CPT International 01/2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EDITORIAL<br />

Foundry technology<br />

made in Germany!<br />

German foundries and their suppliers are resourceful when it comes<br />

to modernization. Evidently with success, because Germany is the<br />

world’s fifth-largest producer of castings – and has been the uncontested<br />

world champion in productivity for years.<br />

Robert Piterek<br />

e-mail: robert.piterek@bdguss.de<br />

This newly designed issue of CP+T<br />

shows particularly clearly the<br />

answers that German engineers<br />

and molding material developers have<br />

found for the daily challenges facing<br />

foundries. The vibration technology<br />

expert Joest, for example, manufactures<br />

casting coolers and sells them worldwide.<br />

The interview with Managing<br />

Director Dr. Marcus Wirtz reveals the<br />

strategic considerations of the company,<br />

but also deals with the consequences<br />

of e-mobility and Industry 4.0<br />

(more on this from P. 6).<br />

The topics covered in other engineering-related<br />

articles range from a new<br />

thermal regeneration plant, through a<br />

shredder solution for aluminum rejects<br />

at the BMW works in Landshut and a<br />

process-integrated blasting plant, to an<br />

intelligent coating unit for automating<br />

coating preparation and inspections.<br />

The company report from P. 12<br />

provides a concrete view of a German<br />

foundry. The iron foundry Dinklage<br />

produces counterweights for forklifts.<br />

Business is booming, but the workforce<br />

at the company is insufficient – a problem<br />

that is affecting many foundries<br />

worldwide.<br />

Countries’ increasingly stringent<br />

environmental legislation in response to<br />

climate change and international treaties<br />

such as the Paris Agreement is forcing<br />

foundries and molding material<br />

developers to find new solutions<br />

regarding the composition of sand<br />

cores and molds. Inorganic substances<br />

have long played a role here. Now a<br />

new process accelerates the hardening<br />

of inorganic sand cores by means of<br />

electricity (more on this from P. 20)<br />

To assist in your orientation at the<br />

GIFA (at which about 1,000 exhibitors<br />

and 80,000 visitors are again expected)<br />

this issue also includes a GIFA Special.<br />

An article deals with Industry 4.0, the<br />

focus topic area of the trade fair. As<br />

GIFA and the quartet of technology<br />

trade fairs called “Bright World of<br />

Metals“ will offer a special show on<br />

additive manufacturing this year the<br />

Special also includes an article on this<br />

“key issue for future production<br />

engineering“. Visit GIFA and gain an<br />

insight into the current state-of-the-art<br />

of foundry technology – I am looking<br />

forward meeting your there!<br />

Have a good read!<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 3

CONTENTS<br />

FEATURES<br />

6 INTERVIEW<br />

Successful, even in uncertain times<br />

Joest is a specialist for vibration technology and<br />

2<strong>01</strong>9 becomes 100 years old – Interview with<br />

Managing Director Dr. Marcus Wirtz<br />

Michael Vehreschild<br />

12 COMPANY<br />

Full order books –<br />

but shortage of personnel<br />

The iron foundry Dinklage in the German federal<br />

state of Lower Saxony uses hand molding processes<br />

to cast counterweights for the forklift sector.<br />

Robert Piterek<br />

17 CLEANING, FETTLING & FINISHING<br />

Process-integrated<br />

blast cleaning of die castings<br />

Die casting of aluminium is an extremely productive<br />

method for the manufacture of large-series<br />

parts which can be controlled at a high level.<br />

Klaus Vollrath<br />

INTERVIEW<br />

Dr. Marcus Wirtz in<br />

conversation with<br />

CP+T reporter<br />

Vehreschild.<br />

COMPANY<br />

A foundry in Lower<br />

Saxony casts counterweights<br />

for the booming<br />

forklift sector.<br />

20 MOLD AND COREMAKING<br />

Development of a new process for fast<br />

electrical hardening of inorganic sand cores<br />

The development of a new process for the hardening<br />

of inorganic sand cores aims at the faster and<br />

more cost-effective production of inorganic sand<br />

cores, Wolfram Bach, Eric Riedel<br />

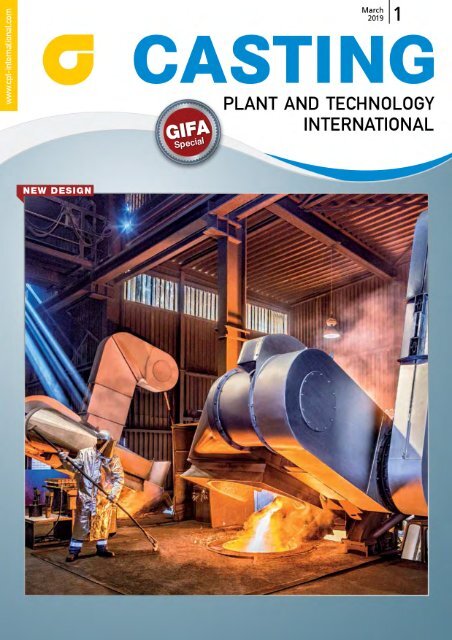

Cover-Photo:<br />

Fritz Winter Eisengießerei GmbH & Co. KG,<br />

Albert-Schweitzer-Straße 15, 35260 Stadtallendorf,<br />

Germany info@fritzwinter.de<br />

www.fritzwinter.de/en<br />

CORE COATING<br />

The ICU is the next<br />

step in simplifying<br />

the coating application<br />

in the foundry<br />

industry.<br />

Fritz Winter is supplier of the global auto mo tive, commercial<br />

vehicle and hydraulic industry with sites in Germany,<br />

USA and China. The company develops and manufactures<br />

castings as well as complex system components.<br />

4

CONTENTS<br />

CLEANING, FETT-<br />

LING & FINISHING<br />

Blast cleaning of<br />

die castings.<br />

26 MOLD AND COREMAKING<br />

From waste to molding material<br />

Optimization of circulation for organically bound<br />

no-bake sands, Marco Cassens<br />

28 3-D-PRINTING<br />

Additive manufacturing –<br />

a plus for modern metal casting<br />

Many industrial manufacturers claim to be excited<br />

about metal additive manufacturing – a process that<br />

makes possible previously unmakeable shapes – but<br />

how many are actually doing anything about it?<br />

Andreas Bastian<br />

31 SPECIAL: GIFA 2<strong>01</strong>9<br />

GIFA 2<strong>01</strong>9 – the future is digital<br />

“The Bright World of Metals” is focusing on digitalization<br />

and Industry 4.0 in 2<strong>01</strong>9, Gerd Krause<br />

Additive manufacturing: the key issue for<br />

production engineering in future<br />

“The Bright World of Metals“ is devoting a special<br />

show to the subject of additive manufacturing.<br />

Gerd Krause<br />

44 CORE COATING<br />

ICU – Intelligent Coating Unit<br />

By intelligent coating control, a great number of<br />

new automation applications become possible.<br />

Christoph Genzler<br />

48 RECYCLING<br />

RECYCLING<br />

Production of cylinder<br />

crankcases at the<br />

BMW Lightmetal<br />

foundry in Landshut.<br />

A new pre-shredder<br />

reduces srap.<br />

Pre-shredder in aluminium foundry reduces<br />

scrap<br />

Implementation of a sophisticated safety concept<br />

for the monitoring of container filling levels.<br />

Sophie Kesy<br />

COLUMNS<br />

3 EDITORIAL<br />

40 GIFA NEWS<br />

50 NEWS IN BRIEF<br />

54 FAIRS AND KONGRESSES/AD INDEX<br />

55 PREVIEW/IMPRINT<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 5

INTERVIEW<br />

6

“Naturally, our employees are central to our<br />

success. Everyone carries the foundry DNA in<br />

themselves.“<br />

Joest is a successful specialist in the field of vibration<br />

technology. The picture shows Dr. Marcus Wirtz in front<br />

of a dryer manufactured by Joest<br />

Successful, even in<br />

uncertain times<br />

100 years of Joest this year – Interview with Managing Director, Dr. Marcus Wirtz<br />

These are turbulent times – the Diesel<br />

emmission scandal, political shocks,<br />

e-mobility and Industry 4.0 challenge<br />

the foundries. Nevertheless, Joest continues<br />

to write its success story unabashed.<br />

Rising sales and employee<br />

figures show that the company is<br />

doing a lot right. Joest can confidently<br />

look forward to its 100th anniversary<br />

next year. How did the company from<br />

Duelmen achieve this? CP+T spoke to<br />

Joests Managing Director, Dr. Marcus<br />

Wirtz.<br />

Photo: Jöst<br />

Your company is successful in the market<br />

and boasts increasing sales and<br />

employee figures. You obviously did a<br />

lot of things right. In your opinion,<br />

what was decisive for this development?<br />

One of the key aspects of our success<br />

story is the history of the company.<br />

Joest celebrates its 100th anniversary<br />

next year. We have remained true to<br />

ourselves throughout the years. We<br />

have been manufacturing vibratory<br />

machines for a long time, but have<br />

remained open-minded and have added<br />

additional technologies to our portfolio.<br />

We have developed these consistently<br />

and made it possible for the company<br />

to continue to grow in a generic<br />

and organic way with new applications<br />

and technologies. Today we offer everything<br />

the market asks for – from small<br />

individual machines to large solutions.<br />

We fulfill the wishes of many foundries<br />

with complete solutions. We have<br />

developed ourselves in line with the<br />

customers and their needs. Listening<br />

On the road to success with Jöst: Managing Director Marcus Wirtz looks to the future with<br />

confidence<br />

and counseling is essential – and of<br />

course experience.<br />

What were the milestones in the<br />

development of Joest?<br />

To steadily strengthen its growth, Joest<br />

has made acquisitions that are optimally<br />

suited. In 1995, we acquired the<br />

Uhde-Schwingungstechnik. Herweg<br />

joined in 2002: In addition to the vibration<br />

technology, Joest now also offers<br />

weighing technology and special solutions.<br />

The conveying in vacuum was<br />

made possible. In 2006, Joest took over<br />

DIETERLE, a manufacturer of lifting and<br />

tipping equipment that transports, lifts,<br />

tilts, doses or decants bulk materials.<br />

DIETERLE GmbH & Co. KG merged with<br />

Joest GmbH + Co. KG early 2<strong>01</strong>8 and is<br />

no longer an independent company,<br />

but another strong Joest group brand.<br />

In this way, we have expanded and supplemented<br />

our portfolio, and now offer<br />

an even wider range of products.<br />

A company is only successful in a team.<br />

What is the role of your employees in<br />

the growth?<br />

Naturally, our employees are central to<br />

our success. We attach great importance<br />

to employing primarily foundry<br />

engineers in our foundry division or<br />

Photo: Michael Vehreschild<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 7

INTERVIEW<br />

employees from the foundry sector.<br />

Everyone carries the foundry DNA in<br />

themselves. This allows for a completely<br />

different access to customers. Furthermore,<br />

Joest has a very good staff structure<br />

of older and younger employees,<br />

from experienced and talented employees.<br />

Today, having on-site contact is<br />

more important than ever in international<br />

business. We have a total of ten<br />

subsidiaries. At least one on each continent,<br />

where we also manufacture, have<br />

spare parts ready and employ<br />

engineers. A key success of the Joest<br />

group lies in the successful internationalization<br />

strategy of the last 20 years.<br />

Now we are present in different countries<br />

and keep a close eye on what each<br />

country needs. This global presence also<br />

makes it possible to balance a weakening<br />

market with a stronger one.<br />

Photo: Michael Vehreschild<br />

How does success translate into<br />

numbers?<br />

The success can be seen in the development<br />

of sales and employee figures.<br />

They rose by 10 to 15 % respectively in<br />

the past three years. Today, Joest has<br />

365 employees in Germany – 15 more<br />

than a year and a half ago. Sales worldwide<br />

rose to more than 90 million<br />

euros.<br />

On the 1st of November<br />

2<strong>01</strong>8 Joests new<br />

tech nical center started<br />

operation.<br />

Good numbers despite adversity – the<br />

Diesel emmission scandal also had an<br />

impact on the suppliers to the automotive<br />

industry. How did it impact Joest?<br />

Of course, the exhaust gas scandal has<br />

damaged the image of German mechanical<br />

engineering. At first there were<br />

irritations, projects were sometimes<br />

postponed. But there were reinvestments,<br />

the irritations are only insignificant.<br />

The scandal was so far not as significant<br />

as expected. We were able to<br />

balance the dent with other applications.<br />

Especially since the European<br />

foundries are becoming more and more<br />

international.<br />

Photo: Jöst<br />

What impact do growing expectations<br />

for efficiency and sustainability have<br />

on your business?<br />

We pay attention, for example, to efficiency<br />

in drive technology, which has<br />

always been one of our core competencies.<br />

An example: We have produced a<br />

large cast iron cooler – the largest vibrating<br />

machine in Europe – which is only<br />

powered by a 15 KW motor. We lower<br />

the energy consumption, even as the<br />

cast coolers get larger and larger. In<br />

addition, we at Joest naturally optimize<br />

our own production processes and production<br />

halls. The conversion to stateof-the-art<br />

technology, such as LED lighting<br />

and cold-beam heating systems,<br />

significantly saves on energy.<br />

How did you manage to meet the<br />

increasing demands?<br />

In fact, the requirements are becoming<br />

more and more complex – but we enjoy<br />

tackling them. To do this, we develop<br />

new processes and optimize machines,<br />

controls and plant technology. This<br />

applies for example to the core sand<br />

crushing. In order to meet high requirements,<br />

we have also steadily increased<br />

our development staff. We also offer a<br />

dual degree program, which we are significantly<br />

expanding for the different<br />

areas. In addition, we are preparing<br />

ourselves as a strong training company<br />

for the future. We currently have 35<br />

trainees – from the commercial sector<br />

to production. As customers increasingly<br />

demand a local presence, Joest<br />

founded another new company in<br />

Korea in 2<strong>01</strong>7. In China and Korea,<br />

there is a clear demand to produce<br />

locally, which we also live up to. We are<br />

well informed about different countries<br />

and we have a combination of local and<br />

international staff here.<br />

Business units usually do not all<br />

develop at the same pace. Which<br />

product portfolio for foundries shows<br />

a particularly strong growth at your<br />

company? What are the reasons?<br />

A current trend is that due to increasing<br />

demand, several brake disk foundries<br />

are investing in box form plants with<br />

horizontal division in order to produce<br />

the castings with a structure which is<br />

point symmetrical to its axis of rotation.<br />

The configuration of the molding boxes<br />

8

“The share of hybrid drives will rise significantly<br />

in the coming years. This requires<br />

about 25 to 30 % more weight in castings. “<br />

Investments are essential -<br />

that‘s what Jöst stands for.<br />

Michael Vehreschild (right)<br />

interviewed Dr.-Ing. Marcus<br />

Wirtz on the question of what<br />

makes Jöst so successful.<br />

Photo: Jöst<br />

is maximized; the performance of<br />

modern molding equipment is significant.<br />

This requires casting/sand separation<br />

plants in appropriate dimensions.<br />

In the production of engine blocks<br />

made of cast iron materials increasingly<br />

methods are used in which the casting<br />

has no direct contact with the wet casting<br />

sand, but rather is enclosed by an<br />

outer contour core structure to meet<br />

the accuracy and reproducibility,<br />

demanded by the required thin casting<br />

wall thicknesses of up to 2.5 mm. Such<br />

filigree castings require special unpacking<br />

procedures. This can not be managed<br />

with conventional separation channels.<br />

In the production of aluminum<br />

cylinder heads and several components<br />

for electric cars in gravity die casting,<br />

the cavities of the castings are mapped<br />

by built cores. For reasons of emission<br />

protection, increasingly inorganic binders<br />

are used for the production of<br />

these cores, replacing the traditional<br />

organic cold box process. It has been<br />

found, however, that the dust produced<br />

during the various post-coring process<br />

steps is significantly finer and partially<br />

respirable, i.e., penetrates into the<br />

alveoli. This considerably raises the<br />

demands placed on the plant technology<br />

with regard to dust-proofness and<br />

wear resistance. Since our concepts consistently<br />

reflect the indispensable feedback<br />

of customer experience, we have<br />

suitable solutions that meet these<br />

requirements.<br />

Which markets may come to the fore?<br />

We can see expansions in Mexico and<br />

Turkey. The automotive industry is growing,<br />

increasing the need for foundries.<br />

Especially since end users expect the<br />

foundry to be located nearby. In addition,<br />

there is an investment backlog in<br />

North America. Much of the production<br />

was shifted especially to China. Now a<br />

lot can come back. The political and<br />

financial problems and conflicts –<br />

recently in Turkey – as well as tweets<br />

from the US, however, can stop such<br />

developments overnight and lead to<br />

shifts to other countries. Therefore, our<br />

international presence is essential.<br />

E-mobility is thus coming increasingly<br />

into the spotlight. How do you rate this<br />

market?<br />

It will be a long time before there are<br />

no more combustion engines left. The<br />

demand for trucks is very high.<br />

Truck transport is increasing enormously<br />

and e-mobility is less important here<br />

and will not represent a solution for the<br />

foreseeable future. I consider the goals<br />

of e-mobility announced by politicians<br />

in Germany to be unrealistic. But I have<br />

the impression that this will calm down<br />

and they will come to their senses, to<br />

more realistic assessments and time frames.<br />

(Including combustion engine).<br />

This includes hydrogen propulsion and<br />

the classic internal combustion engine<br />

in other regions, where these are constantly<br />

optimized. To meet future requirements<br />

for fleet consumption<br />

The share of hybrid drives will rise<br />

significantly in the coming years. This<br />

requires about 25 to 30 % more weight<br />

in castings. According to expert estimates,<br />

this trend will continue until at least<br />

2035. If the share of pure electric<br />

vehicles increases gradually, the proportion<br />

of castings will decrease significantly,<br />

but many castings will be required<br />

for the charging infrastructure and<br />

the growing number of wind turbines.<br />

Could markets develop differently?<br />

In China, North America – and Africa in<br />

the long term – the demand for engines<br />

is immense, and the distances to be<br />

covered are even greater. The internal<br />

combustion engines will continue to<br />

play their part in this. But one thing is<br />

clear: E-mobility is a trend, the share of<br />

E-mobility will continue to grow. There<br />

will be a mix: in the urban area rather<br />

electric motors and hybrid technology<br />

(with internal combustion engine). This<br />

includes hydrogen propulsion and the<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 9

INTERVIEW<br />

classic internal combustion engine in<br />

other regions, where these are constantly<br />

optimized. In order to meet<br />

future requirements for fleet consumption,<br />

the share of hybrid drives will<br />

increase significantly in the coming<br />

years. This requires about 25 to 30 %<br />

more weight in castings. According to<br />

expert estimates, this trend will continue<br />

until at least 2035. If the share of<br />

pure electric vehicles increases gradually,<br />

the proportion of castings will<br />

decrease significantly, but many castings<br />

will be required for the charging<br />

infrastructure and the growing number<br />

of wind turbines.<br />

Industry 4.0 is the future. How do you<br />

position yourself here?<br />

Industry 4.0 is a special opportunity, we<br />

are working intensively with it. We<br />

have already developed some solutions:<br />

Thus, we provide a clear allocation of<br />

data on the castings, bring together<br />

numerous parameters and allow tracing<br />

of data. For example, the customer<br />

knows where things are. The goal is to<br />

detect mistakes earlier and avoid them.<br />

It’s all about reporting of faults, avoidance<br />

of failures and preventive maintenance.<br />

Our vision is that you can tell<br />

why a casting error occurred. All data<br />

– such as temperature, speed, humidity,<br />

inventory and noise level – should be<br />

merged. An important example: The<br />

controllers we develop should not just<br />

control. We already have intelligent<br />

controls – the platform is there, so the<br />

hardware is there. Now let’s see how<br />

we use them, so that these controls can<br />

unfold their full potential. For this purpose,<br />

the controllers are additionally<br />

equipped with intelligent software. We<br />

want to offer both: normal and intelligent<br />

controls.<br />

Without innovations there is no further<br />

development of the company. With<br />

what strategy do you proceed here?<br />

The field of research and development<br />

is essential for us. That is why we work<br />

together with various universities, for<br />

example with the Technical University<br />

of Aachen and the University of Applied<br />

Sciences of Münster, Steinfurt department.<br />

We award master’s and doctoral<br />

theses. Furthermore, I am a member of<br />

the board of the VDMA trade association<br />

Metallurgy and Chairman of the<br />

Department of Mineral Processing.<br />

Here, global strategic issues are discussed.<br />

What investments did you use to accelerate<br />

the development of your company?<br />

We have been here in Dülmen since<br />

1990 and have since been constantly<br />

expanding by investing in new plants<br />

and production capacities such as halls.<br />

The floor area increased from 40,000 to<br />

approximately 65,000 square meters. An<br />

example: Eight years ago, we built a<br />

completely new blasting and painting<br />

plant using state-of-the-art technology.<br />

Since then we can perform all paint specifications<br />

up to the highest quality<br />

requirements in a flexible and timely<br />

manner. This is especially important<br />

when offering premium quality with<br />

JOEST – EXPERTS IN BULK MATERIALS<br />

The foundry business field at Joest offers machines and systems for green and<br />

no-bake sand molding systems. Companies in the steel and metallurgical<br />

industries are supplied with, among other things, hopper discharge chutes for<br />

supplement management, and alloying plants for the various melting processes<br />

in steelworks. In addition to metallurgy, the main business fields are primary<br />

raw materials, secondary raw materials/recycling, as well as chemistry<br />

and food.<br />

Vibration machines and systems for almost all industrial sectors are conceived,<br />

designed, produced and tested at the headquarters in Dülmen on a total<br />

surface area of about 65,000 m². The company, which considers itself an<br />

expert in bulk materials, has undergone strong growth in recent years. Several<br />

subsidiaries have been founded abroad: in South Korea (since 2<strong>01</strong>7), India,<br />

China, Australia, Brazil, South Africa, France, and in the USA. So, according to<br />

Joest, customers all over the world can exploit the company’s expertise with<br />

local support, production and service. Sales volumes and the number of<br />

employees are constantly rising. Joest has 365 employees in Germany, and<br />

more than 700 worldwide. Worldwide sales total more than 90 million euros.<br />

Joest will celebrate its 100-year history next year. The Managing Directors<br />

include Dr. Hans Moormann (also Managing Partner), Dr. Marcus Wirtz and Dr.<br />

Christoph Stephany.<br />

short delivery times. On November 1,<br />

the new technical center went into operation.<br />

We built this even larger. Here<br />

we can run tests with customers for all<br />

solutions as well as machines and prototypes<br />

offered by Joest. Over the past<br />

few years, we have invested a total of<br />

more than 10 million euros in our main<br />

site in Dülmen.<br />

Are there plans for further investment<br />

in the next few years?<br />

Yes, this includes, for example, the new<br />

machine technology of the flame cutting<br />

machine with integrated machining<br />

centers. We also employ welding<br />

robots to achieve productivity at a consistently<br />

high level of quality. As the<br />

world leader in vibration technology<br />

with manufacturing facilities on every<br />

continent, quality is our top priority, no<br />

matter where in the world customers<br />

buy from us. Therefore, we continue to<br />

focus on Germany and plan further<br />

expansions, especially for quality-critical<br />

parts and components.<br />

Investments are important, but also<br />

require qualified employees. How do<br />

you deal with the shortage of skilled<br />

workers?<br />

We must note that it is becoming more<br />

difficult to find trainees. This applies<br />

especially to the field of electrical<br />

engineering. Basically, we are working<br />

very actively to avoid a shortage of<br />

skilled workers. Thus, for example, we<br />

have a good network with associations<br />

and universities. And we can offer<br />

employees many benefits. We have<br />

very good transport connections. We<br />

are in close proximity to Münster as<br />

well as Duisburg, Dortmund and Dusseldorf<br />

– without having to renounce<br />

the advantages of inexpensive rural<br />

living. A great location advantage. The<br />

dual course of study that we offer is<br />

also very attractive. Young employees<br />

have many and good international<br />

opportunities for development. Out of<br />

consideration for the families, the fitters<br />

are still working in the factory.<br />

The employees assemble the machines<br />

here, but then accompany them to the<br />

construction site for final assembly. It<br />

is important for us not only to keep<br />

our employees, but to offer an attractive,<br />

motivating work environment<br />

with prospects. And this is confirmed<br />

by the fact that they want to stay<br />

here!<br />

The interview was conducted by<br />

Michael Vehreschild, Kleve.<br />

10

FOUNDRY –<br />

A PASSION FROM<br />

OUR HEART.<br />

BOB GAGE , BUSINESS LINE MANAGER – FEEDING SYSTEMS<br />

“SETTING THE<br />

STANDARD”<br />

Customizable 3D Filters for Unmatched Reliability and Consistency<br />

Experience live at the GIFA:<br />

Hall 12, Booth A22<br />

ASK Chemicals is at the forefront of casting innovation with progressive technology that drives<br />

our customer base forward. EXACTPORE 3D Filters protect against filter bits by<br />

utilizing an engineered structural design capable of limitless shapes. In addition, this<br />

optimized structure offers nearly perfect pore sizes (e.g. 10 ppi).<br />

www.gifa.ask-chemicals.com

Full order books –<br />

but shortage of personnel<br />

Melt on the march! Cupola<br />

furnaces replenish the molten<br />

iron in the iron foundry<br />

The iron foundry Dinklage in the German federal state of Lower Saxony uses hand molding<br />

processes to cast counterweights for the forklift sector. Business is booming, but the<br />

necessary capacity expansion is at risk because of a lack of personnel. Managing Director<br />

Björn Ploch wants to modernize and expand the works – with Swabian industriousness<br />

and good ideas.<br />

by Robert Piterek, Düsseldorf<br />

Photos: Andreas Bednareck<br />

Drive past special steel producer<br />

Stallkamp and axle manufacturer<br />

Gigant and you reach the Dinklage<br />

iron foundry in the industrial park<br />

of the small town of Dinklage (population<br />

12,800) in the Vechta district of<br />

Lower Saxony. The production hall,<br />

about 70 meters long, stands at right<br />

angles to the administration building,<br />

in front of which employees and visitors<br />

can park their cars. The works, which<br />

looks fairly inconspicuous from the outside,<br />

is an essential element in the production<br />

chain of a type of vehicle<br />

which, although an everyday sight in<br />

industry, is only ever seen on Germany’s<br />

roads firmly strapped to the back of a<br />

truck. The iron foundry is owned by the<br />

Frankfurt-based KION GROUP which<br />

also controls, among other companies,<br />

the major forklift producers Linde<br />

Material Handling and STILL. Components<br />

for excavators and mobile cranes<br />

are also produced here for Switzerland’s<br />

Liebherr group of companies. The<br />

owners of the iron foundry should be<br />

pleased about the extremely good<br />

orders situation. Managing Director<br />

Björn Ploch puts it succinctly: “The<br />

forklift market is booming!” Whereby<br />

his task is the foundry-based production<br />

of the counterweights – necessary for<br />

balancing the loads that the forklifts<br />

busily transport around the factories of<br />

the world – annual sales of which are in<br />

the high double-digit millions of euros.<br />

12

COMPANY<br />

Managing Director<br />

Björn Ploch (left) ex <br />

plains the charging of<br />

the furnace to CP+T-<br />

Edi tor Robert Piterek<br />

– reasonably priced<br />

input material is becoming<br />

increasingly rare.<br />

Work is now in full<br />

swing in the foundry.<br />

Here, on the semi-automatic<br />

molding line.<br />

An older caster treats a mold with an<br />

alcohol-based coating. Almost 40 %<br />

of the workforce is over 55 years old.<br />

The workforce is too old<br />

The hand molding foundry is located in<br />

a region that has no foundry tradition<br />

and where the unemployment rate of<br />

2 % is nearing full employment. A poor<br />

starting point for a works that employs<br />

167 personnel (including agency workers<br />

and trainees) and whose workforce<br />

is gradually ageing too much. “The proportion<br />

of 55-year-olds in the workforce<br />

is currently 38 %,” according to Ploch.<br />

“This will catch us out badly in two or<br />

three years,” the Swabian adds gloomily.<br />

He comes from Königsbronn in the<br />

Swabian Alb region and started working<br />

at the Dinklage iron foundry in<br />

2<strong>01</strong>6.<br />

Ploch’s fascination regarding<br />

foundry work started at SHW in Königsbronn.<br />

Here he developed from a skilled<br />

worker to a master, before taking a<br />

commercial Chamber of Industry and<br />

Commerce course and then moving to<br />

Hasloch to be Works Manager for Kurtz,<br />

where he helped Managing Director<br />

Graziano Sammati expand the smart<br />

foundry. Ploch’s eyes light up when<br />

asked whether he would also set up<br />

Industry 4.0-based production in Dinklage<br />

if it were possible, though he<br />

avoids the comparison. “The technology<br />

and design at Kurtz were brilliant, but I<br />

think that the automated transport systems<br />

there are too susceptible to<br />

faults,” he recalls, and then ventures to<br />

transfer the vision of a smart foundry to<br />

his works: “I see what they have at<br />

Kurtz on rails here – and there would<br />

also have to be a manipulator.” But the<br />

necessary manpower would have to be<br />

recruited here before he could approach<br />

these tasks in concrete terms.<br />

Automatic preparation<br />

of coatings<br />

Some new developments, however,<br />

have been completed and are already<br />

improving the quality and expanding<br />

the capacity of the current 36,000 tonnes<br />

per year of production – because<br />

the order books for 2<strong>01</strong>8 and 2<strong>01</strong>9 are<br />

full to the brim. And the restless Swabian<br />

does not lack plans. Ploch and his<br />

team recently invested in an automatic<br />

coating preparation system from<br />

foundry supplier Foseco, Borken, to<br />

meet customers’ quality demands.<br />

“There was often a lot of mineralization<br />

in the shaft area. When we took<br />

measurements, we found that there<br />

was insufficient viscosity in our old coating<br />

tank. Our water-based dip therefore<br />

failed to provide the desired<br />

effect,” the Managing Director ex <br />

plains. “Our flood basin used to be<br />

manually mixed every morning,” he<br />

recalls. Ploch got the idea for the<br />

Foseco coating preparation system<br />

during a visit to the sister foundry run<br />

by Linde Material Handling in Weilbach,<br />

where an almost identical plant was<br />

already in operation. After a few modifications,<br />

the pool has also been providing<br />

optimally mixed coatings in Dinklage<br />

since January 2<strong>01</strong>8.<br />

Human sources of error are ruled<br />

out by the computer-controlled<br />

movement of the reddish brown liquid,<br />

which is gently stirred in the pool by a<br />

current and then applied to the core.<br />

The mineralization problem at Dinklage<br />

is now a thing of the past, and Ploch is<br />

happy to have a German partner for the<br />

coating. “The advantage of Foseco is its<br />

closeness. Other producers are located<br />

in Italy, and the reaction time is not<br />

quick enough. We have had two problems<br />

since the plant was installed.<br />

Foseco was here in four hours and provided<br />

immediate help, while also offe<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 13

COMPANY<br />

ring service,” stresses Ploch. According<br />

to Foseco, the advantage of the plant is<br />

cost reduction – thanks to a lower reject<br />

rate and less extra work – as well as<br />

increased productivity and optimized<br />

drying, with positive effects on the quality<br />

of the castings.<br />

An alcohol-based coating is not an<br />

alternative solution for Ploch. “On our<br />

casting line we still use alcohol coatings<br />

for the cope and drag boxes, but<br />

water-based for the cores. The disadvantage<br />

of the alcohol coating is that<br />

the surface of the binder bridges can be<br />

destroyed by the heat, resulting in loss<br />

of mold strength. Water-based coating<br />

is gentler, it does its job, evaporates and<br />

I can work on the core again after eight<br />

hours. There is also less smell.” The iron<br />

foundry uses no-bake furan resin sands<br />

with 20 % of new sand and 80 % of old<br />

sand for the cores.<br />

Ploch is a pragmatist through and<br />

through, and is totally involved with his<br />

job. He is prepared to put up with various<br />

hardships: he lives in Dinklage<br />

during the week, commuting to his wife<br />

and children in Heidenheim, 600 kilometers<br />

away, on weekends and for<br />

family celebrations. In addition to his<br />

profession and family, Ploch has two<br />

other passions: the German Premier<br />

League football club VfB Stuttgart and<br />

Thai boxing. He is also working on professionally<br />

rounding out his rise from<br />

foundry mechanic to Managing Director<br />

with an additional course he is taking in<br />

foundry technology at the German<br />

Foundrymen’s Association (VDG) Academy<br />

in Düsseldorf.<br />

The cope and drag boxes are<br />

put together on the closing<br />

machine, then the casting boxes<br />

are transported to the molding<br />

line opposite, where they are<br />

shot.<br />

The molding boxes are prepared<br />

for casting by workers with respirators.<br />

No-bake furan resin<br />

sand is used.<br />

Induction furnace tandem to<br />

replace cupola furnaces<br />

The replacement of the two cupola furnaces<br />

with induction furnaces is fully<br />

planned, but has not yet received final<br />

approval. Every hour, the cupola furnaces<br />

currently supply ten tonnes of melt<br />

of the alloy GJL 250, the only metal<br />

used at Dinklage. While one furnace is<br />

actively melting, the other receives<br />

maintenance – requiring manpower for<br />

which Ploch must maintain 3-shift operation.<br />

This melting system, especially<br />

suitable for serial casting, is now rarely<br />

found in Germany. Only about 60<br />

cupola furnaces are still operating in<br />

German foundries.<br />

The two cupola furnaces have a<br />

central position in the production hall<br />

in Dinklage. Water constantly flows<br />

over the outer shell and the refractory<br />

material of the melting furnaces to<br />

cool them. Ploch and his team have calculated<br />

that 2-shift operation could be<br />

reintroduced with induction furnaces.<br />

At the same time, although the overall<br />

electricity price is rising, the basic price<br />

for the iron foundry would actually fall<br />

as a result of the higher purchase<br />

quantity: 15 instead of 1.6 MW of electricity<br />

a month. There are, however,<br />

numerous other reasons for changing<br />

the melting technology. For one thing,<br />

there is the problem of the smell<br />

(which annoys residents in the immediate<br />

vicinity of the foundry), as well as<br />

difficulty procuring input material. As<br />

flexible as cupola furnaces are, reasonably<br />

priced input material – Grade 3a<br />

commercial casting scrap, consisting of<br />

old radiators and water pipes, up to<br />

now obtained from Poland, the former<br />

East German states and the Czech<br />

Republic – is becoming increasingly<br />

rare, leading to rising prices. A new<br />

induction furnace tandem would double<br />

melt performance while reducing<br />

the workload and eliminating the<br />

smell problem – arguments for the<br />

change that Ploch considers unbeatable.<br />

He estimates the costs for the furnaces,<br />

the periphery and installation at<br />

5 million euros.<br />

In order to equip the foundry for<br />

the future, Ploch also wants to install a<br />

sixth processing center with a 5-axis milling<br />

machine in the machining shop, as<br />

well as buy a molding sand mixer and a<br />

casting cooler. There should also be a<br />

cooling section for the castings, and<br />

drying furnaces for the cores. Solution<br />

14

The iron foundry was able to<br />

ensure mold stability with the<br />

fully automatic coating pools<br />

from Foseco.<br />

of the personnel shortage, however, is<br />

of fundamental importance for increasing<br />

yield with the help of the new<br />

technical equipment in the machining<br />

shop: “I currently have five machines<br />

but only four operators,” the Managing<br />

Director points out.<br />

Five processing centers<br />

are currently in operation<br />

– and there is<br />

already one operator<br />

too few. Machining is<br />

nevertheless to be<br />

expanded.<br />

A forklift counterweight<br />

with sprues and<br />

burrs in the fettling<br />

shop. Most of the work<br />

here is done by agency<br />

staff.<br />

The casters from the Swabian Alb<br />

Work in the production hall is now in<br />

full swing. Most of the space in the hall<br />

is taken up with the semi-automatic<br />

molding plant. Finished drag boxes containing<br />

cores for STILL counterweights<br />

are currently being transported to the<br />

closing machine, where the cope and<br />

drag boxes are automatically put<br />

together. The boxes are perfectly flush<br />

with one another and are then transported<br />

to the casting line opposite,<br />

where they are shot. 65 to 80 molds are<br />

thus filled with red-hot melt every day<br />

– the largest counterweights weigh six<br />

tonnes.<br />

To the left of the molding plant the<br />

drag boxes are prepared for casting,<br />

coated, provided with cores, and secured<br />

against the lifting force. An older<br />

employee is currently hooking a bulky<br />

core to a hall crane and can thus effortlessly<br />

transport it to the waiting drag<br />

box. Elsewhere in the foundry it also<br />

becomes clear that most of the workforce<br />

have already passed the height of<br />

their productive capacity.<br />

In order to get to grips with the personnel<br />

problem, Ploch first got in touch<br />

with his own contacts in the Swabian<br />

Alb. As in the case of his 56-year-old<br />

pattern constructor, who originally<br />

managed a family-run company in<br />

Aalen but had to give it up because he<br />

could not find a successor. Thanks to<br />

Ploch’s persuasive power, the man now<br />

works here in Dinklage.<br />

Trainee Mario Faiss also came to the<br />

small Lower Saxony town from the Swabian<br />

Alb to start his career. He is in his<br />

second year of training to become a<br />

foundry mechanic, and is being introduced<br />

to the profession in the works by<br />

trainer Fred Säwert. He completed his<br />

vocational college work in block lessons<br />

at the Wilhelm Maybach College (WMS)<br />

570 kilometers away in Stuttgart,<br />

although there is also a foundry academy<br />

in nearby Varel. “They do not,<br />

however, have a training foundry of<br />

their own, and that is important for<br />

me,” stresses Ploch, who also learned<br />

his trade at the WMS. “The Maybach<br />

College also explicitly trains casters –<br />

training is divided into pattern constructors<br />

and casters. That is different<br />

from a general vocational school, where<br />

the subject is only available as an elective,”<br />

he adds.<br />

The iron foundry pays for Mario’s<br />

apartment, in addition to his normal<br />

pay packet, in order to make his training<br />

more palatable. Ploch also sent the<br />

21-year-old to the STILL works in Ham<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 15

COMPANY<br />

Painted and unpainted<br />

counterweights<br />

are stored on the<br />

foundry grounds.<br />

burg shortly after he had signed his<br />

contract. “I wanted to show him that<br />

no forklifts can exist without counterweights,”<br />

says Ploch. The visit made an<br />

impression on Mario: “I was able to<br />

experience how the forklift is constructed<br />

around the counterweight in the<br />

factory,” he remembers. He was also<br />

impressed by the machines used. Marco<br />

now feels more at home in the north<br />

than in the south. He enjoys hanging<br />

out with friends, for whom he designed<br />

a very special present: a cast iron backside<br />

with ears! Trainer Säwert is already<br />

preparing himself to receive more<br />

trainees: he has been undergoing<br />

further education as a trainer at the<br />

German Foundrymen’s Association Academy<br />

since September.<br />

Trainer Fred Säwert (left) and trainee Mario Faiss. Faiss comes from the Swabian Alb,<br />

Säwert from East Frisia. More trainees are to be recruited to ensure sufficient personnel<br />

cover.<br />

The e-forklift is on the way<br />

The necessary generational change at<br />

the works comes at a time when the<br />

forklift sector is also in transition.<br />

e-forklifts are increasingly asserting<br />

themselves in factories all over the<br />

world. This also affects the design of<br />

the counterweights. “The weights are<br />

becoming lighter because the battery of<br />

the e-forklift also adds weight,” explains<br />

Ploch. The battery is located in the<br />

middle of the forklift, while the counterweight<br />

is at the back. Ribs have been<br />

integrated into the structure of the<br />

counterweight in order to reduce its<br />

weight.<br />

Crossing the yard, in which two-anda-half<br />

thousand tonnes of charging<br />

material is stored, one reaches the paint<br />

shop, which rounds out the value-creation<br />

of the counterweights and turns<br />

the iron foundry into a ‘system supplier’.<br />

This is where the finished red and<br />

orange counterweights are arranged in<br />

rows, ready for dispatch to Linde and<br />

STILL, where they are installed on diesel<br />

or e-forklifts that will continue to be<br />

required in factory and dispatch logistics<br />

for the foreseeable future. The<br />

struggle to fill vacancies in the region<br />

will remain challenging. Bonus payments<br />

have already been made for procuring<br />

new personnel. The companies<br />

neighboring the iron foundry, Stallkamp<br />

and Gigant, have also poached<br />

one or other urgently required worker<br />

from Ploch. Trainee Mario Faiss will, in<br />

future, help Björn Ploch by recruiting<br />

secondary school-leavers starting their<br />

professional lives, and perhaps the iron<br />

foundry will also succeed in getting an<br />

agency worker to commit themselves<br />

with a fixed contract. There is certainly<br />

enough work in Dinklage – three people<br />

could immediately start work at the<br />

machining shop, and another two or<br />

three for the melting operation in the<br />

foundry. And in order not to lose sight<br />

of Industry 4.0, Ploch also needs IT<br />

experts with foundry knowledge to set<br />

up an ERP system in the medium term<br />

– so that the future also comes to Dinklage<br />

soon!<br />

www.eisengiesserei-dinklage.de<br />

16

CLEANING; FETTLING & FINISHING<br />

Process-integrated<br />

blast cleaning of die castings<br />

At ae group shift housings for<br />

automatic transmissions are cast<br />

on casting line 2 and then blasted.<br />

Die casting of aluminium is an extremely productive method for the manufacture of<br />

large-series components which can be controlled at a high level. In order to achieve<br />

a maximum degree of reliability and quality, casting lines at the ae group in Gerstungen<br />

are laid out to ensure that as many process steps as possible are linked and fully automated,<br />

thus dispensing with manual interventions. A blasting concept was therefore<br />

realized with parts lying flat on conveyor belts and being treated in a continuous process.<br />

This eliminates the unavoidable manual suspension and removal tasks associated<br />

with hanger-type blast machines.<br />

Klaus Vollrath, Aarwangen, Switzerland<br />

Photos: Klaus Vollrath<br />

We supply the automotive<br />

industry with our die-cast<br />

aluminium parts and face the<br />

toughest international competition in<br />

this respect”, says Tino Kunkel, manager<br />

of one of the production lines at the ae<br />

foundry in Gerstungen. Automation of<br />

as many processes as possible is the<br />

recipe employed here for lowering costs<br />

and, simultaneously, enhancing quality.<br />

The fundamental maxim governing the<br />

complete process chain is that castings<br />

should only be physically touched by<br />

hand where absolutely necessary. Operation<br />

of die-casting machinery<br />

(cold-chamber machines with die clamping<br />

forces ranging from 12,500 to<br />

14,000 kN) and its peripheral units is<br />

completely automated. Castings which<br />

have already been deburred on the<br />

die-casting machines are fed onto a<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 17

CLEANING; FETTLING & FINISHING<br />

Discharge side of one<br />

of the shot blast<br />

machines installed at<br />

ae in Gerstungen.<br />

Casting line 2 encompasses<br />

seven<br />

cold-chamber die-casting<br />

machines for aluminium<br />

in the final<br />

expansion stage.<br />

Castings which have already been deburred on the<br />

die-casting machines are fed onto a common conveyor<br />

route at half the height of the facility where<br />

they are forwarded to fine blanking.<br />

common conveyor route at half the<br />

height of the facility where they then<br />

travel on for fine blanking. The process<br />

continues into the next hall where the<br />

parts are first blasted for cleaning and<br />

surface pretreatment before being forwarded<br />

to laser systems by conveyor<br />

belt where they each receive an individual<br />

QR code and are packaged. Very<br />

strict quality criteria apply along the<br />

entire process chain, which is why every<br />

step is carefully monitored and documented.<br />

Similarly strict criteria apply to the<br />

machines employed. These must be<br />

designed or modified and installed so<br />

that they correspond to the process<br />

management and quality philosophy of<br />

the company. In addition to reliable<br />

engineering, human dependability and<br />

the support and service of manufacturers<br />

also play a significant role. Immediate<br />

assistance is expected where problems<br />

arise.<br />

Fully automated continuous<br />

shot blast machines<br />

The ae group opted for AGTOS Type BS<br />

08-05-3.6-08-11.0 machines for cleaning<br />

and surface preparation of castings<br />

from casting line 2 in Gerstungen. Use<br />

of a hanger-type blast machine was<br />

dispensed with, given that relatively<br />

flat, strongly structured parts with a<br />

large surface (but not bulky geometries)<br />

are mainly involved, such as shift<br />

housings for automatic transmissions.<br />

This also had the advantage of permitting<br />

selection of a direct continuous<br />

process without manual interventions.<br />

The solution chosen involves the continuous<br />

transportation of the parts<br />

through the plant with the aid of a<br />

wide-meshed wire conveyor belt. They<br />

are blasted with special abrasive from<br />

above and below during this with the<br />

aid of a total of eight shot blasting turbines,<br />

ensuring all-round cleaning and<br />

surface treatment.<br />

The belt is divided into two tracks<br />

through a central “guide rail” consisting<br />

of plates, meaning that two different,<br />

but typical components (e.g. the<br />

upper and lower parts of a shift<br />

housing) can be processed simultaneously.<br />

As the parts only have minor<br />

indentations, residual abrasive material<br />

can be removed with comparative ease<br />

through a blower unit in the blast<br />

machine outlet.<br />

Treatment of abrasive ensures<br />

stable process parameters<br />

When it comes to treatment of castings<br />

through shot blasting, the condition of<br />

the abrasive employed plays a significant<br />

role. This moves continually in a<br />

cycle, whereby its consistency and composition<br />

are altered during use through<br />

two main interfering factors. These are<br />

soiling of the abrasive through fine<br />

non-metallic and metallic dust and dirt<br />

particles and contamination through<br />

flash and flakes parted during the blasting<br />

process. The abrasive moving in<br />

the cycle therefore needs to be carefully<br />

treated during each passage to<br />

maintain the consistency of its composition<br />

with regard to granular size and<br />

impurities within narrow limits. This<br />

occurs during the return of the abrasive<br />

from the machine abrasive collection<br />

hopper trough to the storage bunker<br />

located on top. Transportation is realized<br />

via a bucket elevator. On reaching<br />

the top, the abrasive passes through a<br />

screening section to remove coarse<br />

impurities such as flash and flakes. This<br />

is followed by wind sifting which sorts<br />

out dirt and dust particles and the<br />

finest abrasive fragments (so-called<br />

18

The castings receive an individual<br />

laser marking following the shot blasting<br />

process.<br />

fines). The abrasive cleaned in this manner<br />

is conveyed to the storage bunker<br />

for the blasting turbines.<br />

Support from the machine<br />

manufacturer<br />

As aluminium is a comparatively soft<br />

material, it can be damaged by excessively<br />

hard blasting. It was therefore<br />

important to evaluate the effect of the<br />

machines prior to deciding on their<br />

purchase. AGTOS was more than willing<br />

to conduct these preliminary trials<br />

on its own machinery. Initial blasting<br />

trials were first conducted on an<br />

AGTOS machine in Emsdetten with<br />

four turbines. Following the positive<br />

results of these tests, further trials<br />

were conducted on a large machine<br />

with eight turbines at the AGTOS plant<br />

in Konin, Poland. This machine was of<br />

the same design as the model being<br />

offered. Notable features here were a<br />

modification of the blasting turbine<br />

layout to optimize the effect of the<br />

blasting abrasive. A special abrasive<br />

consisting of non-ferrous metals which<br />

wide-meshed wire conveyor also facilitates<br />

blasting of the castings from below.<br />

was recommended by AGTOS was also<br />

used during the trials. Flakes from<br />

burrs were removed with this and the<br />

surface of the components roughened<br />

slightly while maintaining the smoothness<br />

of the bore holes which had been<br />

already punched.<br />

Engineering, consulting and<br />

service satisfaction<br />

In addition to the quality of the machines<br />

themselves, consultation and service<br />

competence proved significant criteria<br />

in the decision to purchase the<br />

machinery. The former was favourably<br />

evaluated during the prior test phase,<br />

and the ae group had already gained<br />

positive experience at an earlier stage<br />

of the reliability of AGTOS engineering<br />

and service. Shot blast machines are<br />

exposed to extremely severe stress<br />

during use, meaning that breakdowns<br />

are practically unavoidable. Fortunately,<br />

the response speed of the manufacturer‘s<br />

service department and proactive<br />

maintenance realized in advance<br />

mean that extremely few faults have<br />

been encountered during machine<br />

operation. Following an initial procurement<br />

in 2<strong>01</strong>3 and in the following<br />

years, this operating record now led to<br />

the installation of two further systems.<br />

www.agtos.de<br />

www.ae-group.de<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 19

MOLD AND COREMAKING<br />

Photo: Soplain<br />

Inorganically bound sand cores with different graphite contents, which influences the thermal conductivity of the sand binder mixture and<br />

thus the hardening times.<br />

Development of a new process<br />

for fast electrical hardening of<br />

inorganic sand cores<br />

Inorganics are becoming increasingly important for the production of sand cores. The<br />

development of a new process for the hardening of inorganic sand cores by means of<br />

electricity aims at the faster and more cost-effective production of inorganic sand cores.<br />

Further advantages such as low energy consumption and homogeneous hardening are<br />

promising.<br />

Wolfram Bach, Welsleben, and Eric Riedel, Magdeburg<br />

Introduction<br />

The use of cores is indispensable for the<br />

foundry industry. Complex, internal and<br />

thin-walled geometries as well as indentations<br />

are not possible without lost<br />

cores. Thus, they pave the way for innovative<br />

casting technology solutions in<br />

order to meet the high demands placed<br />

on modern castings today and in the<br />

future. Core production is therefore of<br />

great importance in terms of variety,<br />

complexity and surface quality. Core<br />

shooting in cold box or hot box processes<br />

has been established for many<br />

years. The cold box process, on one<br />

hand, is characterized by the fact that<br />

the sand cores are hardened in nonheated<br />

boxes by a compressed air amine<br />

mist gassing. The required binder for<br />

cold box usually consists of a two-component<br />

system consisting of phenolic<br />

resin and polyisocyanate. The hot box<br />

process, on the other hand, usually uses<br />

moist bound molding materials, which<br />

are completely hardened in the core box<br />

by absorbing the stored heat energy.<br />

Despite the extensive use and high<br />

productivity of core shooting, many<br />

companies are working on further and<br />

new developments in the field of core<br />

production. One of the most important<br />

developments at present is certainly the<br />

additive manufacturing or the colloquial<br />

3-D printing of lost cores. A development,<br />

which is advanced among others<br />

by ExOne, Voxeljet, the BMW AG or<br />

Bosch Rexroth, in order to name only<br />

some companies, and which shows<br />

again that the Additive Manufacturing<br />

procedures are versatile applicable and<br />

are becoming increasingly important.<br />

The motivation behind this develop-<br />

20

3<br />

1<br />

5<br />

6<br />

4<br />

7<br />

7<br />

12<br />

6<br />

11<br />

10<br />

9<br />

8<br />

5<br />

4<br />

2<br />

4<br />

3<br />

1 Upper mould box half<br />

2 Lower mould box half<br />

3 Mounting plate (electrically isolated)<br />

4 Isolation plate<br />

9<br />

5 Electrodes (arranged parallel)<br />

6 Mould material (electrically conductive)<br />

7 Mould cacity<br />

8 Sand-binder mixture / Core<br />

9 Control of voltage<br />

10 Square<br />

11 Isolation screw<br />

12 Alignment bolt<br />

3<br />

Graphics: University of Magdeburg<br />

Figure 1: Schematic illustration of the core box design (left) with detailed illustration of the fastening of the mold material in the mold box.<br />

ment is a reduction in fixed costs, since,<br />

e.g., the production of the necessary<br />

core boxes and tools, the purchase of<br />

which usually only pays off with large<br />

quantities, is no longer necessary or the<br />

production of small batch sizes at large<br />

series costs. Thus, 3-D printing of lost<br />

cores opens up new possibilities with<br />

regard to complexity, individuality and<br />

quality of the models in small and<br />

medium series production, e.g. for manufacturing<br />

of prototypes.<br />

Nevertheless, the manufacturing<br />

processes are too time-consuming for<br />

mass production, especially for larger<br />

geometries, and will remain so for the<br />

foreseeable future. In addition to Additive<br />

Manufacturing, sustainable manufacturing<br />

is at the top of the agenda of<br />

the local and global foundries, not least<br />

due to increasingly stringent political<br />

restrictions on behalf of the EU and the<br />

federal government(s).<br />

The introduction of inorganic binder<br />

systems, such as the Inotec binder system<br />

developed by ASK Chemicals, Hilden, or<br />

the Cordis binder system developed by<br />

Hüttenes Albertus, Düsseldorf, has<br />

already led to great success in reducing<br />

pollutant emissions in recent years. However,<br />

ongoing cost pressure and the<br />

ongoing need for new innovations are<br />

constantly prompting the industry to<br />

make further developments in this area<br />

so that foundries can remain competitive<br />

in the future.<br />

With „Advanced Core Solutions“<br />

(ACS) project, Soplain GmbH, Welsleben,<br />

aims to meet this demand and further<br />

increase the importance of inorganic<br />

binder systems. With the<br />

implementation of a new patent<br />

(DE102<strong>01</strong>7217098) for the production<br />

of lost cores and molds, a process is<br />

under development that adheres to the<br />

basic principle of core shooting and<br />

builds on the existing inorganic binders,<br />

but pursues a new approach to hardening<br />

inorganic sand cores. That way, the<br />

new process strives to be both more<br />

efficient and more environmentally<br />

friendly than previous processes.<br />

Process description<br />

The new process is based on the consideration<br />

that the permanent mold and<br />

sand-binder mixture should have<br />

CASTING PLANT & TECHNOLOGY 1/2<strong>01</strong>9 21

MOLD AND COREMAKING<br />

Graphics: Soplain<br />

Electrical resistance [kΩ]<br />

Phase 1 Phase 2 Phase 3<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Electrical resistance [kΩ]<br />

approximately the same electrical conductivity<br />

at optimum working temperature.<br />

Thus, by applying an electrical<br />

voltage, the same level of electrical current<br />

is able to flow in each area of the<br />

tool and the sand-binder mixture. The<br />

result is a homogeneous electrical<br />

energy distribution. The heating resulting<br />

from the electrical power finally<br />

hardens the sand-binder mixture homogeneous.<br />

As with conventional core shooting<br />

methods, this requires a permanent<br />

mold or core box consisting of several<br />

components. As shown in Figure 1, at<br />

least a two-part mold initially consists<br />

of just as many electrically isolated<br />

plates which serve to accommodate the<br />

individual components. On each mounting<br />

plate is the isolation plate mounted<br />

which then contains the electrodes. The<br />

electrodes will provide the electric current<br />

into the actual, electrically conductive<br />

mold.<br />

The individual components of the<br />

core boxes are connected to the mounting<br />

plate by means of electrically<br />

non-conductive screws and brackets.<br />

Power [W]<br />

Figure 2: Qualitative curve shape for the determination of the characteristic curves of mold/<br />

binder power and electrical resistance.<br />

hot<br />

hot<br />

cold<br />

does not harden<br />

Without adjustment of the specific<br />

electrical resistance<br />

hot<br />

hot<br />

hot<br />

hardens<br />

With adjustment of the specific<br />

electrical resistance<br />

Figure 3: Impact of the electrical properties of the permanent mold and sand-binder mixture<br />

on the hardening process.<br />

t [s]<br />

The individual molds for the sand cores<br />

are assembled by means of a quick-release<br />

system, which enables the permanent<br />

molds to be changed quickly. For<br />

process monitoring, the mold boxes are<br />

equipped with temperature sensors in<br />

order to prevent possible overheating<br />

above the intended temperature range<br />

as specified for the binder. For industrial<br />

use, holes for non-conductive ejection<br />

bolts are provided in the entire tool<br />

(mounting and isolation plate, permanent<br />

mold) to remove the hardened<br />

cores quickly. The selection of a suitable<br />

electrically conductive material for the<br />

permanent mold is made taking the<br />

optimum working temperature of the<br />

sand-binder mixture into account.<br />

Experimental procedure<br />

The efficiency of the processes is highly<br />

depending on the alignment of the<br />

conductivity of the mold material to the<br />

sand-binder mixture. A series of measurements<br />

were carried out to determine<br />

the electrical conductivity of sandbinder<br />

mixtures and various mold<br />

materials to identify the specific temperature<br />

and electrical conductivity<br />

behavior.<br />

In order to determine different<br />

sand-binder mixtures, the different mixtures<br />

where filled into a sample mold,<br />

which was compacted according to real<br />

application conditions. Measuring<br />

devices were attached to the electrical<br />

components of the core boxes to measure<br />

the current and voltage as well as<br />

the temperatures generated at the electrodes.<br />

A constant voltage was then<br />

applied to the electrodes, causing the<br />

specific electrical resistance of the mixture<br />

to change as a function of temperature.<br />

By doing so, the optimal electrical<br />

conductivity could be determined<br />

per material. The optimal electrical conductivity<br />

is defined by allowing the<br />

maximum energy to be conveyed into<br />

the sand-binder mixture per second.<br />

This point is defined by the lowest electrical<br />

resistance. Figure 2 shows the typical<br />

course of both characteristic values<br />

of such a series of measurements.<br />

The typical course can be divided<br />

into three characteristic phases: The<br />

first phase is the formation of charge<br />

carriers, in which the resistance drops<br />

steeply within a very short time (1 to<br />

2 s) after the voltage has been applied.<br />

In the second phase, a distinctly flattened<br />

electrical resistance is now apparent,<br />

accompanied by a continuous<br />

increase in the electrical power present<br />

in the sample. The electrical power is<br />

transformed into heat inside the<br />

sample. Above 100 °C (212 °F) the<br />

evaporation of water begins and charge<br />

carriers from the binder system are<br />

removed from sample. The consequence<br />

is a significant decline in performance<br />

and thus an increase in electrical<br />

resistance follows in phase 3. The optimal<br />

choice of electrical conductivity is<br />

defined by the minimum resistance, as<br />

the maximum power can be applied<br />

(shown in Figure 2 by the red circle).<br />

The specific electrical conductivity of<br />

the sample depends on the desired<br />

sand-binder mixture and can be influenced<br />

by the variation of the additives<br />

and/or the change of the percentage<br />

components. During the trials, the tested<br />

binders required temperatures between<br />

150 °C (302 °F) and 200 °C<br />

(392 °F) to harden. A specific tested<br />

sand-binder mixture had a specific electrical<br />

resistance of approx. 25 Ωm at a<br />

temperature of ~100 °C (212 °F)<br />

-130 °C(266 °F).<br />

Based on the temperature-resistance<br />

curves and the specific electrical resistance<br />

of the sand-binder mixture, a suit-<br />

22

able material for the permanent mold<br />

of the cores to be produced could be<br />

determined. Based on the optimal specific<br />

resistance of the selected sandbinder<br />

mixture, the mold-material<br />

should have a specific resistance of<br />

approx. 25 Ωm at approx. 170 °C<br />

(338 °F) and follow the temperatureresistance<br />

curve of the mixture as far as<br />

possible. Otherwise, if the resistivity of<br />

the permanent mold is too low, the<br />

mold may heat up but the molding<br />

material/binder mixture does not<br />

harden efficiently, as Figure 3 illustrates.<br />

Within the framework of the test<br />

series, various silicon carbide compositions<br />

with a variation of additives of the<br />

ceramic mixtures proved to be suitable;<br />

the final selected ceramic has a specific<br />

electrical resistance of approx. 30 Ωm at<br />

a temperature of 180 °C and is suitable<br />

as a material for permanent molds<br />

under consideration of all necessary prerequisites.<br />

The use of less compatible<br />

materials can lead to longer hardening<br />

times. For possible industrial use in<br />

foundries, criteria for the robustness of<br />

the material were defined in addition to<br />

the aspects of electrical compatibility. A<br />

suitable material must also have good<br />

long-term properties with regard to<br />

breaking strength, surface roughness,<br />

thermal expansion and thermal conductivity.<br />

Depending on the final process also<br />

optimal temperature ranges below the<br />

150-200 °C are possible as sufficient<br />

heat energy can be generated already<br />

as of 100 °C. In this case the electrical<br />

conductivity can be chosen based on a<br />

temperature range between 100 °C to<br />

105 °C.<br />

Integration into the production<br />

process<br />

In a production environment for sand<br />

core manufacturing, the process can be<br />

divided into three basic phases:<br />

warm-up (A), operation (B) and cooling<br />

phases (C). During warm-up phase (A),<br />

the two halves (or more parts) of the<br />

molding box are brought together to<br />

form a closed circuit. The amount of<br />

energy required for the heating process<br />

is supplied by the electrical current.<br />

During the warm-up phase the sandbinder<br />

mixture can be shot into the<br />

mold to validate that sufficient heat is<br />

available and that uniform curing of<br />

the core is possible.<br />

Once the molding material has<br />

reached the required operating temperature<br />

for hardening the binder then<br />

the optimum specific resistance of the<br />

Void in casting, after<br />

machining, seen with a<br />

Hawkeye Pro Hardy 7”<br />

Inspection Solutions...<br />

80 different borescopes, and 20 years<br />

experience helping you select<br />

just the right one!<br />

Sand visible with a<br />

Hawkeye Pro Slim<br />

12” Rigid Borescope<br />

Flash as seen with a<br />

Hawkeye V2<br />

Video Borescope<br />

High-quality rigid, flexible and video borescopes, at<br />

far lower prices than comparable instruments!<br />

Visit us at:<br />

Booth #808 • Atlanta, GA<br />

April 27 - 30, 2<strong>01</strong>9<br />