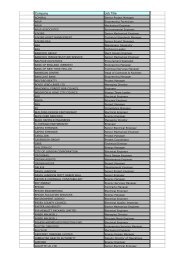

WIP - July - Global Media Publishing Ltd. - UK.com

WIP - July - Global Media Publishing Ltd. - UK.com

WIP - July - Global Media Publishing Ltd. - UK.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.gmp.uk.<strong>com</strong>/power<br />

PROMOTING ON-SITE POWER AND COGENERATION<br />

WORLDWIDE INDEPENDENT POWER<br />

Teaching industry<br />

JUNE 2009

We’ve addressed some<br />

fundamental principles<br />

when designing our<br />

new Genset engines.<br />

Reduced size. Increased power. Lower cost.<br />

The new Genset engines from DEUTZ deliver exceptional<br />

performance, reliability and value for money.<br />

With outputs ranging from 15kVA to 500kVA in a <strong>com</strong>pact<br />

footprint, these engines meet relevant industry emissions<br />

legislation and even include an option which runs on natural<br />

fuel (crude rape oil). And, through our engineering ingenuity<br />

we’ve also managed to reduce the cost of purchasing,<br />

handling and logistics.<br />

Have we generated some interest?<br />

Visit www.deutzuk.<strong>com</strong><br />

Driven.

Editor:<br />

Aidan Turnbull<br />

powereditorial@gmp.uk.<strong>com</strong><br />

Sales Director:<br />

Neb Saric<br />

nsaric@gmp.uk.<strong>com</strong><br />

Publisher:<br />

Richard Teasdale<br />

rteasdale@gmp.uk.<strong>com</strong><br />

Journal Assistant:<br />

Zoë Taylor<br />

ztaylor@gmp.uk.<strong>com</strong><br />

Accounts Division:<br />

Sally Gasson<br />

accounts@gmp.uk.<strong>com</strong><br />

Far East Sales:<br />

C H Park,<br />

Far East Marketing Inc<br />

femchp@unitec.co.kr<br />

German/Danish/Swedish Sales:<br />

Mario Dobresko<br />

mdobresko@gmp.uk.<strong>com</strong><br />

Russia Sales:<br />

Sergy Stanovkin<br />

stanovkin@dars.ru<br />

US Sales & Subscriptions:<br />

Alex Carter<br />

acarter@gmp.uk.<strong>com</strong><br />

Asia-Pacific Correspondent:<br />

John Goss<br />

john.goss@ceejay.<strong>com</strong>.hk<br />

Contributors<br />

Christopher Hopkins; Wartsila; GE<br />

Energy Centrax; Man-Diesel; Cummins<br />

Power Generation; Siemens; BWE;<br />

Rolls Royce; Electrawinds<br />

Published by:<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><br />

<strong>Global</strong> House, 13 Market Square,<br />

Horsham, West Sussex, RH12 1EU,<br />

<strong>UK</strong>. Tel: +44 (0)1403 220750<br />

Fax: +44 (0)1403 220751<br />

Website: www.gmp.uk.<strong>com</strong><br />

© Worldwide Independent Power<br />

(ISSN 1468-7100).<br />

Subscription price £120 (<strong>UK</strong>),<br />

£180 (overseas) per year.<br />

Please send address changes to<br />

Worldwide Independent Power,<br />

<strong>Global</strong> House, 13 Market Square,<br />

Horsham, RH12 1EU, <strong>UK</strong>.<br />

Printed by Manor Creative, <strong>UK</strong><br />

Auditors: ABC application<br />

approved October 2006<br />

In the next issue<br />

• CHP & heat exchangers<br />

• Gas turbines<br />

• Filtration & blading<br />

• Controls & monitoring<br />

• Alternators<br />

• Turnkey Projects<br />

GMP<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><br />

J u n e 2 0 0 9<br />

C O N T E N T S<br />

CHP 14<br />

Considered especially suitable for mid-merit operations, the<br />

latest Centrax Trent 60 generating sets are destined for<br />

France, reports <strong>WIP</strong>.<br />

Cogeneration 16<br />

Aidan Turnbull reports on a recent visit to Electrawinds<br />

Biomass Mouscron, one of Belgium’s most advanced<br />

cogeneration plants based on biofuels.<br />

Benelux Report 20<br />

Belgium, the Netherlands and Luxembourg have all installed<br />

new industrial cogeneration systems designed to boost energy<br />

efficiency and reduce greenhouse gases.<br />

Gen-sets in Italy 22<br />

Renato Bruno is the Director General for Bruno Generators. He<br />

spoke to <strong>WIP</strong> about Italy's need for effective gen-sets.<br />

Gen-set reliability 24<br />

Reliable reserve power capability is necessary to ensure<br />

efficiency of supply, explains Dr.Jacob Klimstra of Wärtsilä.<br />

Maintenance/repair 28<br />

Report on the Herningværket CHP plant, an example of a CHP<br />

installation which produces energy economically thanks to<br />

regular maintenance & upgrading.<br />

Training 30<br />

A high speed diesel generator technology course to teach<br />

professionals has been developed by Cummins.<br />

Gas engines 31<br />

Blending improved cooler cycles with aeroderivative gasturbine<br />

technology isn’t easy - but it has been done, says GE.<br />

R E G U L A R S<br />

Power news from around the world 6<br />

Sharewatch 12<br />

PROMOTING ON-SITE POWER AND COGENERATION<br />

WORLDWIDE INDEPENDENT POWER<br />

JUNE 2009<br />

Teaching<br />

Teaching industry industry<br />

Cummins’ European HQ in Ramsgate,<br />

Kent, <strong>UK</strong>, is running new training courses<br />

for those involved in specifying and<br />

designing diesel generator systems.<br />

[Pic: Cummins Power Generation <strong>Ltd</strong>.]<br />

Biofuels - Mouscron, Belgium.<br />

See Page 16.<br />

Benelux Report<br />

See Page 20.<br />

Our power portfolio includes:<br />

8-10 June - NEC - Birmingham<br />

IP&EE2010<br />

Independent Power & Energy Europe

����������������������������<br />

���������<br />

���������������������������������<br />

EUROPE’S PREMIER EXHIBITION FOR<br />

INDEPENDENT POWER & ENERGY EUROPE<br />

Networking Event for the Stand-By Power & Energy Sector<br />

8-10 JUNE 2010 2010<br />

HALL 2 - BIRMINGHAM NEC, NE , <strong>UK</strong><br />

Co-located<br />

with:<br />

Electrex<br />

Sponsored<br />

By:<br />

www.gmp.uk.<strong>com</strong>/power<br />

www.gmp.uk.<strong>com</strong>/power<br />

GMP<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><br />

<strong>Media</strong><br />

Partner:<br />

W O R L D W I D E I N D E P E N D E N T P O W E R<br />

For Further Details, please contact:<br />

Neb Saric or Richard Teasdale at <strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> Limited<br />

<strong>Global</strong> House, 13 Market Square, Horsham, West Sussex, RH12 1EU, <strong>UK</strong><br />

Tel: +44 (0) 1403 220750 Fax: +44 (0) 1403 220764<br />

E-mail: power@gmp.uk.<strong>com</strong>

WELCOME<br />

A warm wel<strong>com</strong>e to this month’s<br />

issue of Worldwide Independent<br />

Power - as always bringing you<br />

closer to the stories and issues<br />

affecting on-site power and<br />

cogeneration around the world.<br />

For editorial <strong>com</strong>ments, please do<br />

not hesitate to contact the editor.<br />

BIENVENUE<br />

Soyez le bienvenu à cette issue de<br />

Worldwide Independent Power.<br />

Comme d'habitude, nous vous<br />

apportons toujours plus près des<br />

sujets qui affectent l'énergie et la<br />

co-generation sur place autour du<br />

monde.<br />

N'hésitez pas contacter le<br />

rédacteur pour des <strong>com</strong>mentaires<br />

éditoriaux.<br />

WILLKOMMEN<br />

Herzlich Willkommen zur Ausgabe<br />

dieses Monates von Worldwide<br />

Independent Power. Wie immer<br />

bringen wir Sie näher heran an die<br />

Ereignisse und Geschichten der<br />

Stromerzeugungsindustrie rund um<br />

die Welt.<br />

Für redaktionelle Kommentare und<br />

Anregungen wenden Sie sich bitte<br />

an den Autor.<br />

BIENVENIDO<br />

Bienvenido a esta edición de<br />

Worldwide Independent Power.<br />

Como siempre, acercándolo a los<br />

temas que afectan a la energía y a<br />

la cogeneración in-situ. No dude<br />

en contactar con nuestro editor<br />

para cualquier cuestión editorial.<br />

BENVENUTI<br />

Benvenuti a questa nuova edizione<br />

di Worldwide Independent Power.<br />

Come sempre cercheremo di<br />

offrirvi storie e questioni<br />

riguardanti on-site power e<br />

cogeneration a livello globale. Per<br />

<strong>com</strong>menti editoriali, si prega di<br />

contattare l'editore.<br />

Aidan Turnbull<br />

Editor<br />

W ORLDWIDE I NDEPENDENT P OWER • JUNE 2009<br />

EDITOR’S LETTER<br />

Is the cheap energy dream over?<br />

Economic reports suggest that global energy consumption will increase by 44% between 2006<br />

and 2030, driven by strong long-term economic growth in the developing nations of the world.<br />

This is the conclusion of a study from the ‘International Energy Outlook 2009"’(IEO2009)<br />

released by the Energy Information Administration (EIA). While world energy demand in the near<br />

term has slumped slightly as a result of the global economic downturn, most countries already<br />

anticipate that energy consumption growth rates will return to pre-recession levels within a very<br />

few years. China isn’t even waiting for this to happen - it appears to be forging ahead to meet<br />

future demand by building at least one new power plant every week.<br />

If you are into big numbers, here are some for you. Total world energy use is predicted to rise<br />

from 472 quadrillion British thermal units (Btu) in 2006 to 552 quadrillion Btu in 2015 - and then to<br />

678 quadrillion Btu in 2030. As a consequence of this the costs behind energy production have to<br />

<strong>com</strong>e down. What this means is that over the next few years as prices rise, it is the relatively<br />

cheap, unconventional resources - such as extra-heavy oil, coal-to-liquids, and gas-to-liquids, oil<br />

sands and biofuels such as rapeseed oil and fats derived from animals - which could be fuelling<br />

more of the power stations of the future.<br />

Certainly, from examples on the Continent, tallow made from rendered-down cow carcases<br />

appears to be working out as a renewable and ‘green’ energy resource. See page 25 for our full<br />

report on the Mouscron Biomass co-gen plant example in Belgium. Currently producing 18MW of<br />

‘green energy’ - enough to meet the needs of 44,000 families and offer further profit from<br />

recoverable ‘waste’ heat. Its operators suggest that a plant like this can reduce CO2 emissions by<br />

66,000 tonnes a year. The EIA believes that world production of unconventional resources - which<br />

totalled 3.1 million barrels per day in 2006 - will expand to an amazing 13.4 million barrels per day<br />

in 2030 - which represents 13% of total world liquids supply in 2030.<br />

EU Commissioner for Energy, Andris Piebalgs, believes that research and development into<br />

alternative power generation systems along these lines is crucial and reflects the energy and<br />

climate change policies set by the EU. Clearly, the EU has a sort of 20:20 vision.<br />

By 2020 - Piebalgs says - the EU will seek to reduce energy usage across Europe by 20% while - at<br />

the same time - boosting renewable energy to 20% of the EU’s overall final energy consumption.<br />

Greenhouse gas emissions in Europe are also projected to be cut by 20%.<br />

“Making energy systems more sustainable and secure is one of the greatest challenges for Europe.<br />

The potential is definitely there. It is now essential to unlock it and find appropriate ways to work<br />

for industry, research and government to work together to achieve our <strong>com</strong>mon targets,” he says.<br />

This kind of approach would appear to be the way forward to achieving EU Energy and Climate<br />

Change Policy objectives as well as reducing the costs involved with producing energy at affordable<br />

prices. But will it actually happen by 2020? Watch this space.<br />

EUROPE ASIA-PACIFIC MIDDLE EAST<br />

AFRICA AMERICAS<br />

5

6<br />

In brief...<br />

9,000 engineers<br />

needed<br />

The network <strong>com</strong>panies<br />

which transport Britain's<br />

electricity and gas from<br />

source to user will need<br />

to recruit up to 9,000<br />

engineers over the next<br />

five years, a cross party<br />

group of MPs was told. Up<br />

to 6,000 new engineers<br />

will be directly employed<br />

by the electricity<br />

distribution network<br />

operators (DNOs) and gas<br />

distribution networks<br />

(GDNs), while 3,000 more<br />

jobs will need to be filled<br />

by <strong>com</strong>panies in the supply<br />

chain, according to<br />

the <strong>com</strong>panies' industry<br />

body, the Energy Networks<br />

Association (ENA).<br />

Contract for Foster<br />

Wheeler<br />

Foster Wheeler AG has<br />

announced that its<br />

Milan-based subsidiary<br />

Foster Wheeler Italiana<br />

S.p.A, part of its <strong>Global</strong><br />

Engineering and<br />

Construction Group, has<br />

been awarded a contract<br />

by the Rotterdam Climate<br />

Initiative (RCI) for the<br />

provision of engineering<br />

consultancy services<br />

related to RCI's planned<br />

carbon capture, storage<br />

and utilisation solution in<br />

the Rotterdam region.<br />

Cogeneration<br />

contract for Spain<br />

DETISA, an energy<br />

supplier owned by major<br />

Spanish oil <strong>com</strong>pany<br />

CEPSA, has selected GE<br />

Energy's gas turbine<br />

technology for a new<br />

cogeneration project in<br />

San Roque, Cádiz, Spain.<br />

GE will supply a Frame 6B<br />

gas turbine-generator for<br />

the Lubrisur Cogeneration<br />

Plant serving the energy<br />

requirements of the<br />

Gibraltar-San Roque<br />

refinery, with excess<br />

electricity to be sold to<br />

the Spanish grid. The<br />

plant has a capacity of 42<br />

megawatts of power and<br />

also will produce steam to<br />

be used for refinery<br />

processes. Cogeneration is<br />

a growing trend in Spain,<br />

where the government is<br />

pushing for energy<br />

savings, reduced grid<br />

losses and reduced greenhouse<br />

gas emissions.<br />

NEWS<br />

Manchester gets 2nd ENER-G factory<br />

The sustainable power business ENER-G has opened<br />

an additional factory in Salford, Greater Manchester,<br />

to keep pace with worldwide demand for its<br />

renewable and energy efficient technologies. This<br />

means the <strong>com</strong>pany can increase production of its<br />

<strong>com</strong>bined heat and power (CHP) and biogas<br />

generator units by 50% - to meet orders from across<br />

the globe.<br />

Last year the fast-growing business doubled its<br />

original manufacturing space by opening a second<br />

factory in Salford and it has now trebled its original<br />

manufacturing space to 34,000 sq ft, by converting<br />

an adjacent building. ENER-G will train its factory<br />

team in lean manufacturing techniques to introduce<br />

smarter working practices and processes that will<br />

boost efficiency and ensure faster turnaround of<br />

customer orders. As such, initial growth will be<br />

absorbed by existing staff, but new jobs will be<br />

created as production increases further.<br />

ENER-G's CHP systems create electricity and heat<br />

simultaneously and reduce carbon emissions by<br />

around 20% while cutting electricity costs by<br />

approximately one third. They are used by the<br />

British Royal family at Buckingham Palace and<br />

Windsor Castle, as well as in hospitals, hotels,<br />

leisure centres, supermarkets, factories and other<br />

buildings worldwide.<br />

They can be powered by natural gas or renewable<br />

biogases and ENER-G has installed and operates in<br />

excess of 120MW of biogas generation, primarily<br />

from landfill gas. It also applies its technology to<br />

anaerobic digestion, with a number of high profile<br />

projects at wastewater treatment plants such as a<br />

4.5MW biogas cogeneration project in Budapest.<br />

ENER-G helped pioneer CHP technology 25 years<br />

ago. Since then, the <strong>com</strong>pany has used its advanced<br />

technologies to assist organisations across the world<br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER<br />

in reducing their carbon emissions by millions of<br />

tonnes. Energos, which has recently opened one of<br />

its clean energy recovery facilities on the Isle of<br />

Wight and has six other plants in Europe, is<br />

currently rolling out its advanced conversion process<br />

throughout the <strong>UK</strong>. It will start construction on new<br />

facilities in Scotland, Lincolnshire, Merseyside and<br />

Newport over the next 12 months - with further<br />

developments planned in Londonderry and<br />

Derbyshire. Another facility is already under<br />

construction in Sarpsborg, Norway.<br />

Derek Duffill, group managing director, said:<br />

"ENER-G is a fine example of <strong>UK</strong> engineering and<br />

technological excellence. Our innovative products<br />

and services are in demand across the globe -<br />

fuelling our ongoing growth and reflected in our<br />

turnover of £90 million which has grown four-fold<br />

over the past six years. We have 701 employees<br />

worldwide and operating <strong>com</strong>panies in the <strong>UK</strong>,<br />

Hungary, the Netherlands, Lithuania, Norway and<br />

Poland, plus joint ventures in South Africa, Mexico<br />

and Spain."<br />

More information? Visit: www.energ.co.uk<br />

Energy consumption predicted to rise<br />

worldwide over the next 21 years<br />

Worldwide industrial energy<br />

consumption is expected to grow<br />

from 175 quadrillion Btu in 2006<br />

to 246 quadrillion Btu in 2030,<br />

says a report - International<br />

Energy Outlook 2009 (IEO2009)<br />

released by the Energy<br />

Information Administration (EIA).<br />

Industrial energy demand varies<br />

across regions and countries of the<br />

world, based on levels and mixes<br />

of economic activity and technological<br />

development, among other<br />

factors. About 94 percent of the<br />

world increase in industrial sector<br />

energy consumption is projected<br />

to occur in the emerging<br />

economies, where-driven by rapid<br />

economic growth-industrial energy<br />

consumption grows at an average<br />

annual rate of 2.1 percent in the<br />

reference case. The key engines<br />

of growth in the projection are<br />

the so-called "BRIC" countries<br />

(Brazil, Russia, India, and China),<br />

[Left] Industry needs are<br />

hotting up globally, says IEA.<br />

which account for more than twothirds<br />

of the developing world's<br />

growth in industrial energy use<br />

through 2030.<br />

In the IEO2009 reference case,<br />

which does not include specific<br />

policies to limit greenhouse gas<br />

emissions, energy-related carbondioxide<br />

emissions are projected to<br />

rise from 29.1 billion metric tons<br />

in 2005 to 40.4 billion metric tons<br />

in 2030. This represents an<br />

increase of 39 percent.<br />

With strong economic growth<br />

and continued heavy reliance on<br />

fossil fuels expected, much of the<br />

increase in carbon-dioxide<br />

emissions is projected to occur<br />

among the developing nations of<br />

the world, especially in Asia.

FOLLOW THE LIGHT.......<br />

MarelliGenerators is the Generator Division of<br />

MarelliMotori, an international manufacturer of electrical<br />

machines.<br />

MarelliGenerators focuses on Synchronous<br />

Generators from 10 to 7000 kVA.<br />

MarelliService Division boasts a wide experience for all<br />

the industrial rotating electrical machines.<br />

Whenever you need power to rely on follow the light.<br />

Follow MarelliGenerators.<br />

Marelli Motori S.p.A. - Via Sabbionara 1 - 36071 Arzignano (VI) - Italy<br />

Tel. +39 0444 479 711 - Fax +39 0444 479 888 - Web: www.marellimotori.<strong>com</strong> - E-mail: sales@marellimotori.<strong>com</strong><br />

®<br />

MarelliMotori

In brief...<br />

Siemens invests<br />

EUR42 million in<br />

Berlin gas turbine<br />

plant<br />

Siemens is further expanding<br />

production capacity at<br />

its gas turbine<br />

manufacturing plant in<br />

Berlin with the opening of a<br />

further production facility<br />

in the Moabit district. This<br />

expansion of production<br />

capacity will create 200<br />

jobs. Almost one-third of<br />

the total investment of<br />

EUR42 million was<br />

channeled into the new<br />

production facility. From<br />

now on it will be possible<br />

to produce approximately<br />

14,000 gas turbine blades<br />

and vanes at the new plant<br />

every year.<br />

Saudi Arabia choses<br />

ABB<br />

ABB has won orders worth<br />

$100 million for substations<br />

to strengthen Saudi Arabia’s<br />

transmission and<br />

distribution network.<br />

ABB will design, supply,<br />

install and <strong>com</strong>mission<br />

three 110-kilovolt<br />

substations in the Mecca<br />

region. Based on ABB’s gasinsulated<br />

switchgear technology,<br />

the substations have<br />

a <strong>com</strong>pact footprint and<br />

will be located within the<br />

city to serve <strong>com</strong>mercial<br />

and residential areas<br />

under development.<br />

The substations are<br />

scheduled to be<br />

<strong>com</strong>missioned in 2011 and<br />

will be operated by Saudi<br />

Electric Company.<br />

NEM goes to Egypt<br />

Dutch <strong>com</strong>pany NEM has<br />

supplied of water/steam<br />

technology and control<br />

systems for the first hybrid<br />

solar power plant in Egypt<br />

at Al Kuraymat, just south<br />

of Cairo.<br />

The <strong>com</strong>bination of<br />

technology is known as<br />

Integrated Solar Combined<br />

Cycle (ISCC), in which<br />

Combined Cycle stands for<br />

the <strong>com</strong>bination of a gas<br />

turbine and steam turbine.<br />

NEM says it is the only<br />

Dutch <strong>com</strong>pany able to<br />

supply this type of steam<br />

technology for solar power.<br />

8<br />

NEWS<br />

Power for Portugal from GE Energy<br />

GE Energy's Frame 6B gas<br />

turbine technology has been<br />

selected for a cogeneration plant<br />

being built as part of a new<br />

project in the Sines<br />

petrochemical industrial park that<br />

will contribute to the regional<br />

development of Portugal's<br />

Alentejo coastal area and to the<br />

revitalization of the Sines port.<br />

When <strong>com</strong>pleted, the 40megawatt<br />

cogeneration facility<br />

will support a pure tereftalic acid<br />

(PTA) producing plant that will<br />

have a PTA production capacity<br />

up to 700,000 tons per year,<br />

making it one of the largest<br />

production plants of its type in<br />

the world.The PTA plant, to be<br />

named Artenius Sines, will be<br />

owned and operated by La Seda<br />

de Barcelona, a chemical<br />

German city is powered by<br />

cow & horse dung<br />

A new biogas network in the<br />

German city of Lünen is powered<br />

by agricultural waste, including<br />

cow dung and horse manure. Now<br />

90,000 residents can benefit from<br />

this low cost alternative to oil,<br />

coal and Russian gas, say the<br />

authorities<br />

Lünen is the first city in the<br />

world to build and manage a<br />

biogas network. As well as energy<br />

security, this new technology<br />

brings low cost heat and<br />

electricity and new jobs to Lünen.<br />

Fed by local farms, who deliver<br />

animal waste, as well as corn,<br />

wheat and grass, the power plant<br />

is located in the industrial port<br />

next to the river. The gas<br />

network powers a series of ten<br />

quiet Schmitt Enertec<br />

Cogeneration units which feed<br />

electricity into the grid, and heat<br />

into local district heating<br />

networks. The CHP Cogeneration<br />

units are camouflaged as<br />

decorative installations featuring<br />

wood and plants to be<strong>com</strong>e part<br />

of the urban environment.<br />

This feedstock is turned into biogas<br />

in anaerobic digesters.<br />

Looking like giant cup cakes, the<br />

plant produces 6.8MW, enough<br />

energy to supply 26,000 houses<br />

<strong>com</strong>pany and a leader in the PET<br />

packaging sector. According to the<br />

Portuguese Investment Agency,<br />

with its potential for creating<br />

jobs and modernising the<br />

Portuguese chemical industry,<br />

Artenius Sines is considered a<br />

project of national interest by<br />

the Portuguese government.<br />

In addition to its strategic<br />

importance for Portugal, when<br />

<strong>com</strong>pleted, the project will help<br />

increase the supply of PTA across<br />

Europe, which presently imports<br />

about 400,000 tons of the product<br />

from Asia each year. The new GE<br />

Frame 6B gas turbine has been<br />

delivered to the Sines site, which<br />

is south of Lisbon for 21010<br />

operation. Plans are to use<br />

natural gas as the primary fuel<br />

source and limit NOx emissions to<br />

with heat and electricity. Schmitt<br />

was chosen as the main supplier<br />

after a <strong>com</strong>petition which against<br />

leading manufacturers such as GE<br />

Energy and Man. "The project was<br />

a nice challenge for us." said<br />

Frank Schmitt, MD of Schmitt<br />

Enertec "We believe this is a<br />

model for the future of local<br />

power generation", he explains.<br />

"What makes this project exiting<br />

is the <strong>com</strong>bination of<br />

Cogeneration with renewable<br />

energy in an urban environment.<br />

Schmitt Enertec's solution was<br />

superior both in terms of technology<br />

and design," says Peter Kindt,<br />

the chairman of local heat and<br />

power provider Alfagy <strong>Ltd</strong>.<br />

Now closed, the Minister<br />

Achenbach 4 coalmine at Lünen<br />

has been supplanted by a new<br />

biogas network in the city.<br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER<br />

LSdB facility in Barcelona.<br />

15 parts per million (at 15% O2).<br />

The GE Frame 6B is one of the<br />

most widely used gas turbines<br />

ever manufactured. More than<br />

1,100 of these units are in service<br />

or on order worldwide and have<br />

accumulated more than 60 million<br />

operating hours in a wide range<br />

of applications.<br />

New plant destined<br />

for Hungary<br />

Metso has signed an<br />

agreement with Hitachi Europe<br />

GmbH to deliver automation<br />

for a new flue gas<br />

desulphurisation (FGD) facility<br />

Unit III in the Elektrownia<br />

Kozienice S.A. power plant.<br />

Metso's delivery to<br />

Kozienice's new FGD plant Unit<br />

III will include the engineering<br />

and implementation of a new<br />

metsoDNA distributed process<br />

control system. FGD involves<br />

using flue gas stacks to<br />

disperse the emissions by<br />

diluting the pollutants in<br />

ambient air and transporting<br />

Based on the experience<br />

gained with Metso's control<br />

systems at its two existing<br />

FGD plants, Kozienice has<br />

again chosen Metso as the<br />

supplier for the new plant.<br />

The metsoDNA systems at the<br />

three FGD plants will be<br />

connected to the same<br />

metsoDNA network in order to<br />

enable efficient and flexible<br />

controlling and monitoring of<br />

the FGD processes.<br />

The Kozienice power plant<br />

has a total capacity of 2,880<br />

MW, accounting for 11% of the<br />

total Polish electricity<br />

production.The plant is<br />

located 75 km from Warsaw.

���������������������������������������������������������<br />

What if fl awless, trouble-free operations were the norm, not the exception? What if your productivity took off like never before?<br />

With Mobil as your supplier, we can help take you to the next level. Equipment builders worldwide trust Mobil Industrial Lubricants,<br />

for oils designed to work harder and longer. Like Mobil Pegasus 1005, with over 40,000 hours in proven service fi eld testing. It<br />

provides not only peace of mind, but the chance to ignite productivity to enviable new levels. Visit www.mobilindustrial.<strong>com</strong> for more.<br />

©2009 Exxon Mobil Corporation. Mobil and the Flying Horse Design are trademarks of Exxon Mobil Corporation or one of its subsidiaries.

10<br />

In brief...<br />

Mitsubishi to supply<br />

steam generators<br />

Mitsubishi Heavy Industries,<br />

<strong>Ltd</strong>. (MHI) and COMEX<br />

NUCLEAIRE are six months<br />

into a project ordered by<br />

EDF (Electricite De France<br />

S.A.) to supply six replacement<br />

steam generators<br />

(RSG) for pressurized water<br />

reactor (PWR) nuclear<br />

power plants (NPP) in<br />

France. Their delivery will<br />

begin in 2013 and be <strong>com</strong>pleted<br />

in 2014. Within EDF,<br />

the project is managed by<br />

the Generation Nuclear<br />

Engineering Center (CIPN)<br />

at Marseilles.<br />

Indeed, EDF in line with its<br />

NPP <strong>com</strong>ponent renewal<br />

program is sequentially<br />

replacing the existing steam<br />

generators (SG) at its PWR<br />

NPPs, which went into<br />

operation in the 1980s. EDF,<br />

headquartered in Paris, is<br />

the one of the world's<br />

largest electricity suppliers,<br />

providing electricity to<br />

approximately 38.5 million<br />

customers in Europe. The<br />

<strong>com</strong>pany operates 58 PWRs.<br />

MHI previously received its<br />

first order from EDF for the<br />

supply of six RSGs in 2005.<br />

The latest order thus brings<br />

the cumulative number of<br />

units ordered to MHI by EDF<br />

to twelve.<br />

Thielbar joins SEG as<br />

co-leader<br />

Bart Thielbar has joined<br />

Sierra Energy Group (SEG),<br />

a division of Energy<br />

Central. SEG provides IT<br />

and Smart Grid research,<br />

analysis and consulting<br />

services to leading electric<br />

and natural gas utilities and<br />

vendors to the industry.<br />

Thielbar will co-lead new<br />

SEG services, including<br />

consulting and information<br />

technology (IT) research,<br />

analysis and benchmarking.<br />

Thielbar will team with SEG<br />

Vice President Warren B.<br />

Causey to roll out new<br />

services that concentrate<br />

on IT trends within the<br />

energy industry.<br />

Causey has been working<br />

with information technology<br />

for more than 30 years and<br />

with utilities for nearly 20<br />

years.<br />

NEWS<br />

Don’t miss IP&EE at the NEC in 2010<br />

A new report out this month<br />

suggests that - even operating at<br />

just a fifth of their full capacity -<br />

a global network of 2.5 megawatt<br />

wind turbines would easily meet<br />

global electricity demands. So<br />

why isn’t windpower considered<br />

as the primary energy supplier?<br />

The answer to this question -<br />

and others - will be featured at<br />

the highly successful Independent<br />

Power and Energy Europe (IP&EE)<br />

exhibition in 2010. Both IP&EE<br />

and Electrex will join forces in<br />

2010 for a major exhibition to be<br />

held at the NEC in Birmingham,<br />

<strong>UK</strong> on 8-10 June 2010.<br />

The organisers of Electrex<br />

awarded <strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong><br />

(GMP), the publishers of<br />

Worldwide Independent Power<br />

(<strong>WIP</strong>), the responsibility of<br />

organising both shows, including<br />

the sale of stands, arranging<br />

Utility solar power grew in 2008<br />

Utility scale solar installations<br />

grew by about 25% last year<br />

according to an annual survey<br />

conducted by an industry trade<br />

association. The Solar Electric<br />

Power Association (SEPA) "2008 Top<br />

Ten Utility Solar Integration<br />

Rankings" report identified U.S<br />

utilities that have the most significant<br />

amounts of solar electricity<br />

integrated into their portfolio.<br />

"This year's report demonstrates<br />

that solar electricity is finally on<br />

the radar screen of utilities across<br />

the country," said Julia Hamm,<br />

executive director of the Solar<br />

Electric Power Association. "Solar<br />

plants large and small are ready<br />

for significant build-out, and the<br />

utility industry is moving quickly<br />

toward mass adoption to meet a<br />

variety of business needs."<br />

Many utilities doubled the<br />

amount of solar power over the<br />

previous year. Installed solar<br />

capacity of the top ranked utilities<br />

grew from 711 megawatts to 882<br />

megawatts. Renewable portfolio<br />

standards, pending carbon policy,<br />

and the costs of power generation<br />

and fuel resources were cited as<br />

the main reasons solar-generated<br />

electricity was seen as reasons to<br />

sponsorship, advertising and<br />

visitor registration.<br />

At the last IP&EE in April 2008<br />

there were over 60 exhibitors at<br />

the show, of which a third were<br />

impressed enough to book stands<br />

for 2010. Around 10,000 visitors<br />

were recorded at the <strong>com</strong>bined<br />

exhibitions in 2008.<br />

IP&EE is considered the major<br />

industry event which brings<br />

together the leading participants<br />

in the independent power sector<br />

to promote and support<br />

independent power technologies,<br />

ideas and products. The show is<br />

specifically dedicated to the<br />

independent/standby power<br />

industry. New products, cogen<br />

techniques and technology will<br />

feature at this event.<br />

IP&EE has been developed over<br />

the last 10 years to meet the<br />

needs of the growing number of<br />

adopt the technology.<br />

Historically, the solar power<br />

market has been dominated by<br />

customer-driven installations, but<br />

utility installations are gaining an<br />

ever larger share. The report<br />

showed that 88% of new annual<br />

growth was in the service<br />

territories of the Top Ten utilities.<br />

The distribution of solar power is<br />

also spreading geographically. The<br />

report shows that 2008 solar power<br />

growth came almost entirely from<br />

thousands of distributed generation<br />

projects. Ninety-two utilities<br />

participated in the survey, an<br />

increase of more than 80% over<br />

last year, reflecting increased<br />

utility industry interest, SEPA said.<br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER<br />

independent, private, distributed<br />

power and energy users<br />

throughout Europe.<br />

Electrex is the <strong>UK</strong>’s showcase<br />

exhibition for the electrical<br />

industry. Electrex 2008 is probably<br />

best-known for featuring the<br />

latest leading edge technology<br />

and products, services and<br />

innovations from the industry’s<br />

major players andinc excellent<br />

seminar presentations.<br />

Electrex has a long history,<br />

stretching back over 50 years, and<br />

is said to ‘exactly meet the needs<br />

of the electrical contractor’.<br />

More information?<br />

If you would like a brochure<br />

about this event contact either<br />

Neb Saric or Richard Teasdale at<br />

e-mail: power@gmp.uk.<strong>com</strong><br />

or visit the Website:<br />

www.gmp.uk.<strong>com</strong>/power<br />

Doosan Babcock in<br />

deal with RWE<br />

Doosan Babcock, the global<br />

energy technology <strong>com</strong>pany,<br />

today announced a six-year<br />

services contract agreement<br />

with leading electricity<br />

supplier, RWE npower. The<br />

phased contract is for the<br />

<strong>com</strong>prehensive boiler and<br />

associated plant outage and<br />

maintenance services at the<br />

Aberthaw, Didcot, Fawley,<br />

Littlebrook and Tilbury power<br />

stations. The contract has no<br />

fixed value, but the nature of<br />

the work includes major boiler<br />

outages over a period of six<br />

years, and both <strong>com</strong>panies<br />

agree it is a significant<br />

contract award.<br />

The new contract is a<br />

development of an existing<br />

six-year contract between<br />

Doosan Babcock and RWE<br />

npower and was based on a<br />

partnering approach and the<br />

alignment of goals and<br />

objectives to mutual benefit.<br />

There will also be the<br />

potential to introduce further<br />

RWE npower <strong>UK</strong> assets into the<br />

portfolio including major<br />

projects support.

NEWS<br />

AMPS in full swing at Stapleford Park<br />

May 11th, 2009, saw the 2nd AMPS Golf Day held at the famous<br />

Stapleford Park Country House Hotel and Golf Course in<br />

Leicestershire. The sun was out, the birds were chirping and<br />

AMPS members and guests were in full swing - literally - at one of<br />

the most popular events of the year.<br />

Stapleford Park is one of England's finest stately homes and the<br />

course itself is situated in the heart of a Capability Brown landscape,<br />

with ever-changing views of Stapleford's lakes and 500acre<br />

park.<br />

The course configuration is said to reflect the layout of some of<br />

the great links courses, such as the Old Course at St Andrews. It<br />

provides continuing variety in the direction of the holes, as well<br />

as producing a series of stunning vistas to enjoy.<br />

The winning team representing <strong>WIP</strong> at<br />

Altogether, 12 members of the Association of Manufacturers of Stapleford Park: Richard Teasdale of<br />

Power generating Systems (AMPS) rose to the challenge of the <strong>WIP</strong>, Andy Collins (Lombardini), Fay<br />

course and <strong>com</strong>pleted it in record time. Ironically, the 1st prize, Taylor and Tim Cummins of Mecc Alte<br />

the Amps Cup, was won by Darren Tasker, AMPs' own chairman. (<strong>UK</strong>) - far right.<br />

Richard Teasdale, the publisher of <strong>WIP</strong> for <strong>Global</strong> <strong>Media</strong><br />

<strong>Publishing</strong>, the corporate sponsors of the event, said: "Stapleford Park Course is a fantastic venue. The<br />

atmosphere certainly gives it the feel of a truly major event. Our <strong>WIP</strong> team <strong>com</strong>prised a mixture of people,<br />

professionals from three <strong>com</strong>panies, making the most of a unique<br />

opportunity to network within the industry."<br />

Final scores<br />

1st Prize: Darren Tasker (Volvo) won the day with 34 points.<br />

2nd Prize: Danny Gallacher (Brad Containers)<br />

3rd Prize: Fay Taylor, Mecc Alte (<strong>UK</strong>) <strong>Ltd</strong><br />

Richard reported: "What was great about the AMPS Golf Day was<br />

the fact that the focus was on our relationship to one another as<br />

industry professionals and not how well - or poorly - people<br />

played. We all had a really great time.<br />

"If you missed this year's event because you were working you<br />

should really try your best to attend the next one in 2010 because<br />

we just seem to have greater success with each passing year.<br />

"The weather was just right and a host of well-deserved awards<br />

were given out. What more could any golfer ask for?"<br />

Top Diary Dates for Energy Shows 2009- 2010<br />

* COAL-GEN Europe 2009, <strong>July</strong><br />

28th - 30th, Warsaw, Poland. This<br />

will be the first large scale<br />

pan-European conference and<br />

exhibition dedicated to coalfuelled<br />

power generation.<br />

* COAL-GEN USA 2009, August<br />

19th - 21st, 2009, Charlotte, NC,<br />

USA The US coal energy event<br />

featuring coal power trends,<br />

products and technology.<br />

* Power-Gen Asia 2009, 7-9th<br />

October, IMPACT Exhibition<br />

Centre, Bangkok, Thailand.<br />

* Turbomachinery Symposium<br />

September 14-17, 2009 at the<br />

George R. Brown Convention<br />

Center, Houston, TX, USA.<br />

* AMPS POWER EXPO in<br />

association with IP&EE, on 7th-<br />

8th October, London Olympia, <strong>UK</strong>.<br />

* Energy Show 2009 will be<br />

taking place at Shanghai New Int’l<br />

Expo Centre, China, from 3rd -<br />

7th November.<br />

* Algeria Electricity Expo, 3rd-<br />

5th November, 2009.<br />

* Energy Day In Croatia,<br />

November 20th. Organised by:<br />

Croatian Energy Association. Held<br />

in Zagreb, Croatia.<br />

* India Energy, 13th-15th<br />

November, Mumbai Exhibition<br />

Centre, Mumbai, India.<br />

* Vietnam Forum & Energy<br />

Expo, Hanoi, Vietnam, 4th-7th<br />

November, 2009.<br />

* Power-Gen International, Las<br />

Vegas Convention Centre, NV,<br />

USA, 8th-10th December, 2009.<br />

* ENERGAIA - International<br />

Renewable Energies Exhibition &<br />

Richard Teasdale (<strong>WIP</strong>) and Darren<br />

Tasker (Volvo) celebrate their win.<br />

Conference, Paris, France, from<br />

9th-12th December, 2009.<br />

----------------------------------------<br />

2010<br />

----------------------------------------<br />

* Middle East Electricity, 9th-<br />

11th February, Dubai International<br />

Convention Centre, Dubai.<br />

* Distributech, March 23rd-26th,<br />

2010, Tampa Convention centre,<br />

Tampa, Fl, USA.<br />

* IP&EE (Independent Power &<br />

Energy Europe), 8th - 10th June,<br />

NEC Birmingham, <strong>UK</strong>, will run<br />

concurrently with Electrex 2010,<br />

one of the <strong>UK</strong>’s top industry trade<br />

shows. Both highly-regarded<br />

exhibitions are being organised by<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong>.<br />

More info? Visit:<br />

www.gmp.uk.<strong>com</strong><br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER<br />

In brief...<br />

Brazil to get new<br />

technology<br />

ABB has secured a $52<br />

million order from Spanish<br />

technology <strong>com</strong>pany<br />

Abengoa to supply<br />

transformers and shunt<br />

reactors for projects to<br />

interconnect the grids in<br />

Brazil's northern and<br />

southern regions.<br />

ABB’s equipment will<br />

serve three projects under<br />

construction for Manaus<br />

Transmissora de Energia,<br />

one of Brazil’s leading<br />

energy transmission<br />

<strong>com</strong>panies.<br />

Solar expert<br />

announced<br />

Professor I.M. Dharmadasa<br />

has been appointed as<br />

President of the<br />

Professional Association of<br />

Sri Lankans in the <strong>UK</strong>, in<br />

recognition of his work to<br />

bring renewable energy to<br />

Sri Lanka.<br />

Professor Dharmadasa<br />

(Dharme) is a worldleader<br />

in the field of solar<br />

energy and works at the<br />

cutting edge of photovoltaic<br />

cell design. His<br />

research has led to new<br />

techniques to make solar<br />

cells which are more<br />

efficient and that can be<br />

produced at a fraction of<br />

the price of traditional<br />

solar panels. He is based<br />

at Sheffield Hallam<br />

University in the <strong>UK</strong>.<br />

NEREL & RES join<br />

forces<br />

The U.S. Department of<br />

Energy’s (DOE) National<br />

Renewable Energy<br />

Laboratory (NREL) and<br />

Renewable Energy Systems<br />

Americas, Inc. (RES<br />

Americas) have announced<br />

a partnership to evaluate<br />

the design and performance<br />

of vital wind energy<br />

support systems.<br />

Under a Cooperative<br />

Research & Development<br />

Agreement (CRADA), NREL<br />

and RES Americas will<br />

investigat wind turbines,<br />

thermal performance of<br />

underground collection<br />

system electrical cables,<br />

and side-by-side<br />

<strong>com</strong>parisons of alternative<br />

wind speed measurement<br />

systems. The agreement<br />

is worth almost $500,000<br />

over the next two years.<br />

11

12<br />

With the global economy still stuck<br />

under the weight of a recession<br />

and the credit crunch it would<br />

not be surprising if all other economic<br />

considerations were politely ignored for<br />

the time being. But up until the financial<br />

collapse of 2008 the number one global<br />

concern had been the environment, and<br />

consequently the word on everyone's lips<br />

was 'sustainability'. What has happened<br />

to this green ideal in the revealing light of<br />

a recession?<br />

Gordon Brown grabbed the 2009 budget<br />

and recession as an opportunity for a<br />

'green route to economic recovery', for<br />

Brown the recession is clearly a chance to<br />

remould the <strong>UK</strong> economy into a more<br />

environmentally sustainable one, all the<br />

while producing more 'green jobs'. So is<br />

this a rare win-win situation for the normally<br />

opposed ideologies of environmentalism<br />

and business? 'Perhaps' is probably<br />

the fairest answer.<br />

On the one hand you have money and<br />

resources while one the other you have<br />

the environmentalists’ ideal of limiting<br />

human impact on the natural<br />

environment. 'Green jobs' fall somewhere<br />

in between these two points and this is<br />

either an opportunity or a curse. Is this<br />

an opportunity for co-operation and<br />

progress or for watered down initiatives<br />

which are acceptable to all but fail to<br />

address or solve the problem at hand?<br />

An issue that exemplifies this conflict<br />

succinctly is that of 'Biofuels'. Of equal<br />

seriousness for those of a green or<br />

economic bent is the problem of energy<br />

supply and sustainability. Until the<br />

Millennium any mention of 'energy supply'<br />

was practically synonymous with 'oil<br />

supply', and sustainability was concerned<br />

with where to drill next.<br />

Biofuels represent an attractive<br />

alternative to oil for many people.<br />

Getting energy from crops, the basic<br />

premise of biofuel, is attractive to the<br />

SHAREWATCH<br />

Biofuels & green jobs<br />

Sticking to a green agenda means taking a new approach in the face of recession, argues<br />

<strong>WIP</strong>’s economic correspondent Christopher Hopkins.<br />

environmentally-concerned because crops<br />

are renewable and can be carbon neutral,<br />

and thus sustainable, unlike fossil fuels.<br />

Economists like it because it requires<br />

relatively little change for suppliers and<br />

consumers; low capital costs. Growing a<br />

Company<br />

(Currency)<br />

Monthly<br />

share price<br />

52 week<br />

high/low<br />

ABB (CHF) 17.48 11.29/<br />

33.61<br />

Ansaldo (EUR) 12.06 7.71/<br />

12.59<br />

Atlas Copco (SEK) 73.00 40.70/<br />

99.50<br />

Caterpillar (USD) 37.66 21.71/<br />

83.65<br />

Chloride (GBX) 156.00 107.25/<br />

286.75<br />

Cummins (USD) 35.86 17.70/<br />

75.98<br />

Doosan Heavy<br />

Industries (KRW)<br />

Foster Wheeler<br />

(USD)<br />

71400 37300/<br />

124500<br />

27.98 12.73/<br />

79.29<br />

GE (USD) 13.82 5.73/<br />

31.14<br />

John Deere (EUR) 1500 1450/<br />

1500<br />

Kirloskar (INR) 89.80 31.50/<br />

104.95<br />

MAN (EUR) 46.37 26.37/<br />

101.99<br />

Mitsubishi (JPY) 1899 923.00/<br />

3720<br />

MTU (EUR) 23.23 12.87/<br />

27.92<br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER<br />

new crop is not particularly difficult for<br />

agriculture and putting different 'petrol'<br />

into a car is not much of an<br />

inconvenience for the general public. <strong>WIP</strong><br />

Internet link<br />

www.gmp.uk.<strong>com</strong>/power<br />

Change over<br />

month<br />

Change<br />

over year<br />

Change since<br />

Jan. 2008<br />

+8.24% -48.77% -37.35%<br />

-0.41% +21.95% +39.58%<br />

+8.96% -25.13% -17.28%<br />

+11.78% -54.51% -47.52%<br />

-4.29% -44.04% -11.99%<br />

+7.08% -48.66% -23.60%<br />

-14.49% -41.71%<br />

+31.12% -62.29% -61.03%<br />

+13.09% -54.90% -61.78%<br />

0.0% +2.04% +21.46%<br />

+71.54% -10.20%<br />

+1.02% -53.14% -43.26%<br />

+18.69% -47.83% -30.18%<br />

-8.90% -16.38% -30.86%<br />

Rolls-Royce (GBX) 331.50 231.14/<br />

404.79<br />

+1.69% -19.93% -31.83%<br />

Siemens (EUR) 54.40 33.05/<br />

79.80<br />

+6.00% -25.01% -39.14%<br />

Volvo Penta (SEK) 51.70 29.10/<br />

96.75<br />

-3.32% -47.01% -43.18%<br />

Wärtsilä (EUR) 25.87 15.53/<br />

45.92<br />

+10.60% -42.73% -40.23%<br />

Monthly figures taken at the end of May 2009

Now you can servic service ce your substation<br />

without<br />

interrupting interrrupting<br />

the<br />

power supply to yo your ur customers<br />

or exposing yours yourself self to<br />

risk.<br />

Simply connect DEI DEIF’s F’s Remote Maintenance unit to o the local<br />

power network. Con Connected nnected to the<br />

AGC-3<br />

controlle controller, r,<br />

the<br />

unit<br />

will safely safely redirect th the e power<br />

according<br />

to your prefer preference. rence. Your<br />

customers will not even evven<br />

notice the change over.<br />

DEIF<br />

offerssecond-to-none technical suppor support t before, befoore,<br />

during<br />

and after <strong>com</strong>missio <strong>com</strong>missioning oning – for<br />

more<br />

information, information, please pplease<br />

visit<br />

www.deif.<strong>com</strong>.<br />

www www.deif<br />

deif.<strong>com</strong>.<br />

<strong>com</strong><br />

Retain<br />

power<br />

supply supp<br />

l ly<br />

during<br />

planned<br />

ooutage<br />

utage<br />

Features:<br />

• Ma Maximum ximum safety<br />

• Remote management<br />

• Easy service<br />

• Automatic configuration<br />

configuratioon<br />

– un<strong>com</strong>plicated setup setuup<br />

• • Gl <strong>Global</strong> b l t training i i<br />

The<br />

DEIF<br />

Group GGroup<br />

– Head office in Denmark with subsidiaries<br />

in Germany, , Norway, , <strong>UK</strong>,<br />

France,<br />

China, Chhina,<br />

USA,<br />

Brazil and India<br />

DEI DEIF F A/S<br />

· FFrisenborgvej<br />

risenbborgvej<br />

33<br />

·<br />

DK-7800<br />

Skive ·<br />

Te Tel.: el.: +45 9614 96 614<br />

9614<br />

· Fa Fax: ax:<br />

+45 9614<br />

96 9615 15<br />

· info@ info@deif.<strong>com</strong> @deif.<strong>com</strong><br />

· www www.deif.<strong>com</strong> .deif.<strong>com</strong>

14<br />

The recent Centrax Trent 60 sale is<br />

part of a Euro 100m contract placed<br />

by a major French utility. It is<br />

reckoned to be cheap at the price too, for<br />

reliable systems designed to provide<br />

primary power, standby power and<br />

cogeneration in the 200 MW range.<br />

In total, four Trent 60 powered<br />

generator sets, each producing 58MW of<br />

electrical power, have been ordered for<br />

the French EPC project. As the director<br />

of Centrax Gas Turbines, Guy West, puts<br />

it: "The Trent 60 generator set provides<br />

the most advanced and efficient aeroderivative<br />

based power generation system<br />

in the world. Delivering up to 58MW of<br />

electric power with simple cycle<br />

efficiency of 42%, the Trent 60 has<br />

established a new benchmark for fuelefficient<br />

gas turbine power."<br />

Each Trent 60 package is supplied as two<br />

primary modules: gas turbine and AC<br />

generator modules with the mechanical<br />

auxiliary systems and control systems<br />

mounted on the baseplates.<br />

The French connection<br />

The latest contract <strong>com</strong>es as no surprise<br />

to industry analysts as the French have<br />

increasingly been seen to be thinking big<br />

in recent years.<br />

Back in 2008 a French utility ordered<br />

four Trent 60 units from Centrax for a 200<br />

MW power station being developed at a<br />

new purpose-built facility in France.<br />

Centrax now anticipates that by 2011<br />

energy from the new facility will be<br />

reaching the French grid.<br />

The purchase was necessary because of<br />

increased demand in many French regions<br />

which has meant that the electrical grid<br />

has been close to reaching a critical<br />

.<br />

GAS TURBINES<br />

Power to the people<br />

- meeting the cogen challenge<br />

Considered especially suitable for mid-merit operations, the latest Centrax<br />

Trent 60 generating sets are destined for France. <strong>WIP</strong> has the story.<br />

Comparison between the 501 turbine (in front) and the Trent. [Below] In the<br />

Centrax assembly hall the Trent engine is ready to be manouvered into the<br />

package.<br />

W ORLDWIDE I NDEPENDENT P OWER •JUNE 2009

transit capacity. The role of the new<br />

power station is to stabilise the local<br />

power grid and, as a corollary, enhance<br />

sourcing capacity. The engineering specs.<br />

suggest that the new plant will offer<br />

features such as a cold start to full power<br />

(220MW) in under 10 minutes - a very fast<br />

start up capability.<br />

Certainly, the plant's operating cycle,<br />

scheduled to run from November 1st to<br />

March 31st, plus 30 days during the rest of<br />

the year, indicated that the plant's<br />

availability will be higher than 95 %.<br />

"The aero-derivative gas turbine option<br />

put forward by Centrax was selected on<br />

the basis of its ability to achieve quick,<br />

frequent and reliable starts and its<br />

established success in mid-merit<br />

operation," <strong>com</strong>ments Peter Ward,<br />

General Manager for Centrax Gas<br />

Turbines.<br />

Installed as indoor packages, two sets of<br />

Trent 60 generators will be installed in<br />

each turbine hall, and won't even be too<br />

noisy. An improved acoustic specification<br />

means that the generators achieve<br />

60dB(A) at the site boundary and<br />

42.5dB(A) at the nearest dwelling.<br />

At the heart of the Trent 60 is Rolls-<br />

Royce's aeroderivative industrial gas<br />

turbine, based on the well-known RB211<br />

aero engine. In 2007 Centrax signed an<br />

agreement with Rolls-Royce to be<strong>com</strong>e<br />

the exclusive packager of the Trent 60<br />

generating set in Europe.<br />

Standby & base-load duties<br />

Centrax Gas Turbines is a long-standing<br />

British <strong>com</strong>pany which manufactures gas<br />

turbine driven generator sets in the 2.5<br />

MWe to 60.0 MWe range. To date more<br />

than 280 Rolls-Royce powered Centrax<br />

generator sets have been sold worldwide<br />

and are used primarily for CHP and<br />

cogeneration applications in many<br />

industries including paper mills, chemicals<br />

and manufacturing as well as in hospitals<br />

and other critical areas for stand-by and<br />

base-load duties.<br />

Mainly natural gas fuelled, the turbines<br />

can also operate on landfill gas and other<br />

biogases. Centrax generator sets now<br />

have a total experience of 16 million<br />

operating hours in countries around the<br />

world.<br />

As an EPC contractor Centrax tenders for<br />

total power station plant based on the<br />

Trent and, as a full packager, carries the<br />

GAS TURBINES<br />

At the heart of the Trent 60 is Rolls-Royce's aeroderivative industrial gas turbine.<br />

responsibility for selling and building Trent<br />

packages. Guy West, a director of<br />

Centrax, said: "We have had a long and<br />

successful relationship with Rolls-Royce<br />

and have been involved with their 501 gas<br />

turbine for nearly thirty years. It has<br />

proven to be an excellent engine in the<br />

2.5 to 6 MW class and we have been the<br />

leading 501 packager."<br />

Major customers for Centrax Gas<br />

Turbines include world-renowned<br />

<strong>com</strong>panies such as IBM, British Petroleum,<br />

Ford, Heineken, Goodyear Tyres,<br />

GlaxoSmithKline and Pilkington Glass.<br />

Centrax packages operate primarily on<br />

natural gas but other fuels can be used as<br />

an alternative. The main application is<br />

providing an energy source for <strong>com</strong>bined<br />

heat and power (CHP) systems.<br />

In 2009 two Trent 60s were sold to a<br />

Hungarian utility for mid-merit usage in<br />

grid-balancing. The order came from<br />

BKCE, a special-purpose <strong>com</strong>pany in which<br />

the state electricity <strong>com</strong>pany, MVM has a<br />

majority stake. The two outdoor sets are<br />

to be installed at Bakonyi Power Station in<br />

Ajka, two hours west of Budapest.<br />

The first Trent 60 gas turbine to be<br />

ordered for service in South America went<br />

to a power plant based at Colmito, near<br />

Valparaiso, Chile. The Chilean power<br />

W ORLDWIDE I NDEPENDENT P OWER •JUNE 2009<br />

generator Hidroeléctrica La Higuera SA<br />

specified a Trent 60 wet low emissions<br />

dual fuel package, capable of providing<br />

up to 58 MWe at ISO conditions, to<br />

provide secure power back-up to the La<br />

Higuera hydro power plant during the dry<br />

season.<br />

Centrax 501 powered gensets also<br />

provide heat and power on the fixed<br />

Mexilhão offshore platform in the Santos<br />

Basin. More recently there have been<br />

contracts placed in Burmuda, Ireland and<br />

the <strong>UK</strong>.<br />

Since it was founded in 1946, Centrax<br />

has centred its business around the gas<br />

turbine engine. Centrax has also<br />

developed state-of-the-art machining<br />

techniques for gas turbine <strong>com</strong>ponents.<br />

Centrax Director Guy West concluded:<br />

"Efficiency and reliability are of<br />

paramount importance in the energy<br />

generating sector. Evan alternative energy<br />

sources such as wind power needs the<br />

backup power of a mid-merit system like<br />

the Trent, because you can't always be<br />

sure the wind is going to blow."<br />

Internet link<br />

www.centrax.eu.<strong>com</strong><br />

<strong>WIP</strong><br />

15

It’s incredible to think that tallow from<br />

rendered-down dead cows could be<br />

one of the major sustainable fuel<br />

sources behind 18MW of ‘green energy’<br />

being produced by the Mouscron co-gen<br />

facility.<br />

In terms of energy that’s enough to<br />

supply the needs of 44,000 families and<br />

still produce enough recoverable ‘waste’<br />

heat to sell to industry facilities in the<br />

vicinity - and warm up local swimming<br />

pools too.<br />

The other significant fact about the<br />

project, say the operators, is the<br />

remarkable reliability and low wear rates<br />

the engines at Mouscron have achieved<br />

since their installation in 2006.<br />

When the plant was first <strong>com</strong>missioned<br />

the concept of running engines on biofuel<br />

was pretty much uncharted territory.<br />

But with their broad insensitivity to fuel<br />

quality, Mouscron’s large medium speed<br />

diesel engines, designed for heavy fuel<br />

oils, seem to cope readily with carbondioxide<br />

neutral fuels such as plant oils,<br />

animal fats and various blends of waste<br />

oils.<br />

Typically, these are fuels which can<br />

cause considerable problems in high-speed<br />

engines with their more sensitive injection<br />

systems. But thanks to large mediumspeed<br />

diesel engines made by MAN Diesel,<br />

they have effectively be<strong>com</strong>e part of the<br />

global warming solution.<br />

The technology<br />

Electrawinds nv, headquartered in<br />

Ostend, Belgium, is currently the largest<br />

private player on the Belgian market for<br />

renewable energy. Initially a provider of<br />

‘green’ electricity, it began establishing<br />

wind energy projects, but soon began to<br />

invest in other forms of renewable energy,<br />

16<br />

COGENERATION<br />

Belgium’s biofuels & cogen plants:<br />

cows are the answer<br />

Aidan Turnbull reports on a recent visit to Electrawinds Biomass Mouscron, one of<br />

Belgium’s most advanced cogeneration plants based on biofuels.<br />

Electrawinds - unique in Belgium [Below: Tower at the Ostend plant.]<br />

such as biomass and solar energy.<br />

Its business strategy of <strong>com</strong>bining wind,<br />

biomass and solar energy is unique in<br />

Belgium. Electrawinds now operates in<br />

Italy, France and Eastern-Europe.<br />

The story really begins In August 2005<br />

when Electrawinds set up its first 13MW<br />

biofuel-based energy-generating plant in<br />

Ostend.<br />

A template for later projects, the role of<br />

this facility was to convert animal and<br />

vegetable fats into sustainable energy.<br />

Today, the Ostend plant has a capacity of<br />

Mouscron’s large medium speed<br />

diesel engines, designed for heavy<br />

fuel oils, seem to cope readily<br />

with carbon-dioxide neutral fuels<br />

such plant oils and animal fats<br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER

2-Way<br />

Solenoid Valve<br />

FireCide® Valve<br />

GT Compressor<br />

Bleed Valve<br />

Laurence Valves<br />

●Used extensively on GE Turbines,<br />

Frames 5, 6, 7, & 9, including:<br />

Compressor Bleed Valve,<br />

Gas Purge System Vent Valve, etc.<br />

● 2-Way & 3-Way Industrial Solenoid<br />

Valves to Handle a Variety of<br />

Fluids<br />

● FM-Approved Explosion-Proof<br />

Solenoids and Safety Shut-Off<br />

Valves<br />

●Heat-Actuated Fire-Cide® Valves,<br />

FM–Approved for Emergency<br />

Shut-Off<br />

COMBINED HEAT AND POWER<br />

www.lesliecontrols.<strong>com</strong><br />

12501 Tele<strong>com</strong> Drive Tampa, FL 33637 USA<br />

Sales@lesliecontrols.<strong>com</strong><br />

Aeroflow Severe Service<br />

Control Valves<br />

● A Solution for your Problem<br />

Applications, including Boiler<br />

Feedwater, Boiler Feedpump<br />

Recirculation Valves, and<br />

Turbine Bypass Valves<br />

● Zero Seat Leakage -<br />

Less than 1 Drop per<br />

Minute at Rated ΔP<br />

● Custom Characterized Trim<br />

Options<br />

● Steam Conditioning Valves<br />

Also Available<br />

GAS TURBINES<br />

Aeroflow<br />

Centrax - Powering the future<br />

ON-SITE POWER PRODUCTION<br />

TURNKEY POWER PLANT<br />

When you need a source of energy for your business<br />

we provide an answer to your power requirements CENTRAX LIMITED (Gas Turbine Division)<br />

Rolls-Royce industrial turbines<br />

Power range from 2.5 MW to 64 MW<br />

Clear environmental benefits<br />

Newton Abbot, England TQ12 4SQ<br />

Tel: +44 (0)1626 358 000<br />

E-mail: sales@centrax.eu.<strong>com</strong><br />

www.centrax.eu.<strong>com</strong>

13MW and provides green energy for<br />

approximately 35,000 families. According<br />

to its operators this particular installation<br />

is able to reduce CO2 emissions by 66,000<br />

tonnes a year.<br />

Engine specifications<br />

Electrawinds’ Mouscron co-gen plant is<br />

based around a 17.7 MW rated bio-fuel<br />

version of MAN Diesel’s 18 cylinder, veeconfiguration<br />

type 18V48/60 engine (108,5<br />

L/cyl. bore 480 x stroke 640 mm).<br />

It powers 18V48/60B generator sets which<br />

18<br />

CONGENERATION<br />

Mouscron co-gen plant relies on the latest biofuel-burning technology.<br />

14 MW of thermal energy <strong>com</strong>e from<br />

the exhaust gases and coolants.<br />

have been designed to feed electrical<br />

power to the local grid.<br />

The 17.7 MW rated engine at the plant<br />

provides outputs of 17.7 MW (electrical)<br />

and 14.0 MW (thermal) with an overall<br />

efficiency of 85% based on a biofuel made<br />

up of various organic waste oils and fats.<br />

This fuel requires heating and needs a<br />

three-stage fine filtration process.<br />

According to Electrawinds, 14 MW of thermal<br />

energy from its exhaust gases and<br />

coolant are normally used for industrial<br />

processes at nearby cosmetics factory and<br />

for heating a local swimming pool and<br />

leisure centre. Waste oils and fats are<br />

delivered to the plant several times per<br />

week and stored in a purpose-built tank<br />

farm. There is a nearby rendering plant<br />

where the cows are brought in on a daily<br />

basis.<br />

“The viability of the Mouscron cogen<br />

plant is underpinned by the carbon dioxide<br />

trading scheme operated by the<br />

Belgian Government,” explains <strong>com</strong>pany<br />

spokesperson Marleen Vanhecke.<br />

“Green certificates are earned for the<br />

use of a CO2-neutral fuel and credits<br />

accrued at the regulatory body.”<br />

She points out: “The supply of thermal<br />

energy from the plant to the nearby<br />

leisure centre ensures that the Mouscron<br />

plant qualifies as a high efficiency cogeneration<br />

plant, which brings further financial<br />

incentives.”<br />

Three years ago MAN Diesel and<br />

Electrawinds co-operated closely in the<br />

JUNE 2009 • WORLDWIDE I NDEPENDENT P OWER<br />

At Mouscron selective catalytic<br />

reduction systems control emissions of<br />

oxides of nitrogen (NOx).<br />

construction of the Mouscron plant, and<br />

that relationship remains as firm today,<br />

with regular <strong>com</strong>munciations between<br />

engineers and operators.<br />

Amongst the biofuel power and co-gen<br />

technology supplied by MAN Diesel is<br />

selective catalytic reduction equipment to<br />

control emissions of oxides of nitrogen<br />

(NOx).<br />

These SCR systems use urea as the<br />

reducing agent and incorporate a downstream<br />

oxidation catalyst to eliminate<br />

ammonia slip.<br />

Plant Manager at Biomass Mouscron,<br />

Bruno Clemens, <strong>com</strong>mented: “At<br />

Mouscron we can offer our customers the<br />

advantage of producing electrical power<br />

and heating resources through the use of<br />

renewable, biological fuel sources, such<br />

as fats and oils. By using these fuels, customers<br />

avoid using finite, subterraneous,<br />

fossil-fuel resources, limit the Greenhouse<br />

Effect and reduce pollutant emissions.”<br />

Internet link<br />

www.electrawinds.be<br />

<strong>WIP</strong>

1400 kW at 400 V<br />

50 Hz, 4500 kg<br />

f you’re reading this, then so are thousands of others.<br />

Time to put your feet up and let your advertisement do<br />

all the hard work!<br />

300 kW at 400 V<br />

50 Hz, 338 kg<br />

To advertise contact our Power Division at:<br />

<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><br />

Tel: +44(0)1403 220750<br />

Fax: +44(0)1403 220764<br />

e-mail:power@gmp.uk.<strong>com</strong><br />

web: www.gmp.uk.<strong>com</strong><br />

The Worldwide Load Bank Experts<br />

500 kW at 400 V<br />

50 Hz, 522 kg<br />

Avtron Portable Load Banks feature the<br />

highest capacity for their size in the industry!<br />

80 kW at 400 V<br />

50 Hz, 48 kg<br />

Reliable Manual Operation<br />

Over-Temperature Protection<br />

Over-Current Protection<br />

No Cool Down Period<br />

Full Digital Metering<br />

Real-Time Data Logging<br />

����������������������<br />

���������������������������<br />

������������������������<br />

�����������������������<br />

�����������������������������<br />

������www.load-bank.<strong>com</strong><br />

���������������������<br />

������������<br />

���������������������������������������������������������������������������������������������������������������������������

Belgium, the Netherlands, and<br />

Luxembourg have always maintained<br />

a dynamic approach towards<br />

cogeneration. Their governments have<br />

supported a recent EU Strategy for the<br />

future development of Combined Heat<br />

and Power (CHP) and District Heating and<br />

Cooling (DHC) in Europe.<br />

As a result they are hoping to reap the<br />

benefits of achieving the 2020 renewable<br />

energy targets. If they do this will lead to<br />

around 2.8 million jobs in the renewable<br />

energy sector and generate an additional<br />

1.1% to GDP.<br />

Like all European Union (EU) member<br />

states, the Benelux nations must <strong>com</strong>ply<br />

with new EU Directives to install new<br />

industrial, <strong>com</strong>mercial and residential<br />

cogeneration systems which boost energy<br />

efficiency while reducing local fossil fuel<br />

consumption and greenhouse gas emissions.<br />

Ambitious targets have been set for the<br />

development of CHP (doubling the share<br />

of cogenerated electricity from 9% today<br />

to 18% in 2010) and the energy authorities<br />

have stressed the importance of liberalising<br />

the energy markets on CHP/DHC, on<br />

the need to keep prices stable in all<br />

sources of energy and on developing new<br />

technology.<br />

Luxembourg - a focus on biofuels<br />

Redange is a town in Luxembourg where<br />

a <strong>com</strong>munity's energy needs are being met<br />

by biogas derived from cow dung. The<br />

energy is being directed to heat local<br />

swimming pools, a sports centre and a<br />

school. The brainchild of a farmers' cooperative,<br />

Biogas un der Atert, Redange<br />

how has an operational plant designed to<br />

convert methane from cow manure into<br />

20<br />

BENELUX REVIEW<br />

The Benelux approach : boosting<br />

efficiency & reducing emissions<br />

Belgium, the Netherlands, and Luxembourg have all installed new industrial,<br />