Sample landscape profile reprint

A sample of a landscape profile reprint.

A sample of a landscape profile reprint.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

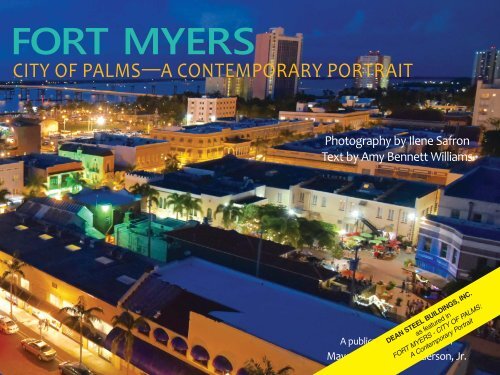

FORT MYERS<br />

CITY OF PALMS—A CONTEMPORARY PORTRAIT<br />

Photography by Ilene Safron<br />

Text by Amy Bennett Williams<br />

A publication of the office of<br />

Mayor Randall P. Henderson, Jr.<br />

DEAN STEEL BUILDINGS, INC.<br />

as featured in<br />

FORT MYERS - CITY OF PALMS:<br />

A Contemporary Portrait

DEAN STEEL BUILDINGS,INC.<br />

❖<br />

Left to right, the Metallic Building Company representative,<br />

Charles and Robert Dean sign the dealership contract in 1968.<br />

Dean Steel Buildings, Inc., is the largest manufacturer of<br />

metal building systems in Florida and continually works to<br />

increase its market share by providing outstanding customer<br />

service and experience in high-wind building designs.<br />

With annual sales of $15 million and climbing, Dean<br />

Steel Buildings, Inc., employs ninety to 100 people at<br />

facilities in Fort Myers; Cedartown and Thomasville,<br />

Georgia; and San José, Costa Rica. Principal customers are<br />

contractors and metal building installers throughout the<br />

Southeast United States and the Americas as well as direct<br />

sales to government agencies and end-use customers.<br />

The genesis for all this success goes back to Robert “Bob”<br />

Dean, a welder and son of a welder, who owned and operated<br />

a welding shop on Anderson Avenue in Fort Myers. In the<br />

early 1950s, Bob began selling and erecting pre-engineered<br />

metal buildings throughout the southern half of Florida,<br />

including the Florida Keys. Originally called Bob Dean Steel<br />

Buildings, Inc., the company purchased and installed metal<br />

buildings manufactured by Stran-Steel Buildings.<br />

His youngest son, Charles, a mechanical engineer, joined<br />

his father in the business in 1967, earned a contractor’s<br />

license, and with his father continued the practice of selling<br />

and erecting pre-engineered metal buildings. The company’s<br />

growth was not without obstacles. In the late 1960s, the<br />

City of Fort Myers refused to issue permits for metal roofs<br />

to be used on commercial buildings. Charles had to<br />

convince the head city building officials that if metal<br />

roofs were good enough for the early settlers—such as<br />

Thomas Edison and Henry Ford—they should be good<br />

enough for commercial buildings of that time.<br />

By 1971, operating under the name Dean Steel Buildings,<br />

Inc., the company purchased and installed metal buildings<br />

made primarily by Metallic Building Company. The company<br />

did so well that between 1970 and 1972, Dean Steel<br />

Buildings, Inc., was the largest volume builder in the<br />

country for Metallic Building Company. In 1973, Charles<br />

purchased the business from his father and was immediately<br />

confronted with a problem: A steel shortage forced Metallic<br />

Building Company to cancel orders placed by the company<br />

and other builders it worked with.<br />

To his credit, Charles saw an opportunity rather than<br />

just a problem and began traveling the state to meet<br />

with builders and ask them if they would buy from him<br />

if he started producing his own building line. The<br />

overwhelmingly positive response he received put Dean<br />

Steel Buildings in the manufacturing business for good.<br />

In 1985 the State of Florida mandated that all Florida<br />

counties develop a land-use plan that eventually required<br />

every commercial building in the state to go through a long<br />

permitting process. This occurred at the same time the economy<br />

began slipping into a recession. To remain competitive,<br />

a major modernization of equipment and processes began in<br />

1988, including the use of computer-aided drafting and the<br />

ability to electronically move information from drafting<br />

directly to the manufacturing machines. All work was done<br />

in-house, a process that continues to this day, allowing the<br />

company to be self-sufficient and highly efficient in its<br />

industry sector.<br />

It was about this time that Charles’ wife, Karen Dean,<br />

daughters, Nanette Dean, Julie Dean Fisher, Jeanie Dean<br />

Richards, Charlotte Dean Edwards, and sons-in-law Ken<br />

Fisher and Jeff Richards joined the organization in various<br />

roles. They joined Charles and Bob, who continued to work<br />

in a support role until Bob’s death in 2006.<br />

In 1992, while the rest of the industry went to China or<br />

India, the company started an engineering and drafting<br />

office in San José, Costa Rica. In a time when the Internet<br />

was still in its fledgling stage, Dean Steel Buildings was<br />

transmitting digital drawings and material lists through<br />

commercial servers in California.

Today, Dean Steel Buildings, Inc., is a member of the Metal<br />

Building Manufacturers Association, is certified ISO 9001,<br />

and accredited to AC-472. Achieving ISO 9001 certification<br />

has allowed the company to focus its operations on:<br />

• Customer satisfaction, providing products with the highest<br />

quality standards possible.<br />

• Problem-solving techniques and continuous improvement<br />

of systems, procedures, products, and people.<br />

• Teamwork, continual training, and employee support.<br />

With the company’s innovative systems, advanced<br />

computer-aided design and manufacturing technology,<br />

there is no limit to its creativity. Dean Steel Buildings, Inc.,<br />

has become the modern, economical form of construction<br />

for practically every building application. From large<br />

commercial and industrial facilities to neighborhood<br />

shopping centers, office buildings, commercial banks, and<br />

even private homes.<br />

The company has four decades of hands-on experience in<br />

every component and every system it produces. Its tradition<br />

of quality and reliability, combined with design flexibility<br />

and personalized service, allows Dean Steel<br />

Buildings to enjoy an outstanding reputation<br />

among architects and contractors.<br />

The company believes competence can only<br />

be achieved if the organization is capable<br />

of managing the training needs of its<br />

staff. The company makes every employee<br />

directly involved in each step of the<br />

process because it depends on its people,<br />

their experience, abilities, and knowledge.<br />

As for the future, Dean Steel Buildings,<br />

Inc., plans to welcome the next generation<br />

into this family owned business as Charles<br />

and Karen’s grandchildren join the company. Dean Steel<br />

Buildings, Inc., will continue providing the quality service<br />

and products its customers have come to expect while<br />

evolving into a more customer-centered business using social<br />

media and Internet advertising. As a result of these efforts<br />

and more, Dean Steel Buildings, Inc., is positioned to grow<br />

its business as the communities in which it operates grow.<br />

❖<br />

Top, left: McArthur Farms.<br />

Top, right: Roi’s Bar-B-Que Restaurant.<br />

Above: Dollar General Store.

www.deansteelbuildings.com