CPT International 02/2019

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Kinetic Assembly Structure reflects the materialization<br />

of a train of thought. The lines form an infinite<br />

loop. voxeljet printed the models of the complex<br />

sculpture in several parts.<br />

The stool „Infiniala“ by designer<br />

Sergej Ehret: Future of Sculpture.<br />

With voxeljet 3-D printing systems,<br />

even the most complex<br />

sculptures that would have been<br />

impossible using traditional molding<br />

techniques can be realized.<br />

3-D printing systems evolutionize<br />

traditional art casting<br />

Art foundry Strassacker creates artistic works using 3-D printing systems by voxeljet<br />

Frederik von Saldern, Friedberg; Peter Mühlhäuser, Süßen<br />

Photos: Voxeljet<br />

Strassacker, one of the oldest and<br />

largest art foundries in Europe, is<br />

modernizing art casting with 3-D<br />

printing from voxeljet, Friedberg, Germany.<br />

The printing technology is used<br />

to create investment casting patterns<br />

and increases the artists’ freedom of<br />

design. Artworks which previously could<br />

not be produced using traditional molding<br />

techniques can now be printed<br />

directly in the form of a casting pattern.<br />

Have you heard of The Bambi<br />

Award? The German Media and Television<br />

Prize, which is awarded annually to<br />

people with visions and for outstanding<br />

achievements? The award winners<br />

include world stars such as Christoph<br />

Waltz, Samuel L. Jackson and Kate<br />

Winslet. But far less known is the company<br />

that produces the coveted bronze<br />

deer: the family owned company Strassacker<br />

from Süßen near Stuttgart. Since<br />

it was founded in 1919, the company<br />

has evolved from the manufacture of<br />

pasta machines and everyday objects to<br />

the production of numerous precious<br />

artworks. The company has made a<br />

name for itself especially in the art<br />

industry and is now a well-known<br />

player. Their customers include world<br />

renowned contemporary artists, who<br />

rely on the Strassackers’ specialist expertise.<br />

Digital model creation at Strassacker<br />

While traditional production<br />

methods have characterized the creation<br />

of works of art to date, today there<br />

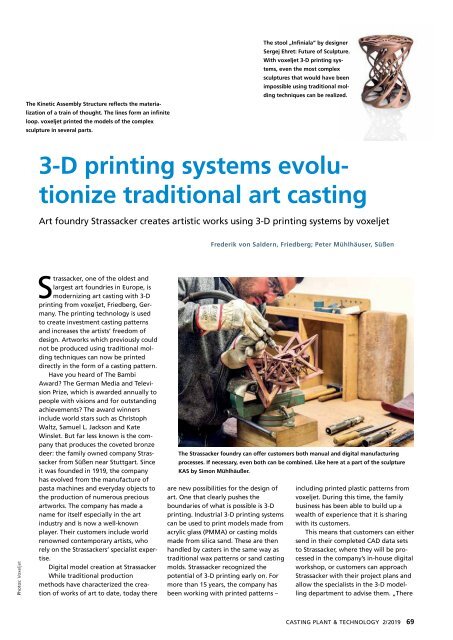

The Strassacker foundry can offer customers both manual and digital manufacturing<br />

processes. If necessary, even both can be combined. Like here at a part of the sculpture<br />

KAS by Simon Mühlhäußer.<br />

are new possibilities for the design of<br />

art. One that clearly pushes the<br />

boundaries of what is possible is 3-D<br />

printing. Industrial 3-D printing systems<br />

can be used to print models made from<br />

acrylic glass (PMMA) or casting molds<br />

made from silica sand. These are then<br />

handled by casters in the same way as<br />

traditional wax patterns or sand casting<br />

molds. Strassacker recognized the<br />

potential of 3-D printing early on. For<br />

more than 15 years, the company has<br />

been working with printed patterns –<br />

including printed plastic patterns from<br />

voxeljet. During this time, the family<br />

business has been able to build up a<br />

wealth of experience that it is sharing<br />

with its customers.<br />

This means that customers can either<br />

send in their completed CAD data sets<br />

to Strassacker, where they will be processed<br />

in the company’s in-house digital<br />

workshop, or customers can approach<br />

Strassacker with their project plans and<br />

allow the specialists in the 3-D modelling<br />

department to advise them. „There<br />

CASTING PLANT & TECHNOLOGY 2/<strong>2019</strong> 69