Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Lufthansa Consulting<br />

38<br />

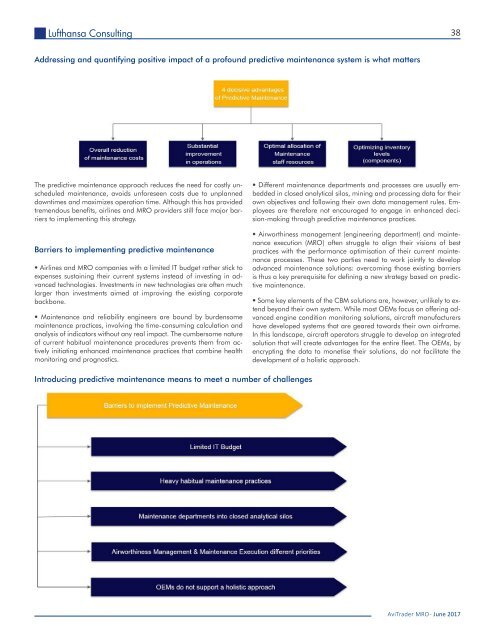

Addressing and quantifying positive impact of a profound predictive maintenance system is what matters<br />

The predictive maintenance approach reduces the need for costly unscheduled<br />

maintenance, avoids unforeseen costs due to unplanned<br />

downtimes and maximizes operation time. Although this has provided<br />

tremendous benefits, airlines and <strong>MRO</strong> providers still face major barriers<br />

to implementing this strategy.<br />

Barriers to implementing predictive maintenance<br />

• Airlines and <strong>MRO</strong> companies with a limited IT budget rather stick to<br />

expenses sustaining their current systems instead of investing in advanced<br />

technologies. Investments in new technologies are often much<br />

larger than investments aimed at improving the existing corporate<br />

backbone.<br />

• Maintenance and reliability engineers are bound by burdensome<br />

maintenance practices, involving the time-consuming calculation and<br />

analysis of indicators without any real impact. The cumbersome nature<br />

of current habitual maintenance procedures prevents them from actively<br />

initiating enhanced maintenance practices that combine health<br />

monitoring and prognostics.<br />

• Different maintenance departments and processes are usually embedded<br />

in closed analytical silos, mining and processing data for their<br />

own objectives and following their own data management rules. Employees<br />

are therefore not encouraged to engage in enhanced decision-making<br />

through predictive maintenance practices.<br />

• Airworthiness management (engineering department) and maintenance<br />

execution (<strong>MRO</strong>) often struggle to align their visions of best<br />

practices with the performance optimisation of their current maintenance<br />

processes. These two parties need to work jointly to develop<br />

advanced maintenance solutions: overcoming those existing barriers<br />

is thus a key prerequisite for defining a new strategy based on predictive<br />

maintenance.<br />

• Some key elements of the CBM solutions are, however, unlikely to extend<br />

beyond their own system. While most OEMs focus on offering advanced<br />

engine condition monitoring solutions, aircraft manufacturers<br />

have developed systems that are geared towards their own airframe.<br />

In this landscape, aircraft operators struggle to develop an integrated<br />

solution that will create advantages for the entire fleet. The OEMs, by<br />

encrypting the data to monetise their solutions, do not facilitate the<br />

development of a holistic approach.<br />

Introducing predictive maintenance means to meet a number of challenges<br />

<strong>AviTrader</strong> <strong>MRO</strong> - June <strong>2017</strong>