PDF, 3.2 MB - Pfleiderer AG

PDF, 3.2 MB - Pfleiderer AG

PDF, 3.2 MB - Pfleiderer AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The unrelenting development of train is also driving development in track systems, which must<br />

keep pace. <strong>Pfleiderer</strong>’s city solutions – for example its “Green Track” system for tramways –<br />

are just one example of this. <strong>Pfleiderer</strong> track systems maintains a constant dialogue with its<br />

customers, particularly with regard to reducing noise levels and in anticipating the aesthetic<br />

demands of city planners.<br />

Capital Expenditure<br />

New plant construction in Novgorod, Russia progressing on schedule<br />

New construction of MDF/HDF plant planned<br />

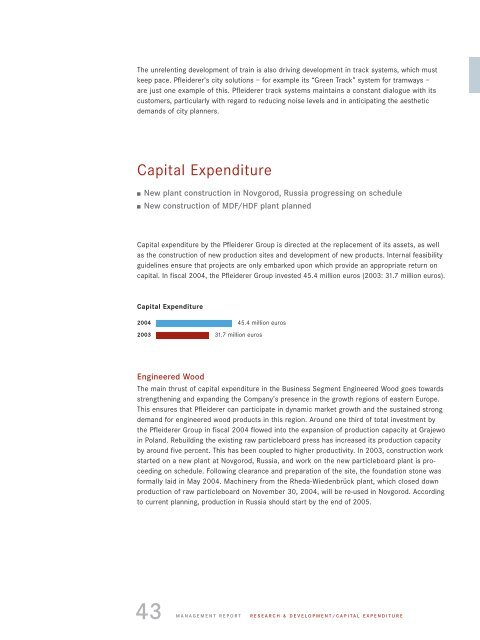

Capital expenditure by the <strong>Pfleiderer</strong> Group is directed at the replacement of its assets, as well<br />

as the construction of new production sites and development of new products. Internal feasibility<br />

guidelines ensure that projects are only embarked upon which provide an appropriate return on<br />

capital. In fiscal 2004, the <strong>Pfleiderer</strong> Group invested 45.4 million euros (2003: 31.7 million euros).<br />

Capital Expenditure<br />

2004<br />

2003<br />

Engineered Wood<br />

The main thrust of capital expenditure in the Business Segment Engineered Wood goes towards<br />

strengthening and expanding the Company’s presence in the growth regions of eastern Europe.<br />

This ensures that <strong>Pfleiderer</strong> can participate in dynamic market growth and the sustained strong<br />

demand for engineered wood products in this region. Around one third of total investment by<br />

the <strong>Pfleiderer</strong> Group in fiscal 2004 flowed into the expansion of production capacity at Grajewo<br />

in Poland. Rebuilding the existing raw particleboard press has increased its production capacity<br />

by around five percent. This has been coupled to higher productivity. In 2003, construction work<br />

started on a new plant at Novgorod, Russia, and work on the new particleboard plant is proceeding<br />

on schedule. Following clearance and preparation of the site, the foundation stone was<br />

formally laid in May 2004. Machinery from the Rheda-Wiedenbrück plant, which closed down<br />

production of raw particleboard on November 30, 2004, will be re-used in Novgorod. According<br />

to current planning, production in Russia should start by the end of 2005.<br />

43<br />

45.4 million euros<br />

31.7 million euros<br />

MAN<strong>AG</strong>EMENT REPORT RESEARCH & DEVELOPMENT/CAPITAL EXPENDITURE