The Macadamia - Autumn 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LOWVELD<br />

ORCHARD<br />

MANAGERS<br />

SHINE<br />

&#$/%<br />

KZN MAC<br />

EXPORTS<br />

ON GROWTH<br />

PATH<br />

THE ART OF<br />

EXPERT TREE<br />

MANIPULATION<br />

<strong>Autumn</strong> <strong>2019</strong><br />

INSECTICIDES

PRODUCERS OF GUARANTEED HIGH QUALITY MACADAMIA TREES<br />

GLOBALGAP - SAMAC<br />

TREES AVAILABLE FOR <strong>2019</strong> SEASON<br />

CONTACT MOUNTAINVIEW NURSERY<br />

Kiepersol, Mpumalanga<br />

orders@mountainviewnursery.co.za<br />

Stefan (M) 071 608 9151<br />

From<br />

the<br />

Editor<br />

Gareth Wright<br />

News coming out of South<br />

Africa’s macadamia industry<br />

remains hugely positive.<br />

Despite a turbulent year predicted for the rand which could<br />

impact on returns, the increasing global demand for the<br />

crop has meant the price is predicted to exceed last year’s<br />

offering according to processors Mayo Macs and the Green<br />

Farms Nut Company (GFNC) which met with shareholders<br />

and farmers across the country during scheduled pre-season<br />

road shows.<br />

Mayo Macs announced a major partnership with a<br />

pasteurisation group in the United States in line with their<br />

growth strategy into the high-end kernel export market and<br />

hopes to continue to break into niche markets particularly<br />

in the USA, Europe, Japan and South Korea where<br />

consumer demand for kernel has grown by 9% since about<br />

2017. <strong>The</strong> marketing companies for both Mayo Macs and<br />

GFNC have warned that the ever-increasing demand for<br />

South Africa’s macadamia nuts worldwide means farmers<br />

and processors have to make sure their businesses are<br />

“ready for the future”.<br />

In this edition of <strong>The</strong> <strong>Macadamia</strong>, you will read about how<br />

KwaZulu-Natal’s largest macadamia nursery, T&T Agric<br />

at Ifafa Beach on the South Coast, has more than doubled<br />

its output of micro-grafted macadamia trees as farmers in<br />

Zambia, Malawi and northern Mozambique plough out<br />

their maize and soya crops in favour of the development of<br />

macadamia orchards. In Zambia where soil is fertile, the<br />

land flat and water plentiful, farmers are planting up to<br />

100ha of macadamia orchards at a go, compared with the<br />

average of about 10ha planted by South African farmers<br />

at any one time. Colin Rand, the horticulture managing<br />

partner at T&T Agric is also on a drive to halve the price<br />

of young macadamia trees to make it easier for sugarcane<br />

farmers to finance the diversification of their operations as<br />

the sugar industry outlook remains bleak on the back of the<br />

increased Health Promotions Levy and the record low sugar<br />

price on world markets. We also highlight a programme<br />

developed by Lowveld farmers to train young graduates to<br />

meet the growing demand for top management skills in the<br />

sector. <strong>The</strong> programme - called Recruitagri - has recently<br />

accepted its second group of interns with learning geared<br />

towards both practical and theoretical training to make sure<br />

the youngsters are work-ready once they complete the yearlong<br />

course. <strong>The</strong>n there are technical articles covering topics<br />

such as farming for increased nut quality, precision drainage<br />

in the orchard and the issue of iron deficiency in the soil.<br />

Mpumalanga expert and consultant, Kobus van Niekerk<br />

outlines how tree growth can be manipulated to prevent<br />

structural weaknesses and breakages once the tree matures<br />

and starts to yield.<br />

At the start of the new season our hope for all those<br />

involved in the industry is that the current positivity<br />

continues and grows into the years ahead. We hope<br />

our readers enjoy this edition as much as we have<br />

putting it together.<br />

WWW.MOUNTAINVIEWNURSERY.CO.ZA

Colleen Dardagan<br />

Contributing Author<br />

34<br />

Contents<br />

04 Innovation Leads to<br />

Substantial Growth<br />

of <strong>Macadamia</strong> Tree<br />

Exports to Zambia<br />

Lindi Botha<br />

Contributing Author<br />

Editor<br />

Gareth Wright<br />

072 223 3498<br />

gareth@blockmedia.co.za<br />

04<br />

10 Mbombela Fabrication Plant<br />

Sets <strong>The</strong> Quality Bar<br />

12 Take Cover:<br />

Protect Your Resources<br />

With Cover Crops<br />

16 Mayo Macs<br />

Breaks New Ground<br />

With US Partnership<br />

JP Hughes<br />

Contributing Author<br />

Laura Myers<br />

Advertising<br />

Advertising<br />

Laura Myers<br />

083 271 5243<br />

laura@macadamiasa.co.za<br />

www.themacadamia.co.za<br />

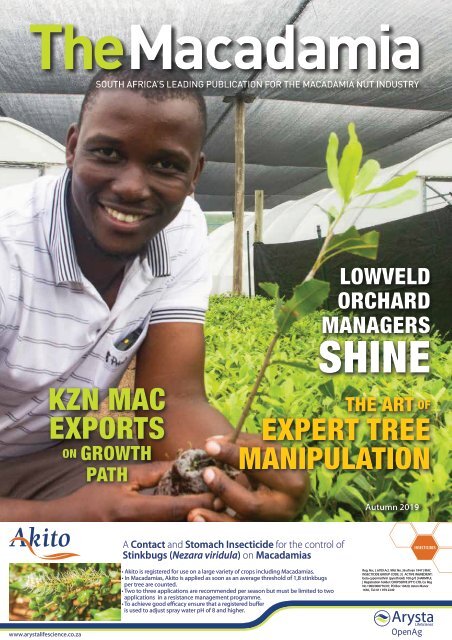

Cover Image<br />

T&T Agric nursery manager,<br />

Mhlengi Sibiya holds a micrografted<br />

macadamia tree which is<br />

destined for export to Zambia.<br />

Image: Colleen Dardagan<br />

This publication is<br />

protected by copyright law.<br />

No part of this publication<br />

may be reproduced in any way<br />

without the permission and<br />

acknowledgement of Block<br />

Media. Opinions expressed<br />

do not necessarily represent<br />

the views of Block Media<br />

or the publishers.<br />

Published By<br />

Block Media<br />

Po Box 1501<br />

Simbithi, Ballito<br />

4390<br />

Printed By<br />

12<br />

10<br />

28<br />

20 Combatting Iron<br />

Deficiencies In<br />

<strong>Macadamia</strong> Orchards:<br />

Solutions For A<br />

Complex Phenomena<br />

24 Practical Training<br />

Grows Mac Farm<br />

Manager Skills<br />

28 Get <strong>The</strong> Most Bang<br />

For Your Buck<br />

With Higher Crackouts<br />

30 Reduce Waterlogging Through<br />

Subsurface Drainage<br />

And Increase Tree Health & Yield<br />

34 Misunderstanding<br />

Sapling Manipulation<br />

Puts Mature Mac Trees At Risk<br />

Elizabeth-Ann Bradley<br />

Design & Layout<br />

a Novus<br />

Holdings<br />

Company<br />

30<br />

20<br />

38 Nuts & Bolts<br />

GFNC Price Offer<br />

Up By 20% in <strong>2019</strong><br />

2 THE MACADAMIA

Innovation<br />

Leads To<br />

Substantial<br />

Growth<br />

Of <strong>Macadamia</strong> Tree<br />

Exports To Zambia<br />

A prediction a year ago by nurseryman<br />

Colin Rand that the demand for<br />

South African-grown macadamia trees<br />

would take off in the SA Development<br />

Countries region has become a reality,<br />

evidenced by thousands of trees from his<br />

business in Ifafa Beach on the KwaZulu-<br />

Natal South Coast already growing on<br />

the banks of Zambia’s Kafue River.<br />

Article & Images<br />

Colleen Dardagan<br />

With more than 30 000 macadamia nut trees delivered<br />

to Zambia and another 90 000 ordered between now<br />

and the end of the year, managing partner at T&T Agric<br />

Colin Rand says opportunities in regions to the north of<br />

South Africa are “infinite”. Rand said exporting trees to<br />

Zambia, Malawi and northern Mozambique offered new<br />

opportunities for South Africa’s burgeoning macadamia<br />

sector, particularly in the export of trees and making SA<br />

technical expertise available to the new growers in the<br />

Southern African Development Countries (SADC). Rand<br />

added that offering macadamia trees at a more affordable<br />

price for potential farmers in South Africa was a priority for<br />

him between now and next year. “My ultimate vision is to<br />

supply macadamia tree nurseries in this country with micrografted<br />

trees to grow out. Our trees cost R30 for a micrografted<br />

tree and R60 for a ready-to-plant unit. What I really<br />

want is for the cost per tree to come down - so I want to<br />

halve the price of the trees, and I am hoping to achieve that<br />

goal over the next 18 months,” he said.<br />

4<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

5

<strong>The</strong> main motivation behind this plan was not only to<br />

make high quality micro-grafted trees available to sugarcane<br />

growers in the province who were yet to make the change to<br />

the nut crop due to the high orchard start-up costs, but to<br />

increase the number of trees for export to the SADC region.<br />

“<strong>The</strong> problem with the sugar industry in KwaZulu-Natal<br />

is everyone wants to convert to macadamias,” said Rand.<br />

“What we must do is reduce our costs per unit and have<br />

trees available at such a lucrative price it won’t deter cane<br />

growers who haven’t got macs in the ground yet to be able<br />

to fund and finance their conversion.”<br />

EXPORT OPPORTUNITIES<br />

Rand, who took over the running of the nursery just 18<br />

months ago, has grown the operation from 240 000 trees<br />

under cover to more than 500 000, with plans to more<br />

than double that number by next year. “<strong>The</strong> Zambia pie on<br />

its own is huge. We have farmers there planting 100ha at<br />

a time compared with here, where growers are putting in<br />

macadamias at 10ha at a time,” he said.<br />

Climatic conditions in Zambia are not as ideal as along<br />

the coast, but most of the farms planting the T&T Agric<br />

trees are along the Kafue River, where the soils are rich and<br />

fertile. “<strong>The</strong> quality of the nuts is affected by altitude. <strong>The</strong>y<br />

have a more intensive growing season and milder winters,<br />

but their biggest challenge is a very dry spring. That is the<br />

hottest time of the year there - September, October and<br />

November - so that will affect the late flowering varieties,<br />

like the Beaumonts and A4s, to a point. But what they do<br />

have is a lot of water for irrigation from the Kafue River.”<br />

<strong>The</strong> trees are transported to Zambia in refrigerated trucks<br />

and can take anything from a week to nine days to arrive on<br />

the farms. “<strong>The</strong> problem with putting them into a normal<br />

truck is if the driver parks the truck or the vehicle breaks<br />

down, the trees will cook. For example, during this last<br />

trip the load was delayed at the Livingstone border post for<br />

three days. Without the refrigerated truck we would have<br />

had to make a plan to water the trees. Instead, condensation<br />

was happening by itself inside the reefer. In fact, the bags<br />

were wet when they arrived in Zambia. I think seven trees<br />

died in-field, so not one was affected by the trip,”<br />

Rand said.<br />

Right T&T Horticulture<br />

managing partner Colin<br />

Rand shows vigorous<br />

root growth on a young<br />

macadamia tree.<br />

Below Left Colin Rand<br />

discusses operations at<br />

KwaZulu-Natal’s largest<br />

macadamia nursery with its<br />

manager, Mhlengi Sibiya.<br />

Below Middle Nurseryman<br />

Colin Rand shows the paper<br />

bags used for the young<br />

macadamia trees once they<br />

have been micro-grafted.<br />

Below Right<br />

A young macadamia<br />

tree rooted using the<br />

tip of a new shoot.<br />

Maximising the load, while at the same time avoiding<br />

overloading, had resulted in a unique innovation developed<br />

at the nursery. “We fabricated special tables to maximise<br />

our load space in the truck. <strong>The</strong> tables, which we have<br />

called maxi-plan pallets, allow us to double the available<br />

floor space. And because we have used paper bags for the<br />

micro-grafted trees – which are about 40cm tall when they<br />

travel, or eight months old from seed - and our specially<br />

formulated lightweight substrate, we have brought the<br />

weight of the load right down. Also sending young trees<br />

that have been in bags for a shorter space of time means<br />

they are able to grow with juvenile vigour once they are<br />

planted, because the units are not pot-bound, and they<br />

haven’t developed the bonsai effect.”<br />

6<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

7

Above Nursery staffer Nogeziwe Qoze<br />

works on a micro-grafted tree.<br />

Above Right Thousands of young macadamia trees in the T&T<br />

Agric nursery at Ifafa Beach on the KwaZulu-Natal South Coast.<br />

HIGH STANDARDS<br />

<strong>The</strong> paperwork linked to the export process starts with<br />

the customers in Zambia first acquiring an import permit<br />

from the Zambian Department of Agriculture. On receipt<br />

of the import permit number, South Africa’s Department<br />

of Agriculture will visit the Ifafa Beach nursery to inspect<br />

the load before issuing the necessary transit paper work.<br />

Officials check for root pathogens, noxious weeds and the<br />

presence of specific insects. “We are accredited with the<br />

Seedling Growers’ Association of South Africa (SGASA)<br />

and the South African <strong>Macadamia</strong> Growers’ Association<br />

(SAMAC), so the process is not so bad for us. Accreditation<br />

means we keep our standards very high. We conform to the<br />

stipulated criteria linked to phyto-sanitary requirements<br />

set down by SGASA. Our water growing medium is also<br />

sent regularly to the Quality Management Services (QMS)<br />

laboratory as prescribed by the accreditation audit,” he<br />

said. <strong>The</strong> growing medium used by the nursery is coco<br />

coir. “<strong>The</strong> way we are propagating trees allows us to cut<br />

our turnaround time by at least half while being able to<br />

supply robust and healthy units,” said Rand. But there<br />

are challenges, he added. “Compared with local clients,<br />

especially those in our area, where we can send the units<br />

that are ready and then wait before sending the rest, for<br />

export, the entire load of 10 000 trees has to be up to<br />

specification all at the same time. We are new exporters, this<br />

last load was only our third, and it really was very stressful.<br />

Also, it takes an entire day, from 6am to 7pm, to load the<br />

truck using my whole labour force of 45 people. It is a slow<br />

and laborious process as each tree has to be packed nicely so<br />

it isn’t damaged. We are also the only commercial nursery<br />

exporting micro-grafted trees grown out in substrate. What<br />

this has allowed us to do, though, is greatly reduce the<br />

timeline and to be able to transport a far lighter product.”<br />

REFINING SYSTEMS<br />

<strong>The</strong> father of three, who spends time in his vegetable<br />

garden to relieve the stress of his working day, believes the<br />

macadamia industry will be the saving grace for KwaZulu-<br />

Natal’s agriculture economy.<br />

“My order book is more than full. I am<br />

getting calls from all over every day for trees.<br />

<strong>The</strong> challenge in the nursery now is to refine<br />

our systems because we want to expand<br />

again. We are doubling our labour force<br />

and looking to halve the price of the trees.<br />

<strong>The</strong>re are a lot of balls in the air and I<br />

cannot afford to drop one, because if I do,<br />

then my customers lose money and time.<br />

We are working on computer systems to<br />

guide us in relation to timelines because<br />

ultimately, I want to be in a position that<br />

when a farmer phones me for trees,<br />

I have stock available on the floor in the<br />

nursery immediately for him. <strong>The</strong>re is just<br />

no room for error now.” - Colin Rand<br />

8<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

9

Mbombela<br />

Fabrication Plant<br />

Sets <strong>The</strong> Quality Bar<br />

With his experience reaching as far<br />

back as his school days, Vincent Allan,<br />

who is the founder and owner of the<br />

Mpumalanga-based MacMachines, says<br />

the demand for high quality and madeto-spec<br />

plant for macadamia processing<br />

operations has resulted in deliveries as<br />

far afield as northern Mozambique with<br />

countries such as Malawi and Zambia<br />

looking to place orders.<br />

Article Colleen Dardagan<br />

Image Supplied<br />

As South Africa’s macadamia industry is set to more than<br />

double its production over the next five years and farmers<br />

across the country’s sugarcane growing regions continue<br />

to replace the crop with macadamia orchards, demand<br />

for high-quality machining is now at a premium. Vincent<br />

Allan who first opened his own steel-fabrication business<br />

in Tzaneen in 2004 said he started to feel the demand for<br />

macadamia processing equipment in about 2008. As a<br />

result, he had moved his business to Mbombela in 2015 to<br />

be closer to his main customers. “Most of my orders are still<br />

coming in from the Mpumalanga region but orders have<br />

definitely increased from farmers in KwaZulu-Natal. We<br />

are also seeing interest starting to grow from macadamia<br />

operations in Mozambique, Malawi and Zambia,” Allan<br />

said. One of his biggest challenges, he said, was two years<br />

ago when his business was commissioned to build a 660-ton<br />

drying facility in Mpumalanga. “<strong>The</strong> area made available<br />

for the facility was in a basement with lots of pillars.<br />

That meant we had to fit 66x10 ton drying bins with 23<br />

conveyors into a very unusual floor space. That was quite<br />

a challenge because everything had to work seamlessly<br />

and without interruption to the flow of the nuts through<br />

the processing plant. I think we must have had about 25<br />

meetings with the farmer during the design process,”<br />

he said.<br />

With a staff complement of 21 people, all of them highly<br />

skilled and trained, Allan said there was now virtually<br />

nothing he couldn’t build for processing macadamia nuts.<br />

“I do all the drawings myself using a computer aided design<br />

system. Once the drawings are completed and approved by<br />

the customer I will then sit with my staff and discuss the<br />

build. I have three teams filled with very experienced people<br />

- some of whom have worked with me from the beginning -<br />

to those who are being trained on the job. If the design<br />

is something new or unusual I will work very closely with<br />

the teams on the project however, the fact is my work force<br />

is very capable,” he added. Allan, who started designing<br />

and making “all types” of steel work when he was still at<br />

school said he believed very strongly in supporting South<br />

African businesses.<br />

Above A de-husking plant delivered to<br />

a Malawi macadamia processing plant.<br />

“All the steel we use we get from local<br />

suppliers. I am sure we could get it cheaper<br />

somewhere else, but I believe in supporting my<br />

neighbouring businesses because not only does<br />

that make sure we have a vibrant economy,<br />

but they support me in return,” said Allan.<br />

10<br />

THE MACADAMIA

Above Right Cover crops, like grasses planted between tree rows, vastly aid in moisture retention and soil health.<br />

Above Left Bare ridges can’t absorb rainwater and have low soil moisture retention.<br />

Take<br />

Cover:<br />

Protect<br />

Your<br />

Resources<br />

With Cover Crops<br />

Article & Images<br />

Lindi Botha<br />

Planting cover crops in macadamia orchards<br />

has innumerable benefits, including water<br />

savings, improved soil health, and trees that<br />

are less prone to stress - ultimately resulting in<br />

greater yields and profitability.<br />

Pristine orchards that are swept clean, without a weed in<br />

sight, might seem like the perfect farm. But dry, exposed<br />

soils and a lack of biodiversity hinder optimal production,<br />

resulting in higher water and pesticide usage. Planting<br />

grasses and legumes between tree rows is a solution to these<br />

problems and comes with a host of other benefits.<br />

Freddie Steyn, an agent for Barenbrug, said cover crops can<br />

be used to improve soil moisture retention and stabilise soil<br />

temperatures, which results in trees that are less stressed.<br />

“Cover crops that produce flowers also attract bees and<br />

will keep pollinators on the farm throughout the year.<br />

Since cover crops aid in developing biological life in the<br />

soil, soil health improves and fertiliser requirements drop.”<br />

He explained that if micro-organisms in the soil flourish,<br />

then much of the work in getting the soil to its optimum<br />

level is done for you. “Since many of the nutrients in<br />

the soil are not in a form that is available to the tree, the<br />

organisms are needed to help break it down into one that is<br />

easily absorbed. “It is therefore important to nurture these<br />

organisms that create a healthier soil. Soil analysis can tell<br />

you what nutrients are lacking but you can’t necessarily see<br />

what the biological life is - I think many farmers would get<br />

a fright if they saw how low it was, as a result of constant<br />

chemical applications from pesticides to fertilisers.”<br />

12<br />

Above Cover crops that produce flowers are ideal to keep bees in the orchards.<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong> 13

CHOOSING THE RIGHT COVER<br />

Steyn said different cover crops serve different purposes<br />

and farmers should consider their ultimate goal before<br />

choosing which to plant. “If your aim is to increase soil<br />

moisture retention then you need plants that produce a lot<br />

of mulching material, like lucerne or any summer grasses.<br />

However, since the trees will eventually grow to a point<br />

where there will be little sun beneath the trees, grasses<br />

that grow in shade must be considered.” While Australian<br />

farmers favour LM grass, as it is ideal not only for its<br />

shade tolerance but its compatibility with mechanised<br />

harvesting operations, Steyn said the cost of planting this<br />

grass in an orchard is significant. A budget-friendly option<br />

is Paspalum Notatum, as it is also shade tolerant and won’t<br />

affect tree growth. This grass can be cut and left under the<br />

trees to form a thick mulch layer. For farmers requiring<br />

assistance with nitrogen corrections in the soil, cover crops<br />

like legumes and clover should be planted. Steyn said<br />

macadamia roots are very deep, but the 80% that takes up<br />

nutrients is in the top 20cm layer of soil. “So you want<br />

your nutrients that are deeper to be brought to the surface.<br />

This is where legumes are beneficial: with their deep root<br />

system, they assist in accessing nutrients deep in the soil<br />

and bring them to the surface for the tree to use. “Lucerne<br />

also draws nutrients out of the soil, but is not removed<br />

from the field when it is cut; instead, being rather left as a<br />

mulch layer so the nutrients are still available in the soil.”<br />

He added that with macadamia land preparation, the soils<br />

are only ripped once so there is only one opportunity to<br />

loosen the soils. “With cover crops that have deep roots you<br />

have a continual opportunity to improve your soil structure<br />

and reduce compaction. Perennial grasses and chicory are<br />

ideal for this.” While cover crops aid in weed suppression,<br />

there is still work to be done to maintain a balance between<br />

allowing cover crops to flourish and eliminating problematic<br />

weeds. Steyn added that while certain weeds can be left in<br />

the orchard, anything that interferes with macadamia tree<br />

growth should be removed, like climbers or anything using<br />

a lot of water. “This is when farmers need brush cutters<br />

to keep the weeds at bay. Unfortunately it requires more<br />

effort, but is necessary to get the benefits of the cover crops.<br />

<strong>The</strong>re are challenges with this system, but the benefits far<br />

outweigh the problems.” During the harvesting season, said<br />

Steyn, the cover crops need to be kept as short as possible<br />

to allow for nut collection. “In March, before harvest starts,<br />

the area will need to be mowed. Any new growth emerging<br />

after that needs to be sprayed with a soft chemical that just<br />

burns the tips, without completely killing the plant. After<br />

the harvesting season, the cover crops will grow out again.”<br />

WATER SAVINGS<br />

Reduced water availability has been a reality for many<br />

farmers over the past few years as the drought has taken<br />

its toll on available water for irrigation, and soil moisture<br />

levels. Steyn said that by using cover crops, the effects of<br />

climate change can be mitigated. “With water restrictions<br />

and the increase in demand as more trees come into<br />

production, farmers might end up halving their yield if the<br />

trees do not get sufficient water. But through mulching, you<br />

can quarter the amount of irrigation needed for a crop.<br />

<strong>The</strong> cover crops do draw moisture as well, but the cover<br />

is still better for soil moisture retention than having a<br />

bare piece of soil.” He noted that for every 1% of organic<br />

material added to the soil, an additional 17mm of rain is<br />

retained in the soil. This equates to 170 000 litre of water<br />

per hectare. “Additionally, through the increase in water<br />

retention, soil temperatures are kept more stable, which is<br />

crucial to reduce stress in the trees. During high summer<br />

temperatures they take a lot of strain, which results in the<br />

November flower drop. This has a big impact on the yield,<br />

so if the drop can be prevented it will have a big effect on<br />

your bottom line. “November flower drop is one of the<br />

biggest challenges we face, so the less stress your trees are<br />

under during that time of year, the better.” Steyn said that<br />

because of climate change, the eastern part of the country<br />

will not get less rain, but it will fall within shorter periods,<br />

so the soil needs to be able to handle downpours and the<br />

farm must be geared to make the best of it - not have<br />

it wash away all your soil and with it, the money spent<br />

on nutrients for topsoil. For this reason, bare ridges are<br />

problematic as they are completely exposed to the rain.<br />

“Each drop that falls on the ground is like a hammer that<br />

hardens the soil, making it even less likely to absorb the<br />

water. <strong>The</strong> water just runs down the sides and doesn’t reach<br />

the shallow roots contained in the ridges. This is why cover<br />

crops are needed to ‘soften the blow’ of the rain, and ensure<br />

it is absorbed.”<br />

BIODIVERSITY<br />

In areas where macadamia farming is conducive, the crop<br />

has dominated the landscape, creating a monoculture<br />

and reducing biodiversity. Steyn said cover crops<br />

provide a partial solution to the problem, which, if<br />

planted throughout the orchards, can drastically increase<br />

biodiversity.<br />

“By planting a variety of cover crops you<br />

create a biodiverse environment where<br />

numerous insects - many of which prey on<br />

insects that are harmful for macadamias -<br />

can flourish. So to a large extent the insect<br />

problem within the orchards sorts itself out<br />

and you don’t require excessive amounts<br />

of insecticides, which ultimately kill the<br />

harmful and beneficial insects,” said Steyn.<br />

Bees, and thereby pollination and fruit set, also benefit<br />

from cover crops as there is more food for them to forage<br />

throughout the year. Steyn said specific cover crops can<br />

be planted in the orchards to provide food for bees. In<br />

addition, herbs like lavender can be planted adjacent to<br />

orchards to provide ample flowers for them. Planting cover<br />

crops is a long term plan that requires additional effort,<br />

he concluded. However, it is a solution to the problems<br />

farmers are already facing in terms of water supply, insect<br />

load, pollination problems and November flower drop. “It<br />

is not a quick fix and farmers should consider starting with<br />

one block at a time to get the management routine in place<br />

and compare the outcomes with other blocks to see firsthand<br />

the benefits in cover crops.”<br />

14<br />

THE MACADAMIA

Mayo Macs<br />

Breaks New<br />

Ground<br />

With US Partnership<br />

Mayo Macs has announced a landmark<br />

joint venture partnership with a United<br />

States-based nut pasteurisation company<br />

as the South African processor looks to<br />

extend its reputation for top quality<br />

kernel exports able to meet stringent<br />

international food safety regulations.<br />

Article Colleen Dardagan<br />

Images Colleen Dardagan & Supplied<br />

Above <strong>The</strong> Mayo Macs team following the recent shareholder<br />

meeting held at the Chantilly Resort outside Darnall on the<br />

KwaZulu-Natal north coast. From left back, John Osborn,<br />

Johan Smit, Sarah-Jane Stewart, Myles Osborn, Jaap van<br />

Oenen, Stuart Gregory. From left front, David McIlrath,<br />

Cobus Venter, PJ Venter, Andrew Sheard, Rohan Orford<br />

Top <strong>The</strong> pasteurisation processing plant in Houston Texas<br />

where all the kernel exported by South Africa’s Mayo Macs<br />

will be processed to meet stringent food safety standards before<br />

being delivered to clients across the globe.<br />

A salmonella outbreak linked to almonds processed in<br />

California in the early 2000s reportedly led to a discovery<br />

that the risk of pathogens on tree nuts was much higher<br />

than previously believed. With the increased focus on food<br />

safety, there is a growing demand for nuts pasteurised at a<br />

log 5 reduction of salmonella strains in the US market.<br />

Since its inception the South African processor Mayo Macs<br />

has focused extensively on the export of top quality kernel,<br />

and with the predicted growth of the domestic nut-in-shell<br />

market in China, the grower-shareholder group has bedded<br />

down a partnership which will not only increase its kernel<br />

export reach into the US and European Union markets,<br />

but is also expected to break new ground in countries such<br />

as Japan, South Korea and Taiwan. Mayo Macs CEO, PJ<br />

Venter told shareholders at a recent meeting outside Darnall<br />

on the KwaZulu-Natal North Coast that what was just a<br />

pipe dream 12 months ago, had not only become a reality,<br />

but had extensively widened their marketing options. “We<br />

are now the only South African processor with a validated<br />

log 5 kill step. For us food safety is a non-negotiable. We<br />

looked at various kill step providers before we settled on<br />

a particular provider and subsequently formed a joint<br />

venture situated outside Houston, Texas,” he said. As<br />

explained in the online Quality Assurance and Food Safety<br />

magazine, “kill-step validation is a pre-emptive scientific<br />

evaluation that provides documentary evidence that a<br />

particular process (e.g. cooking, frying, chemical treatment,<br />

extrusion, etc.) is capable of consistently delivering a<br />

product that meets predetermined specifications. In other<br />

words, it is a collection of evidence that a particular process<br />

involving chemical or physical inputs/parameters in a food<br />

establishment are consistently delivering a desired effect to<br />

ensure the destruction of pathogenic micro-organisms often<br />

expressed as ‘log reduction’.”<br />

While Venter said he would prefer for the pasteurisation<br />

company not to be named due to the competitive nature of<br />

the macadamia industry in South Africa, he said the group<br />

was more than satisfied the pasteurisation plant was number<br />

one in the world when measured on its installed state-of-the<br />

art technology and pasteurisation methodology. “<strong>The</strong>y use<br />

a “dark process”, in other words the entire pasteurisation<br />

process is fully automated, from when the kernels are placed<br />

onto the conveyor through to packaging and labelling.”<br />

During pasteurisation the kernel is heated in two phases to<br />

over 200°F (about 100°C) before being cooled down across<br />

three phases. <strong>The</strong> last unit which dries the kernel can also be<br />

used for roasting if requested by customers. <strong>The</strong> automated<br />

packing system also includes a metal detector. “So, in the<br />

morning workers put down the plastics and the cardboard<br />

boxes behind the machine and that’s all, the whole process<br />

is then computer run.” Venter said.<br />

All the kernel from the Mayo Macs factories in Paddock<br />

on the KwaZulu-Natal South Coast and Rietvallei in<br />

Mpumalanga from this season will be exported to the<br />

States. Venter said the group viewed the joint venture deal<br />

not as a cost to the company, but rather as a profit centre as<br />

the 3-tons-an-hour plant was geared for processing all types<br />

of nuts. “Our products will probably take up about two<br />

hours out of their 24-hour schedule.<br />

16 THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

17

BUMPER CROP<br />

PREDICTED FOR <strong>2019</strong><br />

Mayo Macs has 240 grower shareholders and<br />

110 non-shareholder growers delivering to their<br />

factories in Paddock on the KwaZulu-Natal<br />

South Coast and Rietvallei in Mpumalanga. <strong>The</strong><br />

group’s shareholder member-orchards total over<br />

9 500 ha of which 45% are bearing and 55%<br />

are non-bearing. <strong>The</strong> high percentage of nonbearing<br />

orchards indicates exponential growth in<br />

production for the company over the next few<br />

years. This is also the first season that growers in<br />

the KwaZulu-Natal Midlands will start to supply a<br />

crop to the Paddock plant.<br />

<strong>The</strong> rest of the time other nut-types are pasteurised which<br />

means the unit is fully utilised and we make a return on it<br />

as well. Also we have streamlined our operation meaning<br />

that once the nuts are pasteurised they are not then<br />

returned to South Africa for packaging and distribution but<br />

go directly from the Texas plant to our customers.” he said.<br />

Another plus he said was customers previously buying<br />

unpasteurised kernel directly out of South Africa were now<br />

able to eliminate the cost and the burden of processing<br />

the product themselves before being able to use it. “At<br />

the moment it is only in the US that the log 5 kill step is<br />

regulated, but there is no doubt in our minds that the EU<br />

will soon follow suit as well as countries such as Japan.<br />

South Korea, Japan and Taiwan are new markets - they<br />

consume about 9% of the global supply of kernel - and we<br />

see these as markets with huge potential for growth. Being<br />

able to offer them a product that meets stringent food<br />

safety requirements is going to be a huge plus,” he said.<br />

“Our focus has always been on supplying sound kernel to<br />

high-end customers in the market. That is why we focus so<br />

heavily on the value of our on-farm extension services from<br />

the time a farmer starts planning to plant the trees. We now<br />

have 5 technical advisors, covering all our major production<br />

areas, to ensure we meet all our growers production needs.<br />

To meet the growing international demand for macadamias<br />

we have to be ready, but we are not going to compromise<br />

our brand in any way in the process. We will continue to<br />

concentrate on producing high sound kernel, as well as nutin-shell<br />

to markets such as those in China,” Venter said.<br />

Following on the drought in 2015/2016 the<br />

crop growth in 2018 increased by 34% from<br />

the 2016 season. A bumper tonnage of nut-inshell<br />

is forecasted for the <strong>2019</strong> season. Growershareholders<br />

at the meeting heard about the<br />

completion of extensive capital investments<br />

including a new state-of-the art centralised<br />

laboratory for sample testing, and an oil extraction<br />

plant at the Mayo Macs Rietvallei plant in<br />

Mpumalanga. At the factory in Paddock, upgrades<br />

include a 60-ton delivery point designed to allow<br />

trucks to deliver their loads directly to the new<br />

additional 650-ton drying facility. <strong>The</strong> Paddock<br />

sorting room floor size has been increased and<br />

the area for loading containers was heightened<br />

for ease of packing on trucks destined for the<br />

Durban port. Further announcements included the<br />

installation of a new cracker able to process small<br />

nuts of less than 18mm which were previously not<br />

accepted, and the contracting of a second transport<br />

company to ensure the bumper crop expected in<br />

the forthcoming season is delivered timeously and<br />

without delays to the factories.<br />

<strong>The</strong> Mayo Macs crop outstripped the rest of the<br />

country with a shareholder sound kernel of 38%<br />

versus 31.1% as an industry-wide average (2017<br />

season) and just 1.9% unsound kernel against a<br />

3.0% industry-wide average.<br />

<strong>The</strong> Paddock factory started their processing for<br />

the <strong>2019</strong> harvest on 1 April while processing at<br />

the Rietvallei plant is expected to get underway<br />

on 1 May.<br />

18<br />

THE MACADAMIA

Combatting Iron<br />

Deficiencies<br />

In <strong>Macadamia</strong><br />

Orchards:<br />

Solutions For a Complex Phenomena<br />

Iron deficiencies in macadamia orchards are characterised by yellow<br />

leaves and, eventually, die-back in branches, resulting in lower yields.<br />

While rectifying iron levels can be a lengthy and costly exercise,<br />

orchard preparation at the start can prevent future problems.<br />

Without iron, chlorophyll cannot be formed in a plant.<br />

It is therefore crucial to ensure that this micronutrient is<br />

in perfect balance to make respiration, photosynthesis and<br />

the mobilising of oxygen and sulphur in the plant system<br />

possible. Nico Claassens, business development manager<br />

of plant nutrition at Laeveld Agrochem, explained that<br />

the yellowing of the intervein areas of a leaf is a typical<br />

symptom of iron shortages. “If this is not corrected, dieback<br />

of the leave tips and branches will occur and even<br />

total die-back of the branch or tree. <strong>The</strong> yield and nut<br />

quality of affected trees will decline because no energy is<br />

available to set a crop or to effectively transform water to<br />

oil in the kernel.”<br />

UNDERSTANDING IRON DEFICIENCIES<br />

Claassens said the following factors<br />

cause iron deficiency in macadamias:<br />

Incorrect Soil pH: Iron is most effectively absorbed<br />

in the tree at a soil pH level of 5 to 6.5. At a pH above<br />

7.0, iron will bond with minerals such as calcium and<br />

magnesium, making it insoluble.<br />

Chemical Imbalances: Elements in abundance, such as<br />

phosphate, calcium, magnesium, zinc, manganese, sodium<br />

and carbonates, all have a negative effect on the availability<br />

of iron to the plant roots.<br />

Low Soil Temperatures: At soil temperatures below<br />

13°C, root activity starts to decline rapidly: below 5°C,<br />

iron uptake will stop completely. This is why new growth<br />

occurring after a very cold winter will often show iron<br />

deficiency symptoms.<br />

Article & Images<br />

Lindi Botha<br />

Lack of Oxygen in the Soil: This is mainly caused by<br />

wet and cold soil conditions, which enhance the mobility<br />

of minerals like manganese, preventing the uptake of iron<br />

because of manganese’s superior mobility in the soil. A lack<br />

of oxygen also causes soils to compact, having a negative<br />

effect on available soil oxygen around the root area.<br />

Soil Compaction: Insufficient soil preparation before<br />

planting and lack of organic components in the soil causes<br />

fine sandy soils and high clay soils to become compacted<br />

easily. But iron deficiency can occur in any soil type so land<br />

preparation must be done effectively before planting. <strong>The</strong><br />

soil must also be continuously maintained to ensure proper<br />

root development and health in the coming years. Older<br />

orchards in general suffer from compaction, and rectifying<br />

the problem is expensive and takes time, so prevention is<br />

better than cure.<br />

Low Microbial Activity: Bacillus Ferrooxidans is a<br />

soil-borne bacterium responsible for making elements in<br />

the soil, such as iron, available to the plant. In leached and<br />

sandy soils and those that have been vigorously fumigated<br />

with products like ethylene dibromide (EDB), the microbial<br />

activity will be very low or non-existent.<br />

Root Diseases: Diseases such as phytophthora will have<br />

a negative effect on new root development, which is very<br />

important for the uptake of iron, because iron is only<br />

absorbed by newly active, growing roots.<br />

20<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

21

Above Iron deficiencies will eventually result<br />

in lower yields and die-back of branches.<br />

22<br />

PROACTIVE PREVENTION<br />

Claassens advised that the development of new orchards<br />

be carefully considered to prevent future iron deficiency<br />

problems in macadamias. “Choose well-drained soils that<br />

are above the frost line and which are rich in organic<br />

matter. <strong>The</strong> richer the soil is in minerals and organic<br />

matter, the better the trees will perform. Unfortunately,<br />

macadamia trees don’t have the ability to grow in very<br />

substandard soils. It is therefore important to ensure that<br />

the minimum standards for root development and health<br />

are adhered to.” He said proper soil classification and<br />

preparation would prevent poor performance of the trees<br />

due to iron deficiencies or other shortfalls. “Planting trees<br />

on ridges ensures good drainage and good aeration, which<br />

results in healthy, active roots. <strong>The</strong> height of the ridge will<br />

be determined by the soil depth and physical condition.”<br />

Claassens cautioned against using organic fertilisers high in<br />

phosphates, such as chicken litter. “This could result in a<br />

build-up of phosphates in the soil to the extent where iron<br />

fixation can take place. “Old tobacco soils were known to<br />

be annually fumigated with EDB, which had a detrimental<br />

effect on the soil microbes. Trees to be grown in these<br />

soils should be treated with beneficial microbes when they<br />

are planted. Using good organic mulch, organic acids<br />

and other soil microbe nutrients will help establish and<br />

maintain a healthy macadamia orchard.” To prevent surface<br />

compaction Claassens recommended oxygen-enriched<br />

water, which also assists with creating an oxygen-rich root<br />

zone beneficial for iron uptake by the trees.<br />

“A healthy, well developed root system<br />

guarantees a successful macadamia orchard.<br />

Farmers should also plant trees from<br />

reputable nurseries,” said Claasens.<br />

Above Iron deficiencies are characterised by yellowing of the leaves.<br />

APPLICATION OF IRON PRODUCTS<br />

When iron applications are necessary, Claassens said only<br />

chelated products should be applied, according to the soil<br />

pH: chelating agent EDTA (15%) for soil pH lower than<br />

6.0, chelating agent DTPA (11%) for soil pH lower than<br />

7.0, and chelating agent EDDHA (6%) for a soil pH higher<br />

than 7.0.<br />

When iron or any other cation micronutrient is applied to<br />

the soil in non-chelated form, it has little effect, because the<br />

mineral becomes attached to the soil particles, which then<br />

become negatively charged, very quickly. It is also restricted<br />

by other soil minerals competing for position in the<br />

rhizosphere of the roots. While low iron levels are common<br />

in macadamia orchards, Claassens said although excess iron<br />

can produce symptoms of stunted growth and discoloured,<br />

bronzing foliage, it is unlikely to happen in tree crops like<br />

macadamias because they can withstand high iron levels.<br />

“Over supply can cause a short term toxicity effect due to<br />

the sudden increase of iron in the root zone. This can either<br />

cause root burn or an imbalance with other essential plant<br />

nutrients like zinc, copper, calcium or magnesium. It is<br />

crucial to continuously measure iron levels and ensure the<br />

tree is receiving the correct amounts to flourish,” he added.<br />

THE MACADAMIA<br />

Multicote® Agri (8) Juvenile:<br />

<strong>The</strong> solution for growing new orchards<br />

A single application of Multicote® Agri controlled-release fertilizer provides your<br />

young trees with a balanced nutrition over months, supporting establishment and<br />

enhancing growth.<br />

1. Moisture penetrates<br />

the polymer capsule<br />

2. <strong>The</strong> moisture<br />

dissolvesthe<br />

nutrients in the capsule<br />

Reg. Nr. K 8834 (Act 36 of 1947)<br />

3. Nutrients are released<br />

into the soil by diffusion.<br />

Soil temperature controls<br />

the rate of release.<br />

Nutrition matches growth needs ● Better nutrient use efficiency<br />

Labor saving ● Nutrient availability independent of irrigation<br />

<br />

<br />

Pioneering the Future<br />

Haifa South Africa<br />

PO Box 1409, Brackenfell, 7561, South Africa | Tel: 021 982 0309 | Fax: 021 981 7637 | www.haifa-group.com

Practical Training<br />

Grows Mac Farm Manager Skills<br />

A commercial grower training programme to<br />

shore up the ever widening skills gap in South<br />

Africa’s macadamia industry has successfully<br />

completed its first year, with a second group of<br />

youngsters signed up and busy learning how to<br />

manage the country’s orchards.<br />

Article Peter Hughes<br />

Images Supplied<br />

A training programme set up by seasoned Lowveld<br />

macadamia farmers Guy More, Duncan Macgregor and<br />

Kasper van Rooyen has been met with enthusiasm by the<br />

region’s farmers, who snapped up the first four recruits as<br />

soon as they graduated towards the end of last year.<br />

Macgregor, who farms at Lochaber Estates in South Africa’s<br />

Lowveld, said as co-founder of Recruitagri, he was not<br />

only delighted with the project’s progress since it started in<br />

May last year, but also with the calibre of the first batch of<br />

students. “We’d like to see steady growth in the number of<br />

graduates we turn out, without in any way compromising<br />

on the quality of the training. We are also keen to involve<br />

other interested farmers and agricultural organisations<br />

in Recruitagri. It will help us broaden the internship<br />

experience we can give our trainees and assist in covering<br />

the costs,” Macgregor said. <strong>The</strong> vision, he added, was to<br />

develop an internship programme aimed at turning out<br />

quality graduates. As a result, those applying to participate<br />

in the course require a degree or diploma from a recognised<br />

tertiary institution if they are to be accepted.<br />

King Dlamini, who is now employed as an assistant farm<br />

manager on a 200ha property in the Barberton Valley,<br />

said he landed the job because of his interaction with<br />

agricultural experts and seasoned managers during the<br />

course. “I keep learning every day, and I am so grateful<br />

for the solid platform that Recruitagri gave me,” he said.<br />

Similarly, BSc graduate Ronnie Mamba, who always<br />

dreamed of a career in agriculture, said the year at<br />

Recruitagri had provided a “wonderful bridging year” for<br />

him. Mamba is now employed as a junior farm manager<br />

on a nearby kiwi fruit and macadamia-producing operation.<br />

This year six students were selected from more than<br />

300 applications. Jenny More, a BSc graduate with majors<br />

in psychology and genetics from Wits University, has taken<br />

on the task of managing the non-profit company established<br />

to drive Recruitagri. She said she was not only thrilled to be<br />

heading up the initiative but reports received from the<br />

farmers who employed the first group of graduates had<br />

filled her with confidence.<br />

“<strong>The</strong>ir response shows us<br />

that we are on the right track<br />

and that we are meeting the<br />

great need for agricultural<br />

graduates,” said More.<br />

While the course is yet to be accredited, More said the<br />

content was designed with a good balance of both theory<br />

and practical studies in mind.<br />

Above Learning how to<br />

sample soils are, from<br />

left, Cyril Maseko,<br />

Khethukuthula Maseko,<br />

Sabelo Fankomo,<br />

Xolani Msithini and<br />

Zwakele Silubane.<br />

Right Jenny More<br />

Far Right Roy Porritt,<br />

who was commissioned to<br />

develop the course content,<br />

discusses water infiltration<br />

with Cyril Maseko, left,<br />

and Xolani Msithini.<br />

24<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

25

Former farmer, agriculture expert and consultant<br />

Roy Porritt (right) was commissioned by Recruitagri<br />

to develop the curriculum and to oversee the day-to-day<br />

teaching responsibilities. <strong>The</strong> course includes the theory of<br />

managing soil types, irrigation, tree nutrition and diseases.<br />

<strong>The</strong> students get involved in fire protection, they learn how<br />

to drive a tractor, calibrate irrigation equipment, maintain<br />

machines and tools, and how to handle chemicals safely.<br />

Benchmarking protocol GlobalGap as well as safety, healthy,<br />

environment and quality or SHEQ are dealt with, along<br />

with the legal requirements of farming and responsible<br />

management of the environment. More said apart from the<br />

theory of dealing with soils, water and irrigation, nutrition,<br />

pests and diseases, the interns were also taught the basic<br />

principles of economic systems, finance, sales, marketing,<br />

entrepreneurship, innovation and human resources<br />

management and motivation. “Between the monthly lecture<br />

sessions, the interns work on a rotational basis with existing<br />

farm managers. <strong>The</strong>y also participate in a structured reportback<br />

and discussion session, complete with written and oral<br />

tests,” she said.<br />

For further information on the<br />

programme contact Jenny More at<br />

jenny@more-ct.co.za or Ruline Pieters<br />

at admin@recruitagri.com<br />

Above Cyril Maseko, who was accepted into the class of <strong>2019</strong><br />

at Recruitagri, gets hands-on experience in a pumphouse.<br />

Left Discussing soil profiling are, from left, Xolani Msithini,<br />

Sabelo Fankomo, Zwakele Silubane, Cyril Maseko and<br />

Khethukuthula Maseko.<br />

26<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

27

Get <strong>The</strong> Most Bang<br />

For Your Buck<br />

<strong>The</strong>re is considerable potential for increasing profit by<br />

improving the whole kernel percentage and limiting kernel<br />

discolouration in macadamia crops. As such, a study was<br />

conducted in the Lowveld region by Alwyn du Preez<br />

(above), an independent technical consultant for the<br />

macadamia industry, to determine factors that influence nut<br />

quality and mitigation practices that can be implemented<br />

to reduce this discolouration. Du Preez noted that kernel<br />

recovery is determined by the nut size, shell thickness and<br />

therefore weight of kernel and shell. “This means that with<br />

a higher kernel recovery, fewer nuts will be cracked for the<br />

same amount of kernel, reducing processing costs, and more<br />

kernels are sellable per unit of nut-in-shell (NIS).” <strong>The</strong> same<br />

cultivar can produce nuts that differ in kernel recovery,<br />

whole kernel recovery and kernel discolouration.<br />

To develop optimal management strategies to maximise<br />

productivity and profitability of macadamias, factors that<br />

influence kernel recovery must be considered. Du Preez said<br />

the fruit structures are formed during the first 90 days after<br />

flowering, and the fruit continues to grow until 12 to 15<br />

weeks, until the shell hardens. Climate, soil moisture, crosspollination<br />

and nutrition all influence this process, during<br />

which the shell thickness and kernel size is determined, and<br />

thereby the kernel recovery.<br />

HIGHER YIELDS, BIGGER NUTS<br />

For the study a large set of historical data from different<br />

regions was used to establish and isolate possible factors<br />

involved in kernel recovery and discolouration. Although<br />

With Higher Crackouts<br />

Article & Images Lindi Botha<br />

Higher kernel recovery<br />

and unblemished whole<br />

nuts means more profit<br />

in your pocket. But<br />

with various factors that<br />

ultimately influence<br />

crackout, farmers need<br />

to manage on-farm<br />

practices carefully to<br />

reap the full reward<br />

from the harvest.<br />

these differed between the six regions over two seasons, it<br />

was found that relative humidity and vapour pressure deficit<br />

had an influence on both kernel recovery and whole kernel<br />

recovery. Whole kernel recovery was determined by the<br />

method of curing NIS and was improved by faster delivery<br />

and harvesting time. “We established that whole kernel<br />

recovery correlated with kernel recovery. This means growers<br />

can benefit from increased prices and lower production cost<br />

by increasing kernel recovery and whole kernel recovery<br />

at the same time.” Du Preez found that high whole kernel<br />

recovery was associated with high kernel recovery, early<br />

season harvesting and processing of NIS, the Bungay curing<br />

system of NIS compared with ambient air, low vapour<br />

pressure deficit during the nut maturation period from<br />

middle January to harvest, elevated leaf boron and copper<br />

concentrations, and low manganese leaf concentrations in<br />

November. High crop load, no cross pollination, low leaf<br />

nitrogen and zinc and high leaf potassium concentrations<br />

in November were linked to low kernel discolouration. <strong>The</strong><br />

study found that high kernel recovery was associated with<br />

high orchard altitude, good cross pollination, high yield,<br />

early season harvesting and processing of NIS, high leaf<br />

boron concentrations in November, water management<br />

using deficit irrigation, and low daily maximum relative<br />

humidity during the nut growth stage, which is from<br />

October to middle January. Du Preez said slope and row<br />

orientation of the orchard influences light interception<br />

and is an important factor that will influence the yield<br />

of macadamia trees. “Solar radiation interception is at its<br />

optimum when rows are planted perpendicular to east and<br />

west slopes, and parallel to north and south slopes.”<br />

IRRIGATION AND KAOLIN INFLUENCESCE<br />

Because extreme temperatures of 35°C during the later<br />

stages of nut development have adverse effects on oil<br />

accumulation and nut growth, resulting in poor kernel<br />

quality, moderate temperatures were therefore required in<br />

February during the early oil accumulation period to ensure<br />

a high kernel recovery. “Previous studies have shown that<br />

high temperatures of more than 30°C could be regulated<br />

by evaporative cooling and the use of reflecting substances<br />

like kaolin clay,” said Du Preez. “<strong>The</strong> research included two<br />

irrigation trials and one kaolin trial, to develop possible<br />

orchard practices that increase kernel recovery, whole kernel<br />

recovery and decrease kernel discolouration.”<br />

In the two irrigation trials, water stress was induced<br />

over two growing seasons by applying different levels of<br />

irrigation at different phenological stages. Kernel recovery<br />

was not affected by any of the treatments; however,<br />

Du Preez added that water stress could not be applied<br />

continuously because of frequent high rainfall during the<br />

study. Moderate water stress, however, did not influence<br />

yield. In the kaolin trial, the efficacy of kaolin foliar<br />

applications was evaluated to reduce heat stress: there<br />

was no effect on kernel recovery, nut yield or quality.<br />

“Previous studies have shown that application of kaolin<br />

could potentially be a practical and economical way of<br />

regulating heat stress of macadamia trees. Due to the<br />

season in which our study was conducted not reaching long<br />

periods with maximum daily temperatures exceeding 30°C,<br />

the potential impact of kaolin on heat stress reduction<br />

and kernel recovery and yield could not be fully evaluated.<br />

We did, however, establish that up to five layers of foliar<br />

applied kaolin did not significantly reduce individual leaf<br />

photosynthesis.”<br />

POLLINATION<br />

While macadamia trees flower profusely, only about 0,3%<br />

set as nuts. Since the potential yield of a macadamia tree<br />

is determined during floral initiation, it is important<br />

to manage orchards meticulously during this period to<br />

ensure maximum pollination. Du Preez said his study<br />

showed that macadamia nut yield and fruit size improved<br />

with cross pollination. “It increased the percentage of<br />

macadamia flowers with a pollen tube at the base of the<br />

style, and resulted in an increase in initial fruit set and<br />

sometimes the NIS weight, kernel weight and kernel<br />

recovery. Supplementary pollination increased NIS weight,<br />

kernel weight and kernel recovery in some cultivars, like<br />

A4.” <strong>The</strong> study noted that the Beaumont variety shows an<br />

increased yield and kernel recovery after cross pollination by<br />

various cultivars. But unfortunately Beaumonts flower later<br />

than most of the commercial cultivars, which reduces the<br />

benefits derived from cross pollination. With an increase<br />

in the supply of macadamia nuts as more trees come<br />

into production, and an increasingly quality conscious<br />

consumer, orchards and harvesting practices must be finetuned<br />

to ensure high kernel and high whole kernel recovery<br />

to capitalise on better prices. In addition to commercial<br />

studies to determine better on-farm practices, farmers<br />

should conduct their own trials to find the winning recipe<br />

that delivers high yields at lower costs.<br />

Top A higher yield has been found to<br />

correlate with a higher kernel recovery<br />

Above Although macadamia trees flower<br />

profusely, only 0,3% set as nuts.<br />

28<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

29

Reduce<br />

Waterlogging<br />

Through Subsurface<br />

Drainage<br />

Optimally drained soils are<br />

crucial to orchard health,<br />

ensuring that trees receive<br />

adequate water, oxygen<br />

and nutrients.<br />

We spoke to Johnnie van der<br />

Walt (below) from Precision<br />

Drainage about the benefits<br />

of a subsurface drainage<br />

system in combatting<br />

waterlogged orchards.<br />

Article & Images<br />

Lindi Botha<br />

And Increase Tree Health & Yield<br />

For successful macadamia nut farming, optimal irrigation practices must be<br />

followed, requiring an understanding of how the soil profile will react when<br />

water is added. If drainage is inadequate, it will result in a lack of oxygen in the<br />

soil and reduce the plant’s ability to absorb nutrients. This places stress on the<br />

trees and results in lower yields. Johnnie van der Walt said waterlogged soils also<br />

increase susceptibility to diseases like phytophthora, which occurs after roots have<br />

been submerged in water for only four hours, making it difficult to combat in<br />

areas with poor drainage. “Soil is also negatively affected by poorly drained soils,<br />

as temporarily anaerobic conditions decrease positive soil biological activities,<br />

reducing the soil’s overall health.” He said subsurface drainage systems not only<br />

prevent trees from drowning but also reduce soil salinisation. “In many areas<br />

the irrigation water salinity is gradually increasing as the upstream catchments<br />

supplying water become more saline.<br />

For productive agriculture to continue, adequate leaching and drainage is<br />

necessary to remove salt left in the root zone.” Elevated water tables result<br />

in the mobilisation of the stored salt and when this saline water table comes<br />

close to the soil surface, it results in soil salinisation and waterlogging, with<br />

detrimental effects on production. “Subsurface drainage will treat waterlogging<br />

and salinisation resulting from these shallow water tables. It is also required<br />

where more saline irrigation water is used. With increasing irrigation water<br />

salinity, the leaching requirement is increased, which often cannot be met by<br />

natural drainage.” He added that subsurface drainage does not remove available<br />

water from the soil; it merely removes gravitational water that would drain<br />

naturally if unimpeded by confining layers in the soil. “<strong>The</strong> greatest benefits<br />

of subsurface drainage typically are realised in wet years, but because drainage<br />

promotes deep root development, crops will have better access to soil moisture in<br />

dry years.”<br />

INSTALLING SUBSURFACE DRAINAGE<br />

It was important, Van der Walt said, for farmers to ensure proper drainage<br />

systems are in place, otherwise tree health could be negatively affected. In<br />

overcoming drainage problems, farmers should first identify soil properties<br />

through a credible expert. “Subsurface drainage requirements are determined by<br />

the natural soil properties, either physical, chemical or a combination of both. So<br />

farmers must first do a proper soil analysis before installing a subsurface drainage<br />

system. A general rule of thumb is that the higher the clay content, the more<br />

artificial drainage is required, as the permeability of the fine textured soils is<br />

slower. Soils with shallow restrictive layers can also pose drainage problems as the<br />

effective root zone does not have the capacity to accommodate excess water.”<br />

Above Agricultural Drainage<br />

<strong>The</strong> top illustration represents agriculture land without<br />

drainage improvement. <strong>The</strong> water table is near the soil<br />

surface and water ponds in surface depressions. <strong>The</strong> land<br />

in the bottom illustration is drained by a system subsurface<br />

plastic tubing or clay tile. <strong>The</strong> water table is lowered, which<br />

allows timely field operations and helps increase crop yields.<br />

GREAT<br />

POTENTIAL<br />

FOR IMPROVING<br />

WATER SAVINGS<br />

Besides solving waterlogging in orchards,<br />

subsurface drainage has far greater potential when<br />

considered as a means to harvest excess water. Van<br />

der Walt said existing irrigation can benefit from<br />

irrigation water recycling through underground<br />

drainage systems that, when combined with the<br />

rainwater harvesting systems, greatly improve water<br />

management and availability on the farm. “<strong>The</strong><br />

concepts of rainwater harvesting on a commercial<br />

scale, drainage water recycling and reuse and<br />

subsurface irrigation and fertigation, are still new,<br />

having come to attention due to South Africa’s<br />

water scarcity and prevalence to extreme droughts.<br />

“However, through subsurface drainage systems,<br />

the whole farm can effectively be harnessed as a<br />

catchment area. Measurements taken through a<br />

Global Navigation Satellite System (GNSS) provide<br />

accurate topographical data of the farm, which<br />

identifies where the runoff and natural waterways<br />

occur. This can be used to determine where to<br />

place dams in the lower lying areas of the farm so<br />

they can receive and store the water that has been<br />

diverted through the drainage systems.” Van der<br />

Walt said this concept, however, requires a change<br />

in mindset from the farmer’s side and a complete<br />

change in how a farm is managed.<br />

“We need to move from<br />

a passive to an active<br />

solution to climate<br />

change. In short, the<br />

technology we use makes<br />

it possible to change<br />

the entire farm into an<br />

active catchment area<br />

to accommodate and<br />

store as much rainwater<br />

as possible.”<br />

- Johnnie van Der Walt<br />

30<br />

THE MACADAMIA<br />

AUTUMN <strong>2019</strong><br />

31

Right Guided by lasers and GPS equipment, modern<br />

drain ploughs can lay drainage tiles with precision.<br />

<strong>The</strong> following important points must be<br />

considered when installing subsurface drainage:<br />

Depth and spacing of pipes is determined by soil<br />

structure and texture properties that need to be<br />

sampled and analysed beforehand. Drainage pipe depth<br />

is mainly determined by the depth of the restrictive<br />

soil layer. Generally, finer textured soils are spaced<br />

closer than that of coarse soils. Subsurface drainage<br />

installation can be either via conventional trenched<br />

drains or modern trenchless drainage, also referred to<br />

as tiling, depending on soil properties. <strong>The</strong> former is<br />

labour intensive and takes some time to install correctly<br />

as many manual processes are required. On average<br />

about 300-400 metres per day is possible, while tile<br />

drainage is mechanised and automated and can install,<br />

depending on soil condition and type, upwards of 4000<br />

metres per day.<br />

<strong>The</strong> tiling method, which uses GPS technology, is a<br />

quarter of the cost of a conventional trenched drainage<br />

system. It requires no labourers or the addition of<br />

crusher stone as the drainage pipe is ripped into the<br />

subsurface by a specially designed plough that installs<br />

the pipe automatically on the correct slope and<br />

gradient and forms a perfect hole for the pipe. This,<br />

therefore, does not destroy the soil profile above or<br />

below the pipe, so does not require the crusher stone<br />

layer above the pipe. It should be mentioned that<br />

subsurface drainage works from the bottom up, so the<br />

water flow enters the pipe from the bottom, not from<br />

the top, because of capillary action. Drainage amount<br />

is based on the soil properties and pipe spacing, soil<br />

stratification, pipe size, slope and depth (a deeper<br />

drainage pipe takes longer to drain).<br />

It is important to ensure the drainage system is selfcleaning:<br />

this is designed to flush out small dead hair<br />

roots and sedimentation.<br />

<strong>The</strong>re are three main factors that influence<br />

the cost of subsurface drainage systems:<br />

- Size of the problem area: only the problematic area<br />

needs to be drained, not necessarily the whole field.<br />

- Soil type: fine textured soils require more pipes per<br />

hectare to drain effectively.<br />

- Drainage coefficient: the amount of rainfall and the<br />

irrigation system is a determining factor in deciding<br />

on the pipe size.<br />

<strong>The</strong> cost of subsurface drainage systems in South<br />

Africa installed by GPS-controlled drainage ploughs<br />

ranges from R10 000 per hectare to R25 000 per<br />

hectare, depending on soil physical properties. <strong>The</strong><br />

return on investment is between one and five seasons.<br />

PRODUCTION &<br />

ENVIRONMENTAL<br />

BENEFITS<br />

OF SUBSURFACE DRAINAGE<br />

- Increased yields, visible plant health and vigour.<br />

- Excess salts from irrigation or rain water causing<br />

soil salinisation can be leached out of the<br />

root zone.<br />

- Plant roots receive enough oxygen to<br />

mature properly.<br />

- Plant roots are grown deeper into the soil<br />

so they can absorb more nutrients.<br />

- Storm water runoff is absorbed and downstream<br />

flooding reduced.<br />

- <strong>The</strong> chances of water-borne diseases are reduced.<br />

- Since the soil can absorb and store more<br />

rainfall, runoff from the soil surface is reduced,<br />

so soil erosion is reduced.<br />

- Soil structure is improved. Soil needs to be<br />

drained to avoid soil compaction and structural<br />

damage, both of which reduce yields.<br />

- Soil bearing strength is increased. <strong>The</strong> bearing<br />

strength of soil depends on its water content,<br />

which in turn is affected by the depth of the<br />

water table. Good soil drainage increases soil<br />

strength and reduces damage caused by<br />

farming operations.<br />

Why do the biggest avocado, macadamia and<br />

citrus growers and exporters, among others, use<br />

Heli-Tractor?<br />

Visit our website<br />

or contact<br />

Eugene for<br />

more information<br />

Ask yourself ...<br />

<strong>The</strong> answer is simple: Using<br />

precision laser-guided applications,<br />

chemicals are blasted like a mist blower into highdensity<br />

crops from above (vertically downwards), providing<br />

unsurpassed crop penetration. Better chemical coverage and<br />

efficacy means increased yields for sales and export.<br />

Heli-Tractor is now the ONLY operator in Africa to use the latest<br />

South American electrostatic spraying system technology in our<br />

helicopter.<br />

Heli-Tractor<br />

guarantees better droplet deposition<br />

TRACTOR ELECTROSTATIC SPRAYING<br />

Convert your mist blower to an electrostatic sprayer with our bolt-on<br />

kits. No need to purchase a complete stand alone electrostatic mist<br />

blower and more powerful tractor, when our kit uses what you have<br />

and gives you the most powerful electrostatic charge<br />

so you get the best droplet deposition and coverage<br />

at lower costs. We have multiple kits to fit axial<br />

and cannon mist blowers, as well as high boys and<br />

boom sprayers. Visit our website and see why the top<br />

farmers in the mac, avo and citrus industries have<br />

changed to our electrostatic spraying systems.<br />

32<br />

THE MACADAMIA<br />

Cell<br />

082 652 6705<br />

E-Mail<br />

helitractor@vodamail.co.za<br />

Website<br />

www.helitractor.co.za<br />

<strong>The</strong> only operator in<br />

Africa to use laser<br />

guidance technologies

Misunderstanding<br />

Sapling Manipulation<br />

Puts Mature Mac Trees At Risk<br />