Look no hands! International IDA jury Flaps for choice - Hettich

Look no hands! International IDA jury Flaps for choice - Hettich

Look no hands! International IDA jury Flaps for choice - Hettich

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

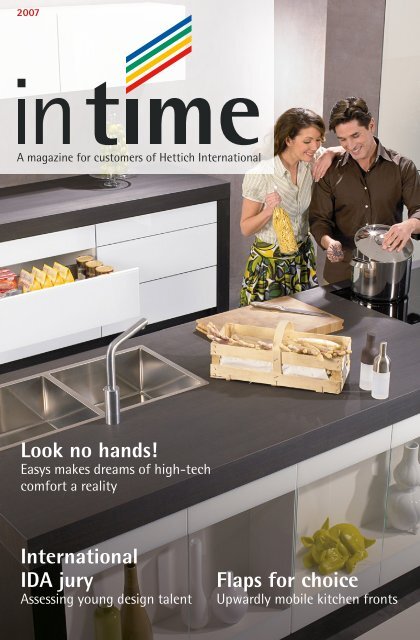

2007<br />

A magazine <strong>for</strong> customers of <strong>Hettich</strong> <strong>International</strong><br />

<strong>Look</strong> <strong>no</strong> <strong>hands</strong>!<br />

Easys makes dreams of high-tech<br />

com<strong>for</strong>t a reality<br />

<strong>International</strong><br />

<strong>IDA</strong> <strong>jury</strong><br />

Assessing young design talent<br />

<strong>Flaps</strong> <strong>for</strong> <strong>choice</strong><br />

Upwardly mobile kitchen fronts

Publication data<br />

Publisher:<br />

<strong>Hettich</strong> Marketing-<br />

und Vertriebs GmbH & Co. KG<br />

P.O. Box 1 40<br />

3 69 Kirchlengern<br />

Germany<br />

Editors:<br />

Cornelia Hackenbruch M.A.<br />

Wilfried Wadsack<br />

Layout & production:<br />

<strong>Hettich</strong> Management<br />

Service GmbH<br />

Tel.: +49 5 3 77-1736<br />

Fax: +49 5 3 77-1737<br />

E-mail: info@de.hettich.com<br />

All rights reserved.

Networking<br />

drives<br />

development<br />

We are moving ahead together. The drive to in<strong>no</strong>vate is a powerful <strong>for</strong>ce. And in<strong>no</strong>vation<br />

can reshape <strong>no</strong>t only products, but also complete process chains. By linking outstanding<br />

products, engineered <strong>for</strong> efficient manufacturing, with lean order processing and reliable<br />

service, we and our partners generate solutions that benefit all concerned.<br />

Jointly developed solutions focus on customer benefits and they depend on all the<br />

partners working effectively together. The stronger the partners, the more effective the<br />

development process, and the better the outcome.<br />

Successful networking depends on the willingness of the development partners to<br />

participate unconditionally and frankly in a project. Some outstanding examples are the<br />

lightweight.network, which links <strong>Hettich</strong> with EGGEr and rEHAu, and the <strong>International</strong><br />

Design Award organized <strong>for</strong> the first time jointly with rEHAu.<br />

Tech<strong>no</strong>logies can be networked too. Add light to a furniture fitting and you have a<br />

completely new product with exciting prospects. Development can sometimes move<br />

<strong>for</strong>ward on a broad front, as with the electrification of the kitchen.<br />

The partnerships we have <strong>for</strong>ged with customers have achieved impressive results. Some<br />

of our national and international cooperations are described in this issue of .<br />

Not all the outcomes are spectacular. But even those that seem humdrum will have<br />

opened the way to more joint projects in the future. This alone is instrumental in building<br />

the strength that profits all concerned.<br />

Dr. Andreas <strong>Hettich</strong><br />

Managing Partner<br />

<strong>Hettich</strong> Holding GmbH & Co. oHG<br />

editorial<br />

3

4<br />

current news<br />

<strong>Hettich</strong> on tour<br />

Trade shows 007/ 008 6<br />

K<strong>no</strong>wledge management<br />

Tech<strong>no</strong>logy Days <strong>for</strong> k<strong>no</strong>wledge<br />

transfer across the company 7<br />

<strong>International</strong> <strong>IDA</strong> <strong>jury</strong><br />

Assessing young<br />

design talent 9<br />

A life outside the limelight<br />

<strong>IDA</strong> prize-winners<br />

and their careers 11<br />

Coping with complexity<br />

Instead of either/or,<br />

why <strong>no</strong>t both…and? 13<br />

in<strong>no</strong>vation<br />

Best <strong>no</strong>t left to chance<br />

In<strong>no</strong>vation management 16<br />

Freedom <strong>for</strong> <strong>choice</strong><br />

Big built-in fridges<br />

<strong>for</strong> American kitchens 18<br />

Cosario<br />

Compact, accessible storage 18<br />

In<strong>no</strong>Tech drawer system<br />

Even more variety 19<br />

Bathrooms to dream in<br />

Styled <strong>for</strong> wellness 0<br />

<strong>Look</strong> <strong>no</strong> <strong>hands</strong>!<br />

Easys makes dreams of high-tech<br />

com<strong>for</strong>t a reality<br />

34<br />

<strong>Flaps</strong> <strong>for</strong> <strong>choice</strong><br />

upwardly mobile kitchen fronts 4<br />

Magische Marke<br />

JOOP! Schlafzimmer generieren<br />

umsatz und Image 5<br />

lightweight.network<br />

The future of furniture is light! 6<br />

Lightweight Test Lab<br />

Opening the door to lightweight<br />

furniture 8<br />

Voluntary high standards <strong>for</strong><br />

office furniture. New guideline:<br />

quality criteria <strong>for</strong> office workplaces 9<br />

Office: functional furniture<br />

Scope <strong>for</strong> flexibility and productivity 30<br />

ProDecor in Spain<br />

Adding value through design 3<br />

service<br />

Time efficiency <strong>for</strong> DIY customers<br />

Praktiker and Max Bahr<br />

make shopping easier 34<br />

Special space <strong>for</strong> storage<br />

Fitting out the Santander<br />

Consumer Bank AG<br />

in Mönchengladbach 36<br />

Dräger Medical uses<br />

In<strong>no</strong>Tech drawers<br />

robert Schörck: cabinetmakers with<br />

skills, k<strong>no</strong>w-how and commitment 38<br />

Carl Wilh. Meyer scores on<br />

closeness to customers<br />

Logistics as uSP 39<br />

<strong>International</strong> <strong>IDA</strong> <strong>jury</strong><br />

Assessing young<br />

design talent<br />

9<br />

13

4<br />

0<br />

contents<br />

news<br />

Fittings <strong>for</strong> over 1000 villas<br />

Palm Jumeirah: the "eighth wonder of<br />

the world“ is ready <strong>for</strong> occupation 4<br />

Returns with <strong>no</strong> questions asked<br />

The road to success <strong>for</strong><br />

Kangjie Kitchens in China 44<br />

Emotional intelligence <strong>for</strong> kitchens<br />

Johnny Grey‘s Australia tour 46<br />

Cabcor, Canada: quality sells kitchens<br />

Kitchen brands Denla and Cuisine<br />

Idéale use fittings from <strong>Hettich</strong> 48<br />

<strong>Hettich</strong> wins MVP Award 2006<br />

from Bentwood Kitchens<br />

In<strong>no</strong>vative products –<br />

outstanding service 49<br />

<strong>Hettich</strong> and Legallais<br />

Partnership <strong>for</strong> success 50<br />

Com<strong>for</strong>t below deck<br />

Maritime Møbler, Norway, makes fine<br />

furniture <strong>for</strong> ships 5<br />

in brief<br />

InLine sliding door fitting:<br />

006 Product of the Year in Poland<br />

Office Excellence Award 006:<br />

53<br />

<strong>Hettich</strong> places second<br />

New <strong>for</strong> British bedrooms:<br />

53<br />

Sharps standardizes on Silent System 53<br />

<strong>Hettich</strong> Polska: The right background 54<br />

<strong>Hettich</strong> Strothmann:<br />

New Design and Sales Centre<br />

<strong>Hettich</strong> Australia:<br />

54<br />

Sydney showroom opening<br />

<strong>Hettich</strong> uK moves into<br />

55<br />

London’s fashion heartland 55<br />

5

2007<br />

May:<br />

K/BIS<br />

Las Vegas/USA<br />

May 8 to 10, 2007<br />

INTERZUM<br />

Cologne/Germany<br />

May 9 to 12, 2007<br />

EEM (EuroExpoMebel)<br />

Moscow/Russia<br />

May 15 to 19, 2007<br />

July:<br />

CBD<br />

Guangzhou/China<br />

July 6 to 9, 2007<br />

September:<br />

BIFE – TIMB<br />

Bucharest/Romania<br />

September 5 to 9, 2007<br />

WOOD-TEC<br />

Br<strong>no</strong>/Czech Republic<br />

September 11 to 14, 2007<br />

6<br />

Trade shows 2007/2008<br />

<strong>Hettich</strong> on tour<br />

ZOW<br />

Shanghai/China<br />

September 12 to 15, 2007<br />

Habitare<br />

Helsinki/Finland<br />

September 19 to 23, 2007<br />

October:<br />

AMBIENTA<br />

Zagreb/Croatia<br />

October 10 to 14, 2007<br />

HOLZ<br />

Basle/Switzerland<br />

October 16 to 20, 2007<br />

ZOW<br />

Porde<strong>no</strong>ne/Italy<br />

October 17 to 20, 2007<br />

WMS<br />

Toronto/Canada<br />

October 26 to 28, 2007<br />

November:<br />

INDEX<br />

Dubai/UAE<br />

November 1 to 5, 2007<br />

MADERALIA<br />

Valencia/Spain<br />

November 7 to 10, 2007<br />

INTERMOB<br />

Istanbul/Turkey<br />

November 10 to 14, 2007<br />

2008<br />

February:<br />

ZOW<br />

Bad Salzuflen/Germany<br />

February 25 to 28, 2008<br />

April:<br />

HOLZ-HANDWERK<br />

Nuremberg/Germany<br />

April 2 to 5, 2008<br />

DesignEx<br />

Sydney/Australia<br />

April 10 to 12, 2008

The first intracompany Tech<strong>no</strong>logy Day was held in November 2000. Since then,<br />

these twice yearly events have proved a successful plat<strong>for</strong>m <strong>for</strong> k<strong>no</strong>wledge<br />

transfer. They also give <strong>Hettich</strong> employees from different departments and<br />

locations a chance to discuss subjects other than routine business. The 10th<br />

Tech<strong>no</strong>logy Day took place in November 2006 and in time felt this jubilee was a<br />

good opportunity to interview organizers Ralf Diener, Technical Director at Paul<br />

<strong>Hettich</strong>, and Cord Niermann, <strong>Hettich</strong> Management Service.<br />

current news<br />

K<strong>no</strong>wledge management<br />

in time: How did the Tech<strong>no</strong>logy Days<br />

actually come into being?<br />

Ralf Diener: This<br />

tech<strong>no</strong>logy <strong>for</strong>um was<br />

the brainchild of Dr.<br />

Wirths. In my first year<br />

with <strong>Hettich</strong>, I began<br />

planning the actual<br />

concept. We had two goals. One was to<br />

speed up the acceptance of new and<br />

<strong>for</strong>ward-looking tech<strong>no</strong>logies across the<br />

whole of our international company. The<br />

other was to promote communication and<br />

an exchange of ideas among <strong>Hettich</strong><br />

employees working in similar fields, but in<br />

different locations. This would help to speed<br />

the pace of change.<br />

in time: Were the Tech<strong>no</strong>logy Days planned<br />

from the start as a regular event?<br />

Ralf Diener: Our goals – k<strong>no</strong>wledge<br />

transfer and more communication – were<br />

long-term goals, so we always knew that<br />

we wanted the event to take place<br />

regularly. For this to be accepted, we had to<br />

have a good <strong>for</strong>mat. We decided on 30minute<br />

talks followed by time <strong>for</strong> discussion.<br />

To this we added the idea of a market<br />

place to allow the participating companies<br />

more scope <strong>for</strong> in-depth presentation of<br />

themselves and their products. The idea was<br />

to facilitate the transition from theory to<br />

practice. By <strong>no</strong>w, this concept – which, of<br />

course, has been polished over the years –<br />

is fully accepted.<br />

Tech<strong>no</strong>logy Days <strong>for</strong> k<strong>no</strong>wledge<br />

transfer across the company<br />

in time: How did people in the German<br />

<strong>Hettich</strong> companies take to the idea of a<br />

Tech<strong>no</strong>logy Day? Did you have to work hard<br />

initially to convince them that taking part<br />

was worth their while?<br />

Ralf Diener: We knew it was important to<br />

get off to a good start. And we succeeded.<br />

An opinion survey we did after the first<br />

Tech<strong>no</strong>logy Day showed that over 93% of<br />

our colleagues felt that the event had lived<br />

up to their expectations. We <strong>no</strong>w carry out<br />

this survey, which includes an assessment<br />

of the speakers and the general organization,<br />

after each event. It provides us with<br />

helpful feedback which we take very<br />

seriously. The fact that each Tech<strong>no</strong>logy Day<br />

is booked out is also a vote in our favour.<br />

7

in time: How would you describe the<br />

international reaction? Do you get many<br />

participants from outside Germany?<br />

Cord Niermann: There are always people<br />

from our plants in Spain and the Czech<br />

Republic, but the fact that the convention<br />

language is German inevitably limits the<br />

number of people from our <strong>for</strong>eign<br />

subsidiaries.<br />

8<br />

in time: Have the<br />

Tech<strong>no</strong>logy Days<br />

proved a successful<br />

tool <strong>for</strong> promoting<br />

interdepartmental<br />

communication?<br />

Cord Niermann: Yes, I‘m convinced they<br />

have. They bring together people from all<br />

over the company. People get to k<strong>no</strong>w each<br />

other better. They swap ideas, and talk<br />

about current projects, applications and<br />

new developments. Good communication at<br />

the Tech<strong>no</strong>logy Days is a basis <strong>for</strong> good<br />

communication in the future too – which<br />

is helpful in resolving problems and<br />

developing solutions.<br />

in time: How do you set about choosing<br />

the topics?<br />

Ralf Diener: I start by drawing up a list of<br />

topics based on my own experience. We<br />

also regularly ask participants to suggest<br />

topics that would interest them and these<br />

get added to the list. We try very hard to<br />

keep a balance across development,<br />

production and logistics.<br />

Cord Niermann: What is currently going on<br />

in the company naturally has a pretty<br />

strong influence on our <strong>choice</strong> of topics<br />

too. For example, the previous Tech<strong>no</strong>logy<br />

Day, number 9, focused on process security;<br />

that was during the roll-out phase of our<br />

new in<strong>no</strong>vation management policy and<br />

certainly contributed to its success.<br />

in time: Is it easy to get external speakers<br />

to give talks?<br />

Cord Niermann: Sometimes it‘s easy,<br />

sometimes it‘s more difficult. Our suppliers<br />

are in general very keen to present their<br />

k<strong>no</strong>w-how. Getting speakers from consulting<br />

companies and educational institutions<br />

is somewhat tougher. There‘s a lot of work<br />

involved in preparing a good 30-minute talk.<br />

in time: What about the participating<br />

companies, do they use the market places<br />

to supports a transition from theory to<br />

practice? Or do they simply see an<br />

opportunity <strong>for</strong> some useful publicity?<br />

Cord Niermann: The value of the market<br />

places is immense. They give people a<br />

chance to evaluate interesting products and<br />

developments related to the main theme of<br />

the event. Bear in mind that many people<br />

prefer to discuss something one-to-one<br />

rather than in front of a large audience.<br />

At the different company booths, they can<br />

speak directly with the experts and put<br />

their questions with the product in front of<br />

them; it‘s a far more effective way of<br />

getting in<strong>for</strong>mation. I believe it‘s true to say<br />

that superficiality and publicity-seeking<br />

don‘t stand a chance.<br />

in time: How do you go about documenting<br />

the Tech<strong>no</strong>logy Days?<br />

Ralf Diener: We make the content of all the<br />

talks and any supplementary in<strong>for</strong>mation<br />

available to all <strong>Hettich</strong> employees via the<br />

company intranet. All external participants<br />

are sent a CD-ROM with the content.<br />

in time: Would you consider making your<br />

experience available to other companies<br />

thinking of setting up a similar plat<strong>for</strong>m?<br />

Participants at <strong>Hettich</strong>’s TechDays, an in-company<br />

event, browse around the ‘market place’, keeping up to<br />

date with trends and developments.<br />

Ralf Diener: We‘re always open to ideas<br />

like this. A lot of the concept that we‘ve<br />

developed and improved over time could be<br />

easily transferred to other events, either<br />

complete or slightly modified.<br />

in time: What are your goals <strong>for</strong> future<br />

Tech<strong>no</strong>logy Days? Are you perhaps<br />

considering inviting more external guests?<br />

Ralf Diener: In the past, we‘ve sometimes<br />

invited customers. If we think the theme is<br />

one that would interest some or all of our<br />

customers – <strong>for</strong> example "Ergo<strong>no</strong>mics and<br />

machine workplaces“ – then we offer them<br />

the option of attending. We also invariably<br />

invite educational institutions. <strong>Hettich</strong><br />

maintains good contacts with the academic<br />

world and the Tech<strong>no</strong>logy Days are a great<br />

place to rein<strong>for</strong>ce and extend them. On<br />

occasion we‘ve also numbered representatives<br />

of professional associations, such as<br />

the VDI or the IHK, among our guests.<br />

Nonetheless, we shouldn‘t lose sight of the<br />

fact that Tech<strong>no</strong>logy Days are internal<br />

events and that is what they will remain.

current news<br />

[<strong>International</strong> Design Award]<br />

2007<br />

<strong>International</strong><br />

<strong>IDA</strong> <strong>jury</strong><br />

With 1,330 entries from 38 countries, this<br />

year‘s competition topped the record set in<br />

2005 (1,153 entries from 24 countries).<br />

This year, the countries most strongly<br />

represented were Germany, Japan and<br />

China. There were also an impressive<br />

number of entries from Poland, India,<br />

Slovakia, Czech Republic, Finland, UK and<br />

Canada. Apart from the acclaim, there is<br />

prize money of a20,000, which is divided<br />

among the educational institutions where<br />

the winning students are enrolled.<br />

The <strong>IDA</strong> competitions are open to<br />

participants from around the world. In this<br />

competition cycle, supervisors (professors,<br />

lecturers) at universities and colleges<br />

with faculties of furniture design and/or<br />

construction were invited to submit<br />

designs by their students in one of two<br />

categories – furniture or fittings. The<br />

general topic <strong>for</strong> the furniture category<br />

was future lifestyles. In the fittings<br />

category, the challenge was to integrate<br />

functionality with aesthetics in designs <strong>for</strong><br />

Assessing young<br />

design talent<br />

The competence of the <strong>jury</strong> members is the measure against which the<br />

authority of the entire <strong>International</strong> Design Award must be measured. In<br />

making their assessments, the jurors bring their expertise and their<br />

professional judgement to bear, but also their intuition and their awareness<br />

of styles and trends. As they judge the entries from around the world, they<br />

are also indirectly ranking the educational institutions represented by the<br />

students. The <strong>International</strong> Design Award 2007, organized jointly by <strong>Hettich</strong><br />

and REHAU, again attracted a record number of entries.<br />

drawers, roller fronts, edge bands or handles.<br />

The number of entries was limited to a<br />

maximum of five per supervisor and category.<br />

The international <strong>jury</strong> had the task of<br />

judging the entries against these and more<br />

ephemeral criteria, such as creativity. The<br />

task made heavy demands on the pooled<br />

experience and judgement of the highcalibre<br />

<strong>jury</strong> members. The 2007 <strong>IDA</strong> <strong>jury</strong><br />

was made up of design professionals from<br />

around the world.<br />

9

[<strong>International</strong> Design Award]<br />

2007<br />

Juliana Bertolini, Johnny Grey, Dr. Feng Hu<br />

Wang, Maja Palczewska, Liat Preiss, Michael<br />

Schmidt, Renata Sias, Andreas Varotsos<br />

(l. to r.)<br />

Juliana Bertolini is a product designer.<br />

She studied at the Instituto Presbiteria<strong>no</strong><br />

Mackenzie and with the SENAI programme<br />

in São Paolo. She herself sees her work as<br />

positioned somewhere between design, art<br />

and fashion. Strongly inspired by natural<br />

shapes and with intense attention to<br />

detail, her designs are expressive and<br />

feminine. Participation in design shows in<br />

Saint Étienne and São Paolo, and in the<br />

Talent Show <strong>for</strong> new designers in Frankfurt<br />

brought her international recognition.<br />

Juliana Bertolini also lectures in industrial<br />

design at Mackenzie University in Brazil.<br />

Johnny Grey trained as an architect; he‘s<br />

passionate about kitchens, furniture and<br />

the world of ideas. And especially the<br />

concept of unfitted sociable kitchens. He<br />

designs custom kitchens with his design<br />

teams in his design centres in San<br />

Francisco and Hampshire, England. The<br />

four books he has written have been<br />

published in thirteen languages. He‘s also<br />

a consultant <strong>for</strong> international companies<br />

and he travels the world as a popular<br />

speaker on kitchen design and architecture.<br />

Maja Palczewska studied interior design<br />

at the school of arts of the University of<br />

Warsaw and <strong>no</strong>w lives in Posen. She‘s<br />

worked <strong>for</strong> more than eight years as a<br />

designer of furniture and furniture<br />

accessories and as an interior designer. A<br />

number of the residential furniture ranges<br />

marketed by major Polish manufacturers<br />

carry her signature. Her most recent<br />

project is an office furniture system.<br />

Dr. Liat Preiss studied architecture in<br />

Milan and also completed a degree course<br />

in interior design. In 1979, she opened her<br />

10<br />

own offices in Milan, moving to Tel Aviv a<br />

few years later. Today, more than a dozen<br />

designers and architects work in her Tel<br />

Aviv offices, from where she has implemented<br />

over 200 projects <strong>for</strong> private and<br />

institutional clients. Liat Preiss has made a<br />

special name <strong>for</strong> herself with her work on<br />

living facilities <strong>for</strong> senior citizens. She<br />

holds a guest professorship at Bar-Ilan<br />

University and is one of the most prominent<br />

architects in Israel.<br />

Michael Schmidt‘s design studio is called<br />

code.2.design. His core competence lies in<br />

creating products <strong>for</strong> customers who<br />

believe in the power of design and his<br />

designs have won several prestigious<br />

awards. He is an in<strong>no</strong>vation partner of the<br />

Fraunhofer-Gesellschaft in Germany.<br />

Renata Sias studied architecture in Milan.<br />

She has built a career specializing in office<br />

architecture and interior design <strong>for</strong> office<br />

worlds. She‘s a frequent contributor to the<br />

specialist style journal Ufficiostile and is a<br />

visiting professor of industrial design in<br />

Milan. She has participated in conferences<br />

and exhibitions on office design in Italy,<br />

France, Greece, Japan and Switzerland.<br />

She also works as a consultant <strong>for</strong> many<br />

leading Italian companies.<br />

Andreas Varotsos was born in Athens and<br />

studied industrial design in Rome. He<br />

cooperates with the Studio IDEA in Rome<br />

and since 1984 has worked <strong>for</strong> companies<br />

in Greece and Italy. He lectures in<br />

industrial design at a number of universities<br />

and universities of applied science,<br />

exhibits at international design shows and<br />

has won design prizes in Germany and the<br />

USA. He won wide re<strong>no</strong>wn as the designer<br />

of the torch and altars <strong>for</strong> the 2004<br />

Athens Olympics.<br />

Dr. Feng Hu Wang studied at Northeast<br />

Forestry University in Harbin City/China<br />

and went on to gain a Ph. D. from the<br />

University of Wales (UK) in 1992. From<br />

1997 to 1999, Dr. Wang was a guest<br />

professor at the University of Maine (USA).<br />

Today he is Dean of the Faculty of<br />

Materials Science and Professor of<br />

Engineering at Northeast Forestry<br />

University. He holds leading positions in<br />

several wood industry professional<br />

associations and he acts as advisor to<br />

government ministries and to specialist<br />

journals and magazines. He has written<br />

seven books and published over 100<br />

articles. In China, Dr. Wang has a high<br />

reputation in the furniture and wood<br />

industries and has served on various juries<br />

during major furniture trade shows in<br />

Guangzhou, Dongguan and Shenzhen.<br />

The <strong>International</strong> Design Award 2007<br />

was the 6th competition cycle since the<br />

inception of the competition. Under the<br />

patronage of the Oberbürgermeister of<br />

Cologne, Fritz Schramma, the competition<br />

will culminate with the an<strong>no</strong>uncement of<br />

the winners at a ceremony during the<br />

Interzum 2007. The ceremony will take<br />

place in Hall 8 at 16:00 hours on May 10<br />

with the prizewinners and their supervisors<br />

present to receive their certificates<br />

and prizes. Next day, their visit to Cologne<br />

will conclude with a reception in the<br />

Cologne city hall. We hope they will all<br />

take away happy memories of the<br />

competition and their time in Cologne.

Doreen Trabhardt, Julia Lodes, Anna<br />

Czerniakiwicz, Jürgen Hierl, Piotr Noga,<br />

Torsten Klocke, Markus Thalhammer,<br />

Volker Schumann (l. to r.)<br />

A life outside<br />

the limelight<br />

Every two years, students from around the world compete <strong>for</strong> the <strong>International</strong><br />

Design Award. The winners, picked by a <strong>jury</strong> of leading design professionals, are<br />

invited to Cologne <strong>for</strong> the awards ceremony. They radiate enthusiasm and opti-<br />

mism. They often comment that winning the prize has been a milestone in their<br />

careers. We wondered what they‘ve been doing since. So we picked eight past<br />

prizewinners at random and asked them.<br />

Two years ago, Doreen Trabhardt won third<br />

prize in the <strong>International</strong> Design Award <strong>for</strong><br />

her Klabur shelf system. It was highly<br />

praised by the <strong>jury</strong> <strong>for</strong> its "idea of two- and<br />

three-dimensional storage space. With its<br />

vertical and horizontal lines, it creates a<br />

wall landscape storing books, entertainment<br />

systems, ornaments or photos. The<br />

design would be fast and simple to<br />

manufacture.“ 2005 was also the year<br />

when Doreen Trabhardt won the Bavarian<br />

Meisterpreis <strong>for</strong> extraordinary achievement.<br />

A trained cabinetmaker with several other<br />

awards under her belt, Doreen went on to<br />

qualify as a state-certified interior designer<br />

at the Special Academy <strong>for</strong> Woodworking in<br />

Cham. Today she is turning her versatile<br />

talents and k<strong>no</strong>w-how to good account as<br />

a design consultant <strong>for</strong> a leading furnishing<br />

business in Erfurt. But she‘s still waiting <strong>for</strong><br />

a manufacturer keen to mass produce her<br />

winning design.<br />

Julia Lodes, who won a first prize in 2003<br />

<strong>for</strong> her Ovo storage container, would be<br />

overjoyed if she could finance the rest of<br />

her studies from design royalties. But so far<br />

<strong>no</strong> manufacturer has taken up the idea.<br />

"Nonetheless, winning the prize was a real<br />

morale booster,“ says Julia, "it motivated<br />

me to keep going.“ Julia has <strong>no</strong>w almost<br />

completed her degree at the Hochschule für<br />

Kunst und Design Burg Giebichenstein in<br />

Halle.<br />

current news<br />

<strong>IDA</strong> prize-winners<br />

and their careers<br />

In 2003, when she won second prize in<br />

the Grips and Handles category, Anna<br />

Czerniakiwicz was a student at the<br />

Politechnika Biakystok Kiydzia Architektury<br />

in Poland. Today she works as a freelance<br />

interior designer, evolving striking interiors,<br />

designing furniture and accessories and<br />

planning colour schemes. As consultant to a<br />

company that plans public spaces, she also<br />

designs places where people enjoy spending<br />

time.<br />

Johannes Feichtinger, Jürgen Hierl and Jutta<br />

Leitner from the Institute <strong>for</strong> Interior Design<br />

at Vienna‘s Technical University worked as a<br />

team to produce their <strong>IDA</strong> entry. It was a<br />

room divider called Raum Trans<strong>for</strong>mer and<br />

it won a first prize in 2001. <strong>Look</strong>ing back<br />

today, Jürgen Hierl can understand why <strong>no</strong><br />

manufacturer has taken up their design.<br />

"I‘m afraid anyone who‘d been willing to<br />

try, would have paid dearly <strong>for</strong> taking the<br />

risk,“ he says ruefully. He <strong>no</strong>netheless values<br />

the experience and says winning has helped<br />

his career. Today he‘s part of a young,<br />

committed and enthusiastic architectural<br />

office in Vienna. His work varies from<br />

project management and planning to public<br />

relations and preparing competition entries.<br />

He has already added a number of other<br />

prizes to his reference list.<br />

As a student at the Academy of Fine Arts in<br />

Kraków, Poland, Piotr Noga collected several<br />

prizes, including a second prize in the Grips<br />

and Handles category, with a design called 11

flab. He also won first prize in an internal<br />

competition held by the Academy to<br />

redesign the Interior Design Faculty‘s<br />

secretariat. His latest design is a chaise<br />

longue called dla dwojga (<strong>for</strong> two). This<br />

eye-catching seating unit lets one person<br />

sit in two different positions, or it can be<br />

shared by two people. "Once I‘ve qualified,<br />

I‘ll find manufacturers <strong>for</strong> my designs,“ says<br />

Piotr Noga confidently.<br />

Torsten Klocke has his future clearly laid<br />

out. He won a first prize in the 2005 <strong>IDA</strong><br />

with a project called o.m.f. (Object with<br />

Function). The <strong>jury</strong> called it "an attractive<br />

sculpture with a practical function“. Once<br />

he has finished his degree at the Hochschule<br />

für Kunst und Design Burg Giebichenstein<br />

in Halle, Torsten Klocke will start working in<br />

the Halle design office he set up with<br />

Juliane Bardtholdt back in summer 2006.<br />

He has the first jobs already lined up. His<br />

website (www.desarteur.de) lists other<br />

prizes he has won and his <strong>no</strong>mination <strong>for</strong><br />

the German Design Prize.<br />

12<br />

"Sticks“ by Meike Noster, Sascha<br />

Schiller, Volker Schumann and<br />

Harald Steber<br />

"I spent several years working as project<br />

leader on re<strong>no</strong>vation projects,“ says Markus<br />

Thalhammer, who won a third prize in 1999<br />

with his Media Tower design. "Now I‘m<br />

employed by Caritas Ludwigsburg-<br />

Waiblingen-Enz as a trainer and lecturer in<br />

Design and Colour, Specialist Calculations<br />

and Basic Carpentry.“ Back in 1999, Markus<br />

Thalhammer was working <strong>for</strong> his master<br />

craftsman‘s diploma in carpentry at the<br />

Meisterschule für das Schreinerhandwerk in<br />

Ebern. The <strong>IDA</strong> prize gave him the confidence<br />

to go on and take the more academic<br />

course leading to a qualification as statecertified<br />

interior designer. His Media Tower<br />

may <strong>no</strong>t have found a manufacturer yet,<br />

but creative and ingenious designs are one<br />

of his hobbies. And they‘ve won him a<br />

couple of other prizes too.<br />

In 1999, Volker Schumann was part of the<br />

workgroup that won first prize <strong>for</strong> Sticks, a<br />

modular bathroom storage system. The<br />

other members of the team were Meike<br />

Noster, Sascha Schiller and Harald Steber,<br />

all from the Faculty of Industrial Design at<br />

the University of Essen. "Yes, it still features<br />

as a really good piece of work in my<br />

portfolio,“ says Volker Schumann. In the<br />

meantime, he has won an IF Design<br />

Award and an award <strong>for</strong> packaging<br />

design. A glance at his reference list<br />

(www.werksdesign.de) shows that his<br />

specialization in bathrooms has paid off.<br />

Thes eight winners slipped back into <strong>no</strong>mal<br />

life after their moment in the limelight.<br />

Un<strong>for</strong>tunately, <strong>for</strong> lack of a manufacturer<br />

prepared to produce and market it, <strong>no</strong>ne of<br />

their designs has turned into bestsellers.<br />

But this is <strong>no</strong>rmal. The designs were<br />

futuristic projects in the best tradition of<br />

blue skies thinking. They were ahead of<br />

their time. Today it might well be worth<br />

some manufacturer‘s while to take a<strong>no</strong>ther<br />

look at the designs. Contacts are easy to set up.<br />

[<strong>International</strong> Design Award]<br />

"Klabur“ by<br />

Doreen Trabhardt,<br />

"Ovo“ by Julia Lodes,<br />

"flab“ by Piotr Noga,<br />

"Raum Trans<strong>for</strong>mer“ by<br />

Johannes Feichtinger, Jürgen<br />

Hierl and Jutta Leitner,<br />

"Media Tower“ by<br />

Markus Thalhammer,<br />

"o.m.f.“ by Torsten Klocke

Coping Instead of either/or,<br />

why <strong>no</strong>t both…and?<br />

with<br />

complexity<br />

In the context of increasing globalization, fiercer international<br />

competition and the accelerating pace of technical change, managers<br />

and employees are facing completely new situations. Conventional<br />

organizational structures and traditional ways of working together<br />

are often inadequate to cope effectively with the complex demands<br />

of worldwide markets. Nature offers models that can teach us to cope<br />

with complexity.<br />

current aktuell news<br />

Most companies today have come a<br />

long way from their origins as local<br />

enterprises serving local people. Typically,<br />

they <strong>no</strong>w work with many different<br />

customers and suppliers embedded in<br />

different cultures. A company might buy<br />

raw materials in Brazil, manufacture<br />

in China, work with sales partners in<br />

Australia and a logistics partner in the<br />

Netherlands, and have their tax returns<br />

handled by specialists in India. Coping<br />

with such complexity strains conventional<br />

hierarchical structures to breaking point.<br />

The Malik Management Zentrum St. Gallen<br />

(CH) takes the view that classical business<br />

administration has very few answers on<br />

how to deal with such complex structures.<br />

The Swiss researchers believe that<br />

bionics and cybernetics provide relevant<br />

insights and models <strong>for</strong> building successful<br />

and effective organizations in a global<br />

environment.<br />

13

Learning from nature<br />

Bionics, or biomimetics, studies natural<br />

systems and applies the k<strong>no</strong>wledge to<br />

create new tech<strong>no</strong>logical solutions.<br />

Evolutionary pressure and trial-and-error<br />

processes over millions of years have<br />

optimized natural systems and made them<br />

highly efficient. Leonardo da Vinci was <strong>no</strong>t<br />

alone in recognizing that there‘s a lot to<br />

be learnt from nature and that the k<strong>no</strong>wledge<br />

transfers can generate inventions.<br />

One of the most familiar examples of<br />

biomimetics is Velcro, used by millions<br />

of people the world over. The idea was<br />

developed by a Swiss scientist in 1948<br />

– removing burrs from his dog‘s fur after<br />

a walk, he got interested in how the burrs<br />

stick, examined them under a microscope<br />

and eventually came up with a fastener<br />

that worked the same way. A more recent<br />

14<br />

transfer of this sort is the lotus effect<br />

coating – its microstructures, imitating<br />

those of lotus leaves, are dirt- and waterrepellent.<br />

Other familiar inventions based<br />

on natural models are the optimized<br />

shapes of ship‘s hulls and planes and<br />

even swimming costumes that imitate<br />

characteristics of sharkskin.<br />

But applications <strong>for</strong> bionics go far beyond<br />

new product solutions. Cybernetics, <strong>for</strong><br />

example, also applies methods learnt from<br />

nature to develop solutions <strong>for</strong> organizations.<br />

It‘s still a relatively young branch<br />

of research, but it‘s important in view of<br />

the fact that even brilliant new technical<br />

solutions deliver practical benefits only<br />

once they have achieved market success.<br />

Developing and launching successful<br />

products and services in today‘s highly<br />

diverse and dynamic markets confronts<br />

management with tough challenges.<br />

Cybernetics seeks to<br />

answer the question<br />

of how an enterprise<br />

should best organize and<br />

manage itself in order to turn<br />

the k<strong>no</strong>wledge and market in<strong>for</strong>mation<br />

it has into competitive advantage.<br />

In analyzing and applying the potential<br />

of biological systems, it‘s essential to<br />

clearly understand the effects found in<br />

nature. This means understanding that<br />

naturally developed structures do <strong>no</strong>t aim<br />

<strong>for</strong> market control. A<strong>no</strong>ther fact to grasp<br />

is that the existence of an organism is<br />

assured <strong>no</strong>t by the optimization of a single<br />

element, but by the optimization of the<br />

whole system and all its interactions.<br />

Biological systems are adaptable, flexible<br />

and efficient, they are capable of<br />

learning and developing, of reacting fast<br />

to changes and of repairing themselves.<br />

Cybernetics deals with the laws that<br />

govern the functioning of complex<br />

systems. British cybernetics guru, Staf<strong>for</strong>d<br />

Beer, was the first to identify the<br />

fundamental importance and the creative<br />

potential of cybernetics <strong>for</strong> organization<br />

management. He defined cybernetics as<br />

"the science of effective organization“.<br />

Beer identified the major problem of<br />

management as the problem of controlling<br />

and regulating complex systems in<br />

dynamic and unpredictable markets.<br />

Biological systems show how complexity<br />

can be turned to advantage.

The Viable System Model<br />

The Management Colloquium of<br />

the Energie-Forum-In<strong>no</strong>vation in<br />

Bad Oeynhausen was sponsored<br />

by the In<strong>no</strong>vation Network OWL<br />

Maschinenbau e. V.<br />

The human central nervous system is the<br />

most efficient control system in nature. It<br />

is capable of coordinating highly complex<br />

processes. It optimizes the way in which<br />

the complex organs in the body work<br />

together. It is capable of adjusting rapidly<br />

to change. It can generate new states and<br />

ideas and it is conscious of itself. Based on<br />

the nervous system, Staf<strong>for</strong>d Beer developed<br />

the Viable System Model (VSM) as a<br />

powerful tool <strong>for</strong> describing and<br />

diag<strong>no</strong>sing an organization. The VSM<br />

shows how self organization, self regulation<br />

and self coordination can be organized,<br />

how stable growth can be generated<br />

and new elements integrated. The most<br />

important aspect of this way of organizing<br />

enterprises is recursivity. Similar to nested<br />

Russian matroschka dolls, each viable<br />

system comprises several other systems,<br />

each viable in itself, and is in turn part of<br />

a viable system. All these systems can be<br />

managed auto<strong>no</strong>mously on the principle<br />

of cell division. To make this possible,<br />

they must have certain functions. Each of<br />

these functions and their interaction with<br />

other functions in VSM is modelled on the<br />

central nervous system.<br />

Once this structural model is clearly<br />

understood, it can be applied to any social<br />

system. It avoids the trap of viewing an<br />

organization only in a <strong>for</strong>mal sense, ie, of<br />

looking only at its organizational structure.<br />

Simply looking at the orgachart says very<br />

little about how the different organiza-<br />

tional units interact. A VSM analysis of the<br />

organizational structure includes all the<br />

different functions ( jobs, groups of jobs,<br />

departments, sections, units, committees<br />

teams, projects, etc.) and how they interact.<br />

In this way, it captures the underlying<br />

structures of the organization.<br />

An analysis of an existing organization<br />

using the Viable System Model answers<br />

the following questions:<br />

· Are all essential management functions<br />

required <strong>for</strong> viability being per<strong>for</strong>med<br />

successfully?<br />

· Are the methods and tools used capable<br />

of generating the requisite variety<br />

(different responses) to react appropriately<br />

to the variety of events likely to<br />

happen and to guarantee the requisite<br />

variety of the whole system?<br />

· How are interaction and communication<br />

functioning? Is the level of interaction<br />

and communication adequate to ensure<br />

the orientation of the organization?<br />

· Is the dispersed k<strong>no</strong>wledge and<br />

in<strong>for</strong>mation that exists within the<br />

company being used to maximum<br />

advantage? Are the meetings and<br />

committees as effective as expected?<br />

· Are those responsible clearly anchored<br />

in the organization?<br />

· Do the existing organizational structures<br />

guarantee effective implementation of<br />

the business strategy?<br />

Bionics sees itself as a method <strong>for</strong> learning<br />

from biological systems, although nature<br />

serves neither simply as a pattern, <strong>no</strong>r as a<br />

blueprint, <strong>no</strong>r a pure analogy. The researchers<br />

at the Malik Management Zentrum<br />

St. Gallen (CH) summarize it like this:<br />

"The essence of management is <strong>no</strong>t to do<br />

business, but to stay in business. It‘s <strong>no</strong>t<br />

a question of survival, but of viability <strong>for</strong><br />

the long term. At issue is healthy growth<br />

versus unhealthy growth, and strength<br />

versus size.“<br />

current news<br />

Sources:<br />

Talk by Dr. Frank Ar<strong>no</strong>ld, Malik<br />

Management Zentrum St. Gallen, at the<br />

Management Colloquium in the Energy-<br />

Forum-In<strong>no</strong>vation in Bad Oeynhausen, an<br />

initiative of the In<strong>no</strong>vation Network OWL<br />

Maschinenbau e. V. www.bionik-zentrum.de<br />

Dr. Martin Pfiffner: Manager lernen von der<br />

Natur (How Managers Learn from Nature),<br />

Südtirol Pa<strong>no</strong>rama, November 2006, pp.<br />

10-12<br />

Dr. Martin Pfiffner: Von biologischen<br />

Systemen lernen (Learning from Biological<br />

Systems), io new management<br />

No. 12/2006, pp. 25-29<br />

Bionics Patents from Nature,<br />

published in collaboration with WWF,<br />

Pro Futura Verlag, 1993<br />

Dr. Frank Ar<strong>no</strong>ld from the Malik<br />

Management Zentrum St Gallen<br />

15

How are new ideas generated? The popular myth holds that it‘s<br />

through a stroke of genius. But the inventor Thomas Alva Edison set<br />

the record straight. ”Genius,” he said, ”is one percent inspiration and<br />

99 percent transpiration.” At <strong>Hettich</strong>, we k<strong>no</strong>w that it‘s a long hard<br />

road from a good idea to a successful product. In our business,<br />

in<strong>no</strong>vation is a complex process, less driven by tech<strong>no</strong>logy than by the<br />

ability to <strong>for</strong>esee and react to technical, eco<strong>no</strong>mic and social change.<br />

We are convinced that in<strong>no</strong>vation is best <strong>no</strong>t left to chance. So we set<br />

up an in<strong>no</strong>vation management system. Taking ideas <strong>for</strong>ward, one step<br />

at a time, results in viable products.<br />

16<br />

In<strong>no</strong>vation management has one<br />

dominant aim: to meet the articulated<br />

and unarticulated needs of the end user.<br />

This inherently complex aim is made<br />

more so, because we also have to take<br />

account of the needs and interests of<br />

the furniture and appliance industries,<br />

furniture retailers, the fittings trade<br />

and artisans such as cabinet makers. All<br />

these groups need to capture eco<strong>no</strong>mic<br />

value and brand differentiation from new<br />

inventions. In order to collect ideas and<br />

to evaluate them in terms of all these<br />

complex demands, <strong>Hettich</strong> has implemented<br />

in<strong>no</strong>vation management as a<br />

core process right across the group. We<br />

involve <strong>no</strong>t only engineers and designers,<br />

but also sales and marketing people. We<br />

believe this is the best way to generate<br />

new products and services that are<br />

closely oriented to customer and market<br />

requirements.<br />

From start to finish, <strong>Hettich</strong>‘s in<strong>no</strong>vation<br />

management focusses on end users and<br />

their current and future needs. The<br />

method we apply is to develop scenarios<br />

in order to identify national and<br />

international trends with a time horizon<br />

of ten years. The scenario outcomes flow<br />

into product studies with a five-year time<br />

horizon. We also use ideas management<br />

techniques, applying a uni<strong>for</strong>m companywide<br />

system to harvest and evaluate<br />

new ideas.<br />

Tests with end users and customer<br />

workshops are valuable tools in trying out<br />

new ideas. Ideas that emerge successfully<br />

from these initial evaluation processes<br />

move on into the product generation process,<br />

which usually lasts one to two years.

Best <strong>no</strong>t left to chance<br />

Today we have a systematic process in<br />

place to develop marketable concepts<br />

and products. The origins of this process<br />

go back ten years to when an ad hoc<br />

in<strong>no</strong>vation team first looked at the<br />

kitchen as a complete whole. What<br />

emerged from their work was Concept<br />

2010, which we presented at the<br />

Interzum 1999 and which was included<br />

in the Living Tomorrow 2 exhibition in<br />

Brussels.<br />

Today we‘re in a position to judge how<br />

well those ideas have stood the test of<br />

time. The integration of mood-setting<br />

light in kitchen front panels is <strong>no</strong>w reality,<br />

thanks to LED tech<strong>no</strong>logy. Concealing<br />

In<strong>no</strong>vation management<br />

kitchen appliances behind electrically<br />

operated front panels is a<strong>no</strong>ther trend<br />

that is taking off. Hobs, ovens and wall<br />

units that slide up and down on telescopic<br />

rails are already at the volume production<br />

stage in some markets. Monitors in the<br />

kitchen are state of the art <strong>for</strong> com<strong>for</strong>t<br />

and convenience. Waste disposal systems<br />

and refrigerators that generate shopping<br />

orders are either already on the market or<br />

close to market readiness.<br />

In short, all the electrified elements in<br />

Concept 2010 seem to have <strong>for</strong>eshadowed<br />

current trends and have been realized<br />

well ahead of the ten-year time horizon.<br />

As always, it is individual details that<br />

in<strong>no</strong>vation<br />

are giving manufacturers of furniture,<br />

kitchens and appliances the tools with<br />

which to differentiate their products from<br />

the competition.<br />

In ten years, <strong>Hettich</strong>‘s in<strong>no</strong>vation management<br />

has developed from a single project,<br />

Concept 2010, into a group-wide process.<br />

This process helps us to channel the<br />

group‘s in<strong>no</strong>vation culture. By definition,<br />

in<strong>no</strong>vation management is a learning<br />

system, and one of the most interesting<br />

challenges in the company today is how<br />

we can continuously improve it. Even as<br />

it stands, <strong>Hettich</strong>‘s in<strong>no</strong>vation management<br />

is probably unique in our industry<br />

sector; it‘s a<strong>no</strong>ther component in the<br />

structure of our outstanding competence.<br />

Concept 2010 ideas that have become reality:<br />

an oven rack that can be lowered to countertop<br />

level, automatic splash protection, electrically<br />

opened pan-drawer<br />

17

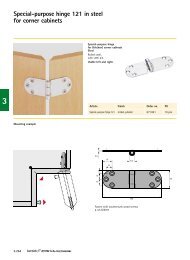

Freedom<br />

<strong>for</strong> <strong>choice</strong><br />

Freedom appliances have attracted a<br />

lot of attention in the industry, especially<br />

because they offer new technical<br />

solutions to the challenges of big built-in<br />

fridges. The hinges, <strong>for</strong> example, were<br />

engineered with special kinematics to<br />

meet the double requirement of the<br />

widest possible opening angle combined<br />

with the ability to support the extra<br />

weight of the large doors and their contents.<br />

Each hinge is capable of supporting<br />

100 kg, despite the problem of far from<br />

ideal height-to-width ratios. Hinges <strong>for</strong><br />

European fridges are generally only specified<br />

<strong>for</strong> half that load.<br />

The face-frame designs which are<br />

virtually standard <strong>for</strong> American kitchen<br />

units posed a special challenge <strong>for</strong> the<br />

Practical, easy-access storage solutions<br />

have long been standard <strong>for</strong> kitchen<br />

base units – different-sized drawers with<br />

versatile organizer systems <strong>for</strong> example.<br />

Wall units, by contrast, still have a long<br />

way to go be<strong>for</strong>e they reach this level of<br />

sophistication. The new Cosario is a step<br />

in the right direction. It adds extra<br />

storage space in an ergo<strong>no</strong>mically<br />

attractive way.<br />

18<br />

Big built-in fridges<br />

<strong>for</strong> American kitchens<br />

Freedom fridges. The product development<br />

engineers at <strong>Hettich</strong> had to create a<br />

hinge <strong>no</strong>t only capable of taking the full<br />

load, but also able to pick e<strong>no</strong>ugh rotary<br />

momentum to complete the movement to<br />

the desired end position.<br />

Working in a development partnership<br />

with BSH, <strong>Hettich</strong> specialists took up the<br />

challenge. The outcome was a kinematic<br />

that included a spring-supported closing<br />

mechanism with integrated freewheeling.<br />

As the door opens on hinges designed<br />

to take the given load, the door swings<br />

out more than twice as far as a standard<br />

European fridge door.<br />

The new hinge makes it all possible.<br />

Large, built-in fridges. Doors that swing<br />

Compact,<br />

accessible storage<br />

Cosario<br />

Mounted below a wall unit, a Cosario<br />

pocket is the ideal place to store herbs<br />

and spices or kitchen gadgets – out of<br />

sight, but handy when needed. Opening a<br />

Cosario is easy. When the catch is released,<br />

the lower level drops down, opening up<br />

two storage areas. All the contents of a<br />

Cosario are fully visible and within easy<br />

reach the moment it’s opened – unlike<br />

a lot of the storage space in a wall unit.<br />

Movable dividers let users allocate the<br />

space to suit their requirements.<br />

wide <strong>for</strong> easy access. Hinges that can<br />

take a huge load.<br />

Someone who opens the fridge to fetch<br />

out the milk isn’t going to be aware that<br />

each hinge is a technical masterpiece.<br />

But they will certainly <strong>no</strong>tice the smooth<br />

action, the reliable strength, and the<br />

great convenience of a hinge that opens<br />

the door just perfectly.<br />

The integrated light strip is an attentiongrabbing<br />

feature. With the Cosario shut,<br />

the light illuminates the countertop;<br />

when it’s open, the contents are illuminated.<br />

Silent System damping means that<br />

the pockets close softly and <strong>no</strong>iselessly.<br />

Cosario combines u<strong>no</strong>btrusive good looks<br />

with in<strong>no</strong>vative tech<strong>no</strong>logy, it’s a winning<br />

way of making better use of wall storage<br />

space. The system can be retrofitted as<br />

required.

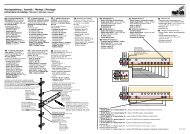

Exclusive kitchen design attracts<br />

customers and supports product<br />

differentiation. At the Interzum 2007,<br />

<strong>Hettich</strong> will be showing new optical<br />

differentiation options <strong>for</strong> its popular<br />

In<strong>no</strong>Tech drawer system. In addition to<br />

silver steel, stainless steel and beech,<br />

<strong>Hettich</strong> is <strong>no</strong>w offering anthracite<br />

coloured side profiles <strong>for</strong> even more<br />

<strong>choice</strong> behind the front panels. Two new<br />

decor strips – chrome finish <strong>for</strong> silver<br />

OrgaWing fans out as the drawer opens,<br />

offering a surprising amount of useful<br />

storage space.<br />

steel drawer profiles and stainless steel<br />

look <strong>for</strong> anthracite coloured profiles – are<br />

eye-catching and offer yet a<strong>no</strong>ther way<br />

of drawing attention to an exclusive kitchen<br />

design. The self-adhesive strips are<br />

simply stuck onto the drawer side profiles<br />

during manufacturing. Alternatively, they<br />

can be ordered already assembled.<br />

There are also new front-panel connectors<br />

<strong>for</strong> interior drawers and pan-drawers,<br />

available in a high-quality stainless steel<br />

in<strong>no</strong>vation<br />

or aluminium finish. They continue the<br />

quality theme behind the fronts, as do<br />

TopSides made of steel, translucent<br />

plastic or glass, and the complete range<br />

of internal organizer systems. This range<br />

of attractive and convenient features<br />

makes it very easy to continue a design<br />

theme throughout a kitchen, including<br />

inside the base units.<br />

In addition to multiple differentiation<br />

options, In<strong>no</strong>Tech and Quadro runners<br />

guarantees perfect drawer action over a<br />

long service life. Silent System damping<br />

is a<strong>no</strong>ther option. For large drawers,<br />

<strong>Hettich</strong> offers a damped heavy-duty<br />

runner designed to operate smoothly with<br />

loads of up to 70 kg. Intelligent internal<br />

organizer elements score on com<strong>for</strong>t and<br />

practicality.<br />

In<strong>no</strong>Tech drawer system<br />

Even more<br />

variety<br />

19

Bathrooms<br />

to dream in<br />

W hole bathroom product ranges are<br />

being revamped in the direction of<br />

design-oriented wellness bathrooms.<br />

Products range from underwater lighting<br />

in the bath to intelligently planned<br />

storage systems that achieve an attractive<br />

synthesis of function and design. People<br />

set their sights on luxurious wellness<br />

showers, generously-sized baths and<br />

stylish wash basins. But they also<br />

20<br />

Styled <strong>for</strong> wellness<br />

A recent survey carried out by the Institute <strong>for</strong> Demoscopics Allensbach (TOPLevel Study<br />

2006) found that luxury bathrooms rank fairly high on the average German‘s list of<br />

desirable features <strong>for</strong> a modern home. Almost one in three of those surveyed wanted an<br />

up-market bathroom. Rather than simply functional places <strong>for</strong> a brisk shower, people want<br />

bathrooms that combine a stylish ambience with the ultimate in com<strong>for</strong>t. This trend opens<br />

up new and exciting prospects <strong>for</strong> suppliers of bathroom fittings<br />

increasingly want storage units with<br />

wide drawers and even heavy-duty deep<br />

drawers. The Allensbach survey confirms<br />

this: 66% of the women and 48% of the<br />

men surveyed in the TOPLevel Study 2006<br />

put cupboards and ample storage space<br />

high on the list of attributes <strong>for</strong> their<br />

dream bathroom.<br />

Intelligent and practical internal organizer<br />

systems <strong>for</strong> bathroom storage units are<br />

to be found in the <strong>Hettich</strong> product range.<br />

Versatile In<strong>no</strong>Tech drawer systems with<br />

their many attractive features are a<br />

must. The ProDecor Collection offers a<br />

wide range of k<strong>no</strong>bs, grips and handles<br />

to accentuate any design style – from<br />

timeless simplicity to dreamy prettiness.

Together they help to trans<strong>for</strong>m big or<br />

small bathrooms into wellness oases.<br />

The In<strong>no</strong>Tech drawer system offers<br />

bathroom suppliers a number of dif-<br />

ferentiation options. The double-walled<br />

steel drawer boxes with two layers of<br />

powder coating <strong>no</strong>t only look good,<br />

they‘re also easy care and resistant to<br />

scratching. There‘s a <strong>choice</strong> of internal<br />

organizer solutions, <strong>for</strong> individual storage<br />

planning and optimal use of available<br />

storage space. In<strong>no</strong>Tech drawers deliver<br />

convincing benefits: plenty of storage<br />

space that‘s easy to organize and keep<br />

tidy, making sure that cosmetics and<br />

care products are easy to find and always<br />

within reach.<br />

Different-sized drawers, deep as well as<br />

wide, slide smoothly on durable Quadro<br />

drawer slides. Integrated Silent System<br />

damping devices emphasize the relaxed,<br />

wellness mood. The ingenious and<br />

u<strong>no</strong>btrusive damping devices ensure that<br />

drawers and deep pull-outs close softly<br />

and silently. It makes <strong>no</strong> difference<br />

whether the drawers are empty or heavily<br />

loaded, or whether they‘re closed with a<br />

shove or gentle pressure.<br />

Pulls and k<strong>no</strong>bs from the ProDecor<br />

Collection set individual accents in an<br />

overall bathroom design. One option is<br />

high-quality, high-gloss chrome finishes<br />

that echo the function and design of<br />

today‘s sophisticated taps and shower<br />

heads. The look and feel of the grips and<br />

pulls is right and their ergo<strong>no</strong>mic design<br />

means that furniture doors and drawers<br />

open and shut with minimum ef<strong>for</strong>t.<br />

For the new wide drawers, ProDecor<br />

offers minimalist aluminium profiles in<br />

a high-gloss chrome finish that are<br />

in<strong>no</strong>vation<br />

supplied in custom lengths.<br />

They emphasize the dominant horizontal<br />

lines of contemporary front panels.<br />

The Allensbach survey picked up the<br />

trend towards ultra-com<strong>for</strong>table,<br />

highly functional and design-oriented<br />

bathrooms. According to the survey, the<br />

willingness of potential purchasers to pay<br />

more depends heavily on their awareness<br />

of quality differences between products<br />

currently on the market. The survey<br />

showed that awareness of quality<br />

differences in bathroom design and<br />

fittings climbed from 28% in 2005 to<br />

34% in 2006. The percentage of consumers<br />

who would be prepared to invest a<br />

substantial amount in high-quality<br />

bathroom fittings rose from 19 to 24% in<br />

the same period.<br />

21

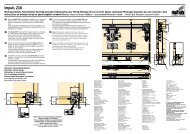

<strong>Look</strong> <strong>no</strong> <strong>hands</strong>!<br />

Some kitchen designers say a kitchen is a lifestyle product integrated into a living space. Trend analysts see<br />

the kitchen as the "new 21st century salon", with a return to the kitchen-cum-eating-area which <strong>for</strong>ms the<br />

hub of social life with friends and family. If this trend is going to win wide acceptance, it will be<br />

important to harmonize living com<strong>for</strong>t and kitchen tech<strong>no</strong>logy as seamlessly as possible. Kitchen drawers<br />

that open electrically are a step in this direction. They communicate com<strong>for</strong>t and emotional value.<br />

22<br />

Easys makes dreams of high-tech<br />

com<strong>for</strong>t a reality

Easys opens even wide pan-drawers smoothly<br />

and automatically<br />

Drawers and pan-drawers fitted with<br />

electric motor drives will open automatically<br />

in response to gentle pressure<br />

anywhere on the front panel. This opens<br />

up fascinating prospects <strong>for</strong> <strong>no</strong>-handle<br />

designs. At the same time, it brings<br />

practical benefits <strong>for</strong> kitchen users. If<br />

your <strong>hands</strong> are full, or smeared with cake<br />

dough, you can simply nudge the front<br />

panel with your knee or your hip and the<br />

drawer will open smoothly and automatically.<br />

Even if you <strong>no</strong>rmally prefer to<br />

use the grip, there’ll always be situations<br />

where it’s more convenient to have the<br />

door open electrically. If it’s a wide and<br />

heavily loaded drawer, you might simply<br />

want to save your back.<br />

<strong>Hettich</strong>’s new Easys is an electronically<br />

activated, electric motor drive. It opens<br />

the drawer smoothly at a constant<br />

speed, irrespective of how wide or how<br />

heavily loaded it is, mirroring a manual<br />

opening movement. For safety reasons,<br />

the opening movement stops the moment<br />

the drawer encounters even the slightest<br />

resistance.<br />

Drawers are closed <strong>no</strong>rmally, by hand.<br />

The mature tech<strong>no</strong>logy of <strong>Hettich</strong> drawer<br />

runners and Silent System damping<br />

guarantee smooth, easy action and <strong>no</strong>iseless<br />

closing. And what if there‘s a power<br />

failure? Simply open the electric drawers<br />

in the usual way.<br />

Easys is extremely quiet. Because the<br />

device needs only a very gentle push, ie,<br />

a short stroke, to activate the motor, gap<br />

dimensions can be kept to a minimum<br />

and the functionality of a sealing lip is<br />

<strong>no</strong>t affected in any way.<br />

Easys requires <strong>no</strong> changes to drawer or<br />

runner design. It can be offered as an<br />

attractive option, because the compact<br />

motor unit fits into the small gap<br />

between the back of the drawer and the<br />

back panel of the cabinet.<br />

At the Interzum, <strong>Hettich</strong> will be<br />

showcasing automatic drawer opening<br />

systems that are almost ready <strong>for</strong> volume<br />

production. The company is also<br />

presenting two concept studies that offer<br />

a view of the next horizons. One study<br />

focuses on a flap fitting that <strong>no</strong>t only<br />

opens, but also closes, automatically. This<br />

makes it possible to close an open flap<br />

ef<strong>for</strong>tlessly even if it’s in a really<br />

awkward position.<br />

in<strong>no</strong>vation<br />

If your <strong>hands</strong> are full, use your knee<br />

to trigger automatic opening!<br />

Extra convenience: electrical opening<br />

<strong>for</strong> hinged doors<br />

The second study shows electric opening<br />

<strong>for</strong> hinged doors with the motor device<br />

and fitting elegantly concealed. The<br />

electronically activated motor unit is so<br />

u<strong>no</strong>btrusive that it could be integrated in<br />

an illuminated top panel or a slim profile<br />

below the cabinet top panel. It takes<br />

only featherlight pressure on the door to<br />

trigger the opening action.<br />

As long ago as the Interzum 1999,<br />

<strong>Hettich</strong> sparked the idea of automatically<br />

opening drawers as part of the much discussed<br />

Concept 2010. Yesterday’s dream<br />

has become today’s reality. It’s part of<br />

the trend towards merging lifestyle and<br />

tech<strong>no</strong>logy that is driving contemporary<br />

kitchen design.<br />

23

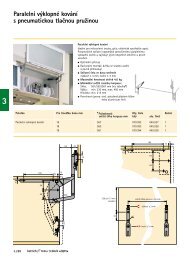

<strong>Flaps</strong> <strong>for</strong> <strong>choice</strong><br />

<strong>Hettich</strong>’s new Vivario flap fitting system scores on looks and logistics.<br />

A modular system with only a few basic variants, Vivario can be used<br />

with a huge bandwidth of flap widths, heights and materials. Vivario<br />

offers kitchen manufacturers and end-users maximum <strong>choice</strong> and<br />

design freedom with wood, glass, plastic or painted flaps.<br />

There’s a lot to be said in favour of<br />

lift-up flaps rather than hinged doors<br />

on kitchen wall units. Especially with the<br />

new Vivario flap fitting, which guarantees<br />

good ergo<strong>no</strong>mics, ef<strong>for</strong>tless action and<br />

soft closing. Other benefits <strong>for</strong> end-users<br />

are a clear view into the unit and easy<br />

access to the contents. There’s also the<br />

safety bonus – kitchen users <strong>no</strong> longer<br />

risk bumping their heads on open cupboard<br />

doors. And there’s the design bonus<br />

– with flap fitting systems, the horizontal<br />

lines of the base unit design can be<br />

repeated in the wall unit fronts. The<br />

result is an optically coherent kitchen<br />

design.<br />

The Vivario range comprises three<br />

variants: Vivario HF the high fold fitting,<br />

Vivario HS the high swing fitting, and<br />

24<br />

Vivario HK the high flap fitting. This<br />

limited number of variants covers a huge<br />

bandwidth of front panel widths and<br />

heights. Spring <strong>for</strong>ce can be adjusted<br />

<strong>for</strong> different flap weights. It takes only<br />

featherlight pressure to raise the flap<br />

smoothly, and it can be arrested securely<br />

at any angle above 45°.<br />

Integrated Silent System damping slows<br />

the closing movement so that the flap<br />

closes <strong>no</strong>iselessly against the cabinet.<br />

The peaceful and relaxed atmosphere is<br />

especially important in view of the<br />

contemporary trend to merging kitchen<br />

and living areas. The damping action is<br />

individually adjustable and easy to match<br />

to different panel sizes and weights.<br />

The attractive fittings with their aluminiumfinish<br />

sleeves continue good design inside<br />

Upwardly mobile<br />

kitchen fronts<br />

the wall unit, so that the harmonious<br />

overall picture is <strong>no</strong>t interrupted when<br />

front panels are open.<br />

It’s <strong>no</strong>t only in kitchens where the<br />

new Vivario product line meets all the<br />

demands of contemporary design and<br />

good ergo<strong>no</strong>mics. It’s the ideal solution<br />

wherever creativity and versatile function<br />

have a role to play: in bathrooms, living<br />

rooms, offices and project furniture.

The JOOP! brand carries huge cachet!<br />

It stands <strong>for</strong> lifestyle <strong>choice</strong>s that are<br />

modern, unstintingly luxurious and<br />

glamorous. The brand marketing <strong>for</strong> the<br />

JOOP! range of bedroom furniture<br />

communicates this message: “JOOP!<br />

BEDROOM – your private retreat.<br />

Reserved just <strong>for</strong> you – and a very special<br />

guest. For a night, <strong>for</strong> a lifetime. The<br />

room where day becomes night. Where<br />

everyday reality and dreams become one.<br />

Where fashion and the individual meet in<br />

the mirror. Ample space <strong>for</strong> good taste,<br />

stylish units and hours of pleasure.”<br />

The JOOP! Collection is a coordinated<br />

range of wardrobes, beds, bed linen,<br />

lights, curtains and accessories in the<br />

typical JOOP! look. It’s sold in selected<br />

stores under license from JOOP! and the<br />

company keeps a careful eye on how its<br />

exclusive products are presented.<br />

Nolte-Möbel produces bedroom furniture<br />

<strong>for</strong> the JOOP! brand. To date the company<br />

has produced four ranges – Inlay, Inside,<br />

Groove and Lines – all manufactured to<br />

the company’s exacting quality standards.<br />

The urbane designs interpret current<br />

trends in the special JOOP! style. They use<br />

in<strong>no</strong>vative fittings solutions to implement<br />

the sophisticated functionality that goes<br />

with the special look. This mean slidingdoor<br />

wardrobes from 230 to 400 cm wide<br />

and up to 223 or 240 cm high. The<br />

generously dimensioned and beautifully<br />

finished chests of drawers are up to 186 cm<br />

wide and up to 76 cm high.<br />

The bigger, the better – wider and taller<br />

doors and drawers create a look of<br />

elegance and luxury. TopLine 22 sliding<br />

door fittings ensure that even large and<br />

heavy doors move smoothly and reliably.<br />

Silent System damping makes sure they<br />

close softly and reliably. The high quality<br />

in<strong>no</strong>vation<br />

A name<br />

to conjure with<br />

JOOP! bedrooms generate sales and build image<br />

Nolte-Möbel in Germersheim, near Karlsruhe, is one of Germany’s leading<br />

manufacturers of storage units and bedroom furniture. With interesting<br />

new projects, the company is convincing customers of the importance of<br />

criteria other than price. Instead of investing huge amounts in promoting<br />

its own brand, Nolte chose an external label with high brand recognition.<br />

In 2005, the company launched the JOOP! Bedroom Collection. Around<br />