Casing and Cementing - The University of Texas at Austin

Casing and Cementing - The University of Texas at Austin

Casing and Cementing - The University of Texas at Austin

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

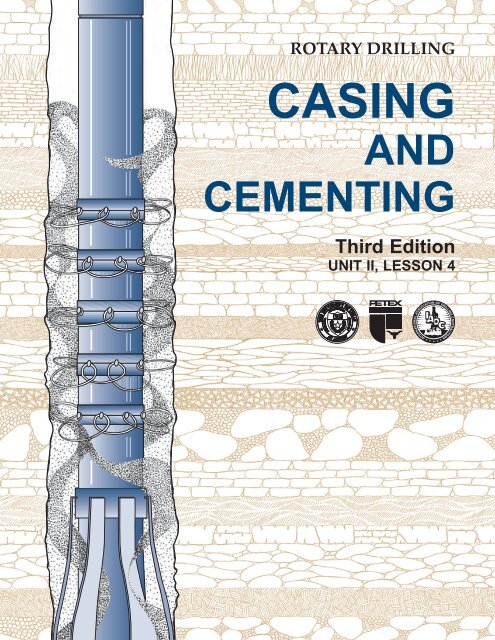

RotaRy DRilling<br />

CASING<br />

AND<br />

CEMENTING<br />

Third Edition<br />

UNIT II, LESSoN 4

<strong>Casing</strong> <strong>and</strong><br />

<strong>Cementing</strong><br />

Unit II, Lesson 4<br />

Third Edition<br />

�<br />

�<br />

�<br />

ROTARY DRILLING SERIES<br />

By William E. Jackson<br />

Published by<br />

PETROLEUM EXTENSION SERVICE<br />

Continuing & Extended Educ<strong>at</strong>ion<br />

<strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Texas</strong> <strong>at</strong> <strong>Austin</strong><br />

<strong>Austin</strong>, <strong>Texas</strong><br />

in cooper<strong>at</strong>ion with<br />

INTERNATIONAL ASSOCIATION<br />

OF DRILLING CONTRACTORS<br />

Houston, <strong>Texas</strong><br />

2001

Library <strong>of</strong> Congress C<strong>at</strong>aloging-in-Public<strong>at</strong>ion D<strong>at</strong>a<br />

Feder, Judy, 1950—<br />

<strong>Casing</strong> <strong>and</strong> cementing / by Judy Feder. — 3rd ed.<br />

p. cm. — (Rotary drilling series ; unit 2, lesson 4)<br />

ISBN 0-88698-191-3 (alk. paper)<br />

1. Oil well casing. 2. Oil well cementing. I. Title. II. Series.<br />

TN871.22.F44 2001<br />

622'.3381—dc21 2001000765<br />

CIP<br />

©2001 by <strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Texas</strong> <strong>at</strong> <strong>Austin</strong><br />

All rights reserved<br />

First Edition published 1968. Second Edition 1982.<br />

Third Edition 2001. Second Impression 2007<br />

Printed in the United St<strong>at</strong>es <strong>of</strong> America<br />

This book or parts there<strong>of</strong> may not be reproduced in any form without<br />

permission <strong>of</strong> Petroleum Extension Service, <strong>The</strong> <strong>University</strong> <strong>of</strong><br />

<strong>Texas</strong> <strong>at</strong> <strong>Austin</strong>.<br />

Br<strong>and</strong> names, company names, trademarks, or other identifying symbols<br />

appearing in illustr<strong>at</strong>ions <strong>and</strong>/or text are used for educ<strong>at</strong>ional<br />

purposes only <strong>and</strong> do not constitute an endorsement by the author<br />

or the publisher.<br />

C<strong>at</strong>alog no. 2.20430<br />

ISBN 0-88698-191-3<br />

No st<strong>at</strong>e tax funds were used to publish this book.<br />

<strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Texas</strong> <strong>at</strong> <strong>Austin</strong> is an equal opportunity employer.

Figures v<br />

Tables viii<br />

Foreword vii<br />

Acknowledgments ix<br />

Units <strong>of</strong> Measurement x<br />

Introduction 1<br />

<strong>Casing</strong> 3<br />

<strong>Casing</strong> Strings 4<br />

Types <strong>of</strong> <strong>Casing</strong> 5<br />

Conductor Pipe 6<br />

Surface <strong>Casing</strong> 7<br />

Intermedi<strong>at</strong>e <strong>Casing</strong> 7<br />

Liner String 8<br />

Production <strong>Casing</strong> 10<br />

To Summarize 11<br />

String Design 12<br />

Design Criteria: Primary Forces 12<br />

Design Criteria: Secondary Forces 15<br />

Design Criteria: Downhole Environment 15<br />

To Summarize 16<br />

Setting the <strong>Casing</strong> 17<br />

Prepar<strong>at</strong>ion 17<br />

Running the <strong>Casing</strong> 22<br />

Stabbing, Making Up, <strong>and</strong> Lowering 27<br />

L<strong>and</strong>ing 32<br />

API St<strong>and</strong>ards 36<br />

To Summarize 41<br />

<strong>Casing</strong> Threads <strong>and</strong> Couplings 42<br />

Proprietary or Premium Connections 45<br />

To Summarize 48<br />

Changing Technology 49<br />

<strong>Cementing</strong> 51<br />

Primary <strong>Cementing</strong> Basics 52<br />

To Summarize 54<br />

Oilwell Cements <strong>and</strong> Additives 55<br />

Additives 57<br />

Special Cements 62<br />

To Summarize 64<br />

Mixing 66<br />

W<strong>at</strong>er Quality 66<br />

W<strong>at</strong>er Quantity 66<br />

Types <strong>of</strong> Mixers 67<br />

Contents<br />

�<br />

�<br />

�<br />

iii

Pumping 70<br />

Displacing the Drilling Mud 70<br />

Pumping the Cement 71<br />

<strong>Casing</strong> Accessories 73<br />

To Summarize 79<br />

Cement Volume Requirements 81<br />

Calcul<strong>at</strong>ing Open-Hole Capacity 82<br />

To Summarize 83<br />

Consider<strong>at</strong>ions After <strong>Cementing</strong> 84<br />

Waiting on Cement 84<br />

Checking the Cement Top 85<br />

Pressure Testing 87<br />

To Summarize 87<br />

Glossary 89

1. <strong>The</strong>se joints <strong>of</strong> casing are ready to be run into the well, where<br />

they will serve <strong>at</strong> least seven important functions. 3<br />

2. Most wells require several strings <strong>of</strong> casing, each <strong>of</strong> which<br />

serves a specific purpose important to the completion <strong>of</strong> the<br />

well. 5<br />

3. Conductor pipe in <strong>of</strong>fshore oper<strong>at</strong>ions extends the “hole”<br />

from the seafloor, up through the w<strong>at</strong>er, to a point in the air<br />

just below the drilling deck. 6<br />

4. A liner is a rel<strong>at</strong>ively short string <strong>of</strong> casing th<strong>at</strong> extends from<br />

the bottom <strong>of</strong> the open hole, up into another string. 8<br />

5. Liner strings are nearly always suspended from the upper<br />

string by means <strong>of</strong> a liner hanger. 8<br />

6. A tie-back string from the liner to the surface may be used if<br />

an existing casing string has been weakened by drilling. 9<br />

7. Whether on or <strong>of</strong>fshore, preventive maintenance is key to<br />

protecting casing as it is prepared to run into the well. 17<br />

8. A thread protector should be in place any time a joint <strong>of</strong> casing<br />

is h<strong>and</strong>led. 18<br />

9. <strong>Casing</strong> resting on stringers 19<br />

10. Before casing is run, threads are inspected for damage th<strong>at</strong><br />

may have occurred during shipping <strong>and</strong> racking. 20<br />

11. Pipe is tallied three times: when it is shipped, when it arrives<br />

<strong>at</strong> loc<strong>at</strong>ion, <strong>and</strong> after the casing string has been run. 22<br />

12. Running casing 23<br />

13. Stabbing casing 24<br />

14. Special bucket <strong>and</strong> sling arrangement raise a joint <strong>of</strong> casing to<br />

the rig floor 27<br />

15. Thread compound may be applied over the entire surface <strong>of</strong><br />

the casing threads just before stabbing. 28<br />

16. Hydraulic power tongs are placed around a joint <strong>of</strong> casing to<br />

make it up to a predetermined torque. 29<br />

17. <strong>Casing</strong> elev<strong>at</strong>ors <strong>and</strong> casing spider support the casing as it is<br />

being lowered into the well. 31<br />

18. L<strong>and</strong>ing the casing involves transferring the casing string<br />

weight to the wellhead, usually with a casing hanger th<strong>at</strong><br />

se<strong>at</strong>s in the casinghead <strong>and</strong> seals the annulus between the<br />

outer <strong>and</strong> inner strings. 32<br />

19. Downhole casing hangers are used to relieve some <strong>of</strong> the load<br />

on the casinghead. 35<br />

20. <strong>Casing</strong> with a coupling (A) <strong>and</strong> a threaded end (B) 42<br />

21. Examples <strong>of</strong> API-threaded connections 43<br />

22. Examples <strong>of</strong> premium-threaded connections 45<br />

Figures<br />

�<br />

�<br />

�<br />

v

vi<br />

Tables<br />

�<br />

�<br />

�<br />

23. Halliburton cementing equipment from the 1920s 51<br />

24. Primary cementing is performed immedi<strong>at</strong>ely after the casing<br />

has been run in the hole, to seal <strong>and</strong> separ<strong>at</strong>e each zone, <strong>and</strong><br />

to protect the pipe. 53<br />

25. <strong>Cementing</strong> trucks transport dry cement blends to the well<br />

site. 55<br />

26. High-energy recircul<strong>at</strong>ing mixers provide thoroughly mixed<br />

slurries <strong>at</strong> a wide range <strong>of</strong> densities <strong>and</strong> r<strong>at</strong>es. 67<br />

27. Internal oper<strong>at</strong>ion <strong>of</strong> a recircul<strong>at</strong>ing mixer 68<br />

28. <strong>The</strong> dem<strong>and</strong>s <strong>and</strong> expense associ<strong>at</strong>ed with <strong>of</strong>fshore oper<strong>at</strong>ions<br />

have led to the development <strong>of</strong> sophistic<strong>at</strong>ed, high-tech<br />

mixing <strong>and</strong> d<strong>at</strong>a acquisition systems. 68<br />

29. Internal oper<strong>at</strong>ion <strong>of</strong> a b<strong>at</strong>ch mixer 69<br />

30. A primary cementing job 71<br />

31. Wiper plugs are placed in the cementing head to wipe mud<br />

<strong>of</strong>f the inside <strong>of</strong> the casing <strong>and</strong> keep it separ<strong>at</strong>ed from the cement.<br />

72<br />

32. A typical casing string with accessories 73<br />

33. A guide shoe 74<br />

34. An autom<strong>at</strong>ic fill-up shoe 74<br />

35. A flo<strong>at</strong> collar prevents backflow <strong>of</strong> cement during the cementing<br />

oper<strong>at</strong>ion. 75<br />

36. Multistage cementing devices are used to cement two or more<br />

separ<strong>at</strong>e sections behind a casing string. 76<br />

37. Bow (A) <strong>and</strong> solid body (B) centralizers 77<br />

38. Scr<strong>at</strong>chers (A) <strong>and</strong> wipers (B) help remove filter cake <strong>and</strong><br />

gelled mud from the well as the casing is run. 78<br />

39. Temper<strong>at</strong>ure survey showing the top <strong>of</strong> cement outside the<br />

casing 85<br />

1. Fluid Displacement <strong>of</strong> <strong>Casing</strong> 25<br />

2. Volume Gains in the Mud Pit from <strong>Casing</strong> Displacement 25<br />

3. API Length Ranges <strong>of</strong> <strong>Casing</strong> 36<br />

4. Specific<strong>at</strong>ion for <strong>Casing</strong> <strong>and</strong> Tubing—API <strong>Casing</strong> List 37<br />

5. Specific<strong>at</strong>ion for <strong>Casing</strong> <strong>and</strong> Tubing—Tensile <strong>and</strong> Hardness<br />

Requirements 39<br />

6. Distance Between Pl<strong>at</strong>es for Electric Weld Fl<strong>at</strong>tening<br />

Tests 40<br />

7. Effects <strong>of</strong> Some Additives on the Physical Properties <strong>of</strong><br />

Cement 58

Foreword<br />

�<br />

�<br />

�<br />

For many years, the Rotary Drilling Series has oriented new<br />

personnel <strong>and</strong> further assisted experienced h<strong>and</strong>s in the<br />

rotary drilling industry. As the industry changes, so must the<br />

manuals in this series reflect those changes.<br />

<strong>The</strong> revisions to both the text <strong>and</strong> illustr<strong>at</strong>ions are extensive.<br />

In addition, the layout has been “modernized” to make the<br />

inform<strong>at</strong>ion easy to get; the study questions have been rewritten;<br />

<strong>and</strong> each major section has been summarized to provide a<br />

h<strong>and</strong>y comprehension check for the reader.<br />

PETEX wishes to thank industry reviewers—<strong>and</strong> our readers—<br />

for invaluable assistance in the revision <strong>of</strong> the Rotary Drilling Series.<br />

<strong>Casing</strong> <strong>and</strong> <strong>Cementing</strong> introduces rig crew members to the<br />

concept <strong>of</strong> casing string design <strong>and</strong> the procedures for properly<br />

h<strong>and</strong>ling pipe while it is on the rack, being picked up, made<br />

up into a string, <strong>and</strong> cemented in the hole. This manual covers<br />

types <strong>of</strong> pipe usually employed, string design consider<strong>at</strong>ions,<br />

running techniques, cementing procedures, casing liner use,<br />

liner setting, <strong>and</strong> cement strength determin<strong>at</strong>ion.<br />

Although every effort was made to ensure accuracy, this<br />

manual is intended only as a training aid; thus, nothing in it<br />

should be construed as approval or disapproval <strong>of</strong> any specific<br />

practice or product.<br />

Ron Baker<br />

vii

Acknowledgments<br />

�<br />

�<br />

�<br />

T he author expresses a sincere appreci<strong>at</strong>ion to the numerous<br />

people who have helped with the prepar<strong>at</strong>ion <strong>of</strong> this edition<br />

<strong>of</strong> <strong>Casing</strong> <strong>and</strong> <strong>Cementing</strong>. In particular, special thanks go to Rick<br />

Covington <strong>of</strong> Halliburton Energy Services, <strong>and</strong> Ed Banker <strong>of</strong><br />

Marubeni Tubulars, Inc. <strong>The</strong>ir time <strong>and</strong> p<strong>at</strong>ience reviewing the<br />

manuscript <strong>and</strong> upd<strong>at</strong>ing inform<strong>at</strong>ion was invaluable.<br />

Thanks also go to Monte Montague, Betsy Mott, <strong>and</strong> Dave<br />

Rees <strong>of</strong> Halliburton, as well as Anjali Prasad <strong>and</strong> John Greenip<br />

<strong>of</strong> Hydril, for loc<strong>at</strong>ing <strong>and</strong> providing illustr<strong>at</strong>ions <strong>and</strong> photographs<br />

for use in the manual. John Greenip was most helpful<br />

in providing assistance in reviewing the text.<br />

All who have contributed time, thought, <strong>and</strong> effort into<br />

this book have worked to make this new edition a success in<br />

providing the most complete inform<strong>at</strong>ion about casing <strong>and</strong><br />

cementing.<br />

ix

x<br />

Units <strong>of</strong> Measurement<br />

�<br />

�<br />

�<br />

Throughout the world, two systems <strong>of</strong> measurement domin<strong>at</strong>e:<br />

the English system <strong>and</strong> the met ric system. To day, the United<br />

St<strong>at</strong>es is almost the only country th<strong>at</strong> employs the En glish sys tem.<br />

<strong>The</strong> English system uses the pound as the unit <strong>of</strong> weight, the<br />

foot as the unit <strong>of</strong> length, <strong>and</strong> the gallon as the unit <strong>of</strong> capacity.<br />

In the En glish system, for example, 1 foot equals 12 inches, 1<br />

yard equals 36 inches, <strong>and</strong> 1 mile equals 5,280 feet or 1,760 yards.<br />

<strong>The</strong> metric system uses the gram as the unit <strong>of</strong> weight, the<br />

metre as the unit <strong>of</strong> length, <strong>and</strong> the litre as the unit <strong>of</strong> capacity.<br />

In the metric system, for example, 1 me tre equals 10 decimetres,<br />

100 centimetres, or 1,000 milli metres. A kilometre equals 1,000<br />

me tres. <strong>The</strong> metric system, un like the English system, uses a<br />

base <strong>of</strong> 10; thus, it is easy to convert from one unit to another.<br />

To convert from one unit to an other in the English system, you<br />

must memorize or look up the val ues.<br />

In the l<strong>at</strong>e 1970s, the Eleventh General Conference on<br />

Weights <strong>and</strong> Measures de scribed <strong>and</strong> adopted the Système<br />

Intern<strong>at</strong>ional (SI) d’U nités. Conference participants based the<br />

SI system on the metric system <strong>and</strong> de signed it as an intern<strong>at</strong>ional<br />

stan dard <strong>of</strong> measurement.<br />

<strong>The</strong> Rotary Drilling Series gives both English <strong>and</strong> SI units.<br />

And because the SI sys tem employs the British spelling <strong>of</strong> many<br />

<strong>of</strong> the terms, the book follows those spelling rules as well. <strong>The</strong><br />

unit <strong>of</strong> length, for ex ample, is metre, not me ter. (Note, however,<br />

th<strong>at</strong> the unit <strong>of</strong> weight is gram, not gramme.)<br />

To aid U.S. readers in making <strong>and</strong> underst<strong>and</strong>ing the<br />

conversion to the SI system, we in clude the following table.

Introduction<br />

�<br />

�<br />

�<br />

<strong>Casing</strong> <strong>and</strong> cementing are essential to drilling oil <strong>and</strong> gas wells.<br />

Lining a hole with casing keeps it from caving in after it is<br />

drilled, sealing the wellbore from encroaching fluids <strong>and</strong> gasses.<br />

<strong>Cementing</strong> the casing in place <strong>at</strong>taches it firmly to the wellbore wall<br />

<strong>and</strong> stabilizes the hole. <strong>Casing</strong> <strong>and</strong> cement both serve additional,<br />

important functions in the well. <strong>The</strong>se functions will be addressed<br />

l<strong>at</strong>er in this manual.<br />

<strong>Casing</strong> <strong>and</strong> cementing procedures have grown more sophistic<strong>at</strong>ed<br />

in recent years as the search for new hydrocarbon-bearing<br />

reservoirs takes wells deeper <strong>and</strong> into more hostile environments<br />

(i.e., deep w<strong>at</strong>er, high pressures <strong>and</strong> temper<strong>at</strong>ures, <strong>and</strong> sour gases).<br />

Engineers <strong>and</strong> metallurgists work continually to refine casing or<br />

cementing designs <strong>and</strong> procedures to h<strong>and</strong>le the challenges associ<strong>at</strong>ed<br />

with <strong>of</strong>fshore <strong>and</strong> remote loc<strong>at</strong>ions, extreme depths, <strong>and</strong><br />

severe conditions.<br />

During the days <strong>of</strong> cable-tool drilling, numerous strings <strong>of</strong><br />

casing had to be set as a well was drilled. With the advent <strong>of</strong> rotary<br />

drilling came better quality muds with gre<strong>at</strong>er ability to control<br />

well pressures. As a result, much more open hole could be drilled.<br />

<strong>Casing</strong> is now generally set to serve a specific purpose <strong>and</strong> is neither<br />

arbitrary nor compulsory for any hole conditions.<br />

�<br />

�<br />

�<br />

1

<strong>Casing</strong><br />

�<br />

�<br />

�<br />

<strong>Casing</strong> <strong>and</strong> tubing account for 15 to 20 percent <strong>of</strong> the completed<br />

cost <strong>of</strong> a well—<strong>of</strong>ten the gre<strong>at</strong>est single item <strong>of</strong> expense<br />

on the well. Failure <strong>of</strong> casing or tubing results in expensive rework<br />

<strong>and</strong> may lead to loss <strong>of</strong> the well, or worse, loss <strong>of</strong> life. Selecting<br />

casing sizes, weights, grades, <strong>and</strong> types <strong>of</strong> threaded connections<br />

for a given situ<strong>at</strong>ion presents an engineering <strong>and</strong> economic challenge<br />

<strong>of</strong> considerable importance.<br />

<strong>Casing</strong> is strong steel pipe used in an oil or gas well to ensure a<br />

pressure-tight connection from the sur face to the oil or gas reservoir.<br />

<strong>Casing</strong> serves <strong>at</strong> least seven important func tions in the well (fig. 1):<br />

1. It prevents the hole from caving in or washing out.<br />

2. It protects freshw<strong>at</strong>er s<strong>and</strong>s from contamin<strong>at</strong>ion by<br />

fluids from lower zones.<br />

3. It keeps w<strong>at</strong>er out <strong>of</strong> the producing for m<strong>at</strong>ion.<br />

4. It confines production to the wellbore.<br />

5. It contains form<strong>at</strong>ion pressures <strong>and</strong> prevents fracturing<br />

Figure 1. <strong>The</strong>se joints <strong>of</strong> casing are ready to be run into the well,<br />

where they will serve <strong>at</strong> least seven important functions.<br />

3

<strong>Cementing</strong><br />

Oilwell cementing is the process <strong>of</strong> mixing <strong>and</strong> placing a<br />

cement slurry in the annular space be tween a string <strong>of</strong> casing<br />

<strong>and</strong> the open hole. <strong>The</strong> cement sets, bonding the casing to the wall<br />

<strong>of</strong> the wellbore for additional stability.<br />

<strong>The</strong> practice <strong>of</strong> cementing began around 1903 in California.<br />

Early methods <strong>of</strong> mixing cement <strong>and</strong> placing it in the hole were<br />

quite crude. Modern cementing practices debuted in 1920, when<br />

Erle Halliburton cemented a well in Oklahoma’s Hewitt Field for<br />

W.G. Skelly (fig. 23). Today, the Halliburton jet mixer remains a<br />

basic device for rapid mixing <strong>of</strong> drilling mud, although it is seldom<br />

used for mixing cement slurry.<br />

In 1903 there was only one type <strong>of</strong> cement <strong>and</strong> no additives.<br />

Today there are eight classes <strong>of</strong> cement <strong>and</strong> more than 40 different<br />

addi tives. Bulk‑cement h<strong>and</strong>ling is stan dard practice, <strong>and</strong> blends<br />

are tailored to specific jobs. Waiting‑on‑cement time has been<br />

reduced from 10 days to less than 24 hours.<br />

Figure 23. Halliburton cementing equipment from the 1920s (Courtesy <strong>of</strong> Halliburton)<br />

�<br />

�<br />

�<br />

51

Glossary<br />

acceler<strong>at</strong>or n: a chemical additive th<strong>at</strong> reduces the setting time <strong>of</strong> cement.<br />

See cement, cementing m<strong>at</strong>erials.<br />

additive n: 1. in general, a substance added in small amounts to a larger<br />

amount <strong>of</strong> another substance to change some characteristic <strong>of</strong> the l<strong>at</strong>ter. In<br />

the oil in dustry, additives are used in lubric<strong>at</strong>ing oil, fuel, drill ing mud, <strong>and</strong><br />

casing cement. 2. in cementing, a substance added to cement to change the<br />

cement characteristics to s<strong>at</strong>isfy specific conditions in the well. A cement<br />

additive may work as an acceler<strong>at</strong>or, retarder, dispersant, or other reactant.<br />

API gravity n: the measure <strong>of</strong> the density or gravity <strong>of</strong> liquid petroleum<br />

products in the United St<strong>at</strong>es; derived from rel<strong>at</strong>ive density in accordance<br />

with the following equ<strong>at</strong>ion:<br />

�<br />

�<br />

�<br />

API gravity <strong>at</strong> 60°F = [141.5 ÷ rel<strong>at</strong>ive density 60/60°F] – 131.5<br />

autom<strong>at</strong>ic fill-up shoe n: a device th<strong>at</strong> is installed on the first joint <strong>of</strong> casing<br />

<strong>and</strong> th<strong>at</strong> autom<strong>at</strong>ically regul<strong>at</strong>es the amount <strong>of</strong> mud in the casing. <strong>The</strong> valve<br />

in this shoe keeps mud from entering the casing until mud pressure causes<br />

the valve to open, allowing mud to enter the casing.<br />

axial compression n: pressure produced parallel with the cylinder axis when<br />

casing hits a devi<strong>at</strong>ion in the hole or a sticky spot <strong>and</strong> stops. <strong>The</strong> force pushing<br />

down on the pipe causes axial compression.<br />

bending n: occurs when tension is increased on one side <strong>of</strong> the pipe while<br />

compression is increased on the other.<br />

billet n: a solid steel cylinder used to produce seamless casing. <strong>The</strong> billet is<br />

pierced lengthwise to form a hollow tube th<strong>at</strong> is shaped <strong>and</strong> sized to produce<br />

the casing.<br />

boot n: a tubular device placed in a vertical position, either inside or outside<br />

a larger vessel, through which well fluids are conducted before they enter the<br />

larger vessel. A boot aids in the separ<strong>at</strong>ion <strong>of</strong> gas from wet oil. Also called<br />

a flume or conductor pipe.<br />

bottom wiper plug n: a device placed in the cement ing head <strong>and</strong> run down<br />

the casing in front <strong>of</strong> cement to clean the mud <strong>of</strong>f the walls <strong>of</strong> the casing <strong>and</strong><br />

to pre vent contamin<strong>at</strong>ion between the mud <strong>and</strong> the cement.<br />

A<br />

B<br />

89

Unit I: <strong>The</strong> Rig <strong>and</strong> Its Maintenance<br />

rotary drilling series<br />

Lesson 1: <strong>The</strong> Rotary Rig <strong>and</strong> Its Components<br />

Lesson 2: <strong>The</strong> Bit<br />

Lesson 3: Drill String <strong>and</strong> Drill Collars<br />

Lesson 4: Rotary, Kelly, Swivel, Tongs, <strong>and</strong> Top Drive<br />

Lesson 5: <strong>The</strong> Blocks <strong>and</strong> Drilling Line<br />

Lesson 6: <strong>The</strong> Drawworks <strong>and</strong> the Compound<br />

Lesson 7: Drilling Fluids, Mud Pumps, <strong>and</strong> Conditioning Equipment<br />

Lesson 8: Diesel Engines <strong>and</strong> Electric Power<br />

Lesson 9: <strong>The</strong> Auxiliaries<br />

Lesson 10: Safety on the Rig<br />

Unit II: Normal Drilling Oper<strong>at</strong>ions<br />

Lesson 1: Making Hole<br />

Lesson 2: Drilling Fluids<br />

Lesson 3: Drilling a Straight Hole<br />

Lesson 4: <strong>Casing</strong> <strong>and</strong> <strong>Cementing</strong><br />

Lesson 5: Testing <strong>and</strong> Completing<br />

Unit III: Nonroutine Oper<strong>at</strong>ions<br />

Lesson 1: Controlled Directional Drilling<br />

Lesson 2: Open-Hole Fishing<br />

Lesson 3: Blowout Prevention<br />

Unit IV: Man Management <strong>and</strong> Rig Management<br />

Unit V: Offshore Technology<br />

Lesson 1: Wind, Waves, <strong>and</strong> We<strong>at</strong>her<br />

Lesson 2: Spread Mooring Systems<br />

Lesson 3: Buoyancy, Stability, <strong>and</strong> Trim<br />

Lesson 4: Jacking Systems <strong>and</strong> Rig Moving Procedures<br />

Lesson 5: Diving <strong>and</strong> Equipment<br />

Lesson 6: Vessel Inspection <strong>and</strong> Maintenance<br />

Lesson 7: Helicopter Safety<br />

Lesson 8: Orient<strong>at</strong>ion for Offshore Crane Oper<strong>at</strong>ions<br />

Lesson 9: Life Offshore<br />

Lesson 10: Marine Riser Systems <strong>and</strong> Subsea Blowout Preventers

To obtain additional training m<strong>at</strong>erials, contact:<br />

PETEX<br />

<strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Texas</strong> <strong>at</strong> <strong>Austin</strong><br />

PETROLEUM ExTENSION SERVICe<br />

1 <strong>University</strong> St<strong>at</strong>ion, R8100<br />

<strong>Austin</strong>, TX 78712-1100<br />

Telephone: 512-471-5940<br />

or 800-687-4132<br />

FAX: 512-471-9410<br />

or 800-687-7839<br />

E-mail: petex@www.utexas.edu<br />

or visit our Web site: www.utexas.edu/ce/petex<br />

To obtain inform<strong>at</strong>ion about training courses, contact:<br />

PETEX<br />

HOUSTON TRAININg CENTER<br />

<strong>The</strong> <strong>University</strong> <strong>of</strong> <strong>Texas</strong><br />

2700 W. W. Thorne Blvd.<br />

Houston, TX 77073<br />

Telephone: 281-443-7144<br />

or 800-687-7052<br />

FAX: 281-443-8722<br />

E-mail: petexhtc@www.utexas.edu<br />

or visit our Web site: www.utexas.edu/ce/petex

2.20430<br />

0-88698-191-3