The Hydraulic Material Handler for Economical ... - Passion-Liebherr

The Hydraulic Material Handler for Economical ... - Passion-Liebherr

The Hydraulic Material Handler for Economical ... - Passion-Liebherr

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

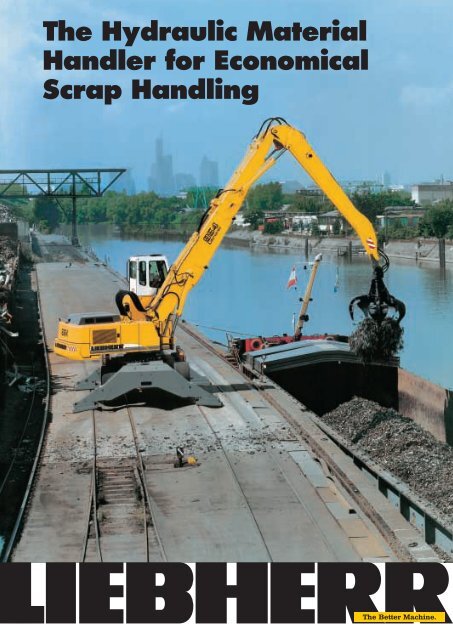

<strong>The</strong> <strong>Hydraulic</strong> <strong>Material</strong><br />

<strong>Handler</strong> <strong>for</strong> <strong>Economical</strong><br />

Scrap Handling<br />

<strong>The</strong> Better Machine.

<strong>Liebherr</strong> material handling machines are in<br />

operation in scrap yards worldwide. You determine<br />

the job specifications and we supply the<br />

technology, tailor made <strong>for</strong> the application at<br />

hand and working conditions.<br />

Whether on a wheeled or crawler undercarriage,<br />

stationary or pedestal mounted,<br />

finding the right machine <strong>for</strong> the job is critical<br />

<strong>for</strong> modern, economical scrap handling.<br />

When handling different types of scrap, the<br />

selection of the appropriate attachment is a<br />

prerequisite <strong>for</strong> an efficient operation. <strong>Liebherr</strong><br />

offers a wide selection of boom types, different<br />

stick lengths and various tools like clamshells<br />

and high per<strong>for</strong>mance magnets.<br />

<strong>The</strong> <strong>Liebherr</strong> material handling machines are<br />

designed <strong>for</strong> stable operation even under the<br />

most extreme working conditions and provide a<br />

solid basis <strong>for</strong> per<strong>for</strong>mance and economy.<br />

A Variety of Machines <strong>for</strong> a Variety of Ap<br />

2

plications.<br />

3

<strong>Hydraulic</strong> excavator A 316 A 904 A 904 A 914 A 924<br />

litronic` Industry litronic` litronic` litronic` Operating weight t 18,9 – 21,0 19,9 – 22,0 17,7 – 22,0 18,5 – 23,0 20,4 – 25,0<br />

lb 41700 – 46300 43900 – 48500 39000 – 48500 40800 – 50700 45000 – 55100<br />

Engine output kW/HP 86/117 85/116 99/135 112/152 112/152<br />

Width of undercarriage m 2,50 2,50 2,50 2,50 2,75<br />

ft-in 8’2” 8’2” 8’2” 8’2” 9’0”<br />

Width over outriggers m 3,80 4,00 4,00 4,00 4,25<br />

ft-in 12’5” 13’1” 13’1” 13’1” 13’11”<br />

Length of boom/stick m 5,50/4,00 6,50/5,00 6,50/5,00 6,80/5,00 6,80/6,00<br />

ft-in 18’0”/13’1” 21’4”/16’5” 21’4”/16’5” 22’3”/16’5” 22’3”/19’8”<br />

A m 10,00 11,20 11,20 11,50 12,50<br />

ft-in 32’9” 36’8” 36’8” 37’8” 41’0”<br />

H m 10,00 12,40 12,40 12,90 13,80<br />

ft-in 32’9” 40’8” 40’8” 42’3” 45’3”<br />

T m 2,50 3,00 3,00 3,25 4,25<br />

ft-in 8’2” 9’10” 9’10” 10’8” 13’11”<br />

Clamshell model 55 65 65 65 65<br />

Capacity m3 0,40 0,60 0,60 0,60 0,60<br />

cuyd 0,52 0,80 0,80 0,80 0,80<br />

Overall height (closed) m 1,75 2,15 2,15 2,15 2,15<br />

ft-in 5’9” 7’0” 7’0” 7’0” 7’0”<br />

Weight kg 1080 1420 1420 1420 1420<br />

lb 2370 3100 3100 3100 3100<br />

Max. lift capacity t 12,5 16,0 16,1 16,2 18,9<br />

lb 27560 35200 35500 35750 41700<br />

All lift capacities are stated in metric tonnes. Indicated loads are based on ISO 10567 and do not exceed 75 % of tipping or<br />

87 % of hydraulic capacity. Machine on firm, level supporting surface, indicated loads can be lifted 360h.<br />

Lift capacities do not include the weight of a grapple and/or magnet, which must be reduced from the above figures.<br />

Load point is the end of the stick.<br />

Wheeled Scrap Handling Machines.<br />

4

H<br />

T<br />

<strong>Hydraulic</strong> excavator A 934 A 934 HD A 944 HD A 954 B HD A 974 B<br />

litronic ` litronic ` litronic ` litronic ` litronic `<br />

Operating weight t 29,3 – 31,3 35,5 – 37,5 49,4 – 51,2 63,0 – 65,0 111,0 – 113,0<br />

lb 64600 – 69000 43900 – 48500 108900 – 112900 138900 – 143300 244800 – 249200<br />

Engine output kW/HP 137/186 137/186 164/223 210/286 317/431<br />

Width of undercarriage m 3,00 3,00 3,30 3,65 4,10<br />

ft-in 9’10” 9’10” 10’10” 11’11” 13’5”<br />

Width over outriggers m 4,70 4,95 5,35 5,70 6,85<br />

ft-in 15’5” 16’3” 17’6” 18’8” 22’5”<br />

Length of boom/stick m 8,50/7,50 8,50/7,50 9,00/7,80 10,30/8,00 12,00/9,00<br />

ft-in 27’10”/24’7” 27’10”/24’7” 29’6”/25’7” 33’9”/26’3” 39’4”/29’6”<br />

A m 15,20 15,40 16,70 18,00 21,00<br />

ft-in 49’10” 50’6” 54’9” 59’0” 68’10”<br />

H m 16,80 17,00 18,00 19,20 23,00<br />

ft-in 55’1” 55’9” 59’0” 62’11” 75’5”<br />

T m 4,60 4,10 5,00 5,40 6,00<br />

ft-in 15’1” 13’5” 16’5” 17’8” 19’8”<br />

Clamshell model 70 C 70 C 72 B 72 B 75<br />

Capacity m 3 0,80 1,10 1,20 1,40 2,00<br />

cuyd 1,05 1,45 1,60 1,80 2,60<br />

Overall height (closed) m 2,40 2,40 3,00 3,00 3,00<br />

ft-in 7’10” 7’10” 9’10” 9’10” 9’10”<br />

Weight kg 1710 1830 2650 2700 3230<br />

lb 3770 4035 5850 5950 7100<br />

Max. lift capacity t 17,8 18,8 22,4 26,5 32,3<br />

lb 39250 41450 49400 58400 71200<br />

For further in<strong>for</strong>mations see the latest specification sheet <strong>for</strong> the respective machine.<br />

A<br />

5

Crawler Scrap Handling Machines.<br />

6<br />

<strong>Hydraulic</strong> excavator R 904 R 914 R 924 R 934 R 944<br />

litronic ` litronic ` litronic ` litronic ` litronic `<br />

Operating weight t 21,0 – 22,0 23,3 – 24,3 24,5 – 27,8 28,9 – 31,2 36,4 – 39,4<br />

lb 46300 – 48500 51400 – 53600 54000 – 61300 63700 – 68800 80260 – 86900<br />

Engine output kW/HP 92/125 105/143 112/152 137/186 164/223<br />

* Width of undercarriage m 2,75 – 3,60 3,00 – 3,85 3,00 – 4,15 3,15 – 4,15 3,15 – 4,35<br />

ft-in 9’0” – 11’9” 9’10” – 12’7” 9’10” – 13’7” 10’4” – 13’7” 10’4” – 14’3”<br />

Length of boom/stick m 6,50/4,00 6,80/5,00 6,80/5,00 7,00/6,00 7,70/6,00<br />

ft-in 21’4”/13’1” 22’3”/16’5” 22’3”/16’5” 22’11”/19’8” 25’3”/19’8”<br />

A m 10,20 11,50 11,50 12,60 13,50<br />

ft-in 33’5” 37’8” 37’8” 41’4” 44’3”<br />

H m 11,40 12,80 12,80 13,00 15,00<br />

ft-in 37’4” 41’11” 41’11” 42’7” 49’2”<br />

T m 2,20 3,50 3,50 3,40 3,90<br />

ft-in 7’2” 11’5” 11’5” 11’2” 12’9”<br />

Grapple model 65 65 70 C 70 C 70 C<br />

Capacity m 3 0,40 0,60 0,80 0,80 1,10<br />

cuyd 0,52 0,80 1,05 1,05 1,44<br />

Overall height (closed) m 1,95 2,15 2,40 2,40 2,40<br />

ft-in 6’5” 7’0” 7’10” 7’10” 7’10”<br />

Weight kg 1340 1450 1710 1710 1830<br />

lb 2950 3200 3770 3770 4035<br />

Max. lift capacity t 10,9 11,5 13,7 18,2 20,7<br />

lb 24000 25350 30200 40150 45600<br />

* Depending on undercarriage version and width of pads<br />

All lift capacities are stated in metric tonnes. Indicated loads are based on ISO 10567 and do not exceed 75 % of tipping or<br />

87 % of hydraulic capacity. Machine on firm, level supporting surface, indicated loads can be lifted 360h.<br />

Lift capacities do not include the weight of a grapple and/or magnet, which must be reduced from the above figures.<br />

Load point is the end of the stick.

H<br />

T<br />

<strong>Hydraulic</strong> excavator R 954 B R 964 B R 974 B R 984 C<br />

litronic ` litronic ` litronic ` litronic `<br />

Operating weight t 50,9 – 61,0 65,8 – 70,2 83,3 – 91,5 125<br />

lb 112200 – 134500 145100 – 154800 183650 – 201700 275600<br />

Engine output kW/HP 210/286 270/367 360/490 504/685<br />

* Width of undercarriage m 3,45 – 4,55 3,80 – 4,55 4,35 – 5,25 5,85<br />

ft-in 11’2” – 14’11” 12’5” – 4’6” 14’3” – 17’2” 19’2”<br />

Length of boom/stick m 8,80/7,00 9,50/6,70 12,00/9,00 12,00/9,00<br />

ft-in 28’10”/22’11” 31’2”/21’11” 39’4”/29’6” 39’4”/29’6”<br />

A m 15,40 16,10 20,90 20,70<br />

ft-in 50’6” 52’9” 68’6” 67’10”<br />

H m 16,30 17,40 22,00 22,20<br />

ft-in 53’5” 57’1” 72’2” 72’10”<br />

T m 5,10 4,90 6,90 6,40<br />

ft-in 16’8” 16’1” 22’7” 21’0”<br />

Grapple model 72 B 72 B 75 85<br />

Capacity m 3 1,40 1,60 1,60 2,40<br />

cuyd 1,85 2,10 2,10 3,15<br />

Overall height (closed) m 3,00 3,00 2,90 3,40<br />

ft-in 9’10” 9’10” 9’6” 11’2”<br />

Weight kg 2690 2720 3230 5700<br />

lb 5930 6000 7120 12570<br />

Max. lift capacity t 25,9 34,4 24,1 30,9<br />

lb 57100 75800 53100 68100<br />

For further in<strong>for</strong>mations see the latest specification sheet <strong>for</strong> the respective machine.<br />

A<br />

7

Optimal visibility of the working area is ensured<br />

through the elevated cab. <strong>Liebherr</strong> offers<br />

different cab elevations, the most com<strong>for</strong>table<br />

version being the hydraulically adjustable cab.<br />

<strong>The</strong> cab is mounted on a parallelogram linkage,<br />

which can be adjusted steplessly. <strong>The</strong> operator<br />

can choose the cab height and adjust it anytime<br />

within the elevation range.<br />

A protective guard can be mounted onto the<br />

front windshield to protect the operator, without<br />

restricting the opening of the front windshield.<br />

<strong>Hydraulic</strong> Cab Elevation.<br />

8

A fixed cab elevation is provided by intermediate<br />

sections between the upper deck and<br />

the cab. <strong>Liebherr</strong> offers various intermediate<br />

sections depending on the task at hand and<br />

customer specifications. <strong>The</strong> operator’s eye<br />

level can be elevated by 800, 1200 or 1500 mm.<br />

A strong cab protection is available to protect<br />

the operator and the cab.<br />

Fixed Cab Elevation.<br />

9

Multi-tine Grapples <strong>for</strong> Scrap Handling<br />

316 litronic `<br />

904 Industry<br />

904 litronic `<br />

914 litronic `<br />

924 litronic `<br />

934 litronic `<br />

944 litronic `<br />

954 B litronic `<br />

964 B litronic `<br />

974 B litronic `<br />

984 C litronic `<br />

992 litronic `<br />

Model<br />

55 64 65 69 70 C 71 72 B 75 85 95<br />

Scrap Handling with Grapple.<br />

10<br />

<strong>Liebherr</strong> offers a wide range of clamshells<br />

<strong>for</strong> every machine type. Multi-tine grapples<br />

were developed <strong>for</strong> industrial scrap handling.<br />

Sturdy construction, excellent stability and<br />

high shell closing <strong>for</strong>ce are all necessary in<br />

order to meet the tough demands of scrap<br />

handling. A large capacity and a low grapple<br />

weight guarantee a high payload resulting in<br />

economical scrap handling.

Magnets are used to load, clean-up or sort ferromagnetic metals – steels and alloys containing a<br />

certain amount of manganese. <strong>The</strong> magnet requires power, which is supplied by a unit installed in<br />

the hydraulic excavator consisting of a generator, a switching device and a monitoring device.<br />

<strong>The</strong> size of the magnets depends on the load capacity of the scrap handling machine and the<br />

specific weight of the metal to be handled.<br />

In order to ensure safe operation in the entire swing area of the scrap handler, the magnet’s<br />

operating weight should never exceed half of the machine’s maximum lifting capacity at full utilization.<br />

Scrap Handling with Magnet.<br />

11

LIEBHERR-HYDRAULIKBAGGER GMBH, D-88457 Kirchdorf/Iller, ç (0 73 54) 80-0, Fax (0 73 54) 80-72 94<br />

www.liebherr.com, E-Mail: info@lhb.liebherr.com<br />

With compliments:<br />

LHB/VF 8420680-2-01.02 Printed in Germany by Eberl. Subject to change without notice.