Weber number becomes another similarity parameter that needs to be considered along with the Reynolds number. Geometric variables will obviously still be important. Thus a general formulation for problems involving flow with a free surface can be expressed as Dependent pi term f a / i (7.24) / , e / , rV/ m , V 2g/ , rV 2 / s b As discussed previously, / is some characteristic length of the system, / i represents other pertinent lengths, and e/ is the relative roughness of the various surfaces. Since gravity is the driving force in these problems, Froude number similarity is definitely required so that V m 2g m / m V 2g/ The model and prototype are expected to operate in the same gravitational field 1g m g2, and therefore it follows that V m V / m B / 1l / (7.25) Thus, when models are designed on the basis of Froude number similarity, the velocity scale is determined by the square root of the length scale. As is discussed in Section 7.8.3, to simultaneously have Reynolds and Froude number similarity it is necessary that the kinematic viscosity scale be related to the length scale as n m n 1l /2 3 2 (7.26) The working fluid for the prototype is normally either freshwater or seawater and the length scale is small. Under these circumstances it is virtually impossible to satisfy Eq. 7.26, so models involving free-surface flows are usually distorted. The problem is further complicated if an attempt is made to model surface tension effects, since this requires the equality of Weber numbers, which leads to the condition V7.18 Boat model s mr m sr 1l /2 2 (7.27) for the kinematic surface tension 1sr2. It is again evident that the same fluid cannot be used in model and prototype if we are to have similitude with respect to surface tension effects for l / 1. Fortunately, in many problems involving free-surface flows, both surface tension and viscous effects are small and consequently strict adherence to Weber and Reynolds number similarity is not required. Certainly, surface tension is not important in large hydraulic structures and rivers. Our only concern would be if in a model the depths were reduced to the point where surface tension becomes an important factor, whereas it is not in the prototype. This is of particular importance in the design of river models, since the length scales are typically small 1so that the width of the model is reasonable2, but with a small length scale the required model depth may be very small. To overcome this problem, different horizontal and vertical length scales are often used for river

- Page 340 and 341: 316 Chapter 6 ■ Differential Anal

- Page 342 and 343: 318 Chapter 6 ■ Differential Anal

- Page 344 and 345: 320 Chapter 6 ■ Differential Anal

- Page 346 and 347: 322 Chapter 6 ■ Differential Anal

- Page 348 and 349: 324 Chapter 6 ■ Differential Anal

- Page 350 and 351: 326 Chapter 6 ■ Differential Anal

- Page 352 and 353: 328 Chapter 6 ■ Differential Anal

- Page 354 and 355: 330 Chapter 6 ■ Differential Anal

- Page 356 and 357: 7 Dimensional Analysis, Similitude,

- Page 358 and 359: 334 Chapter 7 ■ Dimensional Analy

- Page 360 and 361: 336 Chapter 7 ■ Dimensional Analy

- Page 362 and 363: 338 Chapter 7 ■ Dimensional Analy

- Page 364 and 365: 340 Chapter 7 ■ Dimensional Analy

- Page 366 and 367: 342 Chapter 7 ■ Dimensional Analy

- Page 368 and 369: 344 Chapter 7 ■ Dimensional Analy

- Page 370 and 371: 346 Chapter 7 ■ Dimensional Analy

- Page 372 and 373: 348 Chapter 7 ■ Dimensional Analy

- Page 374 and 375: 350 Chapter 7 ■ Dimensional Analy

- Page 376 and 377: 352 Chapter 7 ■ Dimensional Analy

- Page 378 and 379: 354 Chapter 7 ■ Dimensional Analy

- Page 380 and 381: 356 Chapter 7 ■ Dimensional Analy

- Page 382 and 383: 358 Chapter 7 ■ Dimensional Analy

- Page 384 and 385: 360 Chapter 7 ■ Dimensional Analy

- Page 386 and 387: 362 Chapter 7 ■ Dimensional Analy

- Page 388 and 389: 364 Chapter 7 ■ Dimensional Analy

- Page 392 and 393: 368 Chapter 7 ■ Dimensional Analy

- Page 394 and 395: 370 Chapter 7 ■ Dimensional Analy

- Page 396 and 397: 372 Chapter 7 ■ Dimensional Analy

- Page 398 and 399: 374 Chapter 7 ■ Dimensional Analy

- Page 400 and 401: 376 Chapter 7 ■ Dimensional Analy

- Page 402 and 403: 378 Chapter 7 ■ Dimensional Analy

- Page 404 and 405: 380 Chapter 7 ■ Dimensional Analy

- Page 406 and 407: 382 Chapter 7 ■ Dimensional Analy

- Page 408 and 409: 384 Chapter 8 ■ Viscous Flow in P

- Page 410 and 411: 386 Chapter 8 ■ Viscous Flow in P

- Page 412 and 413: 388 Chapter 8 ■ Viscous Flow in P

- Page 414 and 415: 390 Chapter 8 ■ Viscous Flow in P

- Page 416 and 417: 392 Chapter 8 ■ Viscous Flow in P

- Page 418 and 419: 394 Chapter 8 ■ Viscous Flow in P

- Page 420 and 421: 396 Chapter 8 ■ Viscous Flow in P

- Page 422 and 423: 398 Chapter 8 ■ Viscous Flow in P

- Page 424 and 425: 400 Chapter 8 ■ Viscous Flow in P

- Page 426 and 427: 402 Chapter 8 ■ Viscous Flow in P

- Page 428 and 429: 404 Chapter 8 ■ Viscous Flow in P

- Page 430 and 431: 406 Chapter 8 ■ Viscous Flow in P

- Page 432 and 433: 408 Chapter 8 ■ Viscous Flow in P

- Page 434 and 435: 410 Chapter 8 ■ Viscous Flow in P

- Page 436 and 437: 412 Chapter 8 ■ Viscous Flow in P

- Page 438 and 439: 414 Chapter 8 ■ Viscous Flow in P

366 Chapter 7 ■ Dimensional Analysis, Similitude, and Modeling<br />

400<br />

Drag coefficient, C D<br />

200<br />

100<br />

80<br />

60<br />

40<br />

20<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.1<br />

0.08<br />

0.06<br />

2 4 68 2 4 68 2 4 68 2 4 68 2 4 68 2 4 68 2 4 68<br />

10 –1 10 0 10 1 10 2 10 3 10 4 10 5 10 6<br />

Reynolds number, Re = ____ ρ Vd<br />

μ<br />

F I G U R E 7.7 The effect of Reynolds number on the drag coefficient, C D , for a<br />

smooth sphere with C where A is the projected area of sphere, Pd 2 D d 1 2 ARV 2 ,<br />

4. (Data from<br />

Ref. 16, used by permission.)<br />

<br />

At high Reynolds<br />

numbers the drag is<br />

often essentially independent<br />

of the<br />

Reynolds number.<br />

V<br />

Another interesting point to note from Fig. 7.7 is the rather abrupt drop in the drag coefficient<br />

near a Reynolds number of 3 10 5 . As is discussed in Section 9.3.3, this is due to a change<br />

in the flow conditions near the surface of the sphere. These changes are influenced by the surface<br />

roughness and, in fact, the drag coefficient for a sphere with a “rougher” surface will generally be<br />

less than that of the smooth sphere for high Reynolds number. For example, the dimples on a<br />

golf ball are used to reduce the drag over that which would occur for a smooth golf ball. Although<br />

this is undoubtedly of great interest to the avid golfer, it is also important to engineers<br />

responsible for <strong>fluid</strong>-flow models, since it does emphasize the potential importance of the surface<br />

roughness. However, for bodies that are sufficiently angular with sharp corners, the actual<br />

surface roughness is likely to play a secondary role compared with the main geometric features<br />

of the body.<br />

One final note with regard to Fig. 7.7 concerns the interpretation of experimental data when<br />

plotting pi terms. For example, if r,<br />

m, and d remain constant, then an increase in Re comes from<br />

an increase in V. Intuitively, it would seem in general that if V increases, the drag would increase.<br />

However, as shown in the figure, the drag coefficient generally decreases with increasing Re. When<br />

interpreting data, one needs to be aware if the variables are nondimensional. In this case, the physical<br />

drag force is proportional to the drag coefficient times the velocity squared. Thus, as shown<br />

by the figure in the margin, the drag force does, as expected, increase with increasing velocity. The<br />

exception occurs in the Reynolds number range 2 10 5 6 Re 6 4 10 5 where the drag coefficient<br />

decreases dramatically with increasing Reynolds number (see Fig. 7.7). This phenomena is<br />

discussed in Section 9.3.<br />

For problems involving high velocities in which the Mach number is greater than about 0.3,<br />

the influence of compressibility, and therefore the Mach number 1or Cauchy number2, becomes significant.<br />

In this case complete similarity requires not only geometric and Reynolds number similarity<br />

but also Mach number similarity so that<br />

V m<br />

c m<br />

V c<br />

(7.22)<br />

This similarity requirement, when combined with that for Reynolds number similarity 1Eq. 7.212,<br />

yields<br />

c<br />

c m<br />

n n m<br />

/ m<br />

/<br />

(7.23)