fluid_mechanics

192 Chapter 5 ■ Finite Control Volume Analysis integral involves mass flowrates at sections 112 and 122 so that from Eq. 5.4 we get or cs rV nˆ dA m # 2 m # 1 0 m # 1 m # 2 and from Eqs. 1, 5.6, and 5.7 we obtain r 1 A 1 V 1 r 2 A 2 V 2 or since A 1 A 2 V 1 r 2 r 1 V 2 Air at the pressures and temperatures involved in this example problem behaves like an ideal gas. The ideal gas equation of state 1Eq. 1.82 is r p (4) RT (1) (2) (3) Thus, combining Eqs. 3 and 4 we obtain V 1 p 2T 1 V 2 p 1 T 2 118.4 psia21540 °R211000 ft s2 1100 psia21453 °R2 219 fts (Ans) COMMENT We learn from this example that the continuity equation 1Eq. 5.52 is valid for compressible as well as incompressible flows. Also, nonuniform velocity distributions can be handled with the average velocity concept. Significant average velocity changes can occur in pipe flow if the fluid is compressible. E XAMPLE 5.3 Conservation of Mass—Two Fluids GIVEN The inner workings of a dehumidifier are shown in Fig. E5.3a. Moist air 1a mixture of dry air and water vapor2 enters the dehumidifier at the rate of 600 lbmhr. Liquid water drains out of the dehumidifier at a rate of 3.0 lbmhr. A simplified sketch of the process is provided in Fig. E5.3b. FIND Determine the mass flowrate of the dry air and the water vapor leaving the dehumidifier. Fan Section (1) m • 4 m • 5 Control volume Cooling coil Motor Cooling coil F I G U R E E5.3a m • 1 = 600 lbm/hr Condensate (water) F I G U R E E5.3b m • 2 = ? Fan Section (2) Section (3) m • 3 = 3.0 lbm/hr SOLUTION The unknown mass flowrate at section 122 is linked with the known flowrates at sections 112 and 132 with the control volume designated with a dashed line in Fig. E5.3b. The contents of the control volume are the air and water vapor mixture and the condensate 1liquid water2 in the dehumidifier at any instant. Not included in the control volume are the fan and its motor, and the condenser coils and refrigerant. Even though the flow in the vicinity of the fan blade is unsteady, it is unsteady in a cyclical way. Thus, the flowrates at sections 112, 122, and 132 appear steady and the time rate of change of the mass of the contents of

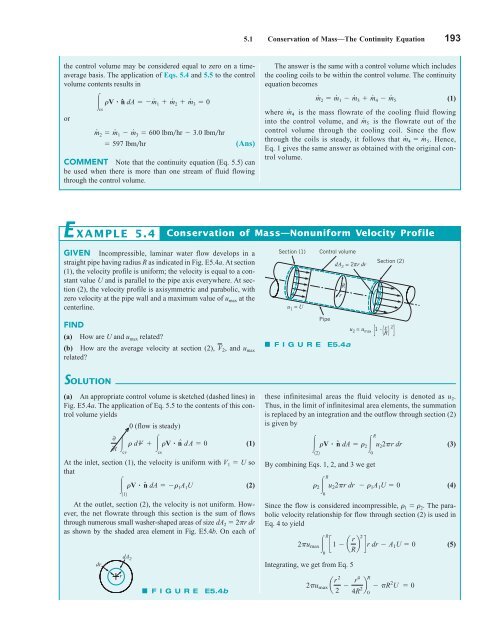

5.1 Conservation of Mass—The Continuity Equation 193 the control volume may be considered equal to zero on a timeaverage basis. The application of Eqs. 5.4 and 5.5 to the control volume contents results in rV nˆ dA m # 1 m # 2 m # 3 0 cs or m # 2 m # 1 m # 3 600 lbmhr 3.0 lbmhr 597 lbmhr (Ans) COMMENT Note that the continuity equation 1Eq. 5.52 can be used when there is more than one stream of fluid flowing through the control volume. The answer is the same with a control volume which includes the cooling coils to be within the control volume. The continuity equation becomes m # 2 m # 1 m # 3 m # 4 m # 5 where m # 4 is the mass flowrate of the cooling fluid flowing into the control volume, and m # 5 is the flowrate out of the control volume through the cooling coil. Since the flow through the coils is steady, it follows that m # 4 m # 5. Hence, Eq. 1 gives the same answer as obtained with the original control volume. (1) E XAMPLE 5.4 Conservation of Mass—Nonuniform Velocity Profile GIVEN Incompressible, laminar water flow develops in a straight pipe having radius R as indicated in Fig. E5.4a. At section (1), the velocity profile is uniform; the velocity is equal to a constant value U and is parallel to the pipe axis everywhere. At section (2), the velocity profile is axisymmetric and parabolic, with zero velocity at the pipe wall and a maximum value of u max at the centerline. FIND (a) How are U and u max related? (b) How are the average velocity at section (2), V 2 , and u max related? Section (1) u 1 = U Control volume Pipe dA 2 = 2 πr dr R r F I G U R E E5.4a Section (2) [ ( ) ] u 2 = u max 1 - _ r 2 R SOLUTION these infinitesimal areas the fluid velocity is denoted as u . (a) An appropriate control volume is sketched (dashed lines) in 2u max R c 1 a r 2 (5) R b d r dr A 1 U 0 0 dA 2 Fig. E5.4a. The application of Eq. 5.5 to the contents of this control volume yields 0 (flow is steady) 2 Thus, in the limit of infinitesimal area elements, the summation is replaced by an integration and the outflow through section (2) is given by 0 r dV (1) 0t cv rV nˆ dA 0 rV ˆn dA r 2 R u 2 2pr dr cs 122 0 (3) At the inlet, section (1), the velocity is uniform with V 1 U so that By combining Eqs. 1, 2, and 3 we get 112rV ˆn dA r 1 A 1 U (2) 2 R u 2 2r dr 1 A 1 U 0 0 (4) At the outlet, section (2), the velocity is not uniform. However, the net flowrate through this section is the sum of flows through numerous small washer-shaped areas of size dA 2 2r dr Since the flow is considered incompressible, 1 2 . The parabolic velocity relationship for flow through section (2) is used in Eq. 4 to yield as shown by the shaded area element in Fig. E5.4b. On each of dr Integrating, we get from Eq. 5 r F I G U R E E5.4b 2u max a r 2 2 r4 R 4R 2b R 2 U 0 0

- Page 166 and 167: 142 Chapter 3 ■ Elementary Fluid

- Page 168 and 169: 144 Chapter 3 ■ Elementary Fluid

- Page 170 and 171: 146 Chapter 3 ■ Elementary Fluid

- Page 172 and 173: 148 Chapter 4 ■ Fluid Kinematics

- Page 174 and 175: 150 Chapter 4 ■ Fluid Kinematics

- Page 176 and 177: 152 Chapter 4 ■ Fluid Kinematics

- Page 178 and 179: 154 Chapter 4 ■ Fluid Kinematics

- Page 180 and 181: 156 Chapter 4 ■ Fluid Kinematics

- Page 182 and 183: 158 Chapter 4 ■ Fluid Kinematics

- Page 184 and 185: 160 Chapter 4 ■ Fluid Kinematics

- Page 186 and 187: 162 Chapter 4 ■ Fluid Kinematics

- Page 188 and 189: 164 Chapter 4 ■ Fluid Kinematics

- Page 190 and 191: 166 Chapter 4 ■ Fluid Kinematics

- Page 192 and 193: 168 Chapter 4 ■ Fluid Kinematics

- Page 194 and 195: 170 Chapter 4 ■ Fluid Kinematics

- Page 196 and 197: 172 Chapter 4 ■ Fluid Kinematics

- Page 198 and 199: 174 Chapter 4 ■ Fluid Kinematics

- Page 200 and 201: 176 Chapter 4 ■ Fluid Kinematics

- Page 202 and 203: 178 Chapter 4 ■ Fluid Kinematics

- Page 204 and 205: 180 Chapter 4 ■ Fluid Kinematics

- Page 206 and 207: 182 Chapter 4 ■ Fluid Kinematics

- Page 208 and 209: 184 Chapter 4 ■ Fluid Kinematics

- Page 210 and 211: 186 Chapter 4 ■ Fluid Kinematics

- Page 212 and 213: 188 Chapter 5 ■ Finite Control Vo

- Page 214 and 215: 190 Chapter 5 ■ Finite Control Vo

- Page 218 and 219: 194 Chapter 5 ■ Finite Control Vo

- Page 220 and 221: 196 Chapter 5 ■ Finite Control Vo

- Page 222 and 223: 198 Chapter 5 ■ Finite Control Vo

- Page 224 and 225: 200 Chapter 5 ■ Finite Control Vo

- Page 226 and 227: 202 Chapter 5 ■ Finite Control Vo

- Page 228 and 229: 204 Chapter 5 ■ Finite Control Vo

- Page 230 and 231: 206 Chapter 5 ■ Finite Control Vo

- Page 232 and 233: 208 Chapter 5 ■ Finite Control Vo

- Page 234 and 235: 210 Chapter 5 ■ Finite Control Vo

- Page 236 and 237: 212 Chapter 5 ■ Finite Control Vo

- Page 238 and 239: 214 Chapter 5 ■ Finite Control Vo

- Page 240 and 241: 216 Chapter 5 ■ Finite Control Vo

- Page 242 and 243: 218 Chapter 5 ■ Finite Control Vo

- Page 244 and 245: 220 Chapter 5 ■ Finite Control Vo

- Page 246 and 247: 222 Chapter 5 ■ Finite Control Vo

- Page 248 and 249: 224 Chapter 5 ■ Finite Control Vo

- Page 250 and 251: 226 Chapter 5 ■ Finite Control Vo

- Page 252 and 253: 228 Chapter 5 ■ Finite Control Vo

- Page 254 and 255: 230 Chapter 5 ■ Finite Control Vo

- Page 256 and 257: 232 Chapter 5 ■ Finite Control Vo

- Page 258 and 259: 234 Chapter 5 ■ Finite Control Vo

- Page 260 and 261: 236 Chapter 5 ■ Finite Control Vo

- Page 262 and 263: 238 Chapter 5 ■ Finite Control Vo

- Page 264 and 265: 240 Chapter 5 ■ Finite Control Vo

5.1 Conservation of Mass—The Continuity Equation 193<br />

the control volume may be considered equal to zero on a timeaverage<br />

basis. The application of Eqs. 5.4 and 5.5 to the control<br />

volume contents results in<br />

rV nˆ dA m # 1 m # 2 m # 3 0<br />

cs<br />

or<br />

m # 2 m # 1 m # 3 600 lbmhr 3.0 lbmhr<br />

597 lbmhr<br />

(Ans)<br />

COMMENT Note that the continuity equation 1Eq. 5.52 can<br />

be used when there is more than one stream of <strong>fluid</strong> flowing<br />

through the control volume.<br />

The answer is the same with a control volume which includes<br />

the cooling coils to be within the control volume. The continuity<br />

equation becomes<br />

m # 2 m # 1 m # 3 m # 4 m # 5<br />

where m # 4 is the mass flowrate of the cooling <strong>fluid</strong> flowing<br />

into the control volume, and m # 5 is the flowrate out of the<br />

control volume through the cooling coil. Since the flow<br />

through the coils is steady, it follows that m # 4 m # 5. Hence,<br />

Eq. 1 gives the same answer as obtained with the original control<br />

volume.<br />

(1)<br />

E XAMPLE 5.4<br />

Conservation of Mass—Nonuniform Velocity Profile<br />

GIVEN Incompressible, laminar water flow develops in a<br />

straight pipe having radius R as indicated in Fig. E5.4a. At section<br />

(1), the velocity profile is uniform; the velocity is equal to a constant<br />

value U and is parallel to the pipe axis everywhere. At section<br />

(2), the velocity profile is axisymmetric and parabolic, with<br />

zero velocity at the pipe wall and a maximum value of u max at the<br />

centerline.<br />

FIND<br />

(a) How are U and u max related?<br />

(b) How are the average velocity at section (2), V 2 , and u max<br />

related?<br />

Section (1)<br />

u 1 = U<br />

Control volume<br />

Pipe<br />

dA 2 = 2 πr dr<br />

R<br />

r<br />

F I G U R E E5.4a<br />

Section (2)<br />

[ ( ) ]<br />

u 2 = u max 1 - _ r 2<br />

R<br />

SOLUTION<br />

these infinitesimal areas the <strong>fluid</strong> velocity is denoted as u .<br />

(a) An appropriate control volume is sketched (dashed lines) in<br />

2u max R<br />

c 1 a r 2<br />

(5)<br />

R b d r dr A 1 U 0<br />

0<br />

dA 2<br />

Fig. E5.4a. The application of Eq. 5.5 to the contents of this control<br />

volume yields<br />

0 (flow is steady)<br />

2<br />

Thus, in the limit of infinitesimal area elements, the summation<br />

is replaced by an integration and the outflow through section (2)<br />

is given by<br />

0<br />

r dV (1)<br />

0t<br />

cv<br />

rV nˆ dA 0<br />

rV ˆn dA r 2 R<br />

u 2 2pr dr<br />

cs<br />

122<br />

0<br />

(3)<br />

At the inlet, section (1), the velocity is uniform with V 1 U so<br />

that<br />

By combining Eqs. 1, 2, and 3 we get<br />

112rV ˆn dA r 1 A 1 U<br />

(2)<br />

2 R<br />

u 2 2r dr 1 A 1 U 0<br />

0<br />

(4)<br />

At the outlet, section (2), the velocity is not uniform. However,<br />

the net flowrate through this section is the sum of flows<br />

through numerous small washer-shaped areas of size dA 2 2r dr<br />

Since the flow is considered incompressible, 1 2 . The parabolic<br />

velocity relationship for flow through section (2) is used in<br />

Eq. 4 to yield<br />

as shown by the shaded area element in Fig. E5.4b. On each of<br />

dr<br />

Integrating, we get from Eq. 5<br />

r<br />

F I G U R E E5.4b<br />

2u max a r 2<br />

2 r4 R<br />

4R 2b R 2 U 0<br />

0