WORLD OF INDUSTRIES 02/2019

WORLD OF INDUSTRIES 02/2019

WORLD OF INDUSTRIES 02/2019

- TAGS

- industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>02</strong>/<strong>2019</strong><br />

www.world-of-industries.com<br />

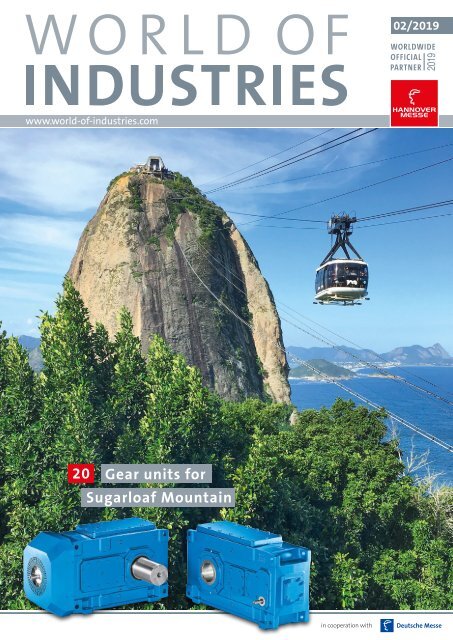

20<br />

Gear units for<br />

Sugarloaf Mountain<br />

in cooperation with

HANNOVER MESSE<br />

PIONEERS GET NEW<br />

TECHNOLOGY FIRST.<br />

1 – 5 April <strong>2019</strong><br />

Hannover ▪ Germany<br />

hannovermesse.com<br />

#HM19<br />

Home of industrial pioneers<br />

1

EDITORIAL<br />

10 years of innovation<br />

Dear readers,<br />

ten years ago, the idea for this magazine came into the world. We had the<br />

idea to publish a journal that follows the industry all around the globe.<br />

Today, we can proudly announce, that this dream became reality. We<br />

were (and still are) successful. <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> offers you all the<br />

latest from the different worlds of motion and drives, industrial<br />

automation as well as intralogistics and supply chain management.<br />

Thanks to our collaboration with the Deutsche Messe AG, we are always<br />

right at the heartbeat of the industry. We report live from the fairgrounds<br />

all around the world and offer you comprehensive insights into the<br />

different markets and innovations all around the globe.<br />

In this special issue of <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong>, we celebrate our 10 year<br />

anniversary by looking back and retelling the history of this magazine but<br />

also by recollecting different highlights of our publishing history. Thus,<br />

you will find an extensive interview with the masterminds behind<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong>, Dr. Michael Werner, the publishing director<br />

behind this magazine, and Christian Kluge, Director International<br />

Relations of Deutsche Messe AG, on pages 6-7. Additionally, we put<br />

together our favorite job reports and the most spectacular success stories<br />

from the last ten years (pages 8-9). But in the end, it is not enough to<br />

solely reminisce. Of course, we dare to look into the future, too. Therefore,<br />

we will ask business leaders in this issue as well as in the upcoming ones<br />

what their expectations for the next ten years look like (page 35).<br />

And now, please raise your glasses and let us drink a toast to <strong>WORLD</strong> <strong>OF</strong><br />

<strong>INDUSTRIES</strong>: Cheers! Prost! Skål! Santé! Gom bui! Serefe! Wáshe<br />

zdarówje! ...<br />

The editorial team<br />

of World of Industries<br />

A CLASS <strong>OF</strong><br />

ITS OWN<br />

optoNCDT 1420<br />

Laser triangulation sensors for<br />

fast and precise measurements<br />

Compact and user-friendly:<br />

easy integration into confined spaces<br />

Robust and long-life design<br />

Repeatability from 0.5µm<br />

Small light spot<br />

Analog and digital outputs<br />

Unique ease of use via web browser<br />

Presets for various surfaces<br />

NEW<br />

Tel. +49 8542 1680<br />

www.micro-epsilon.com/opto

ELEKTRISCHE VENTIL- UND<br />

PUMPENANSTEUERUNG<br />

16 I 25 Jahre mechatronische<br />

Antriebslösungen für die Hydraulik<br />

oup-fluidtechnik.de<br />

5445<br />

09 September 2018<br />

ORGAN DES FORSCHUNGSFONDS<br />

FLUIDTECHNIK IM VDMA<br />

08 I LOUNGE<br />

„Hydraulik bietet unzählige<br />

Möglichkeiten technischer<br />

Innovation“<br />

Christine Grotz<br />

TITELSTORY<br />

und warten per App<br />

86 I S<strong>OF</strong>TWARE<br />

So effizient lassen sich<br />

Stirnräder auslegen<br />

92 I HANNOVER MESSE<br />

Diese Neuheiten sollten<br />

Sie nicht verpassen<br />

www.engineering-news.net<br />

14 I GIPFELTREFFEN<br />

„Wir sind gut aufgestellt“<br />

Mit Hartmut Rauen auf dem Main Tower<br />

www.antriebstechnik.de<br />

Organ des Forschungsvereinigung Antriebtechnik e.V.<br />

19174<br />

04 APRIL <strong>2019</strong><br />

Mit System: All-in-One-Lösung<br />

30 zur industriellen Markierung<br />

in cooperation with<br />

www.industrielle-automation.net<br />

„Wir bringen digitale<br />

Kurze Taktzeiten im<br />

Special – Trends in<br />

22 Intelligenz in Kabellösungen“ 32 Automatisierungsverband 46 Robotik und Automation<br />

19239<br />

www.foerdern-und-heben.de<br />

FÖRDERTECHNIK<br />

MATERIALFLUSS<br />

LOGISTIK 4.0<br />

2884<br />

06 Juni 2018<br />

22 I NEUES KLEINTEILE-<br />

REGALBEDIENGERÄT<br />

VEREINT VIELFÄLTIGES<br />

ANFORDERUNGSPR<strong>OF</strong>IL<br />

16 I PRODUKTE UND SYSTEME<br />

Roboterpalettierung ermöglicht 100<br />

Prozent mehr Output<br />

34 I MENSCHEN UND MÄRKTE<br />

Recht Logistik verdankt Logcoop<br />

Großauftrag in der Display-Logistik<br />

38 I PERSPEKTIVEN<br />

Beendet die Blockchain<br />

die Zettelwirtschaft?<br />

TABLE <strong>OF</strong> CONTENT<br />

06<br />

16<br />

FLUIDTECHNIK<br />

4<br />

September 2018<br />

22 I GETRIEBE<br />

Bequem parametrieren<br />

Making the supply chain<br />

future oriented<br />

24<br />

26 32<br />

NEWS AND MARKETS<br />

03 EDITORIAL<br />

10 NEWS AND MARKETS<br />

12 TECHNOLOGY AND TAX CUTS CAN<br />

BAIL GERMANY OUT, IN CASE <strong>OF</strong> AN<br />

ECONOMIC DOWNTURN<br />

14 SMART LOGISTICS EQUIPMENT AND<br />

MACHINERY TO DRIVE GROWTH IN<br />

LOGISTICS SECTOR IN THE COMING<br />

DECADES<br />

16 HANNOVER MESSE <strong>2019</strong>: TAKING YOU<br />

TO THE FOREFRONT <strong>OF</strong> THE FOURTH<br />

INDUSTRIAL REVOLUTION<br />

10 TH ANNIVERSARY<br />

06 2009-<strong>2019</strong>: 10 YEARS<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> HOW<br />

AN IDEA CAME TO LIFE ...<br />

08 10 YEARS <strong>OF</strong> <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong><br />

– 8 GREAT PROJECTS<br />

35 GLOBAL INDUSTRY: PAST AND FUTURE<br />

MOTION AND DRIVES<br />

19 PRODUCT NEWS<br />

20 GEAR UNITS FOR SUGARLOAF<br />

MOUNTAIN<br />

22 CABLE CARRIERS WITH CHEMICAL-<br />

RESISTANT PLASTIC DEAL WITH HIGH<br />

ACID EXPOSURE<br />

24 DRIVE TECHNOLOGY COMPLIANT<br />

WITH FOOD AND PHARMACEUTICAL<br />

PACKAGING INDUSTRY STANDARDS<br />

AUTOMATION<br />

26 FOCUSSING ON ROBOTICS<br />

AND AUTOMATION<br />

28 POWERFUL AND SOLID: SAFETY OVER<br />

IO-LINK IN A MACHINING CENTER<br />

30 LABEL INSPECTION AT THE<br />

HIGHEST LEVEL<br />

LOGISTICS<br />

32 A HEALTHY BATCH <strong>OF</strong> SAFETY<br />

4 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong>

Visit us!<br />

bauma, Munich, Germany<br />

April 08 – 14, <strong>2019</strong><br />

Hall B2, stand 413<br />

Visit us!<br />

POWTECH, Nuremberg,<br />

Germany<br />

April 09 - 11, <strong>2019</strong><br />

Hall 1, stand 1-627<br />

SOME THINK<br />

SORTATION<br />

TECHNOLOGY<br />

IS COMPLICATED.<br />

WE THINK DIFFERENT.<br />

We know the challenges of handling a broad variety of items. With our<br />

new BG Sorter family, we have once again redefined innovative and<br />

highly efficient sortation. Our systems are tailor-made to meet your<br />

business‘ specific needs while still providing the expected ease of<br />

operation and maintenance. Leave the business-critical sortation of<br />

items in reliable hands with high throughputs and capacities that meet<br />

the demands of tomorrow‘s material handling world.<br />

For further information visit beumergroup.com.

<strong>02</strong>/<strong>2019</strong><br />

www.world-of-industries.com<br />

Christian Kluge<br />

20 Gear units for<br />

Sugarloaf Mountain<br />

Dr. Michael Werner<br />

in cooperation with<br />

Christian Kluge and Dr. Werner<br />

brought the idea of<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> to life<br />

WIN_WIN_<strong>2019</strong>_<strong>02</strong>_EN_E-Paper_001 1 08.03.<strong>2019</strong> 09:59:11<br />

2009-<strong>2019</strong>: 10 years World of Industries<br />

How an idea came to life ...<br />

It was a turbulent time for the global economy,<br />

triggered by the property bubble in the USA. At this<br />

exact time, a German publisher and Deutsche Messe<br />

AG dared to launch an international cross-media<br />

project on the market. The objective was to report on<br />

the latest exciting technological achievements. We<br />

spoke to Christian Kluge, Deutsche Messe, and Dr.<br />

Michael Werner, the Publishing Manager, about the<br />

beginnings and developments of World of Industries.<br />

Always on the lookout for exciting technologies: Our editorial<br />

teams are attending trade fairs around the world<br />

Ideas are often developed at the strangest times, including the<br />

idea to develop an international, cross-media project – <strong>WORLD</strong><br />

<strong>OF</strong> <strong>INDUSTRIES</strong> – ten years ago.<br />

Werner: It must have been 2011 when I met Christian for the first<br />

time at a trade fair stand. At the time, we had already been working<br />

on special publications in China for two years. Back then, it<br />

was mostly printed editions that we sent by post to readers in<br />

companies. The idea that we developed at that trade fair stand was<br />

incredibly simple: The publisher produces editorial content all<br />

about international trade fairs conducted by Deutsche Messe AG,<br />

and Deutsche Messe in turn supports international sales with its<br />

international subsidiaries.<br />

Kluge: A crucial question was posed by Michael: How would we<br />

get our publications to the right readers in China at the PTC and<br />

CeMAT Asia trade fairs? It was my idea to send all visitors an electronic<br />

copy of the publication. In addition to the printed publications,<br />

this gave us the opportunity to considerably increase our<br />

reach by including channels in the USA, Turkey, Russia, India, etc<br />

– so that’s how everything started.<br />

How does a German publisher suddenly start operating at an<br />

international level?<br />

10 TH ANNIVERSARY<br />

Werner: We looked at it from a customer’s point of view. If the innovations<br />

of a German company are being presented at a trade fair<br />

in China, the USA, Turkey, Russia, India or anywhere else in the<br />

world, we as a publisher must be in a position to be able to report<br />

on it. Over the last ten years, the focus has increasingly shifted from<br />

printed publications towards the Internet and social media.<br />

At the start, you wanted to spread the idea of “Made in<br />

Germany” around the world. Nowadays “World of Industries” is a<br />

lot more?<br />

Werner: Definitely! We started off with exported English publications.<br />

Nowadays we are increasingly communicating with com-<br />

6 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 1/<strong>2019</strong>

oup-fluidtechnik.de<br />

5445<br />

ORGAN DES FORSCHUNGSFONDS<br />

FLUIDTECHNIK IM VDMA<br />

Christine Grotz<br />

TITELSTORY<br />

Mit Hartmut Rauen auf dem Main Tower<br />

19174<br />

www.industrielle-automation.net<br />

September 2018<br />

www.foerdern-und-heben.de<br />

2884<br />

pany subsidiaries around the world and are cooperating directly<br />

with these locations.<br />

Kluge: I personally do not know of a comparable format that offers<br />

exhibitors, the publisher and us as a trade fair organizer such a<br />

global platform all year round.<br />

At the time Deutsche Messe was already internationally active<br />

and very successful. Why did it also need such a communication<br />

tool?<br />

Kluge: Firstly, exhibitors and visitors operate on a global scale and<br />

secondly, World of Industries already informs its readers before<br />

and during the trade fair about the next events and their topics,<br />

markets, and participants. I believe the combination of thematic<br />

content and markets is excellent.<br />

Communication across borders can often entail hidden<br />

challenges. Was that the case? And if so, how did you overcome<br />

them?<br />

Kluge: Deutsche Messe has the opportunity to collaborate with<br />

many excellent partners. Our colleagues in China, the USA, Turkey,<br />

etc. do the same job on the ground. The greatest challenge<br />

was to clearly illustrate the priorities and opportunities this project<br />

had to offer. We have had to be very hands on with this project.<br />

Nowadays World of Industries is more than a project, it is a<br />

complete platform. How can the readers benefit from this and<br />

what can they expect to read?<br />

Werner: From an editorial perspective, we always want to strike a<br />

balance between specialist information and reporting on trade<br />

fairs. Communication usually starts about four weeks before the<br />

trade fair via the websites for the publisher and trade fair, via<br />

newsletters from both partners and of course by means of activities<br />

on the social networks, which have become increasingly important<br />

in recent years. The trade fair book is available digitally as<br />

an e-paper but a printed version is also available at the exhibition<br />

site – provided in English around the world and in Mandarin in<br />

China.<br />

Which of these particular channels should individuals interested<br />

in technology take a look at?<br />

Werner: The website www.world-of-industries.com is the starting<br />

point for all publishing activities. Although social media is becoming<br />

increasingly important. From our perspective, LinkedIn in<br />

particular is developing very quickly. As a reader, it is of course<br />

best to subscribe to one of the newsletters from the trade fair or<br />

publisher. That will ensure you definitely do not miss a thing.<br />

Readers will especially benefit from the live posts and numerous<br />

videos posted by the team at trade fairs around the world.<br />

Werner: Definitely. From an editorial perspective we operate in<br />

three different stages. Before the trade fair – at the trade fair – after<br />

the trade fair. The live feed from the exhibition site is particularly<br />

important to us. Although that does not have the same level of<br />

success at every location, as it is dependent on the infrastructure.<br />

We are relying on moving images, our editors capture exciting<br />

topics on site in video interviews, which are then published on the<br />

website as well as in the e-paper and in the next printed edition.<br />

Kluge: In brief, moving images are more authentic, work better,<br />

and provided a clearer overview of the relevant message. Rough<br />

edges and corners are even an advantage when it comes to social<br />

media and their performance.<br />

Over the last ten years, World of Industries has grown into a<br />

strong brand that covers topics from automation, motion &<br />

drives, and intralogistics. Are these topics that will be suitable for<br />

future trade fair concepts?<br />

Kluge: Good question, our trade fairs always represent the markets.<br />

It is quite possible that topics will disappear and new ones<br />

will be added. That applies to us and the editorial staff alike. But<br />

that is exactly what makes it exciting.<br />

What are your future plans, what can the reader expect?<br />

Werner: We are going to develop with the market. From an editorial<br />

perspective, World of Industries is currently one of our most<br />

interesting projects and the one where we learn the most along<br />

the way. That keeps us on our toes and ensures we increase our<br />

skills, which turn helps to strengthen our core business in German-speaking<br />

Europe. In this regard, I hope we face many new<br />

challenges over the coming years.<br />

Kluge: If you just take a look at the main topics at the Hanover<br />

trade fair, such as artificial intelligence or platform economics and<br />

the opportunities and innovations that they have to offer. Add a<br />

touch of international cooperation and we can expect to see some<br />

exciting projects. One example is the “Industrial Transformation<br />

Asia Pacific” event. This is a new format for us and a new platform<br />

for exhibitors. This in turn will provide World of Industries with<br />

some exciting topics.<br />

www.world-of-industries.com<br />

09 September 2018<br />

FLUIDTECHNIK<br />

www.engineering-news.net<br />

FÖRDERTECHNIK<br />

MATERIALFLUSS<br />

LOGISTIK 4.0<br />

06 Juni 2018<br />

22 I NEUES KLEINTEILE-<br />

REGALBEDIENGERÄT<br />

VEREINT VIELFÄLTIGES<br />

ANFORDERUNGSPR<strong>OF</strong>IL<br />

ELEKTRISCHE VENTIL- UND<br />

PUMPENANSTEUERUNG<br />

16 I 25 Jahre mechatronische<br />

Antriebslösungen für die Hydraulik<br />

World of Industries<br />

is the best<br />

of four “worlds”:<br />

fluid power,drive<br />

technology, industrial<br />

automation and<br />

intralogistics<br />

08 I LOUNGE<br />

„Hydraulik bietet unzählige<br />

Möglichkeiten technischer<br />

Innovation“<br />

22 I GETRIEBE<br />

Bequem parametrieren<br />

und warten per App<br />

86 I S<strong>OF</strong>TWARE<br />

So effizient lassen sich<br />

Stirnräder auslegen<br />

92 I HANNOVER MESSE<br />

Diese Neuheiten sollten<br />

Sie nicht verpassen<br />

14 I GIPFELTREFFEN<br />

„Wir sind gut aufgestellt“<br />

04 APRIL <strong>2019</strong><br />

Making the supply chain<br />

future oriented<br />

www.antriebstechnik.de<br />

Organ des Forschungsvereinigung Antriebtechnik e.V.<br />

Mit System: All-in-One-Lösung<br />

30 zur industriellen Markierung<br />

in cooperation with<br />

„Wir bringen digitale<br />

Kurze Taktzeiten im<br />

Special<br />

22 Intelligenz in Kabellösungen“ 32 Automatisierungsverband<br />

19239<br />

4<br />

– Trends in<br />

46 Robotik und Automation<br />

16 I PRODUKTE UND SYSTEME<br />

Roboterpalettierung ermöglicht 100<br />

Prozent mehr Output<br />

34 I MENSCHEN UND MÄRKTE<br />

Recht Logistik verdankt Logcoop<br />

Großauftrag in der Display-Logistik<br />

38 I PERSPEKTIVEN<br />

Beendet die Blockchain<br />

die Zettelwirtschaft?<br />

The latest, exciting topics are<br />

available on the website at<br />

www.world-of-industries.com<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong> 7

10 years of World of Industries –<br />

8 great projects<br />

This year, we celebrate 10 years of World of Industries. Since 2009, we follow the<br />

latest trends in engineering, automation and logistics. During this decade we<br />

were able to present you some of the most spectacular projects and solutions<br />

from all around the world. These are our favorite articles from tens years of<br />

reporting from the industry. Please click or enter the links into your browser to<br />

read the job reports.<br />

It was only meant to stay there for five<br />

years. Now it has already been there<br />

more than 15 years. I travelled to London,<br />

England to learn more about the<br />

condition of the Schaeffler bearings<br />

installed in it. Even at corporate headquarters<br />

in Germany I was able to gain<br />

interesting insights into the history of<br />

the Ferris wheel which was once the<br />

largest in the world.<br />

Long-Ma, the dragon-scaled winged<br />

horse of Chinese mythology, had to<br />

come to life during the official<br />

ceremony in the Beijing<br />

Olympic Stadium in<br />

October 2014. France<br />

and China planned<br />

to celebrate the<br />

50th anniversary<br />

of their diplomatic<br />

relations.<br />

With only 12<br />

months lead time<br />

Dintec, a wellknown<br />

system<br />

integrator for electric<br />

drives and hybrid<br />

applications, accepted<br />

the challenge to power the<br />

dragon-horse.<br />

http://bit.ly/WINDintec<br />

http://bit.ly/WINSchaeffler<br />

10 TH ANNIVERSARY<br />

When ICR, the Italian perfume manufacturer from Milan set out to bring<br />

its intralogistics up to the state of the art, it was also a decision with<br />

ramifications for the future. ICR found a partner for the job of jointly<br />

developing a suitable concept with intralogistics specialist Jungheinrich.<br />

In this manner a special system solution was developed<br />

featuring industrial trucks equipped with RFID technology and<br />

oriented towards the strategic market goals of ICR.<br />

http://bit.ly/WINJungheinrich<br />

8 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 1/<strong>2019</strong>

At the port of Callao in Peru,<br />

Beumer installed pipe conveyors<br />

with a length of around three<br />

kilometers for transporting<br />

copper, lead and zinc concentrates<br />

for completion<br />

in 2014.<br />

http://bit.ly/WINBeumer<br />

Dassault Aviation has performed test flights with a<br />

Falcon 7X using a Flir Systems thermal imaging camera<br />

that can differentiate between laminar flows and<br />

turbulent flows, allowing developing technologies for<br />

cleaner and quieter next-generation aircraft.<br />

http://bit.ly/WINFlir<br />

The annual Robo Cup is played to<br />

determine the best football-playing<br />

robots. Several US universities<br />

developed the Darwin-OP robot in<br />

co-operation with South Korean<br />

robotic specialist Robotis and won<br />

both, the RoboCup 2012 and 2013.<br />

http://bit.ly/WINMaxon<br />

Europe‘s largest<br />

plant for<br />

protective gas<br />

hardening<br />

is located<br />

in Bochum-<br />

Riemke. Machine<br />

parts<br />

up to 5.2 m in<br />

diameter and<br />

5.0 m height<br />

are engulfed in<br />

one furnace. Gears<br />

can even be treated<br />

vertically therein and thereby<br />

remain highly customized and dimensionally<br />

stable. Reason enough to send for an<br />

American gear manufacturer to send their<br />

21 -ton gear on the long journey from the<br />

USA to Germany.<br />

http://bit.ly/WINReese<br />

Four<br />

rotary<br />

impellers,<br />

mounted<br />

one above<br />

the other on<br />

the left and<br />

right, propel the<br />

snow as far as 40 m.<br />

Up to 8,500 t of this white<br />

“cargo” can be moved efficiently<br />

each and every hour. In the Alps,<br />

four railway snow blowers, manufactured<br />

by the Swiss company<br />

Zaugg AG Eggiwil, keep the lines<br />

operated by the Rhaetian Railway<br />

clear all year round.<br />

http://bit.ly/WINRexroth<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 1/<strong>2019</strong> 9

W RLDWIDE NEWS<br />

Weidmüller wins German Design Award <strong>2019</strong><br />

The electrical engineering company Weidmüller received the German Design Award<br />

<strong>2019</strong> for its innovative range of terminal blocks “Klippon Connect” in the Excellent<br />

Product Design Industry category. The terminal block convinced the international<br />

jury, primarily because it is easy and convenient to use. The clear and straightforward<br />

product structure of the terminal block won over the 46 design specialists from<br />

11 countries during the evaluation. The German Design Award presented by the<br />

German Design Council recognises pioneering products and projects within the<br />

German and international design landscape. This year, the German Design Award<br />

received more than 5,400 entries from 63 countries in the area of product and communication<br />

design. Image caption: Andreas Rutz (l.) and Arnd Schepmann (r.) were delighted<br />

to receive the award in the Excellent Product Design Industry category.<br />

www.weidmueller.com<br />

Asmet automates with TGW<br />

Asmet Sp. z.o.o Sp.k., one of Poland’s leading wholesalers<br />

and manufacturers of special fasteners, has<br />

awarded TGW with logistics consultation and the<br />

erection of a new automated logistics center at<br />

Moszna-Parcela, near Warsaw. With the installation of<br />

the new automated distribution center,<br />

the Polish hidden champion<br />

particularly intends to increase<br />

the level of customer service<br />

and storage capacity for<br />

further global growth.<br />

The order includes the<br />

construction of a new<br />

automated DC based on a<br />

shuttle system, the<br />

integration of multi-functional<br />

workstations for order<br />

picking and packing as well as<br />

the creation of spacious zones for<br />

in- and outbound and an empty tote buffer. The core<br />

of the new logistics solution is a partially equipped,<br />

3-aisle shuttle system with a total of 60,000 storage<br />

locations for totes.<br />

www.tgw-group.com<br />

R+W: Construction of<br />

new headquarters<br />

started<br />

R+W, the specialist for industrial<br />

and precision couplings, is<br />

building a new headquarters in<br />

Wörth am Main in Lower<br />

Franconia, Germany. Work<br />

started at the new Weidenhecken<br />

industrial park in February, where<br />

the new headquarters will be constructed<br />

on a roughly 7,000 m 2 plot. Around<br />

2,500 m 2 will be used for the production facilities<br />

and another approx. 1,000 m 2 will be for office space. “This development<br />

will enable us to significantly increase our capacities in a short amount of<br />

time,” explains the Managing Director, Steffen Herter. This work is necessary<br />

because of the increasing demand in the booming machine manufacturing<br />

market. More than EUR 8 million is being invested in the development that<br />

comprises office and production facilities, production equipment, the expansion<br />

of the German and international teams, as well as product developments. The<br />

move to the new facilities is planned for the end of the summer later this year.<br />

The location was selected in close collaboration with the parent company<br />

Poppe+Potthoff based in Werther, Westfalen, Germany.<br />

www.rw-couplings.com<br />

NEWS AND MARKETS<br />

www.mayr.com<br />

Brake technology 4.0 —<br />

upgrade now!<br />

ROBA ® -brake-checker: Permanent<br />

brake monitoring of switching<br />

condition, temperature and wear<br />

your reliable partner<br />

Mayr.indd 1 12.<strong>02</strong>.<strong>2019</strong> 14:23:32<br />

10 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong>

Jungheinrich: Strategic investment in<br />

lithium-ion technology<br />

Wittenstein SE: Dr. Bertram Hoffmann takes<br />

over as Chairman of the Board and CEO<br />

Change at the helm of the South-West German<br />

mechatronics corporation: Dr. Bertram<br />

Hoffmann (55) will soon be taking over as new<br />

Chairman of the Board and CEO of Wittenstein<br />

SE. A Doctor of Engineering, he is<br />

currently a member of the Executive Board of<br />

Bosch Rexroth AG. Hoffmann will succeed<br />

Wittenstein SE Board Spokesman Dr. Bernd<br />

Schimpf, who will be leaving the company on<br />

March 31, <strong>2019</strong>, at the start of the new fiscal year<br />

<strong>2019</strong>/20. Hoffmann studied Engineering at Karlsruhe<br />

University of Applied Sciences. In 2012, Hoffmann moved to Bosch<br />

Rexroth AG and became Member of the Executive Board responsible for<br />

the Business Unit Renewable Energies. In 2015, he accepted additional<br />

responsibility as Member of the Executive Board for the Business Unit<br />

Mobile Applications and was also made Executive Vice President of the<br />

Business Unit Mobile Applications, responsible for engineering.<br />

www.wittenstein.de/en-en<br />

Jungheinrich AG and Triathlon Holding GmbH have come<br />

together to found JT Energy Systems GmbH, a joint venture<br />

focused on the production and recycling of lithium-ion<br />

battery systems. The company will be based in Glauchau,<br />

Saxony. The founding is subject to approval of the project<br />

by the relevant competition authorities. Jungheinrich holds<br />

a 70 per cent share in the joint venture with Triathlon<br />

taking the remaining 30 per cent. The company is due to<br />

begin operations in August <strong>2019</strong>. JT Energy<br />

Systems intends to create around 100<br />

new jobs at the plant in the next few<br />

years. The aim of the joint venture<br />

between Jungheinrich and<br />

Triathlon is for the two<br />

companies to expand their<br />

production capacities to<br />

cover the ever-increasing<br />

demand for lithium-ion<br />

battery systems and to<br />

further develop their<br />

technological leadership in<br />

this field. JT Energy will<br />

supply products to both<br />

companies.<br />

www.jungheinrich.com<br />

INFO:<br />

VDW – Generalkommissariat EMO Hannover <strong>2019</strong><br />

Verein Deutscher Werkzeugmaschinenfabriken e.V.<br />

Corneliusstraße 4 · 60325 Frankfurt am Main · GERMANY<br />

Tel.: +49 69 756081-0 · Fax: +49 69 756081-74<br />

emo@vdw.de · www.emo-hannover.de<br />

VDW.indd 19xxx_World 1 of industries_185x130_gb.indd 1 26.<strong>02</strong>.<strong>2019</strong> 25.<strong>02</strong>.19 12:11:03 14:06<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong> 11

Technology and tax cuts<br />

can bail Germany out,<br />

in case of an economic downturn<br />

NEWS AND MARKETS<br />

Last quarter of 2018 and the first quarter of <strong>2019</strong><br />

has not been a very positive one for Germany, but<br />

nevertheless, <strong>2019</strong> still looks to be a positive year as<br />

Industry 4.0 and similar advanced technologies<br />

start to penetrate deeper into German<br />

manufacturing set-up. Going forward, these<br />

technologies will become the new growth drivers of<br />

German manufacturing industry.<br />

T<br />

raditionally seen as the powerhouse of Europe, Germany’s<br />

economy is starting to cause concern with uncertainties over<br />

global trade and the manufacturing industry. In January <strong>2019</strong>, the<br />

European Commission revised the growth forecasts for the country<br />

and is now expected to grow by 1.1 % this year, from a previous forecast<br />

of 1.8 %. Germany is Euro zone’s largest economy, this means<br />

that any deceleration will likely be bad news for the rest of the<br />

Europe as well. The Commission also lowered its prospects for the<br />

Euro area as a whole. The region is now set to grow by 1.3 % this year,<br />

from a previous forecast of 1.9 %. The slowdown was caused mainly<br />

by factors, like global trade tensions and weakening exports growth<br />

due to slowdown in emerging economies including China. Recent<br />

data from the German statistical office shows that the country posted<br />

a growth of 1.5 % in 2018, as compared to 2.2 % in the previous<br />

year. German industrial production also declined by 0.4 % monthon-month<br />

in December — following a fall of 1.3 % in November,<br />

making this the fourth consecutive month of decline. This has been<br />

the weakest growth rate in five years. Also, factory orders data<br />

showed a 1.6 % decline in December.<br />

While we have to brace ourselves for another weak quarter in the<br />

first quarter of <strong>2019</strong>, there could be some positive momentum in<br />

the spring. With serious trade negotiations between the U.S. and<br />

China under way, and UK’s Brexit on-going negotiations, chances<br />

Author: Sushen Doshi, International Correspondent for World of Industries<br />

are that progress on these issues will be the game changer that<br />

could turn the sentiment around. This would bring around a<br />

humble return in growth momentum in Germany and the euro<br />

zone. In case of an economic downturn, the German government is<br />

working on bringing in tax cuts and increasing government<br />

spending. Though many experts have discouraged general tax cuts<br />

for Germany in recent years, due to high state debts, the finance<br />

ministry believes that such measures would be justified as a means<br />

against a possible recession. Speaking to a German newspaper, the<br />

Finance Minister Olaf Scholz said, “The good times in which the<br />

state kept taking in more taxes than expected are coming to an end,”.<br />

From rags to riches<br />

After German re-unification, the economic performance of western<br />

Germany was initially strong. In fact, GDP grew at a solid rate of 5 %<br />

until 1991. However, it deteriorated by 1992 and remained dismal<br />

for the remainder of the 1990s. During this time, the unemployment<br />

rate nearly doubled, as GDP growth averaged a meager 1.5 % per<br />

year. In 1994, the Germans feared that the unification of the two<br />

Germanys had failed. By 1999 and 2000 Germany was tagged as<br />

“the sick man of Europe” and in 2003 the German economy was in<br />

deep recession. Since 2004, Germany has emerged from its economic<br />

sluggishness with an exceptional performance. In recent<br />

years, people commonly interpret the rebirth of the German economy<br />

as a new Wirtschaftswunder, an economic miracle which has<br />

brought back the prestige and diplomatic assertiveness that can<br />

determine the fate of the rest of Europe.<br />

Over the past few years, other European countries like Sweden<br />

and France have also had comparable growth rates. But the German<br />

exception lies in having permanently transformed its economic<br />

model in line with the global challenges. The transformation has<br />

also allowed the achievement of the traditional shared goals of the<br />

German society – full employment and low income inequality –<br />

which have always characterized the social market economy. German<br />

governments, both state and federal, have also accompanied<br />

the economy’s internationalization process which was initiated by<br />

large companies and major financial institutions. The common<br />

political analysis behind this is that a population of around<br />

80 million, which produces more than 5 % of global GDP, can<br />

12 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong>

maintain its standard of living only by tying its growth to that of<br />

countries and bringing 6 billion people out of relative poverty. For<br />

this reason, the entire German production system had to and was<br />

able to strengthen its export orientation, while facing the major<br />

geopolitical changes that have directly involved the country: the<br />

German reunification, the European monetary unification, Eastern<br />

Europe opening to international trade. The reality is that, the<br />

process of transformation of German economy was born long<br />

before becoming a political project. It was born under the impulse<br />

of a group of industrial and financial players who were subject to<br />

intense pressure of global competition. Only later, an intensive set<br />

of government-led economic reform programs accompanied the<br />

transformation of production, allowing the entire economy to<br />

benefit from their acquired competitive success.<br />

Export scenario for Germany<br />

In 2017 alone, Germany shipped nearly $ 1.5 trillion worth of goods<br />

around the globe. In dollar terms it reflects a gain of more than<br />

7.5 % from the previous year. In the first nine months of 2018,<br />

Germany exported goods worth $ 1.2 trillion. This 9-month metric<br />

puts German exports on track for an annualized $ 1.5 trillion<br />

estimated for all of 2018. From a continental perspective, around<br />

two thirds of German exports by value were delivered to other<br />

European countries, approximately 18 % were sold to Asian<br />

countries and 10 % to North America. With Germany’s population<br />

of nearly 80 million people, its total $ 1.5 trillion in 2017 exports<br />

translates to roughly $ 18,000 for every resident in the country. The<br />

top industry sectors driving the exports were as follows:<br />

n Automobiles and components: $ 250 billion<br />

n Machinery including computers: $ 245 billion<br />

n Electrical machinery, equipment: $ 150 billion<br />

n Optical, technical, medical apparatus: $72 billion<br />

n Aircraft and aviation products: $ 40 billion<br />

Germany’s focus on advanced manufacturing<br />

technologies<br />

For the next 5-10 years, advanced manufacturing technologies are<br />

set to provide the best export potential for industry sectors such as<br />

machine tools, industrial machinery, robotics, information and<br />

communication technology, process control instrumentation and<br />

electronics equipment, additive manufacturing and advanced<br />

materials. On the domestic front as well, till 2<strong>02</strong>5, more than 80 % of<br />

German manufacturers plan to invest more than $ 100 billion every<br />

year into smart manufacturing technologies.<br />

Germany is the fifth largest robot market in the world with about<br />

20,000 industrial robots being used in industries such as automotive,<br />

electrical and electronics, metal working, chemical, plastics,<br />

and the food industry. Overall the robotics and automation sector<br />

in Germany saw a successful period with sales figures reaching<br />

nearly € 15 billion in 2017, posting a growth of 13 %. All three sectors<br />

of German robotics and automation were on a strong growth<br />

course. The machine vision sector experienced a growth of around<br />

17 % taking its annual turnover to € 2.6 billion. The German robotics<br />

sector also experienced a dynamic period of growth with sales<br />

rising by 17 % to € 4.2 billion. The largest sub-sector of German<br />

robotics and automation, the integrated assembly solutions saw a<br />

sales growth of 9 %, reaching a new record of € 7.6 billion. After the<br />

enormous investments of the electronics and automotive industries<br />

in 2016-17, order intake in the first half of 2018 was no longer as<br />

dynamic as the previous years, due to a normal cyclical effect. In<br />

addition, political developments with protectionist tendencies in<br />

North America and Asia had a dampening effect on the willingness<br />

to invest. This has given the robotics and automation companies a<br />

breathing space and to reduce the order backlog. A high order backlog<br />

and the extended delivery times for systems are reasons for a<br />

partial shift in sales to <strong>2019</strong>. The transformation of the powertrain in<br />

particular requires new technological competencies and manufacturing<br />

solutions. New components such as the battery or the hybrid<br />

drive require new automation solutions with diverse measuring<br />

and testing tasks. With Asia’s electronics sector undergoing heavy<br />

automation, the demand for German products will be on the rise in<br />

the coming years. Further growth opportunities are also seen in the<br />

metal, plastic, medical technology and the food and packaging industry.<br />

A growth rate of at least 5 % is expected again in <strong>2019</strong>,<br />

provided that the political and economic situation does not hinder<br />

investments in automation.<br />

Photo: fotolia z<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong> 13

Smart logistics equipment and<br />

machinery to drive growth in logistics<br />

sector in the coming decades<br />

NEWS AND MARKETS<br />

With conventional growth slowing down in China,<br />

all industry sectors are adjusting to this ‘new<br />

normal’, to ensure their readiness for the coming<br />

decades enterprises even in logistics sector are<br />

swiftly moving towards latest technologies like<br />

logistics 4.0 and smart logistics equipment. At the<br />

LET event in Guangzhou, one can witness the<br />

direction in which logistics sector in China headed.<br />

D<br />

ecades of double digit growth has made China not just a manufacturing<br />

powerhouse, but also one of the biggest logistics<br />

market in the world. The logistics industry has played an extremely<br />

essential role in China’s rise to top. However, in comparison to<br />

developed industrial nations China’s logistics industry faces high<br />

operational costs and relatively low efficiency. The ratio of China’s<br />

logistics cost to GDP is roughly around 14 %, as compared to USA’s<br />

nearly 8 %. Taking automobile sector for example, the logistics cost<br />

ratio in China is somewhere around 8-9 %, whereas in Europe and<br />

America is around 3 % and 5 % in Japan. According to World Bank’s<br />

international Logistics Performance Index, which covers six key<br />

aspects: customs, infrastructure, international shipments, logistics<br />

competence, tracking &tracing, and timeliness, China is ranked<br />

26th in world. Showcasing big gaps over its competitors like<br />

Germany, Japan etc. Realizing this fact, China’s government has<br />

already taken strategic measures to reduce logistics costs and<br />

improve logistics efficiency to spur the real economy.<br />

Author: Sushen Doshi, International Correspondent for World of Industries<br />

But, over the last two years, the growth rate of China’s logistics services<br />

revenues has been facing pressure from a slowdown in the<br />

country’s GDP. According to data from China National Bureau of<br />

Statistics, the transportation and warehousing revenues have been<br />

growing much less than the average growth rate of the country. In<br />

terms of profitability as well, a continuous rise in warehousing costs<br />

and labor costs have been deteriorating the profitability for the<br />

entire sector. In the long-term, with an aging population, labor<br />

shortages will arise and due to rising urbanization the shortage of<br />

warehousing space will be inevitable, thus leading to rise and rise of<br />

operational costs.<br />

Currently, industry’s structure is also a lot more traditional in<br />

nature, which gives immense scope for modernization and<br />

incorporation of latest technologies. Now, China looks towards<br />

high-end manufacturing industry and the domestic consumption<br />

boom to drive up the demand for logistics services. From 2018,<br />

public sector as well as private companies are looking to prioritize<br />

on upgradation of logistics facilities and equipment to enhance the<br />

efficiency of the industry. Under such circumstances, smart logistics<br />

is gaining ground and becoming a key area to focus on for the whole<br />

industry to improve. Smart logistics has significant potential, for<br />

example, with modern warehousing concepts, companies can save<br />

nearly 50 % on land costs and labor costs. By fully monitoring the<br />

whole process of material transfer and storage, the efficiency and<br />

accuracy can be improved. Furthermore, with data collected by<br />

smart logistics systems, enterprises can more provide value-added<br />

services and derive new business models for customers.<br />

Future market opportunities<br />

China’s ambitious belt and road initiative is one of the driving engines<br />

for future development. It contributes largely to exports, and<br />

is expected to continue boosting logistics demand in the future. At<br />

present, most provinces and cities en route the ‘belt and road’ are<br />

14 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong>

accelerating the development of logistics industry, especially the<br />

mid-western area represented by Zhengzhou, Xi’an, Lanzhou, and<br />

Urumqi, in a vision to build themselves as logistics hubs. After the<br />

establishment of transportation logistics hubs, certain export processing<br />

enterprises targeting Europe and other regions may choose<br />

to produce, process, disassemble and package locally; it would also<br />

form clusters of populations in the mid-western area, accelerating<br />

its process of development.<br />

China’s intelligent logistics market reached Yuan 200 billion in<br />

2016, experts predict it will exceed 1 trillion Yuan by 2<strong>02</strong>5. Some<br />

emerging technologies including drone, robotics and automation,<br />

and data analytics are in high demand in logistics industry, as well<br />

as wearable devices, 3D printers, driverless trucks and artificial intelligence<br />

are being used in storage, transportation, delivery and<br />

other end parts of logistics. As China’s manufacturing sector undergoes<br />

transformation, factories will also focus on reforming their logistics<br />

operations, thus leading to an enormous demand for intelligent<br />

factory logistics systems. In China’s smart logistics segment,<br />

vendors are generally classified into three types; hardware suppliers,<br />

software suppliers and comprehensive suppliers. Amongst<br />

them, the comprehensive suppliers are the ones with a better competitive<br />

advantage thanks to their integrated services. Most of the<br />

foreign companies operating in this space are comprehensive suppliers,<br />

and enjoy a competitive edge in terms of technologies and<br />

project experience with strengths in high-end logistics hardware<br />

and software. Whereas domestic companies, with advantages in<br />

price and local reach have a competitive edge in mid-range and<br />

low-end projects. Domestic manufacturers mainly serve as equipment<br />

suppliers or system sub-contractors with each of them operating<br />

on a small scale. With the improvement in R&D as well as<br />

availability of intelligent logistics equipment, the systems provided<br />

by domestic manufacturers are able to meet the needs of most general-purpose<br />

applications, significantly impacting the market share<br />

of foreign manufacturers who are engaged in complete intelligent<br />

logistics equipment production. Moving forward, domestic manufacturers<br />

need to further increase their input in R&D to improve the<br />

level of hardware, lean production and software performance.<br />

Rising demand in the future for intelligent equipment in pricesensitive<br />

industries will provide more space for the development of<br />

domestic manufacturers which offer competitive prices. Based on<br />

integration experience and knowledge gained over time, domestic<br />

manufacturers will have the opportunity to expand their scales and<br />

become stronger in some application fields.<br />

Logistics equipment and technology exhibition<br />

While in the midst of multi-level transition of China’s economy as<br />

well as manufacturing and logistics industry sectors, events such as<br />

LET (Logistics equipment and technology exhibition), become the<br />

guiding light for large and small enterprises. LET, is a CeMAT Asia<br />

event, and is the biggest smart logistic equipment and technology<br />

trade fair in South China. Since the first edition in 2010, LET has<br />

grown to become a successful brand in itself over the last nine years.<br />

With the exhibition expanding its floor space display area, increasing<br />

number of visitors and exhibitor companies, and improving level<br />

of its exhibits, LET is becoming one of the strongest events in the<br />

South China region. Now in its 10th edition, the logistic equipment<br />

and technology show aims to cater the market with latest trends in<br />

technology, innovation and services in the sector. With a floor space<br />

of 20,000 square meters and around 32,000 visitors in 3 days, the LET<br />

show was a big success in 2018. The 10th edition of the LET show will<br />

be hosted at the China Import & Export Complex in Guangzhou<br />

from 29th - 31st May. <strong>2019</strong>.In <strong>2019</strong>, the LET event will be stronger, as<br />

it will be hosted by Hannover Milano Best Exhibitions (Guangzhou)<br />

Co.,Ltd, a joint venture between Guangzhou Best Exhibition Co.,<br />

Ltd. and Hannover Milano Fairs Shanghai Ltd. The show will combine<br />

the strengths of both the partners, and become one of the most<br />

influential shows for the Chinese logistics market.<br />

Like previous years, the show promises to provide a high-quality<br />

trade fair platform for exhibitors to display, communicate and find<br />

partners for co-operation in Chinese logistics market. In 2018, nearly<br />

300 top logistics equipment and technology companies from all<br />

over the world participated and brought their advanced exhibits<br />

like, intelligent forklift trucks, smart logistics systems, logistics robots,<br />

AGV, green material handling technology, lithium battery fast<br />

charging technology, laser slam unmanned guiding technology,<br />

smart factory solutions, etc. Furthermore, nearly 100 industry experts<br />

and scholars shall be present onsite to discuss on current<br />

trends of intelligent logistics, automation, information technology,<br />

advanced manufacturing, Industry 4.0 and Logistics 4.0. Visitors<br />

can interact with exhibitor companies and work together to develop<br />

tailor made solutions for the South China market.<br />

Over the last few years, China’s e-commerce industry has seen<br />

explosive growth, and so has the demand for logistics products and<br />

services like AGV, robots, logistics IT, sorting and delivery systems<br />

etc. At LET too, visitors have expressed their interests in these areas.<br />

The product category at LET includes mechanical handling equipment<br />

like cranes, elevators, cable cars, lifting equipment and platforms,<br />

hoisting platforms, bulk goods and monorail conveyors, trolleys,<br />

industrial trucks, forklifts, robotic handling systems, driverless<br />

transport systems, storage and retrieval equipment for shelves and<br />

racks, components of drive technology, hydraulics and pneumatics.<br />

The display area also has products for warehousing and shelving systems,<br />

industrial doors and gates, pallets, bins and containers, cleaning<br />

systems for warehouses and storage facilities etc. Exhibitors will<br />

also showcase various packaging and order picking systems, weighing<br />

and metering devices, labelling and identification systems etc. In<br />

terms of logistics software, visitors can see software for material flow<br />

and movement, various types of sensors and auto-identification systems,<br />

branch specific software for transportation logistics etc.<br />

Photograph: Fotolia<br />

www.chinalet.cn<br />

Editorial Directors:<br />

Dirk Schaar, Email: d.schaar@vfmz.de<br />

Winfried Bauer, Email: w.bauer@vfmz.de<br />

Editorial board:<br />

Peter Becker (Editor-in-chief), Email: p.becker@vfmz.de<br />

Nicole Steinicke (Editor-in-chief), Email: s.steinicke@vfmz.de<br />

Manfred Weber, Email: m.weber@vfmz.de<br />

Svenja Stenner, Email: s.stenner@vfmz.de<br />

Assistant editors: Svenja Stenner, Petra Weidt<br />

Design/Layout: Anna Schätzlein, Sonja Daniel,<br />

Anette Fröder, Mario Wüst<br />

Epaper designer: Katja Rüdell<br />

Managing editor: Winfried Bauer<br />

Publishing house: Vereinigte Fachverlage GmbH<br />

Lise-Meitner-Str. 2, 55129 Mainz, Germany<br />

Commercial Register No.: HRB 2270, District Court of Mainz<br />

VAT-ID: DE149063659<br />

Privacy Statement: ds-vfv.vfmz.de<br />

Managing director: Dr. Olaf Theisen<br />

Publishing director: Dr. Michael Werner,<br />

Email: m.werner@vfmz.de<br />

Correspondent India: Sushen Haresh Doshi M.Sc.<br />

Advertising sales director:<br />

Beatrice Thomas-Meyer, Email: b.thomas-meyer@vfmz.de<br />

Advertising sales manager:<br />

Oliver Jennen, Email: o.jennen@vfmz.de<br />

Andreas Zepig, Email: a.zepig@vfmz.de<br />

Sales representatives<br />

Austria: Heinz-Joachim Greiner,<br />

Email: verlagsbuero-greiner@vfmz.de<br />

France: Marc Jouanny, Email: marc-jouanny@wanadoo.fr<br />

Great Britain, Ireland: Roberto Tondina<br />

Email: roberto@ts-communications.co.uk<br />

Italy, Switzerland: Hermann Jordi,<br />

Email: info@jordipublipress.de<br />

Sweden, Finland, Norway: Malte Mezger,<br />

Email: verlagsbuero-mezger@vfmz.de<br />

Taiwan: Amy Liu, Email: amy@hf-taiwan.tw<br />

USA, Canada, Mexico: Patrick Venezia Jr,<br />

Email: verlagsbuero-venezia@vfmz.de<br />

Advertising disposition:<br />

Annemarie Benthin, Email: a.benthin@vfmz.de<br />

Helge Rohmund, Email: h.rohmund@vfmz.de<br />

Nevenka Islamovic, Email: n.islamovic@vfmz.de<br />

In cooperation with: Hannover Fairs International GmbH,<br />

Messegelände, 30521 Hannover, Germany<br />

Internet: www.world-of-industries.com

Hannover Messe <strong>2019</strong>: taking you to the<br />

forefront of the fourth industrial revolution<br />

Over the last few years, Industry 4.0 has been the buzz word for the entire<br />

industrialized world, and Hannover Messe has been it’s the global hotspot. It has<br />

been revolutionizing the industrial sector just like the steam engine, mass<br />

production and automation did. And the best part is, we are just getting started.<br />

NEWS AND MARKETS<br />

The foundation for this modern industrial revolution is the<br />

continuous exchange of data between production, logistics and all<br />

operations, making our factories more intelligent, efficient and<br />

sustainable. Few years ago, when the talk of fourth industrial revolution<br />

began, the mood around was ecstatic. This led to a rapid but haphazard<br />

development of products and solutions. Without completely<br />

understanding the opportunities and challenges that Industry 4.0<br />

brings, companies were working on random solutions and missing<br />

out on the bigger picture. This is where Hannover Messe comes in.<br />

Events like Hannover Messe, provide a broader view of the risks<br />

involved and the solutions needed to be developed. Regular visitors at<br />

Hannover Messe can surely feel the difference in standard and quality<br />

of Industry 4.0 products and technologies from six years ago and today.<br />

The level of sophistication and ability to find solutions on more and<br />

more complex problems of the industry has also increased. In the<br />

beginning, companies were focusing on the low hanging fruits and<br />

benefits of Industry 4.0, now with more and more organizations<br />

joining hands and sharing knowledge, the industry has started to<br />

unravel the real potential of Industry 4.0 technologies. Today, along<br />

with large corporations even smaller companies are investing their<br />

capital, human and technological resources to move closer to the<br />

vision of total digitalization.<br />

Just like every year, this year too, industry experts, professionals,<br />

manufacturers and end-users from all over the world shall gather on<br />

the fair grounds of Hannover Messe from 1 st - 5 th April, <strong>2019</strong>. This five<br />

day mega-event will see more than 220,000 visitors and 6500 exhibitor<br />

companies. With it’s lead theme as ‘Integrated Industry - Industrial Intelligence’,<br />

this year the focus will be on integrating artificial intelli-<br />

gence and industry 4.0 technologies. Along with digitalization, another<br />

important technology that has been picking up speed is artificial<br />

intelligence. In a smart factory, where machines, interfaces, and<br />

components communicate with one another, large amounts of data is<br />

accumulated. This data when analyzed, can optimize processes, find<br />

new solutions and make predictions. At Hannover Messe, visitors can<br />

understand what artificial intelligence and machine learning can<br />

make possible in industrial applications – both now and in the future.<br />

Meet your new colleague, ‘the Cobot’<br />

One of the biggest attractions at Hannover Messe has been the rise of<br />

Cobots or collaborative robots. Unlike traditional industrial robots, that<br />

perform their work in physically isolated units, cobots react to people<br />

and not just follow pre-programmed commands. Equipped with sensors,<br />

they observe the movements and positions of humans and assist<br />

workers directly without exposing the humans to any risk of injury.<br />

They are flexible, easy to program and easy to move, weighing just ten<br />

kilograms. With “direct guidance,” method, the robot only moves upon<br />

receiving direct input from a human, such as by touching the robot<br />

arm. This ensures the employee has complete control over the cobot at<br />

all times. With the rise of this technology, it has now become possible<br />

even for SME’s to invest in robotics and boost their competitiveness, as<br />

Cobots are cheaper than actual robots. With Germany being one of the<br />

leaders in robotics, it isn’t surprising that here Cobots are in demand as<br />

well. At Hannover Messe <strong>2019</strong>, visitors can meet and interact with the<br />

leading developers of cobots to understand their advantages and limitations,<br />

in order to make an informed decision.<br />

16 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong>

Predictive maintenance: repair before breakdowns<br />

In Germany, the topic of predictive maintenance has become increasingly<br />

important in recent years, and is inseparable from the themes of<br />

Industry 4.0. Today, machine manufacturers are working to equip their<br />

machines and industrial systems with sensors that enable remote<br />

monitoring, that can measure vibration, temperature or humidity, for<br />

example. Specialized maintenance software collects this sensor data,<br />

evaluates it and recognizes in advance when a component might be in<br />

danger of failing. Defective components that could soon lead to a system<br />

shutdown are identified and can be replaced before damage actually<br />

occurs. The key advantages of predictive maintenance are cost effectiveness,<br />

controlled breakdowns, reduced maintenance and energy<br />

costs. Right from the inception stage of this technology, Hannover<br />

Messe has been backing it up. At Hannover Messe <strong>2019</strong> as well, you can<br />

discover the innovations first hand that are headed towards the market.<br />

Digital twin: a clone for your machine<br />

Another technology that has been trending in Europe and America is<br />

the digital twins, i.e. digital representations of physical machines. Right<br />

from the initial design phase through to production even after the sale<br />

of the product, the virtual twin stays connected with physical product<br />

with sensors that send status data on a constant basis. The incoming<br />

data is gathered and compared against the original design and specifications.<br />

If a discrepancy is detected, then engineers can work on potential<br />

solutions directly on the digital twin - after which the real machine<br />

can then be updated to resolve the problem as quickly as possible. In<br />

the future, all stakeholders will be networked: suppliers, producers and<br />

customers. At Hanover Messe <strong>2019</strong>, visitors can look towards building a<br />

strong network between machine builders, electrical engineers and IT<br />

service providers who can work together on the twin technology.<br />

Hannover Messe <strong>2019</strong>: Trade Fair line up<br />

As the world’s largest and most influential industrial trade fair, Hannover<br />

Messe covers the most fundamental industry sectors. With 6<br />

international leading trade fairs at the same time under one roof, it<br />

offers an extensive collection of products and technologies. The trade<br />

show line up at Hannover Messe includes - Integrated Automation<br />

Motion and Drives (IAMD), Digital Factory, Integrated Energy, Industrial<br />

Supply, Research Technology and ComVac. The IAMD show<br />

is Hannover Messe’s flagship brand and one of the world’s leading<br />

show that attracts more than 2000 exhibitors and 100,000 visitors<br />

from around the globe. As the global hotspot for Industry 4.0. that<br />

covers everything to do with industrial automation, industrial IT,<br />

power transmission, and fluid power technology – from mechanical<br />

engineering and robotics to process automation. Product category at<br />

IAMD includes mechanical power transmission systems and equipment<br />

like belt and chain drives, couplings and clutch units, various<br />

types of braking systems and accessories for brakes, entire gears<br />

units, geared motors and bearings. Electrical equipment that<br />

includes, electric switch gears, contactors and relays, electric motors,<br />

frequency drives, cables and cabling accessories, electronic and<br />

opto-electronic components. The robotics display includes industrial<br />

as well as mobile robots including cobots, driverless transport systems,<br />

programming and engineering services for robotics. IAMD<br />

also has on display products and systems from the fluid power technology<br />

like hydraulic pumps, hydraulic and pneumatic cylinders,<br />

gear pumps, hydraulic variable speed drive units, control valves,<br />

pipes, hoses and connectors, filters for hydraulic and oil lubrication<br />

systems, pneumatic actuator drives, hydraulic and pneumatic sealing<br />

devices, products and systems for condition monitoring and<br />

predictive maintenance. In industrial automation segment, IAMD<br />

focuses on control systems like HMI, PLC, Scada, embedded systems<br />

and industrial PCs, sensors and actuators, communication network<br />

and field bus systems, measuring and test equipment.<br />

The Digital Factory is a trade show dedicated for industrial IT solutions<br />

and integrated processes. Here visitors can find a full array<br />

of solutions for tomorrow’s smart factories – for example, additive<br />

manufacturing systems for non-metals, artificial intelligence and<br />

machine learning systems, advanced simulation systems, image<br />

processing software, industrial cloud services for condition monitoring<br />

and predictive maintenance, data management software,<br />

and the required IT hardware, operating systems for industrial IT,<br />

virtual reality systems for industrial applications, software solutions<br />

for PLM, ERP, MES, raw materials and production planning etc.<br />

Integrated Energy: With increasing industrialization, the global<br />

energy consumption is bound increase. Also, the energy generation is<br />

set to increase especially in the renewable energy sector. Even today,<br />

we can experience the imbalance between energy production, storage<br />

and consumption. More than anything else, today the energy sector<br />

requires efficient utilization of the energy resources, but also sensibly<br />

connecting the energy production and storage system to form an<br />

integrated energy system. Smart grids ensure the efficient coordination<br />

of production, storage, grid management and consumption so<br />

that suppliers can maintain a smooth system. Hannover Messe <strong>2019</strong>,<br />

features the Energy show, a trade show for integrated energy systems<br />

and e-mobility. This show has on display latest technologies in energy<br />

generation and distribution systems, heat management for office and<br />

production buildings, virtual power plants, load management and<br />

energy intelligence software, energy data management and optimization<br />

systems, electrical energy conversion and storage systems like<br />

transformers, accumulators, chargers, UPS, hydrogen and fuel cells<br />

etc. The e-mobility sector is also featured prominently at Hannover<br />

Messe with spotlight on electric transport vehicles for goods and passengers,<br />

infrastructure solutions for e-mobility like charging stations,<br />

cables and replaceable battery systems etc.<br />

Photographs: Deutsche Messe AG<br />

www.hannovermesse.de<br />

<strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 2/<strong>2019</strong> 17

Hannover Messe:<br />

Home of industrial pioneers<br />

Christian H. Kienzle , CEO, Argo-Hytos<br />

Kirsten Billhardt, Marketing Strategist - Internet of<br />

Things, Dell<br />

THE SLOGAN <strong>OF</strong> HANNOVER MESSE IS A<br />

VERY GOOD APPROACH, BECAUSE IT WILL<br />

DEMONSTRATE THE COMPETENCE <strong>OF</strong> OUR<br />

INDUSTRY <strong>WORLD</strong>WIDE. ALSO IT SHOWS THE<br />

EMOTIONS TO BE ON THE SHOW.”<br />

DELL’S WAR IS TO HELP TO ENABLE A<br />

MANUFACTURING CUSTOMER TO ACHIEVE<br />

THEIR PIONEERING DREAMS.”<br />

www.world-of-industries.com/hm_usa_2<br />

www.world-of-industries.com/hm_usa_1<br />

Richard Huss, CEO, Festo USA<br />

Dr Jochen Köckler, CEO, DMAG<br />

PEOPLE ARE COMING TOGETHER FOR A<br />

TRADE SHOW. ALL <strong>OF</strong> OUR EXHIBITORS ARE<br />

PERSONS WHO <strong>OF</strong>FER SOMETHING TO MAKE<br />

LIFE MORE COMPETITIVE IN THE INDUSTRIAL<br />

<strong>WORLD</strong>.”<br />

AS HANNOVER MESSE GOES TO BE THE HOME<br />

<strong>OF</strong> INDUSTRIAL PIONEERS, FESTO <strong>OF</strong> COURSE<br />

WILL HAVE A NEW BIONIC PRODUCT, TO SHOW<br />

HOW NATURE HAS THE MOST ENERGY EFFICIENT<br />

AND MOTION EFFICIENT WAY <strong>OF</strong> DOING THINGS.”<br />

www.world-of-industries.com/hm_usa_7<br />

www.world-of-industries.com/hm_usa_8<br />

Chris Dennen, Marketing Manager, Igus<br />

Christina Chatfield, Vice President of Digital<br />

Strategy, Harting<br />

HOME <strong>OF</strong> INDUSTRIAL PIONEERS, THAT<br />

REALLY EQUALS HARTING FOR ME. THE<br />

FOUNDER WILHELM HARTING WAS ACTUALLY<br />

THE INVENTOR <strong>OF</strong> THE RECTANGULAR<br />

CONNECTOR. THESE DAYS, EVERYBODY IS TALKING ABOUT THE<br />

“HARTING CONNECTOR”.<br />

www.world-of-industries.com/hm_usa_3<br />

WE ARE VERY EXCITED ABOUT THE NEW<br />

THEME, BECAUSE WE BRING A LOT <strong>OF</strong> OUR<br />

INNOVATIONS FOR OUR CUSTOMERS WHICH<br />

THEY REALLY NEED TO BE AN INDUSTRIAL PIONEER.”<br />

www.world-of-industries.com/hm_usa_4<br />

Michael Koch, CEO, Michael Koch GmbH<br />

NEWS AND MARKETS<br />

Industry experts, professionals, manufacturers<br />

and end-users from all over the world shall gather<br />

on the fair grounds of Hannover Messe from 1 st<br />

- 5 th April, <strong>2019</strong>. World of Industries was present<br />

at the Hannover Messe USA and visited<br />

well-known companies. They were asked: “One of<br />

the themes of the Hannover Messe <strong>2019</strong> is “Home<br />

of Industrial Pioneers”. Does your company also<br />

see itself as a pioneer – and if so, in what sense?”<br />

WE BELONG TO THE HANNOVER MESSE AND<br />

WE ARE SUPPORTING INDUSTRIAL PIONIEERS<br />

E.G. BY THE HERMES AWARD.”<br />

www.world-of-industries.com/hm_usa_5<br />

Hala Zeine, President Digital Supply Chain and<br />

Manufacturing, SAP<br />

A PIONEER IS SOMEONE WHO IS ALWAYS<br />

PUSHING THE EDGE. [..] WE SEE OUR ROLE AS<br />

SUPPORTING OUR CUSTOMERS USING THAT<br />

INNOVATION AND THAT’S PIONEERING SPIRIT.”<br />

www.world-of-industries.com/hm_usa_6<br />

18 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> 1/<strong>2019</strong><br />

Images: Dr. Michael Werner, Deutsche Messe AG

Energy-efficient high hressure hydraulics<br />

High-pressure hydraulic pumps from the PZH series produced by<br />

Nachi are designed to ensure the economic operation of bending<br />

presses and injection molding machines. Hydraulic presses and<br />

injection molding machines usually use a lot of energy. These<br />

axial piston pumps can be used to design the drives more<br />

efficiently. They generate up to 350 bar of pressure at a volume<br />

flow rate of up to 72 cm³/revolution. Eleven pistons<br />

ensure an even and low pulsating flow of<br />

hydraulic oil and also guarantee that<br />

the pump operates quietly. Their<br />

sturdy, cast casings, generously<br />

dimensioned roller bearings, and<br />

the spherically hardened swash<br />

plate mean that the pumps can<br />

even be used in harsh ambient<br />

conditions for long periods. The<br />

pump shafts are equipped with feather<br />

keys so that they can be driven with suitable<br />

electric motors and can transfer the required torques. Pressure,<br />

performance, and volume controllers are specially designed by<br />

the manufacturer for the pumps of the individually optimized<br />

hydraulic systems.<br />

EtherCAT with CiA4<strong>02</strong> drive profile<br />

JVL has launched the CiA4<strong>02</strong> drive profile<br />

and synchronization for EtherCAT. The<br />

EtherCAT module with this drive profile<br />

for JVL servo and step motors<br />

supports CSP and CSV, as well as<br />

older operating modes. The JVL<br />

EtherCAT module is equipped<br />

with two Ethernet connections<br />

and an integrated switch with<br />

which a line, star, tree, and ring topology can be implemented<br />

without additional hardware. Opto-insulated<br />

I/Os are integrated in the module thus enabling other<br />

sensors, etc. to be controlled without any external I/O<br />

modules. This keeps the number of devices in the<br />

network to a minimum and reduces cable costs. All of the<br />

indexes in the JVL MAC motor are also accessible via the<br />

EtherCAT connection thus providing complete control of<br />

the motor configuration and movements. JVL motors<br />

equipped with EtherCAT are plug and play compatible<br />

and can be used with PLCs from Beckhoff as well as other<br />

manufacturers of EtherCAT masters such as Omron,<br />

Lenze, or Trio.<br />

background: fotolia<br />

www.nachi.de<br />

www.jvl.dk<br />

DER ANTRIEB<br />

Reliable. Versatile. Global.<br />

Hall 15<br />

Stand H31<br />

THE GEAR UNIT<br />

Strong bearings<br />

Quiet running<br />

THE MOTOR<br />

High efficiency<br />

Global standards<br />

THE DRIVE ELECTRONIC<br />

Field distribution system<br />

Easy implementation<br />

Getriebebau NORD GmbH & Co. KG | Fon +49 4532 289-0 | info@nord.com<br />

nord.com

Gear units for<br />

Sugarloaf Mountain<br />

Sugarloaf Mountain in Rio de Janeiro is one of the most famous landmarks in the world. It is thus<br />

not surprising that every tourist wants to enjoy the view of the beautiful vista made up of the<br />

sea, city, and Christ the Redeemer statue. To ensure that operations continue to run smoothly in<br />

future, modern Flender gear units were installed in the cableway that runs to the<br />

peak of the mountain as part of a retrofit project. The individuals responsible for the<br />

prestigious project decided to choose a premium supplier from Germany.<br />

Author: Andreas Lüdiger is Vice<br />

President Service Sales at Flender<br />

GmbH in Bocholt, Germany<br />

MOTION AND DRIVES<br />

Thousands of tourists want to “scale” the world famous Sugarloaf<br />

Mountain in the Brazilian city of Rio de Janeiro. A column-free<br />

cableway takes tourists up the 395 m tall granite rock that protrudes<br />

out of the sea. Tourists start at sea level taking the first cableway to<br />

Morro da Urca from where they can catch a second cableway, often<br />

referred to as “O Bondinho”, to the top of Sugarloaf Mountain. At the<br />

summit you are rewarded with a panoramic view of the open sea,<br />

the city of Rio de Janeiro nestled between the cliffs, the famous<br />

beach at Copacabana, and the world famous, 38 m tall statue of<br />

Christ the Redeemer located at the peak of the Corcovado mountain<br />

about five kilometers away.<br />

The first cableway was placed into operation in 1912/13 and was<br />