Manual Field Bus Controller - New Lift

Manual Field Bus Controller - New Lift

Manual Field Bus Controller - New Lift

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

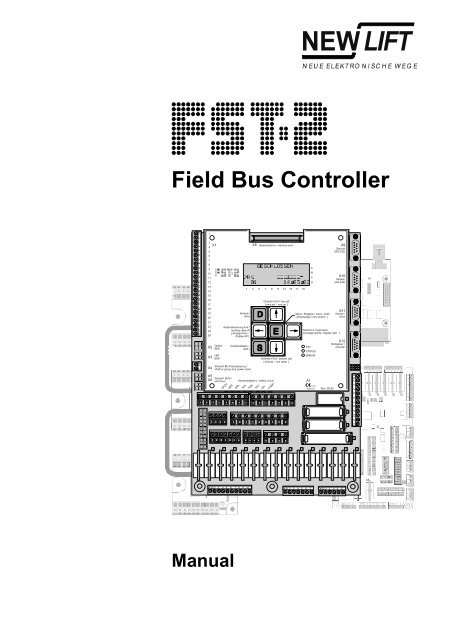

<strong>Field</strong> <strong>Bus</strong> <strong>Controller</strong><br />

X1<br />

. 2<br />

. 3<br />

. 4<br />

. 5<br />

. 6<br />

. 7<br />

. 8<br />

. 9<br />

. 10<br />

. 11<br />

. 12<br />

. 13<br />

. 14.<br />

15<br />

1 2 3 4 5 6 7 8 149<br />

10<br />

. 16<br />

. 17<br />

. 18.<br />

19<br />

. 20.<br />

21<br />

. 22<br />

. 23.<br />

24<br />

11 12 13 14 15 16 17 18 19 20<br />

X4<br />

. 2<br />

1 2 3 4 5 6 7 8 X5 9 10<br />

Schach t BUS /<br />

X6 shaft bus<br />

11 12 13 14 15 16 17 18 19 20<br />

1 2 3 4 5 6 7 8 9 10<br />

T<br />

11 12 13 14 15 16 17 18 19 20<br />

<strong>Manual</strong><br />

1<br />

3<br />

X1<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

X2<br />

X3<br />

X4<br />

Option<br />

BUS<br />

[ Umschalttaste /<br />

shift ]<br />

GESCHLOSSEN<br />

###@###-<br />

>A<<br />

14:03:02<br />

01<br />

SKZU<br />

SPB<br />

SPA<br />

TKA<br />

T<br />

X8 Speicherkart e / memory-card<br />

1 3 5 7 9 11 13 15 17 19<br />

Antrieb /<br />

drive<br />

Außensteuerun g Aus /<br />

landing calls off<br />

[ Anzeige links /<br />

display left ]<br />

HHT<br />

BUS<br />

Schacht-BU S Einspeisun g /<br />

shaft or group-bus powe r input<br />

KB<br />

T<br />

D<br />

Sicherheitskrei s / safety circuit<br />

KC<br />

N<br />

H<br />

FKNH<br />

SKZU SPB SPA TKA TKB TKC NH LT FKNHLT<br />

Oberster Ruf / top call<br />

[ eins auf / one up ]<br />

Unterster Ruf / bottom call<br />

[einsab/ one down ]<br />

Rev. D2.2b<br />

X20.2 .3 .4 .5 .6 .7 .8 .9 .10 X21.2 .3 .4 .5 .6 .7 X22.2 .3 .4 .5 .6<br />

A1<br />

A<br />

B<br />

C<br />

D<br />

Menü , Eingabe / menu, enter<br />

[ Infoanzeige / info screen ]<br />

FST<br />

STATUS<br />

ERROR<br />

0036<br />

AEB-004<br />

X9<br />

Service<br />

(RS-232)<br />

X10<br />

Modem<br />

(RS-232)<br />

X11<br />

Antrieb /<br />

drive<br />

Testmen ü / test menu<br />

[ Anzeige rechts / display right ]<br />

X12<br />

Drehgeber /<br />

encoder<br />

X6 2 . 3 . 4 . 5 6 . 7 8 . 9 X5 2 3 . 4 . 5 X4 2 3 . 4 X3 . 2 3 4 . 5 6 X2 . 2 . 3 4 . 5 . 6 X1<br />

. 2 . 3 . 4 . 5 . 6 7 8 9<br />

X7 .2 .3 .4 .5 .6<br />

X13.<br />

2<br />

. 3<br />

. 4<br />

. 5<br />

. 6<br />

. 7<br />

. 8<br />

. 9<br />

. 10<br />

. 11<br />

. 12<br />

X20.2 .3 .4 .<br />

T<br />

X8 .2 .3 .4 .5 .6<br />

X9 .2 .3 .4 .5 .6<br />

X19.2 .3 .4 .5 .6 .7 .8 X18.2 .3 .4 .<br />

X15. 2 . 3 . 4 X14. 2 . 3 4 . 5 . 6 X13<br />

2 3 . 4<br />

X11.<br />

2 . 3 4 . 5 X10.<br />

2 . 3 4 . 5 . 6 . 7 . 8 . 9<br />

X17 2 3 . 4 X16<br />

2 3 . 4

Publisher NEW LIFT Steuerungsbau GmbH<br />

Lochhamer Schlag 8<br />

D-82166 Gräfelfing<br />

Phone: +49 (0) 89 / 89 866 - 0<br />

Fax: +49 (0) 89 / 89 866 - 300<br />

Doc. No. FST-2_HB.EN12/05<br />

Date of issue 12/05<br />

Software version V1.100-0350<br />

Copyright © 2005, NEW LIFT Steuerungsbau GmbH<br />

All rights including those of copying and reproduction of parts of this<br />

description and of the translation are reserved by the publisher.<br />

No part of this description may be reproduced in any form or copied with an<br />

electronic replication system without the written permission of the<br />

publisher.<br />

FST-2_HB.EN12/05

Table of contents<br />

1 About this manual .............................................................................................. 5<br />

1.1 General........................................................................................................................... 5<br />

1.2 Signs and Symbols used ....................................................................................... 5<br />

1.3 Further information................................................................................................... 6<br />

2 General Safety Regulations ......................................................................... 7<br />

2.1 Standards and regulations applied.................................................................... 7<br />

2.2 Electromagnetic compatibility (EMC)................................................................ 8<br />

2.3 Handling electronic components........................................................................ 8<br />

3 FST-2-<strong>Controller</strong> user interface ................................................................ 9<br />

3.1 LC-Display and messages ................................................................................... 10<br />

Main screen..................................................................................................................... 10<br />

Line A .............................................................................................................................. 10<br />

Line B .............................................................................................................................. 11<br />

Line C .............................................................................................................................. 13<br />

Line D .............................................................................................................................. 27<br />

Information texts.............................................................................................................. 28<br />

Information page.............................................................................................................. 31<br />

3.2 Keypad functions ................................................................................................... 32<br />

Frequency converter with DCP interface......................................................................... 32<br />

When switching on .......................................................................................................... 32<br />

Main screen..................................................................................................................... 33<br />

Main menu and test menu............................................................................................... 33<br />

Error list ........................................................................................................................... 34<br />

Information page.............................................................................................................. 34<br />

3.3 LEDs.............................................................................................................................. 34<br />

4 Technical data ..................................................................................................... 35<br />

4.1 Component overview – bus plan ...................................................................... 36<br />

4.2 FST-2-<strong>Controller</strong>....................................................................................................... 37<br />

FST-2_HB.EN12/05 1

Table of contents<br />

Safety Monitoring Device................................................................................................. 44<br />

4.3 FSM car control module........................................................................................ 53<br />

4.4 FPM car panel module........................................................................................... 65<br />

4.5 FPE car panel extension module ..................................................................... 72<br />

4.6 FPA car control panel adapter ........................................................................... 77<br />

4.7 ADM landing call module ..................................................................................... 81<br />

4.8 RIO-ADM remote I/O module............................................................................... 84<br />

4.9 RIO-FPM remote I/O module ............................................................................... 87<br />

4.10 LON bus....................................................................................................................... 91<br />

4.11 Trailing ribbon cable .............................................................................................. 92<br />

5 Menu tree .................................................................................................................95<br />

5.1 General......................................................................................................................... 95<br />

5.2 MAIN MENU – Service.......................................................................................... 104<br />

5.3 MAIN MENU – Drive .............................................................................................. 106<br />

5.4 MAIN MENU – Config ........................................................................................... 111<br />

5.5 MAIN MENU – Positioning.................................................................................. 127<br />

5.6 MAIN MENUE – Calls............................................................................................ 134<br />

5.7 MAIN MENUE – System....................................................................................... 136<br />

5.8 MAIN MENUE – Doors.......................................................................................... 139<br />

5.9 MAIN MENU.............................................................................................................. 144<br />

5.10 TEST MENU.............................................................................................................. 145<br />

6 Programmable inputs and outputs .................................................... 147<br />

2 FST-2_HB.EN12/05

Table of contents<br />

General.......................................................................................................................... 147<br />

Programming ................................................................................................................. 148<br />

Setting the RAW register............................................................................................... 148<br />

Function “landing call” ................................................................................................... 153<br />

Function “fire signal” ...................................................................................................... 154<br />

Function “priority landing” .............................................................................................. 155<br />

Function “position indicator” .......................................................................................... 156<br />

Function “flag”................................................................................................................ 157<br />

User error ...................................................................................................................... 161<br />

Function “signal”............................................................................................................ 162<br />

Function “evacuation”.................................................................................................... 164<br />

Function “special drive” ................................................................................................. 166<br />

Function “alarm misuse”................................................................................................ 167<br />

Function “speed threshold”............................................................................................ 168<br />

Function “ramp drive” .................................................................................................... 169<br />

Function “override floor blocking” .................................................................................. 170<br />

Function “block floors” ................................................................................................... 171<br />

7 Error List ................................................................................................................ 173<br />

7.1 LC-Display ................................................................................................................ 173<br />

7.2 Keypad functions .................................................................................................. 173<br />

7.3 Event messages..................................................................................................... 174<br />

7.4 Error messages...................................................................................................... 175<br />

8 Index ......................................................................................................................... 181<br />

FST-2_HB.EN12/05 3

Table of contents<br />

4 FST-2_HB.EN12/05

1 About this manual<br />

1.1 General<br />

1 About this manual<br />

1.1 General<br />

The FST-2 manual is a comprehensive reference work for experienced lift<br />

service experts.<br />

Goals of this manual<br />

1.2 Signs and Symbols used<br />

- describe the characteristics of the LON bus technology<br />

- describe technical details and functions of the FST-2 and its<br />

components<br />

- describe the operation of the FST-2<br />

- describe the configuration of the FST-2<br />

- describe the FST-2 menu and its settings<br />

- describe the messages of the FST-2<br />

Below you can find a description of the signs and symbols used in this<br />

manual.<br />

Symbols + Key combination:<br />

Press the linked keys simultaneously.<br />

� Action:<br />

Actions are executed immediately and will not be saved as permanent<br />

settings.<br />

FST-2_HB.EN12/05 5

1 About this manual<br />

1.3 Further information<br />

LC-Display and keypad In the left column you will find the LC-Display of the FST-2-<strong>Controller</strong> with<br />

a grey background. The displays and messages or possible keypad<br />

functions are explained in the table.<br />

LC-Display<br />

1.3 Further information<br />

Line or<br />

key<br />

The following documentation is available for the FST-2-<strong>Controller</strong> and its<br />

components:<br />

- Description of FST-2-<strong>Controller</strong><br />

- FST-2 Installation & Commissioning<br />

- FST-2 Quick Guide<br />

- FST-2 <strong>Manual</strong> (this document)<br />

- GST <strong>Manual</strong><br />

Description of display or keypad functions<br />

- System description – pawl Device<br />

- Installation & Commissioning – FAX Modem<br />

- Quick Guide EAZ-256<br />

- Quick Guide EAZ-VFD<br />

- Quick Guide EAZ-LCD<br />

- Quick Guide FST-2-IRT<br />

- <strong>Manual</strong> for Fireman Mode<br />

- System description – Speech Output<br />

- System description – Attika Control<br />

- System description – Bank-Control<br />

- System description – Ramp-Drive<br />

- System description – Panel Test<br />

- System description – Safety curtain<br />

NEW LIFT is happy to provide this documentation on request. Please<br />

contact our marketing department.<br />

6 FST-2_HB.EN12/05

2 General Safety Regulations<br />

2.1 Standards and regulations applied<br />

2 General Safety Regulations<br />

2.1 Standards and regulations applied<br />

The FST-2-<strong>Controller</strong> must be in technically perfect condition and may only<br />

be used in accordance with regulations and in awareness of safety and<br />

risks. The “FST-2 Installation & Commissioning” manual as well as the<br />

relevant guidelines for the prevention of accidents and the guidelines of<br />

local power utilities must be observed.<br />

The FST-2-<strong>Controller</strong> complies with:<br />

- Regulation for lift systems<br />

(German regulation for lift systems, AufzV)<br />

- Safety regulations for the construction and installation of passenger<br />

lifts, building hoists and service lifts (DIN EN 81 Parts 1 and 2)<br />

- Technical regulations for lifts (TRA, Technische Regeln für Aufzüge)<br />

Operation of lift systems (TRA 007)<br />

Testing parts and components (TRA 101)<br />

Passenger lifts, building hoists and service lifts (TRA 200)<br />

- Regulations for the erection of power installations with rated voltages of<br />

up to 1kV (DIN VDE 0100)<br />

- Measures for contact voltage protection in the engine room (DIN EN<br />

60990)<br />

- Data sheet on safety measures during installation, maintenance and<br />

servicing or repair of lift systems (ZH 1/312)<br />

FST-2_HB.EN12/05 7

2 General Safety Regulations<br />

2.2 Electromagnetic compatibility (EMC)<br />

2.2 Electromagnetic compatibility (EMC)<br />

An accredited inspection body has verified that the FST-2-<strong>Controller</strong> and<br />

its components comply with the standards, limits and test intensities<br />

according to EN 12015/1995 and EN 12016/1995.<br />

The FST-2-<strong>Controller</strong> and its components are:<br />

- resistant against electrostatic discharges<br />

(EN 61000-4-2/1995)<br />

- resistant against electrostatic fields<br />

(EN 61000-4-3/1997)<br />

- resistant against transient disturbances<br />

(EN 61000-4-4/1995)<br />

2.3 Handling electronic components<br />

The field strengths of electromagnetic disturbances radiated by the FST-2-<br />

<strong>Controller</strong> and its components do not exceed the permitted limits.<br />

(EN 55011/1997)<br />

Leave electronic components in their original packaging until installation.<br />

Touch a grounded piece of metal prior to opening the original packaging to<br />

prevent damage from static charges.<br />

All bus inputs and outputs not in use must be equipped with a terminal<br />

resistance (terminator).<br />

8 FST-2_HB.EN12/05

3 FST-2-<strong>Controller</strong> user interface<br />

Fig. 3.1 FST-2-<strong>Controller</strong> user interface<br />

3 FST-2-<strong>Controller</strong> user interface<br />

The user interface of the FST-2-<strong>Controller</strong> is located on the FST-2 main<br />

circuit board in the control cabinet of the lift system. The FST-2 user<br />

interface consists of front panel, LC-Display, keypad and LEDs.<br />

SAFETY CCT CLOSED<br />

FST-2_HB.EN12/05 9

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

3.1 LC-Display and messages<br />

Main screen<br />

Line A<br />

SAFETY CCT CLOSED<br />

###@###<br />

>AX<<br />

13:06:56<br />

00<br />

Safety circuit messages<br />

in Line A<br />

The LC-Display consists of four lines A, B, C and D with 20 digits each.<br />

After switching on and during normal operation, the FST-2-<strong>Controller</strong><br />

displays the main screen.<br />

A Maximum active state of the safety circuit<br />

B Active state or error<br />

C Status of the lift system / diagnostic message<br />

D Data for current drive mode<br />

Line C has a special status. In normal mode (after switching on), it displays<br />

status messages (see “Status messages in line C” on page 13). When<br />

switching with key combination �+�+� it displays diagnostic<br />

messages, see “Diagnostic messages in line C” on page 14.<br />

Also see “Keypad functions” on page 32.<br />

Display Description<br />

CCT CLOSED The safety circuit is completely closed<br />

SAFETY<br />

(FST X14.1 & FST X14.2).<br />

MISSING The input “Safety circuit closed” has no power.<br />

SFTY-CLOSED<br />

Possible reasons:<br />

- Terminal FST X14.1 has no power (normally<br />

bridged with X14.2)<br />

- Relay K14 on the FST is faulty<br />

LOCK B OPEN The shaft door contact of door side B is<br />

DOOR<br />

interrupted (FST X14.2 and X14.3).<br />

LOCK A OPEN The shaft door contact of door side A is<br />

DOOR<br />

interrupted (FST X14.3 and X14.4).<br />

A OPEN The car door contact of door side A is<br />

DOOR<br />

interrupted (FST X14.4 and X14.5).<br />

B OPEN The car door contact of door side B is<br />

DOOR<br />

interrupted (FST X14.5 and X14.6).<br />

C OPEN The car door contact of door side C is<br />

DOOR<br />

interrupted (FST X14.6 and X14.7).<br />

DOOR OPEN A manual door contact is interrupted<br />

MANUAL<br />

(FST X14.6 and X14.7).<br />

END<br />

EMERGENCY<br />

SWITCH<br />

The top emergency end switch of an hydraulic<br />

lift is interrupted (FST X14.6 and X14.7).<br />

10 FST-2_HB.EN12/05

Line B<br />

State messages in line B<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Display Description<br />

STOP An emergency switch in the shaft is interrupted<br />

EMERGENCY<br />

(terminals FST X14.7 and X14.8).<br />

STOP-CAR An emergency switch on the car is interrupted<br />

EMERGENCY<br />

(terminal FST X32.4).<br />

The messages DOOR C OPEN, MANUAL DOOR OPEN and EMERGENCY<br />

END SWITCH are triggered by the same safety circuit input of the FST-2<br />

(TC input: FST-2 X14.6) and exclude each other.<br />

Display Description<br />

LOW! The 24V supply of the FST-2 board (FST X1.1<br />

24V<br />

and X1.2) is below the permitted range of 24V -<br />

10%. Check power supply and wiring.<br />

CALLS OFF Landing control is blocked by a safety circuit<br />

LANDING<br />

interruption (interruption before terminal FST<br />

X32.4), line A EMERGENCY displays STOP,<br />

“EMERGENCY see STOP” on page 11.<br />

CONTROL OFF Landing control was switched off manually.<br />

LANDING<br />

Possible sources:<br />

� - key of the FST-2 keypad<br />

- Programmable input of an external RIO<br />

module<br />

- Input FST X1.14<br />

- Programmable input of the FST-2-<strong>Controller</strong><br />

- Key switch on car panel (FPM input X4.34)<br />

- Key switch on landing panel (ADM input<br />

X3.12 / X3.13)<br />

A fire input is active. Possible reasons:<br />

FIREMAN<br />

- Fire input on landing call module (ADM input<br />

X3.12 / X3.13)<br />

- Programmable input of the FST-2-<strong>Controller</strong><br />

- GST Group <strong>Controller</strong> (see GST <strong>Manual</strong>)<br />

TEST The manual end switch test is running, see test<br />

END-SWITCH<br />

menu.<br />

MON. TEST The manual test of the deceleration monitoring<br />

ES-SPEED<br />

function at the top and bottom limits is running,<br />

see test menu.<br />

The controller is in evacuation mode. Possible<br />

EVACUATION<br />

sources for the evacuation signal:<br />

- Programmable input of the FST-2-<strong>Controller</strong><br />

- Programmable input of the GST Group<br />

<strong>Controller</strong><br />

- LMS over PAM protocol adapter module<br />

FAX The controller is in fax mode (see Installation &<br />

SEND<br />

Commissioning – Fax modem).<br />

FST-2_HB.EN12/05 11

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Display Description<br />

OFF The controller was shut down. Possible<br />

LIFT<br />

sources:<br />

- Car light failure<br />

- Input “Car Light OFF”, FST X1.13<br />

- Programmable input/output of an external<br />

RIO module<br />

- Programmable input/output of the FST-2-<br />

<strong>Controller</strong><br />

- Externally by the GST Group <strong>Controller</strong> or the<br />

LMS <strong>Lift</strong> Monitoring System<br />

MODE Fireman mode is activated. Possible sources:<br />

FIREMAN<br />

- Key switch on car panel (FPM X4.4)<br />

- Programmable input/output of the FST-2-<br />

<strong>Controller</strong><br />

- The state was saved after a power failure and<br />

has been reconstructed. Fireman<br />

Function<br />

Reset must be used to reset this<br />

Mode<br />

state.<br />

- Key switch on landing panel (ADM input<br />

X3.12 / X3.13)<br />

- GST Group <strong>Controller</strong> (see GST <strong>Manual</strong>)<br />

TRANSFER<br />

FILE<br />

ACTIVE<br />

The controller is in remote data transmission<br />

mode to transfer files to a GST Group<br />

<strong>Controller</strong> or to a PC.<br />

The controller is in inspection mode (input FSM<br />

INSPECTION<br />

X22.2).<br />

Attention: Line A of the FST-2 display must<br />

EMERGENCY show STOP-CAR!<br />

- A calibration drive was started. The number of<br />

CALIBRATION<br />

remaining runs is displayed.<br />

The hinged car apron is open (due to a shaft<br />

APRON-OPEN!<br />

door interruption). Monitoring is done via a<br />

programmable input of the FST-2-<strong>Controller</strong>.<br />

DRIVE ACTIVE The controller performs a learn drive.<br />

LEARN<br />

DRIVE-START The controller performs a learn drive.<br />

LEARN<br />

DRIV-�OK! Learn drive completed successfully.<br />

LEARN<br />

DRIVE-ABORT The learn drive was cancelled due to a fault.<br />

LEARN<br />

The reason is entered in the error list.<br />

CURTAIN The safety curtain replacing the car door was<br />

SAFETY<br />

interrupted. The contact is in the safety circuit<br />

instead of the car door contacts (see System<br />

description – Safety curtain).<br />

.. A runtime monitoring error has occurred. There<br />

DRM<br />

are different types of runtime monitoring<br />

functions that can shut down the lift.<br />

MODE The controller is in installation mode.<br />

INSTALLATION<br />

The controller performs an orientation drive to<br />

ORIENTATION<br />

the top or bottom limit after switching on (only<br />

when using INK – incremental positioning). The<br />

orientation drive can take place automatically or<br />

when the first call is placed.<br />

12 FST-2_HB.EN12/05

Line C<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Display Description<br />

DRIVE ACTIVE The controller sends the car to a programmed<br />

PARK<br />

parking floor.<br />

LANDING A priority landing drive was triggered. Possible<br />

PRIORITY<br />

sources:<br />

- Key switch on landing panel (ADM input<br />

X3.12 / X3.13)<br />

- Programmable input of the FST-2-<strong>Controller</strong><br />

- Programmable input of an external RIO<br />

module<br />

CAR A priority car drive was triggered. Possible<br />

PRIORITY<br />

sources:<br />

- Key switch on car panel (FPM input X4.37)<br />

- Automatically after a type Auto 2 priority<br />

landing drive.<br />

The controller is in auxiliary mode (input FST<br />

AUXILIARY<br />

X18.2).<br />

Attention: Line A of the FST-2 display must<br />

EMERGENCY show STOP!<br />

ACTIVE The hydraulic lift is sent to the lowest landing.<br />

HOMING<br />

ACTIVE The controller is in service mode, see test<br />

SERVICE<br />

menu.<br />

REQUIRED! One of the service counters has exceeded a set<br />

SERVICE<br />

limit.<br />

STOP The controller was stopped via the FST-2<br />

SYSTEM<br />

menu.<br />

The overload input on the FSM or on a<br />

OVERLOAD<br />

programmable input is active.<br />

ERROR - A user error has occurred. The number of the<br />

USER<br />

error is displayed.<br />

MODE The controller is in VIP mode. Possible sources<br />

VIP<br />

VIP mode:<br />

- LMS over PAM protocol adapter module<br />

- Programmable input of the FST-2-<strong>Controller</strong><br />

- FPM input X4.34 on car panel<br />

LOAD The full load input of the FSM is active.<br />

FULL<br />

Status messages in line C Line C is divided and displays one of the following status messages in the<br />

left and in the right part. For scrolling the status messages in the left part<br />

use the key combination �+�, for the right part use the key combination<br />

�+�.<br />

The door positions marked with A also apply to doors B and C.<br />

FST-2_HB.EN12/05 13

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

<br />

>A<<br />

Status Display Description<br />

Car doors Door A completely open<br />

Door A closed<br />

Door A is opening<br />

<br />

Door A is closing<br />

->A>

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Display Description<br />

00000 Diagnosis of absolute value encoder<br />

LIK-Errs:00000<br />

function (see page 16), this display is<br />

irrelevant when using incremental<br />

positioning.<br />

Real-time display of increments counted by<br />

ENC:10000000[989680]<br />

the encoder on plug X2. The counted<br />

increments together with the covered<br />

distance can help when calculating the<br />

required Resolution.<br />

KO KU ZB Current state of the solenoid switches with<br />

Gray=43210<br />

incremental positioning, see page 16<br />

F1=00 F2=00 Current state of the FSM for door A, see<br />

Door-A:<br />

page 16<br />

F1=00 F2=00 Current state of the FSM for door B, see<br />

Door-B:<br />

page 16<br />

F1=00 F2=00 Current state of the FSM for door C, see<br />

Door-C:<br />

page 16<br />

VST=0000 Internal motor state (see page 19) and<br />

Motor=00<br />

states of the pre-selection contact outputs<br />

(see page 20)<br />

Real=00 Generated and actual position messages<br />

Pos:Virt=0b<br />

from the car, see page 20<br />

State of the safety circuit, see page 22<br />

SHK=SABCN<br />

Call=00 Internal NEW LIFT diagnostic message<br />

Mgr1:Drv=00<br />

B=00 C=00 Internal NEW LIFT diagnostic message<br />

Mgr2:A=02<br />

VT=V2 Next possible stop (NextPoss) that can<br />

NextPoss=ff<br />

be approached and the set speed (VT), see<br />

page 22<br />

EXIN1=EGALPUDR State of input EXIN1, see page 22<br />

Port<br />

EXIO2=76543210 State of input EXIN2, see page 23<br />

Port<br />

H8IN1=ZBSMVO State of input H8IN1, see page 23<br />

Port<br />

L=1 V=0 K=0 State of outputs on FSM X8 and X19, see<br />

FSM-X6:<br />

page 23<br />

00 00 00 00 Source of the special drive signals fireman,<br />

SRC:00<br />

fireman mode, landing control OFF, lift off<br />

and service mode, see page 24<br />

255% E0 F0 O0 State of the weight sensor, see page 25<br />

LWE:<br />

State of the project specific parts of the<br />

Proj.Status=........<br />

program (internal)<br />

m1 c0 f0 Mb005 State of the PC-Card slot, see page 26<br />

PC:s0<br />

In=005 Out=002 Incoming and outgoing data packets of the<br />

Pkt\s<br />

FST-<strong>Controller</strong> in [packets/sec]<br />

0000000 P=[00] State of the pawl device, see page 26<br />

ASV:<br />

msgs=00123 Number of message packets from the FSM<br />

FSM<br />

car control module to the FST-2-<strong>Controller</strong><br />

FST-2_HB.EN12/05 15

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Absolute value encoder<br />

function<br />

LIK-Errs:00000 00000<br />

State of incremental<br />

positioning<br />

Gray=43210 KO KU ZB<br />

The two numbers on the display show the number of encoder failures since the last<br />

activation of the system. The left number shows the different values resulting from<br />

double scanning, the right number shows the number of failed plausibility checks.<br />

Sporadic errors are compensated by the FST Software and can be tolerated. A<br />

continuous increase of one of these values indicates an encoder or cable failure.<br />

Left number:<br />

Right number:<br />

Display Description<br />

00000<br />

or constant value<br />

Communication between the FST-2-<strong>Controller</strong><br />

and the absolute value encoder is working<br />

correctly. Double scanning to suppress electric<br />

interference does not show any differences.<br />

constantly rising value Double scanning to suppress electric<br />

interference does show differences. There is<br />

electric interference on the connection cable<br />

between FST-2-<strong>Controller</strong> and encoder. Check<br />

connection cable and inform your NEW LIFT<br />

Hotline.<br />

Display Description<br />

The position values of the absolute value<br />

00000<br />

encoder are plausible (are within the regular<br />

shaft). There are no invalid jumps in the<br />

position value.<br />

The position values of the absolute value<br />

RANGE<br />

encoder are not plausible (are outside the<br />

regular shaft). Check direction of rotation of the<br />

encoder and commission the linear positioning<br />

function, see “Installation and Commissioning<br />

<strong>Manual</strong>”.<br />

There are invalid jumps in the position value.<br />

DELTA<br />

Absolute value encoder faulty.<br />

Code Description<br />

43210 State of Gray-coded pre-limit switches for high-speed lifts (optional)<br />

KO Correction switch top (KO) active<br />

KU Correction switch bottom (Ku) active<br />

ZB Zone switch B active<br />

16 FST-2_HB.EN12/05

States of the FSM car<br />

control module<br />

Door-A: F1=00 F2=00<br />

Fig. 3.2 Hexadecimal encoding of an 8-bit register<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

State bytes F1 and F2 describe the states of eight functions each in realtime<br />

(8 bits, hexadecimal code). Hexadecimal bytes are coded number by<br />

number. Each number has a decimal value according to the following table:<br />

Hexadecimal<br />

number<br />

Decimal<br />

value<br />

0<br />

0<br />

1<br />

1<br />

2<br />

2<br />

3<br />

3<br />

4<br />

4<br />

5<br />

5<br />

6<br />

6<br />

7<br />

7<br />

8<br />

8<br />

9<br />

9<br />

10<br />

a<br />

11<br />

b<br />

12<br />

c<br />

13<br />

d<br />

14<br />

e<br />

15<br />

f<br />

FST-2_HB.EN12/05 17<br />

digit<br />

digit

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Each number codes four functions (bits) of the F1/F2 table with its decimal<br />

value. The decimal value of the number corresponds to the sum of the<br />

values of the activated functions according to the following tables.<br />

F1 = Bit Number Value Setting Byte F1<br />

0<br />

1 active FSM car control module configured<br />

1 Number 1<br />

2 active Door locked<br />

2<br />

(right number)<br />

4 active Door reversing<br />

3 8 Door completely<br />

open<br />

Limit switch “door open”<br />

4<br />

1 Door completely Limit switch “door closed”<br />

Number 2<br />

closed<br />

5<br />

6<br />

(left number)<br />

2<br />

4<br />

active<br />

active<br />

Photocell interrupted<br />

Reversing contact<br />

7 8 active Minimum load input*<br />

F2 = Bit Number Value Setting Byte F2<br />

0<br />

1 on Car light sensor*<br />

1 Number 1<br />

2 active Inspection signal “fast”<br />

2<br />

(right number)<br />

4 active Inspection signal “down”<br />

3 8 active Inspection signal “up”<br />

4<br />

1 active Inspection signal “ON”<br />

5 Number 2<br />

2 active Door closing motor<br />

6<br />

(left number)<br />

4 active Door opening motor<br />

7 8 active Door ready for drive<br />

SAFETY CCT CLOSED<br />

F1=6c F2=21<br />

Door-A:<br />

13:06:<br />

00<br />

* Signal only relevant for door versions A and B.<br />

Example:<br />

State byte F1 = 6c and state byte F2 = 21<br />

This results in the following hexadecimal numbers:<br />

F1:<br />

Number 1 = “c” (decimal = 12)<br />

Number 2 = “6” (decimal = 6)<br />

F2:<br />

Number 1 = “1” (decimal = 1)<br />

Number 2 = “2” (decimal = 2)<br />

The decimal numbers are calculated from the following values:<br />

F1:<br />

Number 1 = 12 = 8 + 4<br />

18 FST-2_HB.EN12/05

Internal motor states<br />

Motor=00<br />

Internal states of the preselection<br />

relays<br />

Vst=0000<br />

Number 2 = 6 = 4 + 2<br />

F2:<br />

Number 1 = 1<br />

Number 2 = 2<br />

These values result in the following active bits:<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

F1:<br />

Number 1 = 8 + 4<br />

=>according to the table for F1 (Number 1) bits 2 and 3 are active<br />

=>the door is reversing and limit switch “open” has switched<br />

Number 2 = 4 + 2<br />

=>according to the table for F1 (Number 2) bits 5 and 6 are active<br />

=>the photocell is interrupted and the reversing contact has<br />

switched<br />

F2:<br />

Number 1 = 1<br />

=>according to the table for F2 (Number 1) bit 0 is active<br />

=>the door is reversing and limit switch “open” has switched<br />

Number 2 = 2<br />

=>according to the table for F2 (Number 2) bit 5 is active<br />

=>the car light sensor is active and the door motor is closing<br />

Internal motor states are coded according to the following table:<br />

Motor = Value motor state<br />

Motor ready<br />

00<br />

Motor starting<br />

01<br />

Motor running<br />

02<br />

03 Motor approaching stop position<br />

04 Motor braking<br />

05 Motor stopping<br />

digit<br />

digit<br />

digit 3<br />

digit<br />

4<br />

Fig. 3.3 Hexadecimal encoding of a 16-bit register<br />

8-11<br />

12-15<br />

FST-2_HB.EN12/05 19

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Position messages<br />

Pos: Virt=0b Real=00<br />

The four digit display provides a real-time description of the states of the<br />

pre-selection relays in hexadecimal code according to the following table.<br />

Hexadecimal values are coded number by number as described in<br />

page 17.<br />

VST = Bit Number Value Setting pre-selection relay<br />

0<br />

1 active Output FST K0<br />

1<br />

Number 1<br />

2 active Output FST K1<br />

2<br />

(right number)<br />

4 active Output FST K2<br />

3 8 active Output FST K3<br />

4<br />

1 active Output FST K4<br />

5 Number 2 2 active Output FST K5<br />

6 4 active Output FST K6<br />

7 8 active Output FST K7<br />

8<br />

1 active Output FST K8<br />

9 Number 3 2 active Output FST K9<br />

10 4 active Output FST K10<br />

11 8 active Output FST K11<br />

12<br />

1 active Output FST K12<br />

13 Number 4 2 active Zone signal B<br />

14<br />

15<br />

(left number)<br />

4<br />

8<br />

active<br />

active<br />

Safety circuit bypass FST K20<br />

Enable zone switching FST K21<br />

The generated (virtual) and actual (real) position messages of the car<br />

describe the states of eight switches each (8 bits, hexadecimal code) in<br />

real-time according to the following table. Hexadecimal values are coded<br />

number by number as described in page 17.<br />

Virt = Bit Number Value Setting virtual position<br />

0<br />

1 active Level (A and B)<br />

1 Number 1 2 active Level (A and B) with motor stopped<br />

2<br />

3<br />

(right number)<br />

4<br />

8<br />

active<br />

active<br />

Approach area<br />

Zone switch B (FST K23)<br />

4<br />

1 active Relevelling “up”<br />

5 Number 2 2 active Relevelling “down”<br />

6<br />

(left number)<br />

4 active Enable zone switching (FST K21)<br />

7 8 Not assigned<br />

20 FST-2_HB.EN12/05

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Real = Bit Number Value Setting real position<br />

0<br />

1 active Zone message (FST K22 & K23 active at the same time)<br />

1 Number 1 2 active Correction switch top KO (INK)<br />

2<br />

(right number)<br />

4 active Correction switch bottom KU (INK)<br />

3 8 active Level bottom LB (INK, optional)<br />

4<br />

1 active Level top LT (INK, optional)<br />

5 Number 2 2 active Brake monitoring (FST X1.19 & X1.20)<br />

6<br />

(left number)<br />

4 active Motor monitoring (FST X1.22)<br />

7 8 active Zone switch B (with INK)<br />

FST-2_HB.EN12/05 21

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

States of the safety circuit<br />

Shk=SABCN<br />

Next possible stop<br />

NextPoss=ff<br />

Current set speed<br />

Vt=V2<br />

Input EXIN1<br />

Port EXIN1=EGALPDUR<br />

The state of the safety circuit is coded according to the following table:<br />

Code Description<br />

Locking device open<br />

S<br />

Door A open<br />

A<br />

Door B open<br />

B<br />

Car door C (revolving door, emergency end switch top) open<br />

C<br />

Emergency stop<br />

N<br />

The next possible stop that can be approached by the car is coded with<br />

hexadecimal values according to the following table:<br />

Code NextPoss=<br />

Description<br />

All floors possible (car is at rest)<br />

ff<br />

No further floor possible (when decelerating)<br />

fe<br />

Next possible stop = code (hexadecimal)<br />

00..3f<br />

The current set speed of the motor is coded according to the following<br />

table:<br />

Code Vt=<br />

Description<br />

Drive speed 1 .. 8 (for standard drives)<br />

V1..V8<br />

ve Approach speed<br />

Fast inspection speed<br />

Vi<br />

Relevelling speed<br />

Vn<br />

Input EXIN1 displays the states of the controller inputs according to the<br />

following table:<br />

R<br />

U<br />

D<br />

Bit Terminal Setting Description<br />

FST X18.2 active Auxiliary control ON<br />

FST X18.3 active Auxiliary control UP<br />

FST X18.4 active Auxiliary control DOWN<br />

P<br />

L FST X1.14 active Car light OFF<br />

A<br />

G<br />

E<br />

FST X1.15 active Landing control OFF<br />

active GST found<br />

active Alarm<br />

22 FST-2_HB.EN12/05

Input EXIO2<br />

Port EXIO2=76543210<br />

Input H8IN1<br />

Port H8IN1=ZBSMUO<br />

FSM-X6<br />

FSM-X6: L=1 V=0 K=0<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Input/output EXIO2 displays the states of the programmable inputs and<br />

outputs according to the following table:<br />

Bit Terminal Setting Description<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

FST X1.4 active Programmable input/output 0<br />

FST X1.5 active Programmable input/output 1<br />

FST X1.6 active Programmable input/output 2<br />

FST X1.7 active Programmable input/output 3<br />

FST X1.8 active Programmable input/output 4<br />

FST X1.9 active Programmable input/output 5<br />

FST X1.10 active Programmable input/output 6<br />

FST X1.11 active Programmable input/output 7<br />

Input H8IN1 displays the inputs of the drive processor according to the<br />

following table:<br />

O<br />

U<br />

M<br />

S<br />

B<br />

Z<br />

Bit Terminal Setting Description<br />

0 Not assigned<br />

1 Not assigned<br />

FSM X13.1 active Correction switch top “KO”<br />

FSM X13.3 active Correction switch bottom “KU”<br />

FST X1.22 active Motor monitoring<br />

FST X1.23 active Standstill monitoring<br />

FST X1.19/20 active Brake monitoring<br />

FST X13.9 active Zone message<br />

The FSM-X6 display shows the states of the following outputs of the car<br />

control module:<br />

L=<br />

0<br />

1<br />

Code Terminal Setting car light<br />

FSM X19.1 active Car light OFF<br />

FSM X19.1 not active Car light ON<br />

V=<br />

0<br />

1<br />

Code Terminal Setting car ventilator<br />

FSM X19.4 not active Car ventilator OFF<br />

FSM X19.4 active Car ventilator ON<br />

FST-2_HB.EN12/05 23

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Source of special drive<br />

signals<br />

SRC:00 00 00 00<br />

Code Terminal Setting K= door lock solenoid<br />

0 FSM X8.3 not active Door lock solenoid released<br />

1 FSM X8.3 active Door lock solenoid activated<br />

The special drive signals fire, fireman mode, landing control OFF, lift off<br />

and service mode can be activated by different signal sources (e.g. ADM,<br />

FPM etc.). The sources are displayed as follows:<br />

Fig. 3.4 Signals sources of SRC display<br />

Coding of the source display:<br />

Code Code for fire signal<br />

01 ADM landing call module<br />

02 Programmable input/output of the FST-<strong>Controller</strong><br />

04 GST Group <strong>Controller</strong><br />

Code Code for fireman mode signal<br />

01 FPM car panel module, X4.4<br />

02 Programmable input/output of the FST-<strong>Controller</strong><br />

The state was saved after a power failure and has been<br />

04<br />

reconstructed.<br />

ADM landing call module<br />

08<br />

10 GST Group <strong>Controller</strong><br />

Source of “Service Mode”<br />

Source of “<strong>Lift</strong> Off”<br />

Source of “Landing Control Off”<br />

Source of “Fireman Mode”<br />

Source of “Fire Mode”<br />

24 FST-2_HB.EN12/05

Weight sensor<br />

LWE: 255% E0 F0 O0<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Code Code for landing control OFF signal<br />

� key of the FST keypad<br />

01<br />

Programmable input/output of an external RIO module<br />

02<br />

04 Input “Landing control OFF”, FST X1.15<br />

08 Programmable input/output of the FST-<strong>Controller</strong><br />

FPM car panel module, X4.34<br />

10<br />

ADM landing call module<br />

20<br />

40 Push button mode (see “Special call mode” on page 135)<br />

Code Source for lift off signal<br />

<strong>Lift</strong> off after a car light failure<br />

01<br />

02 Input “Car light OFF”, FST X1.14<br />

Programmable input/output of an external CUS module or ADM<br />

04<br />

Programmable input/output of the FST-<strong>Controller</strong> or external RIO<br />

08<br />

module<br />

External by the GST Group <strong>Controller</strong> or the LMS lift monitoring<br />

10<br />

system<br />

Code Source for service mode signal<br />

External via LMS lift monitoring system<br />

01<br />

02 TEST MENU – Service Mode ON<br />

04 Programmable input/output of the FST-<strong>Controller</strong><br />

The state of the weight sensor inputs and the loading level of the car when<br />

using analogue weight sensors is displayed as follows:<br />

Fig. 3.5 State of the weight sensor<br />

State of Input “Overload”, FSM X5.4<br />

State of Input “Full-Load”, FSM X5.3<br />

State of Input “Minimum Load”, FSM X5.2<br />

Loading Level of the Car in %<br />

(when using analogue weight sensor)<br />

“0”: Input not active<br />

“1”: Input active<br />

FST-2_HB.EN12/05 25

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

PC-Card<br />

PC:s0 m1 c0 f0 Mb005<br />

State of pawl<br />

device<br />

ASV: 0000000 P=[00]<br />

Code Description<br />

No PC-Card inserted<br />

s0<br />

s1 PC-Card inserted – card type not detected<br />

PC-Card inserted – card type detected / card OK<br />

s2<br />

PC-Card inserted – card type not detected / error<br />

s3<br />

m0 PC-Card memory type unknown<br />

m1 Card type: static RAM<br />

m2 Card type: flash memory<br />

CIS memory: no CIS found<br />

c0<br />

CIS status: CIS OK<br />

c1<br />

f0 Flash type: PC-Card unknown / unusable<br />

Flash type: AMD A28F040 – 512kB memory module<br />

f1<br />

Flash type: INTEL I28f016 – 2MB memory module<br />

f2<br />

Size of memory storage in 0.1 MB steps<br />

Mb<br />

The state of the pawl device is coded as follows:<br />

ASV: .......<br />

0<br />

Bit Setting Description<br />

(right)<br />

active Pump for bolt control ON<br />

1 active Valve “extend bolt” activated<br />

2 active Valve “retract bolt” activated<br />

3 active End switch “bolt extended” active<br />

4 active End switch “bolt retracted” active<br />

5<br />

6 active Input “re-pumping” active<br />

(left)<br />

active Input “car bottomed” active<br />

P=[..]<br />

0 Standstill<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

0<br />

1<br />

2<br />

Digit<br />

1 (right)<br />

Code Description<br />

1 (right) Main contactors ON, waiting for star-delta start-up<br />

1 (right) <strong>Lift</strong> car (approx. 30mm / 1 3/16")<br />

1 (right) Motor run-on active<br />

1 (right) Waiting for bolts to extend or retract<br />

1 (right) Bolts extended or retracted completely<br />

1 (right) Waiting for input “car bottomed”<br />

1 (right) Delay after stop<br />

2 (left) No bolt movement<br />

2 (left) Bolts are retracting<br />

2 (left) Bolts are extending<br />

26 FST-2_HB.EN12/05

Line D<br />

Drive mode messages<br />

in line D<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

P=[..]<br />

3<br />

4<br />

Digit Code Description<br />

2 (left) Re-pumping active<br />

2 (left) Error in bolt control<br />

T<br />

Column Display Description<br />

1 Auto test drive active<br />

S<br />

s<br />

{<br />

}<br />

10<br />

[13]<br />

[13<br />

13]<br />

X13<br />

13X<br />

G<br />

g<br />

R<br />

F<br />

10:44:12<br />

2<br />

No serial connection to the frequency converter<br />

(FST-2 X11)<br />

Data transmission to the frequency converter<br />

via serial connection is faulty (FST-2 X11)<br />

Direction display UP<br />

3-4 Current floor of car<br />

5-8<br />

Direction display DOWN<br />

Car and landing call to target floor<br />

9<br />

Car call to target floor<br />

Landing call to target floor<br />

Car control blocked<br />

Landing control blocked<br />

Not assigned<br />

10 FST-2 is integrated in a GST Group <strong>Controller</strong><br />

11<br />

FST-2 is integrated in a GST Group <strong>Controller</strong><br />

but communication with the GST is faulty<br />

Flashes when recording data on the PC card<br />

12 Not assigned<br />

13-20<br />

Card is cleared<br />

Current time of the FST-2<br />

FST-2_HB.EN12/05 27

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

Information texts<br />

When triggering actions in the FST menu, information texts may be<br />

displayed. They contain information about the results of the action.<br />

Display Description<br />

EMERGENCY OPERATION<br />

*!!<br />

!!*<br />

The controller is in emergency operation mode. Drives are not possible.<br />

Emergency operation is activated by pressing the � key while switching the<br />

system on.<br />

STUCK :... The landing call from the specified floor and door side is permanently activated<br />

ADM<br />

(is stuck).<br />

unconfigured! A landing call module connected to the shaft bus is not configured. Inform your<br />

ADM<br />

NEW LIFT Hotline!<br />

Reject CODE: A landing call was placed but not carried out. The code displays the reason for<br />

ADR<br />

the suppression, see “ADR Reject codes:” on page 30.<br />

INHIBIT ON! Mutual start-up blocking via the LMS bus is active. Starting will be delayed until<br />

DRIVE<br />

the networked systems have completed their acceleration phases.<br />

wait! The triggered action has not been completed. Please wait!<br />

Please<br />

SENT OK! A status fax was sent successfully via the modem interface.<br />

FAX\SMS<br />

-> GST! A fax/sms (text message) is sent to the group controller where it will be sent via<br />

FAX\SMS<br />

the FAX-modem.<br />

NOT SENT! Transmission of a status fax via the modem interface was aborted. Check<br />

FAX\SMS<br />

modem and telephone connection. MAIN MENU - Configuration<br />

See<br />

Modem\Fax\LMS<br />

-<br />

NOT FOUND! The inserted PC-Card does not contain the file(s) required for the triggered<br />

FILE<br />

action.<br />

software update The software of the FST-2 is updated with a PC-Card. The progress in [%] is<br />

FST<br />

displayed in line C.<br />

UPDATE COMPLETE! The software update of the GST Group <strong>Controller</strong> is complete.<br />

GST<br />

CAR ACTIVE... Soft priority car is waiting for standstill after the pending car call. See MAIN<br />

PRIO<br />

- Configuration - Prio-landing\car.<br />

MENUE<br />

Reject CODE: A car call was placed but not carried out. The code displays the reason for the<br />

IDR<br />

suppression, see “IDR Reject codes:” on page 30.<br />

abort! The calibration drive was aborted. Check function of connected drive speeds.<br />

Calibration<br />

Locate reason for drive abortion in the error list.<br />

SIGNAL The car is on the top floor and the correction top signal is missing (only when<br />

NO<br />

using INK – incremental positioning). Check function of KO switch. Check<br />

settings MAIN MENUE - Positioning - Increm.Positng. -<br />

in<br />

KO\KU-level.<br />

SIGNAL The car is on the bottom floor and the correction bottom signal is missing (only<br />

NO<br />

when using INK – incremental positioning). Check function of KU switch. Check<br />

settings MAIN MENUE - Positioning - Increm.Positng. -<br />

in<br />

KO\KU-level.<br />

TRANSFER ERR! An error has occurred during copying of the controller configuration.<br />

CONFIG<br />

CONFIG TRANSFER OK! <strong>Controller</strong> configuration copied successfully.<br />

CONFIG[D] CORRUPT! A parameter of the drive configuration is not plausible. Change a parameter in<br />

MAIN MENU - Drive and undo the change again. The information text<br />

disappears after saving the settings.<br />

28 FST-2_HB.EN12/05

Display Description<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

CORRUPT! A parameter of the system configuration is not plausible. Change a parameter<br />

CONFIG[S]<br />

MAIN MENU - Configuration in and undo the change again. The<br />

information text disappears after saving the settings.<br />

DRIVE FAILURE! The started learn drive was not successful. Check function of signals zone B,<br />

LEARN<br />

correction bottom and correction top.<br />

START FAILURE! The started learn drive was aborted due to the car not moving even with pre-<br />

LEARN<br />

selection active.<br />

STARTED! A DRM-test was triggered.<br />

DRM-TEST<br />

DRM-TEST FINISHED! The DRM-test was completed successfully.<br />

NUISANCE DETECT! The car nuisance protection function has triggered. See MAIN MENU -<br />

CAR<br />

- Anti Nuisance.<br />

Configuration<br />

IN THE ZONE! The started learn drive cannot be completed because the car is not in the door<br />

NOT<br />

zone. Check function of zone B signal and settings MAIN MENU -<br />

in<br />

- Increm.Positng. - ZoneB-Level.<br />

Positioning<br />

IN FLOOR-0! The started learn drive cannot be completed because the car is not on the<br />

NOT<br />

lowest floor (check correction switch bottom, KU).<br />

FROM END FLOOR! The car is at an end floor. The triggered end switch test cannot be started from<br />

NOT<br />

this floor.<br />

An alarm button was operated or is faulty (see wiring diagram).<br />

CALL<br />

EMERGENCY<br />

ACTIVATED!<br />

FROM END FLOOR! The triggered drive test can only be started from an end floor.<br />

ONLY<br />

REMOVED! The inserted PC-Card was removed from slot X8.<br />

PC-CARD<br />

FLASH TYPE?? The memory type of the inserted PC-Card is unknown. The PC-Card cannot be<br />

PC-CARD<br />

used.<br />

EMPTY! The inserted PC-Card was cleared successfully.<br />

PC-CARD<br />

LOW BATTERY! The battery voltage of the inserted PC-Card is too low. Change battery!<br />

PC-CARD<br />

OK! The inserted PC-Card has been recognized by the controller and can be used.<br />

PC-CARD<br />

TYPE????! The inserted PC-Card is not recognized by the controller and cannot be used.<br />

PC-CARD<br />

Update File Updating the software. The inserted PC-Card is checked for update files.<br />

Checking<br />

RECORDING RESTART! An already started recording was restarted.<br />

RECORDING STOPPED! Recording is stopped.<br />

RECORDING NEWSTART! A new recording is started.<br />

LEVEL! The supervisor level is accessed with a master password. It enables setting<br />

SUPERVISOR<br />

hidden parameters.<br />

FILE FOUND The file required for the software update was found on the PC-Card. The<br />

UPDATE<br />

software is updated.<br />

COMPLETE! The software update of the LON module was completed successfully.<br />

UPDATE<br />

TO RESET... Automatic RESET after changing basic parameters (e.g. Drive type). This<br />

WAITING<br />

may take a few seconds.<br />

SLIPPAGE!! During the last drive of the learn drive, hysteresis of the connected solenoid<br />

EXCESSIVE<br />

switches KO, KU and zone B was detected (only when using INK – incremental<br />

positioning). If a value greater than 10 mm is measured this message is<br />

displayed. Hysteresis will be limited to 10 mm automatically.<br />

Nudging (forced closure) of the car door is activated. Photocell and reversing<br />

DOOR-NUDGING!<br />

contacts are ignored. MAIN MENU - Doors - Doors<br />

See<br />

- Photocell and MAIN MENU - Doors - Doors<br />

Selective<br />

- Nudge Time.<br />

Selective<br />

FST-2_HB.EN12/05 29

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

ADR Reject codes:<br />

IDR Reject codes:<br />

Code Description<br />

5 Call from an unconfigured ADM<br />

6 Landing calls are currently blocked<br />

20 The call is from an unregistered door side or floor (see call menu)<br />

21 The call is currently blocked (programmable input)<br />

22 The call is currently blocked (LMS remote monitoring)<br />

24 The call is stuck<br />

Control is a push button control (not collective) and the lift is<br />

25<br />

currently occupied<br />

The call is currently blocked (MA35 control)<br />

26<br />

Code Description<br />

Anti nuisance (car is empty)<br />

10<br />

11 Anti nuisance (maximum number of car calls exceeded)<br />

20 The call is from an unregistered door side or floor (see call menu)<br />

21 The call is currently blocked (programmable input)<br />

The call is currently blocked (LMS remote monitoring)<br />

22<br />

The call is stuck<br />

24<br />

The call is currently blocked (Attika control)<br />

25<br />

Control is a push button control (not collective) and the lift is<br />

26<br />

currently occupied<br />

The call is currently blocked (MA35 control)<br />

27<br />

28 The call is currently blocked (ramp control)<br />

30 FST-2_HB.EN12/05

Information page<br />

FST-2 Information -<br />

-<br />

Ver.:14-16<br />

HW<br />

VER.:V1.100-0350<br />

SW<br />

:18\05\2005<br />

Messages in<br />

lines B, C and D<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.1 LC-Display and messages<br />

The information page contains important information on the individual<br />

configuration of your FST-2-<strong>Controller</strong>.<br />

It can be accessed with key combination �+� and closed with �. The<br />

�/� keys are used to navigate through the information page.<br />

A Information page<br />

B Hardware version 12-16 of FST-2<br />

C Software version V1.100-0350 of FST-2<br />

D Release date of the software version<br />

Display Description<br />

VER.:14-16 Hardware version of the FST-2 board<br />

HW<br />

Software version with release date<br />

Ver.:V1.100-0350<br />

SW<br />

:18\05\2005<br />

Ver:0104 Software version of the operating system<br />

Boot<br />

Ver: FSM00125 Software version of the FSM car control<br />

FSM<br />

module. If no software version is displayed<br />

here there is no bus connection to the FSM.<br />

Ver: FPM00128 Software version of the FPM car panel<br />

FPM<br />

module. If no software version is displayed<br />

here there is no bus connection to the FPM.<br />

Internal identification of the controller. The<br />

<strong>Lift</strong>ID:A<br />

ID displayed here must correspond to the<br />

jumper settings of FSM and FPM.<br />

Neuron-ID..<br />

00 22 C1 fb 00<br />

01<br />

SystemID..<br />

bench<br />

Test<br />

number..<br />

Factory<br />

RC9900234<br />

Unique ID for identification of the FST-2-<br />

<strong>Controller</strong><br />

System location or name<br />

Order number of the individual lift system<br />

Start:12\07\05 08:23 Date and time of activation<br />

:12\07\05 10:23 Date and time of last calibration drive<br />

CAL<br />

14:03 Start date and time of the current statistics<br />

STATS:27\07\05<br />

recording<br />

12:05 Date and time of the last change of a<br />

Cfg:12\07\05<br />

parameter in the FST menu<br />

12:06 Date and time of the current backup copy in<br />

CfgBk:12\07\05<br />

the internal buffer<br />

12:07 Date and time of the last reset of the error<br />

Err:12\07\05<br />

list<br />

Current security level of the FST-2<br />

Sec.Level:1<br />

FST-2_HB.EN12/05 31

3 FST-2-<strong>Controller</strong> user interface<br />

3.2 Keypad functions<br />

3.2 Keypad functions<br />

Frequency converter with DCP interface<br />

When switching on<br />

The FST-2-<strong>Controller</strong> is operated using seven keys. The keys have<br />

different functions in the different displays.<br />

�<br />

�<br />

Operation and parametrising of frequency converters with<br />

DCP interface can be done from the FST-2 menu (FST X11<br />

connected). The display of the frequency converter can be<br />

simulated on the FST-2 display by pressing the � key once.<br />

The FST-2 keys provide access to the functions of the<br />

frequency converter. The FST-2 display returns to standard<br />

mode by pressing the � key again.<br />

Pressing and holding key � during the switch-on sequence of<br />

the FST-2 starts emergency operation. In emergency<br />

operation no drives are possible. Emergency operation is<br />

required if the FST-2 cannot be switched on in normal mode<br />

due to a malfunction. The complete FST menu and the PC-<br />

Card functions are active in emergency mode!<br />

32 FST-2_HB.EN12/05

Main screen<br />

SAFETY CCT CLOSED<br />

###@###<br />

>A<<br />

13:06:56<br />

00<br />

Main menu and test menu<br />

MENU<br />

MAIN<br />

><br />

Drive<br />

Configuration<br />

>Positioning<br />

><br />

Clock setting<br />

13:45:01<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�+�<br />

�+�<br />

�+�<br />

�+�<br />

�+�<br />

�+�+�<br />

Set car call to top floor<br />

Set car call to bottom floor<br />

3 FST-2-<strong>Controller</strong> user interface<br />

3.2 Keypad functions<br />

Switch landing control on and off (switch function)<br />

Open test menu<br />

Open main menu<br />

Press before switching on and hold until the start-up sequence<br />

of the FST-2 is completed: Emergency operation is activated,<br />

see “*!! EMERGENCY OPERATION !!*” on page 28.<br />

Set car call to next floor up<br />

Set car call to next floor down<br />

Scroll through the right status messages in line C<br />

Scroll through the left status messages in line C<br />

Display information page<br />

Toggle diagnostic messages in line C on and off<br />

�+�+�+� <strong>Controller</strong> RESET<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

Move cursor up<br />

Move cursor down<br />

Exit submenu<br />

Change menu level<br />

Select submenu / menu item<br />

Increase value<br />

Decrease value<br />

Move cursor left<br />

Move cursor right<br />

Confirm settings<br />

FST-2_HB.EN12/05 33

3 FST-2-<strong>Controller</strong> user interface<br />

3.3 LEDs<br />

Error list<br />

[00037\00040]<br />

ERROR<br />

10:18:26 [012]<br />

28.09<br />

close failed<br />

Door<br />

03 V00 R01 I00<br />

FLOOR:<br />

Information page<br />

FST-2 Information -<br />

-<br />

Ver.:12-16<br />

HW<br />

VER.:V1.100-0026<br />

SW<br />

:18\05\1999<br />

3.3 LEDs<br />

�<br />

�<br />

�+�<br />

�+�<br />

�<br />

�<br />

�<br />

Switch to 2nd to 8th information byte in line D<br />

Switch to initial display in line D<br />

To previous error message<br />

To next error message<br />

Scroll one line up<br />

Scroll one line down<br />

Back to main screen<br />

Three LEDs on the front panel of the FST-2-<strong>Controller</strong> display the device<br />

status.<br />

�<br />

LED Colou<br />

r<br />

State Reason Action<br />

RUN green on The power supply is on<br />

The hardware of the FST-2-<br />

<strong>Controller</strong> is working correctly<br />

off No power Check the 24V power supply of the FST-<br />

2-<strong>Controller</strong><br />

The hardware of the FST-2-<br />

<strong>Controller</strong> is faulty<br />

Inform your NEW LIFT Hotline!<br />

STATUS green on The drive processor is working<br />

correctly<br />

flashing Landing control OFF switches landing control back on<br />

off Fault in drive processor Inform your NEW LIFT Hotline!<br />

ERROR red on Drive not possible Line B shows the reason of the error. A<br />

drive is only possible after the error has<br />

been corrected.<br />

flashing One or more errors were added to<br />

the error list<br />

off There is no error or event<br />

The ERROR LED is off after the error list<br />

has been called up.<br />

34 FST-2_HB.EN12/05

4 Technical data<br />

4 Technical data<br />

The FST-2 <strong>Lift</strong> <strong>Controller</strong> from NEW LIFT is the result of many years of<br />

product experience in the area of lift system controller design and close cooperation<br />

with various component manufacturers, technical regulatory<br />

authorities and of course our customers.<br />

The lift control system consists of the FST-2 main circuit board with user<br />

interface, electronic assemblies and cables. The individual components of<br />

the FST-2 <strong>Lift</strong> <strong>Controller</strong> are described, and dimensions, jumpers, LEDs,<br />

terminals and plugs are explained. All FST-2 components described in this<br />

manual are shown in the “FST-2-<strong>Controller</strong> component overview (bus<br />

plan)” on page 36.<br />

FST-2_HB.EN12/05 35

4 Technical data<br />

4.1 Component overview – bus plan<br />

4.1 Component overview – bus plan<br />

green<br />

( 10)<br />

blue<br />

( 7)<br />

blue<br />

( 7)<br />

blue<br />

( 7)<br />

blue<br />

( 7)<br />

blue<br />

( 7)<br />

blue<br />

( 7)<br />

FST-A<br />

A B X 4 Opt.<br />

ADM-S<br />

ADM-S<br />

ADM-S<br />

ADM-S<br />

ADM-S<br />

ADM-S<br />

ADM-S<br />

Fig. 4.1 FST-2-<strong>Controller</strong> component overview (bus plan)<br />

NEW LIFT provides an overview of the individual components known as<br />

“bus plan” that is supplied with the circuit documentation of each lift system.<br />

For each electronic assembly, installation site, associated bus and the<br />

respective LON bus cable lengths are specified in the bus plan. Each<br />

electronic assembly is clearly labelled on the circuit board. Using this<br />

labelling, the individual components can be identified on the bus plan.<br />

S/<br />

0/<br />

A/<br />

6/<br />

A<br />

S/<br />

0/<br />

A/<br />

5/<br />

A<br />

S/<br />

0/<br />

A/<br />

4/<br />

A<br />

S/<br />

0/<br />

A/<br />

3/<br />

A<br />

S/<br />

0/<br />

A/<br />

2/<br />

A<br />

S/<br />

0/<br />

A/<br />

1/<br />

A<br />

S/<br />

0/<br />

A/<br />

0/<br />

A<br />

36 FST-2_HB.EN12/05<br />

0,<br />

5<br />

trailing cable 32,5 m<br />

FSM<br />

FPM<br />

IK<br />

IK<br />

Example:<br />

type/bus/door/floor/FST<br />

S / 0 / A / 0 / A<br />

Legend<br />

:<br />

IK = Inspection Cabinet<br />

FK = car / COP<br />

Hose with colour code<br />

on the bus cable ends:<br />

0,<br />

5m<br />

= sw<br />

= schwarz=<br />

black<br />

1,<br />

0m<br />

= rt<br />

= rot<br />

= red<br />

3,<br />

0m<br />

= ws<br />

= weiss<br />

= white<br />

5,<br />

0m<br />

= ge<br />

= gelb<br />

= yellow<br />

7,<br />

0m<br />

= bl<br />

= blau<br />

= blue<br />

10,<br />

0m<br />

= gn<br />

= grün<br />

= green<br />

15,<br />

0m<br />

= sw<br />

= schwarz=<br />

black<br />

20,<br />

0m<br />

= rt<br />

= rot<br />

= red

4.2 FST-2-<strong>Controller</strong><br />

4 Technical data<br />

4.2 FST-2-<strong>Controller</strong><br />

All common types of cable and hydraulic lifts can be operated using the<br />

FST-2-<strong>Controller</strong>. The pre-assembled FST-2-<strong>Controller</strong> can easily be<br />

adapted to any individual lift system on site using the FST menu. <strong>New</strong><br />

software versions can be installed at any time via the PC-Card slot without<br />

changing system-specific settings.<br />

Components and features of the FST-2-<strong>Controller</strong>:<br />

Components:<br />

- FST-2 main circuit board with separate processors for call processing,<br />

drive control and bus management<br />

- Integrated repeater for electrical isolation of shaft bus and car bus<br />

- RS-585 / RS-422 / RS-232 controller interfaces for communication with<br />

drive regulators<br />

- Encoder interface for connecting common absolute value and<br />

incremental encoders<br />