PDF, 3.2 MB - Pfleiderer AG

PDF, 3.2 MB - Pfleiderer AG

PDF, 3.2 MB - Pfleiderer AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Research & Development<br />

New “MultiFunctionPanel” successfully introduced<br />

Ballastless “RHEDA 2000®” sleeper further developed to reduce noise<br />

The <strong>Pfleiderer</strong> Group’s research and development activities are directed at optimizing production<br />

processes and products. Products and services are continually improved in close cooperation<br />

with customers and partners to meet market demands. Some 69 quality managers, laboratory<br />

technicians, product designers and applications specialists were also engaged in research at<br />

development work in the Business Segments Engineered Wood and Infrastructure Technology in<br />

2004. Overall, the <strong>Pfleiderer</strong> Group spent 2 million euros on research and development during<br />

fiscal 2004 (2003: 2 million euros).<br />

Reseach & Development<br />

2004<br />

2003<br />

Engineered Wood<br />

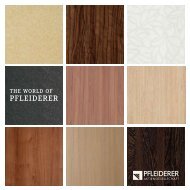

Research and development activities by the Business Segment Engineered Wood focus on the<br />

use of recycled wood, optimization of the value added chain and continued product development.<br />

The feedback from an ongoing dialogue with customers flows back into research for new types<br />

of surface finishes and facings for the kitchen furniture industry. <strong>Pfleiderer</strong> Engineered Wood’s<br />

latest development is its MultiFunctionPanel (MFP) from wodego®. With its high flexural and<br />

cross-tension strength, this new carrier is an economic alternative to oriented stranded board<br />

(OSB) for interior outfitters and carpenters. MultiFunctionPanel is strong enough to be used<br />

as a bearing element in interior construction, for flooring or in shop and trade fair stands.<br />

Infrastructure Technology<br />

High demands are placed on all research and development activities in the Business Center track<br />

systems, part of the Business Segment Infrastructure Technology. The high technological standards<br />

of the individual products involved demands a continuous process of innovation and development<br />

of system concepts. One example of this is the optimization of the RHEDA 2000® sleeper system.<br />

The latest development in monolithic track is a mass-spring system. This innovation can be used<br />

in locations with particularly high demands – for example in mountainous terrain, tunnels and stations<br />

or to reduce secondary air noise on neigbouring buildings. The mass-spring system acts<br />

as an elastic element between upper track layer and substructure, effectively reducing vibration.<br />

Absorbing vibration in turn reduces noise levels. At present, around 9 kilometers of ballastless<br />

RHEDA 2000® track in the north-south line in Berlin is being constructed using the mass-spring<br />

system.<br />

42<br />

2.0 million euros<br />

2.0 million euros