twin sphere flanged - Thorburn Flex Inc

twin sphere flanged - Thorburn Flex Inc

twin sphere flanged - Thorburn Flex Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

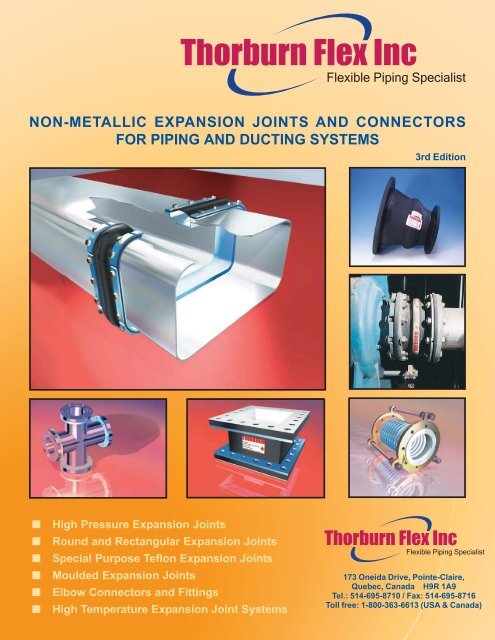

NON-METALLIC EXPANSION JOINTS AND CONNECTORS<br />

FOR PIPING AND DUCTING SYSTEMS<br />

■ High Pressure Expansion Joints<br />

■ Round and Rectangular Expansion Joints<br />

■ Special Purpose Teflon Expansion Joints<br />

■ Moulded Expansion Joints<br />

■ Elbow Connectors and Fittings<br />

■ High Temperature Expansion Joint Systems<br />

<strong>Thorburn</strong> <strong>Flex</strong> <strong>Inc</strong><br />

<strong>Flex</strong>ible Piping Specialist<br />

3rd Edition<br />

<strong>Thorburn</strong> <strong>Flex</strong> <strong>Inc</strong><br />

<strong>Flex</strong>ible Piping Specialist<br />

173 Oneida Drive, Pointe-Claire,<br />

Quebec, Canada H9R 1A9<br />

Tel.: 514-695-8710 / Fax: 514-695-8716<br />

Toll free: 1-800-363-6613 (USA & Canada)

<strong>Thorburn</strong> <strong>Flex</strong> <strong>Inc</strong><br />

<strong>Flex</strong>ible Piping Specialist<br />

THORBURN’S EMPLOYMENT OF<br />

STATE-OF-THE-ART TECHNOLOGY<br />

<strong>Thorburn</strong>’s committment to development is<br />

reinforced through the use of CAD (Computer<br />

Aided Design) system technology and finite<br />

engineering analysis, which permits <strong>Thorburn</strong><br />

to pinpoint potential critical areas and provide<br />

timely sound engineered solutions<br />

FOUNDER, Jack <strong>Thorburn</strong><br />

Shown is Jack <strong>Thorburn</strong>, who founded the<br />

company in 1954, enjoying one of his passions,<br />

sailing. Unfortunately, Jack passed away on<br />

February 16th 1995. He will be sorely missed.<br />

The company’s leadership passed on to Jack’s<br />

eldest son, Robert, in September 1994.<br />

<strong>Thorburn</strong> is an innovative manufacturer of specialized<br />

engineered flexible piping systems (i.e. custom hose<br />

assemblies and expansion joints). Since 1960, <strong>Thorburn</strong>’s<br />

corporate mission evolution and business philosophy<br />

have been customer driven and targeted to select niche<br />

applications where <strong>Thorburn</strong> can achieve clear positions<br />

of sustainable technological and market-share leadership.<br />

DESIGNING, BUILDING AND SUPPLYING<br />

THE WORLD’S FINEST<br />

EXPANSION JOINT AND CONNECTOR SYSTEMS

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

EXPERIENCE YOU CAN DEPEND ON<br />

Since 1960, <strong>Thorburn</strong> has devoted its expanding<br />

facilities and engineering expertise to the design,<br />

development and manufacture of flexible piping<br />

systems. Integrally associated with this product mix<br />

are <strong>Thorburn</strong>’s non-metallic expansion joints and<br />

connectors for piping and ducting systems.<br />

Specify <strong>Thorburn</strong> ducting and piping<br />

expansion joints and connectors and put your<br />

mind to rest.<br />

■ Emergency shut-down products at your service<br />

Tell us when you need the expansion joint or connector.<br />

Usually, we can supply sizes up to 36” in two days, 54” in<br />

three days and sizes up to 72” in four days.<br />

■ Compatible product line<br />

<strong>Thorburn</strong> has the most complete line of expansion joints<br />

and connectors in the industry. If we don’t have it, it’s not<br />

made. Call <strong>Thorburn</strong> for your single source of supply.<br />

■ Quality control<br />

<strong>Thorburn</strong> has a rigid certified quality control system to<br />

provide you with consistent quality products.<br />

■ Design integrity<br />

<strong>Thorburn</strong>’s non-metallic expansion joints are designed<br />

for tough, demanding industrial, commercial and<br />

municipal applications, such as: air conditioning, heating<br />

and ventilating systems, petrochemical, industrial process<br />

piping systems, power generating (fossil fuel and nuclear<br />

plants), marine, pulp and paper, waste water and sewage<br />

systems.<br />

Page 1<br />

QUALITY CONTROL<br />

■ CSA CAN3 Z299.1 certified<br />

■ ISO 9001<br />

■ Nuclear to ASME Section III NCA-4000<br />

Subsection NQA-1 CSA N285.0<br />

■ Welders and welding procedures ASME<br />

Section IX; VIII B31.1 and B31.3<br />

■ ASME B31.1, B31.3 Pressure piping<br />

certification<br />

■ Full traceability if required<br />

■ Size round up to 144” I.D.<br />

Rectangular, your design limits or our<br />

shipping door 14’ x 19’<br />

Test programs and design verification tests<br />

■ Expansion joint deflection test under design<br />

pressure<br />

■ Burst and hydrostatic testing to 150,000 psi<br />

■ Seismic and shock loading analysis<br />

■ External pressure testing for underwater<br />

service<br />

Our sincerest thanks to the many valued<br />

customers who have purchased <strong>Thorburn</strong>’s<br />

flexible piping products over the years. We look<br />

forward to working together with you and<br />

meriting your continued support for many years<br />

to come.<br />

Robert <strong>Thorburn</strong><br />

President

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

SUMMARY OF THORBURN'S NON-METALLIC<br />

FLEX CONNECTORS AND EXPANSION JOINTS<br />

MIGHTY-SPOOL HIGH PRESSURE PIPING EXPANSION JOINTS<br />

SPECIAL HAND BUILT LOW PRESSURE<br />

ROUND AND RECTANGULAR EXPANSION JOINTS<br />

Summary<br />

<strong>Thorburn</strong>'s custom designed low pressure round and rectangular elastomeric<br />

expansion joint systems.<br />

Arch profile: No arch to extra wide multiple arches.<br />

End connections: Integral moulded flat-face <strong>flanged</strong> drilled to<br />

your requirements or with labour saving cuff ends.<br />

Pressure/Temperature range:: Full vacuum to 25 psi / -60ºF<br />

to 400ºF.<br />

Size: Round up to 144"; Rectangular up to 19' x 14'.<br />

Specials: Can be made with concentric and eccentric, with special<br />

flanges, offsets or transition.<br />

SPECIAL PURPOSE TEFLON EXPANSION JOINTS<br />

Summary<br />

Summary<br />

<strong>Thorburn</strong>'s traditional work horse is the handcrafted elastomeric expansion joint system.<br />

It can be custom designed to suit specific application requirements. Available with any<br />

known elastomeric compound.<br />

Arch profile: High narrow arch design available with single, multiple or filled arches.<br />

End connections: Integral moulded flat-face drilled to your requirements or cuff ends<br />

with labour saving.<br />

Pressure/temperature range: Full vacuum to 300 psi / -60ºF to 400ºF<br />

Size I.D.: 1" to 144"<br />

Specials: Can be made with concentric, eccentric, special flanges, offsets, transition or<br />

from heavy duty externally pressurized designs.<br />

For extra high pressure external pressurized expansion joints, see page 67<br />

Teflon is the most versatile media resistant compound known to man<br />

and <strong>Thorburn</strong> offers the industry the broadest range of teflon expansion<br />

joints, either in moulded pure PTFE or teflon lined rubber or metal.<br />

Arch profile: Various to suit application.<br />

End connections: Flanged and drilled to your requirements.<br />

Pressure/Temperature range: Full vacuum to 300 psi / -60ºF to 400ºF.<br />

Size: 1/2" to 96" round.<br />

Page 2<br />

FOR DETAILS SEE PAGES 13 TO 20, 67<br />

FOR DETAILS SEE PAGES 22 TO 23<br />

FOR DETAILS SEE PAGES 54 TO 67

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

SUMMARY OF THORBURN'S NON-METALLIC<br />

FLEX CONNECTORS AND EXPANSION JOINTS<br />

MOULDED EXPANSION JOINTS FOR DETAILS SEE PAGES 34 TO 41<br />

Summary<br />

<strong>Thorburn</strong>'s moulded expansion joint series are economical joints and come in three basic<br />

styles: 1) Extra wide arch for double the movement per arch with full faced rubber flanges;<br />

2) Spherical self-cleaning arch system with floating flanges; 3) Small diameter spherical<br />

arch with threaded female ends. <strong>Thorburn</strong>'s moulded expansion joints are made from only<br />

limited amounts of elastomers.<br />

Arch profile: Long flowing self-cleaning style available in single or double moulded arches<br />

or multiple handbuilt versions.<br />

End connections: Flanged and female union style.<br />

Pressure/Temperature range: 26" Hg to 300 psi / -60ºF to 300ºF.<br />

Size I.D.: 1/2" to 36" round.<br />

Special: The moulded arch design can be made in a handbuilt version.<br />

ELBOW PUMP CONNECTORS AND FITTINGS FOR DETAILS SEE PAGES 42 TO 53<br />

Summary<br />

<strong>Thorburn</strong>'s rubber elbow connectors and fittings are designed to<br />

replace metallic or rubber lined products for pipe vibration, noise<br />

reduction or lateral movement. They are available in economical<br />

moulded as well as handbuilt versions. Available in any size of known<br />

elastomers.<br />

Arch profile: No arch, smooth tube.<br />

Pressure/Temperature range: Full vacuum to 300 psi / -60ºF to<br />

400ºF.<br />

Size: Round up to 30".<br />

Specials: <strong>Thorburn</strong>'s custom fittings can be made with transition<br />

joints, lateral, crosses or with custom radius elbows.<br />

DUCTING EXPANSION JOINT SYSTEMS FOR DETAILS SEE PAGES 68 TO 84<br />

Summary<br />

<strong>Thorburn</strong>'s <strong>Flex</strong>i-Duct Series FDR & FDC are non-metallic ducting expansion<br />

joints custom built and designed to provide stress relief in ducting systems<br />

by absorbing movement caused by thermal changes. They also act as vibration<br />

isolators, shock-absorbers and compensate for minor misalignment.<br />

Pressure: To ± 3 psi<br />

Temperature: Model FDR: below 400ºF; Model FDC: above 400ºF<br />

Special: Available in round or rectangular profiles<br />

Page 3

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

Introduction .................................................................... 6, 7<br />

Pipe simulation testing ...................................................... 8<br />

Applications<br />

<strong>Thorburn</strong> 42HP-HDX is specifically designed to provide<br />

under seawater piping relief with external or internal<br />

pressure differentials up to 225 psi. <strong>Thorburn</strong>’s 42HP-<br />

HDX technology was chosen for Canada’s largest<br />

offshore oil rig project: Hibernia<br />

Power generating industry ............................................. 9<br />

Marine / Commercial HVAC applications ..................... 10<br />

Waste water sewage treatment<br />

and drinking water treatment plant applications .......... 11<br />

Pulp and paper making process applications .............. 12<br />

Spool type expansion joints<br />

Introduction ............................................................ 13, 14<br />

Technical specifications: pressure,<br />

temperature, materials ................................................. 15<br />

Model 42HP: dimensional specifications ..................... 16<br />

Model 42HP movement/force/spring<br />

rate with single open arch design ................................ 17<br />

Models 42HP-CR (concentric) and 42HP-ER<br />

(eccentric) reducers specifications ........................ 18, 19<br />

Sleeve type Model 30DB ............................................. 20<br />

Low pressure round and rectangular expansion joints<br />

Models 15R (no arch) and 15RA (arch type) ............... 21<br />

Models 42HPO (offset type) and 42HPEF<br />

(enlarged flange type) .................................................. 21<br />

Models 15RR-LP (rectangular) and 15R-LP (round) ... 22<br />

Boot-<strong>Flex</strong> Model TCT ................................................... 23<br />

TABLE OF CONTENTS<br />

Page 4<br />

Technical data on flanges and control units<br />

Common flange dimension/drilling chart,<br />

mating pipe thickness for expansion joints,<br />

rubber pipe, retaining rings, control units ..................... 24<br />

Split retaining ring technology ...................................... 25<br />

Style CR Control rod assemblies - Introduction ........... 26<br />

Control rod assembly dimensions, ratings,<br />

how to order ................................................................. 27<br />

Installation and guiding practices<br />

Guiding, anchoring, installation, maintenance .... 28 to 31<br />

How to order custom rubber pipe expansion joints . 32, 33<br />

Moulded expansion joints<br />

TM20 Extra wide arch - Introduction ............................ 34<br />

TM20 Specifications .................................................... 35<br />

Introduction to Precision moulded Easy-<strong>Flex</strong> long<br />

flowing spherical arch expansion joint<br />

Series 101, 102 and 201 ........................................ 36, 37<br />

Easy-<strong>Flex</strong> Style 101 moulded single <strong>sphere</strong><br />

expansion joint system ................................................. 38<br />

Shown is a <strong>Thorburn</strong> 60” Mighty-Spool Model<br />

42HP multi-arch expansion joint system for the<br />

Ste-Marthe-du-Cap-de-la-Madeleine, Quebec,<br />

water treatment facility. This application’s<br />

requirements included absorbing ground settling<br />

movement and piping expansion.

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

Easy-<strong>Flex</strong> Style 201 moulded <strong>twin</strong> <strong>sphere</strong><br />

expansion joint system ................................................. 39<br />

Optional flange drilling ................................................. 40<br />

Easy-<strong>Flex</strong> Style 102 <strong>twin</strong>-<strong>sphere</strong> female<br />

metal threaded union rubber connectors ..................... 41<br />

Elbow-<strong>Flex</strong> expansion joints Series REF/REFR .... 42, 43<br />

Elbow connectors and fittings<br />

Flanged pump connector Model 60RPC ................ 44, 45<br />

Ultra-quiet coupled pipe connectors ............................ 46<br />

Paper mill suction couch Model 28TW ......................... 47<br />

<strong>Flex</strong>ipipe 60TMH and 61TMH - Introduction ................ 48<br />

<strong>Flex</strong>ipipe custom rubber hand crafted flexible pipes<br />

and fittings from 2” to 30” I.D. ....................................... 49<br />

<strong>Flex</strong>ipipe hose ends ..................................................... 50<br />

How to order flexipipe assemblies ............................... 51<br />

<strong>Thorburn</strong>’s special handcrafted rubber fittings ............. 52<br />

Fitting dimensions and ordering details ....................... 53<br />

Special purpose teflon expansion joints<br />

Model 42HP Spool type teflon lined exp. joints ...... 54, 55<br />

Easy-<strong>Flex</strong> Style 101 moulded teflon lined exp. joints ... 56<br />

Molded teflon expansion joints<br />

Power-<strong>Flex</strong> expansion joint system .............................. 57<br />

Power-<strong>Flex</strong> movement specifications ........................... 58<br />

How to calculate pressure temperature relationship<br />

for Power-<strong>Flex</strong> teflon expansion joint system ............... 59<br />

<strong>Thorburn</strong>’s lateral 60TMH-L custom rubber fitting system<br />

TABLE OF CONTENTS<br />

Page 5<br />

Shown is <strong>Thorburn</strong> self-cleaning, long flowing, single<br />

moulded spherical arch Series 101 expansion joint with<br />

floating flanges<br />

Power-<strong>Flex</strong> vacuum and dimensional data .................. 60<br />

Power-<strong>Flex</strong> typical styles and ordering information ...... 61<br />

Tef-<strong>Flex</strong> moulded PTFE expansion joints..................... 62<br />

Tef-<strong>Flex</strong> movement, weight and liner length data ......... 63<br />

Thor-Shield “safety shield” / Tef-<strong>Flex</strong> torque valves...... 64<br />

Hot-<strong>Flex</strong> “HF” teflon lined metal exp. joint system ........ 65<br />

Hot-<strong>Flex</strong> construction and ordering information ........... 66<br />

Special expansion joints<br />

Externally pressurized rubber expansion<br />

joint system .................................................................. 67<br />

Non-metallic ducting expansion joint systems<br />

<strong>Flex</strong>i-Duct Series FDR & FDC - Introduction ............... 68<br />

Why use non-metallic <strong>Flex</strong>i-Duct.................................. 69<br />

Applications ................................................................. 70<br />

Elastomeric and composite ducting - Introduction ....... 71<br />

<strong>Flex</strong>i-Duct engineering design concepts ................ 72, 73<br />

<strong>Flex</strong>i-Duct design considerations ........................... 74, 75<br />

Angle frame styles ................................................. 76, 77<br />

Moulded corner type “MC” ........................................... 78<br />

Materials, temperature limits, chemical compatibility ... 79<br />

How to order <strong>Flex</strong>i-Duct ......................................... 80, 81<br />

Installation instructions .......................................... 82, 83<br />

Data required ............................................................... 84<br />

Thermal expansion of pipe .......................................... 85<br />

Conversion Factors ................................................... 86, 87<br />

Warning, Warranty ........................................................... 88

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

THORBURN ELASTOMERIC PIPING EXPANSION<br />

JOINT AND CONNECTOR SYSTEM<br />

■ <strong>Flex</strong>ible piping system<br />

<strong>Thorburn</strong>’s elastomeric expansion joint<br />

and connector piping systems are<br />

sections of flexible pipe which are<br />

inserted into a rigid piping<br />

system. Regardless of materials<br />

and construction arrangements, <strong>Thorburn</strong>’s<br />

rubber piping expansion joints<br />

and connectors are designed to absorb<br />

various types of movements in a<br />

specified pressure/temperature range.<br />

■ Relieves piping stress<br />

The purpose of <strong>Thorburn</strong>’s rubber<br />

piping expansion joints is to relieve<br />

strain and stress in a piping system<br />

caused by thermal changes,<br />

misalignment, seismic activity,<br />

equipment vibration, load stresses,<br />

pump surges or ground settling.<br />

TYPICAL THORBURN 42HP<br />

SPOOL TYPE ARCH DESIGN<br />

CROSS<br />

SECTION<br />

Metal Wire<br />

Rubber<br />

Tube<br />

Carcass<br />

Fabric<br />

Reinforcing<br />

Cushion<br />

Rubber<br />

Rubber<br />

Cover<br />

Whether your piping problem is<br />

misalignment, noise or movement<br />

induced, let <strong>Thorburn</strong>’s<br />

expansion joint technology show<br />

you the way!<br />

■ Shape size range<br />

Round 1/2” to 144” I.D. Rectangular up to 20 feet; also<br />

available custom concentric, eccentric and transition ends<br />

custom built from various elastomers and fabrics. If you<br />

have any requirements, call <strong>Thorburn</strong> for a timely solution.<br />

■ End connections<br />

Flanged (metric/imperial), CUFF (Clamp-on style) or<br />

beaded for swivel <strong>flanged</strong> connections.<br />

■ Expansion joint arch types<br />

Custom handbuilt spool, double movement extra wide, long<br />

flowing spherical or no arch are custom designed by<br />

<strong>Thorburn</strong> to meet specific application requirements.<br />

THORBURN’S RUBBER EXPANSION JOINTS AND CONNECTORS<br />

QUALITY ASSURANCE CERTIFICATION AND COMPLIANCE<br />

■ ASME B31.1 and B31.3 pressure piping registration<br />

■ Rubber Manufacturers Association IP-2<br />

■ Fluid Sealing Association (FSA), Rubber Expansion Joint Division, Technical<br />

Handbook 5th and 6th Ed.<br />

■ CSA CAN3 Z299.1 QMI certified / N285.0 Class 6<br />

■ ISO 9001<br />

■ ASME Section III NCA-4000 Subsection NQA-1 (nuclear Class 1, 2, 3), N285.0<br />

■ Welders and Welding Procedures, ASME section IX, VIII B31.1 and B31.3<br />

THORBURN 60TMH<br />

AND 61TMH FLEXIBLE<br />

RUBBER PIPE<br />

CONNECTORS<br />

Page 6<br />

Helical wire reinforcement Tube<br />

Split retaining rings<br />

Fabric reinforcement<br />

<strong>Thorburn</strong> style 60TMH (wire reinforced), 61TMH (non wire<br />

reinforced) flexible rubber pipe connectors, Model 60RPC<br />

pump connectors and fittings are reinforced straight rubber<br />

pipes fabricated from various elastomers and fabrics primarily<br />

designed to absorb noise and vibration in a piping system.<br />

These custom connectors are also available as elbows, tees,<br />

laterals. In addition, <strong>Thorburn</strong> has the design and<br />

manufacturing capabilities to supply custom moulded branch<br />

and transition assemblies end. End connections’ types are the<br />

same as for rubber expansion joints.<br />

<strong>Thorburn</strong>’s rubber pipe connectors are detailed on pages 42 to 53

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

THORBURN RUBBER EXPANSION JOINT SYSTEM<br />

MEANS QUALITY PROTECTION EVERY TIME<br />

<strong>Thorburn</strong> rubber expansion joints are custom designed by engineers<br />

and fabricated by skilled craftsmen following rigid step-by-step<br />

quality control standards. <strong>Thorburn</strong>’s rubber expansion joints are used<br />

to address and solve defined pipe motion problems. If you have a<br />

specific requirement or want to reduce maintenance cost in your<br />

piping system, specify the right product the first time by calling<br />

<strong>Thorburn</strong>’s flexible piping specialist team today.<br />

Typical hand built <strong>Thorburn</strong><br />

rubber expansion joint<br />

Typical metallic bellows<br />

expansion joint<br />

<strong>Thorburn</strong>’s rubber pipe expansion joints absorb<br />

and isolate movement better. Here is why:<br />

■ High resistance to shock<br />

Unlike a metal joint, <strong>Thorburn</strong> rubber expansion joints absorb movements<br />

in all directions without stress and are capable of preventing unexpected<br />

shock induced movements caused by pumps, blowers and other agitating<br />

equipment, particularly during plant start-ups or shutdowns.<br />

Page 7<br />

<strong>Thorburn</strong>’s rubber expansion joint’s compact<br />

design simplifies installation<br />

THORBURN RUBBER EXPANSION<br />

JOINT’S DISTINCTIVE ADVANTAGES<br />

■ Compact to simplify installation<br />

■ Absorbs movement in all directions<br />

■ Reduces mechanical noises<br />

■ Compensates for misalignment<br />

■ Eliminates electrolysis between<br />

dissimilar metals<br />

■ Relieves strain in the piping system<br />

■ Doesn’t require gaskets<br />

■ Vibration and sound absorption<br />

<strong>Thorburn</strong>’s elastomeric joints offer significant advantages over a metallic joint, preventing transmission of vibration without harming<br />

the joint.<br />

■ Freedom from embrittlement<br />

Failure of a metal expansion joint is due primarily to continuous flexing and built-up stress points resulting in a fracture at the point<br />

of embrittlement . Constant/intermittent flexing keeps the rubber “alive” and eliminates flex cracking in <strong>Thorburn</strong>’s rubber expansion<br />

joints.<br />

■ Great recovery from movement<br />

When a metal joint is fully compressed, it assumes a permanent set. <strong>Thorburn</strong>’s rubber expansion joint continues to return to its<br />

original position.<br />

■ Freedom from corrosion<br />

To achieve comparable corrosion resistancy metal bellows would have to employ exotic alloys at a tremendous cost. In addition,<br />

<strong>Thorburn</strong>’s rubber expansion joints in sea water will not corrode nor does the continuous flexing permit scale to form.<br />

■ Superior abrasive and erosion resistance<br />

Thin metallic bellows will typically wear out at the root over time with minimum abrasion, where as a rubber joint can be manufactured<br />

with a smooth abrasion resistant lining to protect it from the harmful effects of sea water salt, slurry and other abrasive media.

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

FIRST IN RUBBER EXPANSION JOINT PIPE<br />

SIMULATION TESTING<br />

<strong>Thorburn</strong> is the only manufacturer capable of testing large diameter rubber expansion joints up to<br />

120” I.D. under actual design pressure or vacuum conditions, while simulating any design movement or<br />

series of movements experienced in a piping system during operation (i.e. design axial compression,<br />

extension and/or lateral deflection movements).<br />

Shown is <strong>Thorburn</strong>’s 42HP expansion joint subjected to a<br />

pressurized axial extension movement<br />

<strong>Inc</strong>reases quality and reduces costs<br />

<strong>Thorburn</strong>’s pipe simulator has dramatically increased the safety<br />

and quality standards of rubber expansion joints while reducing<br />

costly and dangerous failures from occurring during commissioning<br />

or during actual service.<br />

Shown is <strong>Thorburn</strong>’s 42HP spool type arch profile subjected to<br />

pressurized compression movement<br />

Page 8<br />

Exclusive <strong>Thorburn</strong> technology<br />

<strong>Thorburn</strong>’s pipe simulator allows rubber expansion joints to be<br />

subjected to actual field conditions before being put into service.<br />

Therefore, it provides the means to truly verify expansion joint<br />

performance and design capabilities as well as detect any defective<br />

or faulty expansion joints before commissioning them into service.<br />

Shown is an arch profile of <strong>Thorburn</strong>’s 42HP subjected to lateral<br />

movement under positive or negative pressure<br />

Typical applications for pipe simulator<br />

■ Superior verification testing<br />

Engineers and designers preferring to increase the quality of<br />

its piping system can specify <strong>Thorburn</strong> pipe simulation testing<br />

to verify the expansion joint design and performance<br />

capabilities before putting new expansion joints into service.<br />

■ Power generating industry preventive maintenance<br />

testing<br />

The quality standards required by both fossil fuel and nuclear<br />

electrical power generating industries can benefit by periodical<br />

pipe simulation testing of its existing expansion joints to verify<br />

the quality and uncover any potential weakness that could<br />

lead to a dangerous and costly failure.

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

POWER GENERATING INDUSTRY<br />

<strong>Thorburn</strong> has extensive successful experience in designing, manufacturing and supplying high pressure elastomeric expansion<br />

joints up to 108” (274 cm) I.D. to the world’s fossil fuel and nuclear power electrical generating stations.<br />

TYPICAL THORBURN RUBBER<br />

EXPANSION JOINT APPLICATIONS<br />

FOUND IN POWER GENERATING<br />

STATIONS<br />

■ Condenser circulating water<br />

system pump inlet and outlet<br />

■ Raw service water pump inlet and<br />

outlet<br />

■ Raw service water system heat<br />

exchanger inlet and outlet<br />

■ Raw service water strainer outlet<br />

■ Raw service water discharge line<br />

to the header<br />

REACTOR BUILDING<br />

Fuel<br />

Loading<br />

Machine Reactor<br />

Steam<br />

Typical <strong>Thorburn</strong> expansion joint<br />

being installed at electrical<br />

generator station<br />

TURBINE BUILDING<br />

Turbine<br />

<strong>Thorburn</strong>’s expansion joints were chosen for the AECL designed Candu Korean<br />

Wolsong 2, 3, 4 nuclear power generating stations<br />

<strong>Thorburn</strong>’s pipe simulator specialists pressure/vacuum testing<br />

<strong>Thorburn</strong> style 42HP rubber expansion joints under full design<br />

dynamic movement conditions<br />

Generator<br />

Circulating<br />

Water<br />

Page 9<br />

<strong>Thorburn</strong>’s packaging professionals<br />

meticulously preparing a 108” I.D.<br />

<strong>Thorburn</strong> 42HP joint for shipment<br />

Power industry expansion joints routing and location<br />

N.B. Power engineer inspecting a 24” I.D. <strong>Thorburn</strong> 42HP<br />

expansion joint at the Belledune generating station unit 2

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

MARINE APPLICATIONS<br />

<strong>Thorburn</strong> rubber expansion joints provide an economical solution in the isolation of noise transmission,<br />

vibration and connecting misaligned pipe found in offshore platforms and large marine vessels.<br />

<strong>Thorburn</strong> rubber expansion joints were chosen for<br />

Canada’s and one of the world’s largest off shore oil<br />

drilling platform. The Hibernia Project is situated in the<br />

Atlantic Ocean off the coast of Newfoundland, Canada.<br />

■ Air intake on diesel engines<br />

■ Ballast<br />

■ Between scoop and the condensers<br />

■ Circulating lines to the condenser<br />

■ Fog foam lines<br />

■ Schools ■ Stores ■ High rise office towers ■ Hotels<br />

<strong>Thorburn</strong> rubber expansion joints were<br />

chosen to provide stress and noise relief for<br />

the Canada Post headquarters building’s<br />

piping system in Ottawa, Ontario, Canada<br />

TYPICAL MARINE INSTALLATIONS<br />

■ Fire and bilge pump lines<br />

■ Forced draft lines<br />

■ Overboard discharge<br />

■ Sanitation system<br />

■ Ventilation lines<br />

Typical <strong>Thorburn</strong> rubber expansion joint<br />

location and routing<br />

■ Air ducts ■ Compressor lines ■ Circulating water lines ■ Pump suction and discharge ■ Turbine to condenser ■ Refrigeration<br />

Page 10<br />

<strong>Thorburn</strong>’s marine vessel rubber expansion joints routing and<br />

location<br />

OFFSHORE APPLICATIONS<br />

■ Mud pump-lines<br />

■ Diesel fuel lines<br />

■ Fresh water and sea water lines<br />

■ Permanent ballast water secondary<br />

containment piping system<br />

COMMERCIAL AND INSTITUTIONAL BUILDINGS<br />

AIR CONDITIONING, HEATING, VENTILATION SYSTEMS<br />

■ Apartment buildings<br />

■ Hospitals<br />

Typical commercial and institutional<br />

building installations for <strong>Thorburn</strong> rubber<br />

expansion joints

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

WASTE WATER SEWAGE TREATMENT<br />

DRINKING WATER TREATMENT PLANTS<br />

Consultants specify <strong>Thorburn</strong> rubber expansion joints<br />

and fittings to maximize design flexibility<br />

■ Aeration lines<br />

■ Raw sewage lines<br />

■ Grit pump lines<br />

Installing a typical rubber expansion<br />

joint in a waste water sewage<br />

treatment plant<br />

■ Sludge pumps<br />

■ Sinter sludge ash lines<br />

Page 11<br />

<strong>Thorburn</strong>’s rubber expansion joints were chosen for the multimillion<br />

dollar “Ville de Québec” water filtration project<br />

1 Aeration basin floating cover: connections are served with <strong>Thorburn</strong>’s 60TMH<br />

assemblies to provide the required flexibility to cover the changing level with<br />

variations in sewage flow.<br />

2 Air blowers: make extensive noise and the discharge is very hot. <strong>Thorburn</strong> high<br />

temperature (chlorobutyl) model TM20 joint can reduce noise by over 20 decibels.<br />

The air blower inlet side is connected with a <strong>Thorburn</strong> 30DB clamp-on type<br />

expansion joint to isolate vibration and pipe movement.<br />

3 Sludge pump lines are ideally suited for <strong>Thorburn</strong> long flowing arch style 202<br />

expansion joints. These expansion joints relieve stress from ground settlement or<br />

pipe and pump vibration misalignment.<br />

4 <strong>Thorburn</strong> 60TMH-E elbow fittings have proven even to outwear stainless steel<br />

elbows. Therefore, maintenance is greatly reduced for example on extremely<br />

abrasive slurry lines, such as sinter sludge ash.<br />

5 <strong>Thorburn</strong> 60TMH custom assemblies provide the required flexibility and design<br />

to dump sludge from plant to truck and loading docks or barge.<br />

Typical waste water treatment plant

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

■ Process piping systems<br />

■ Slurry lines<br />

■ Heating and cooling systems<br />

■ Pump inlet and discharge lines<br />

Saveall<br />

Beater<br />

PULP AND PAPER MAKING PROCESS<br />

Applications for <strong>Thorburn</strong> rubber expansion joints and<br />

custom connectors<br />

Wood source<br />

Power supply<br />

Refiner<br />

Schematic view of pulp & paper processing.<br />

■ Black liquor lines<br />

■ Suction box<br />

■ Causticizer and digester piping<br />

■ White water piping<br />

Pulpwood<br />

stacker Barking drum Water purification<br />

Washer Chipper Chip<br />

storage bin<br />

Bleached<br />

pulp<br />

storage<br />

Jordan<br />

Flow<br />

box<br />

Steam and<br />

power plant<br />

Mixing box<br />

Dandy<br />

roll<br />

FOURDRINIER<br />

Suction<br />

boxes Suction roll<br />

Pulp washers<br />

PRESSES<br />

Bleaching<br />

Bleaching<br />

Bleaching<br />

Screens<br />

Slice<br />

Felt<br />

blankets<br />

Case study: When Bowater<br />

Mersey Paper Co. had a<br />

problem with expansion joints<br />

located on their white water<br />

piping system, <strong>Thorburn</strong><br />

provided the solution with its<br />

42HP Series teflon lined<br />

rubber expansion joint system.<br />

Problem solved!<br />

Chip<br />

conveyors Digestor Blow<br />

tank Slaked<br />

lime<br />

storage<br />

Unbleached<br />

pulp<br />

storage<br />

DRYERS<br />

Page 12<br />

Brown<br />

stock<br />

Size press<br />

Cooking<br />

liquor<br />

Evaporator<br />

Black<br />

liquor<br />

Calender<br />

Green<br />

liquor<br />

storage<br />

Green<br />

liquor<br />

mixing tank<br />

Waste<br />

treatment plant<br />

Slaking<br />

tank<br />

Lime<br />

sludge<br />

CALENDERS<br />

Lime<br />

Kiln<br />

Slitter<br />

Filter<br />

Winder<br />

<strong>Thorburn</strong>’s flexible rubber piping and fitting technology was<br />

used to upgrade the traditional open trough piping found<br />

between the caustizer and slacker tank at Miramichi Pulp and<br />

Paper in New Castle, N.B.

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

MIGHTY-SPOOL<br />

HIGH QUALITY SPOOL JOINT SYSTEM<br />

35LP LOW PRESSURE 50SP MEDIUM PRESSURE 42HP HIGH PRESSURE 42HPX EXTRA HIGH PRESSURE<br />

Mighty-Spool Light-Weight<br />

Model 35LP and Multiple Arch<br />

Expansion Joint<br />

<strong>Thorburn</strong> Mighty-Spool single and<br />

multiple arch types are available in<br />

light-weight series Model 35LP. Dimensionally<br />

the same as the standard<br />

product, except for reduced body thickness,<br />

this series is designed for very<br />

low pressure and vacuum applications.<br />

Mighty-Spool multiple arch expansion<br />

joints are composites of the single arch<br />

design and are capable of movements<br />

of a single arch multiplied by the<br />

Mighty-Spool Hand Crafted Quality<br />

<strong>Thorburn</strong>’s Mighty-Spool expansion joints are the work horses of our rubber expansion<br />

joint line meeting or exceeding the design requirements listed in the FSA type A.1, A.2 and<br />

A.3 spool arch type joints. <strong>Thorburn</strong> does not employ marginal practices or materials,<br />

which reduce safety factors. All <strong>Thorburn</strong> Mighty-Spool joints meet a minimum 4 to 1<br />

safety factor at rated operating temperatures and pressures. <strong>Thorburn</strong>’s standard Model<br />

42HP High Pressure represents 65% of our sales.<br />

Fig. 1: Mighty-Spool single<br />

open arch design<br />

Mighty-Spool Filled Arch System<br />

<strong>Thorburn</strong> Mighty-Spool open arch design may be modified to reduce<br />

possible turbulence, prevent the collection of solids in the arch way, which<br />

could obstruct the joint movement. To solve such problems, <strong>Thorburn</strong>’s<br />

Mighty-Spool joints may be supplied with a bonded-in place soft filler rubber<br />

in the arch, providing a smooth interior bore. It should be noted that filled<br />

arches reduce movement capability to half (50%) and increase the spring rate<br />

by 4 times of the normal movements and spring rates of comparable size,<br />

Mighty-Spool open arch expansion joints. This general rule is similar for all<br />

<strong>Thorburn</strong> rubber expansion joints with filled arches.<br />

A<br />

Flange & Ret. Ring O.D.<br />

Nominal Pipe Size<br />

Joint I.D.<br />

B C<br />

F<br />

G<br />

E<br />

D<br />

To order Mighty-Spool expansion joints,<br />

please see pages 32 and 33 for details.<br />

Steel Retaining Ring<br />

Page 13<br />

<strong>Thorburn</strong> Mighty-Spool expansion joints are<br />

available in sizes from 1” to 144” I.D.<br />

Steel Retaining Ring<br />

Fig. 2: Mighty-Spool multiple open arch design<br />

number of arches. The spring rate for a multi-arch type expansion joint is equal to the spring rate for a single arch design divided by the<br />

number of arches. This general rule is similar for all <strong>Thorburn</strong> rubber expansion joints.<br />

In order to maintain lateral stability and prevent sagging when the joint is installed in a horizontal position, a maximum number of arches<br />

supplied is 4.<br />

Special note: <strong>Thorburn</strong> can provide special designs to accommodate movements of<br />

30” (600 mm). If greater movement or special ends are required in your piping system,<br />

call <strong>Thorburn</strong> flexible piping specialists today for an economical and timely solution.<br />

A<br />

A<br />

Equally Spaced<br />

Bolt Holes<br />

Hole<br />

Die<br />

Bolt Circle Bolt<br />

A<br />

Flange & Ret. Ring O.D.<br />

Nominal Pipe Size<br />

Joint I.D.<br />

B C<br />

Spool type expansion joint with filled and open arch<br />

design with a flange by sleeve type connecting end<br />

F<br />

Section AA<br />

G<br />

E<br />

D

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

<strong>Thorburn</strong>’s rubber expansion joint<br />

construction features<br />

Though <strong>Thorburn</strong> manufactures and supplies a wide<br />

variety of expansion joints, all our rubber joints have<br />

4 basic components: tube, reinforcement, cover and<br />

end connections. Shown to the right is <strong>Thorburn</strong> Mighty-<br />

Spool high pressure joint with integral flange.<br />

Tube:<br />

Seamless elastomeric leak proof lining specifically<br />

designed to maintain fluid leak tight integrity of the<br />

expansion joint and protect the carcass from penetration<br />

or saturation of the media being transferred. <strong>Thorburn</strong>’s<br />

expansion joint tubes can be designed to transfer chemical<br />

and petroleum products, sewage, gases as well as abrasive<br />

media.<br />

MIGHTY-SPOOL<br />

BUILT-IN QUALITY PIPE JOINTS<br />

<strong>Thorburn</strong> 108” Model<br />

42HP<br />

Cover placement<br />

during expansion joint<br />

rubber moulding and<br />

carcass building stages<br />

Typical Mighty-Spool cross-section expansion joint with integral flanges<br />

Page 14<br />

STYLE 42HP<br />

Integral flange<br />

Gap filler hard rubber<br />

Metallic<br />

reinforcement<br />

Protective cover<br />

High profile arch<br />

Reinforcement:<br />

a) Fabric Reinforcement: The fabric reinforcement is the flexible and supporting member between the tube and cover. Fabrics of<br />

high strength synthetic fibres are used depending on pressure and temperature requirements. All fabric plies are calendered to<br />

permit flexibility between the fabric plies and to reduce service strain.<br />

b) Metallic Reinforcement: Consists of coated high tensile spring steel wire and/or solid steel rings embedded in the carcass. The<br />

purpose of the metallic reinforcements is to strenghten the joint permitting the rated working pressures and to supply the joint with<br />

the necessary rigidity for thermal vacuum service. Specially compounded filler rubbers are used between the layers of metallic<br />

reinforcement to prevent migration when pressurized. Special metallic reinforcement is used when <strong>Thorburn</strong> rubber expansion<br />

joints are used for external service.<br />

Cover:<br />

The primary function of the cover is to protect the carcass from outside damage or abuse. Special elastomers can be supplied to resist<br />

chemicals, oils, sunlight, acid fumes, ozone, sea water, etc.<br />

End connections:<br />

Integral flanges are constructed of fabric reinforcement, smooth finish, full-faced flange that form a tight seal against the mating pipe<br />

flanges without the need of gaskets. Also available are soft cuff clamp-on ends designed to fit over a pipe and be clamped on.<br />

Inner liner<br />

Carcass<br />

<strong>Thorburn</strong> Mighty-Spool single open arch design being prepared for<br />

hydrostatic pressure testing

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

TECHNICAL SPECIFICATIONS<br />

THORBURN RUBBER PIPE EXPANSION JOINT AND PIPE CONNECTORS<br />

Nominal<br />

Design of Expansion Joint Construction<br />

Pipe Size Model 35LP Model 50SP Model 42HP Model 42HPX<br />

I.D. of Low Pressure Medium Pressure High Pressure Extra High<br />

Exp. Design Design Design Pressure Design<br />

Joint FSA Series A FSA Series B FSA Series C<br />

Positive Negative Positive Negative Positive Negative Positive Negative<br />

<strong>Inc</strong>hes PSIG in. of hg. PSIG in. of hg. PSIG in. of hg. PSIG in. of hg.<br />

1/4 to 4 165 26 165 30 200 30 300 30<br />

5 to 12 140 26 140 30 190 30 275 30<br />

14 85 15 65 30 130 30 225 30<br />

16 to 20 65 15 50 30 110 30 200 30<br />

22 to 24 65 15 45 30 100 30 175 30<br />

26 to 40 55 15 45 30 90 30 150 30<br />

42 to 66 55 15 40 30 80 30 150 30<br />

68 to 96 45 15 40 30 70 30 125 30<br />

98 to 108 40 15 40 30 60 30 90 30<br />

110 to 144 30 15 40 30 50 30 80 30<br />

Nominal<br />

Pipe Size<br />

I.D. of<br />

Exp.<br />

Joint<br />

Tolerances for <strong>Thorburn</strong> Rubber Pipe & Expansion Joints<br />

Non-<br />

Exp. critical<br />

joint flange Bolt<br />

Face to face length “F” 2 (inches)<br />

All dimensions to be an average reading.<br />

Applies to open or filled arch.<br />

I.D. 1 O.D. 1 line 3 0 to 6 7 to 12 14 to 18 20 & up<br />

0 to 10 ±3/16 ±1/4 ±3/16 ±1/8 +1/8 ±3/16 +3/16 4<br />

-3/16 -1/4<br />

12 to 22 ±1/4 ±3/8 ±1/4 ±1/8 +1/8 ±3/16 +3/16 4<br />

-3/16 -1/4<br />

24 to 46 ±3/8 ±1/2 ±5/16 +1/8 ±3/16 +3/16 ±1/4 4<br />

-3/16 -1/4<br />

48 to 70 +3/8 +3/4 ±3/8 ±3/16 +3/16 ±1/4 +1/4 5<br />

-1/2 -1/2 -1/4 -5/16<br />

72 & up +3/8 +1 ±1/2 +3/16 ±1/4 +1/4 +1/4 6<br />

-5/8 -3/4 -1/4 -5/16 -3/8<br />

1) All diameters to be measured with a “Pi” tape.<br />

2) All linear dimensions to be measured with a steel rule and averaged.<br />

3) Bolt line = Actual I.D. + 2 (Average “X” Dimension) + Bolt hole diameter<br />

Mechanical Vibration in a Steel Piping System Reduced with the<br />

Installation of <strong>Thorburn</strong>’s Pipe Connectors or Expansion Joints<br />

Pipe<br />

Installation in Pipe with a:<br />

System<br />

Vibration<br />

Frequency<br />

Expansion Joint<br />

8” ID x 6” F/F<br />

Vibration reduction at<br />

Rubber Pipe<br />

8” ID x 24” F/F<br />

Vibration reduction at<br />

HZ 10 PSIG 50 PSIG 80 PSIG 10 PSIG 50 PSIG 80 PSIG<br />

40 37% 55% 72% 87% 91% 93%<br />

68 60% 68% 78% 95% 96% 99%<br />

125 44% 50% 60% 98% 99% 99%<br />

250 44% 50% 50% 96% 97% 99%<br />

500 65% 89% 90% 91% 93% 94%<br />

1000 90% 96% 98% 82% 91% 96%<br />

2000 94% 95% 96% 99% 99% 99%<br />

4000 90% 93% 97% 99% 99% 99%<br />

8000 89% 89% 94% 97% 97% 98%<br />

Example: If an 8” steel piping system had a major vibration frequency of 1000 HZ at 50 PSIG,<br />

the installation of an expansion joint into the system, the percentage of reduction of vibration<br />

would be 96%.<br />

# of<br />

Measurements<br />

to<br />

be<br />

Averaged<br />

Page 15<br />

Pressure Characteristics of <strong>Thorburn</strong><br />

Mighty-Spool Expansion Joints<br />

Notes:<br />

1) Pressure limitations are based on a minimum 4 to 1 safety<br />

factor at 180ºF (82ºC) for rated pressure.<br />

2) For higher pressure and/or temperature expansion joint,<br />

contact <strong>Thorburn</strong> flexible piping specialists for details.<br />

3) Always advise <strong>Thorburn</strong> if expansion joint will be subjected<br />

to full vacuum.<br />

4) Model 42HP also available for external deep sea water<br />

service. Please specify <strong>Thorburn</strong> Model 42HPX-HD and<br />

provide all related service and design requirements.<br />

Type of elastomer Class Type of fabric Class<br />

Gum rubber Std. I Cotton Std. I<br />

Natural rubber Std. I Rayon Std. I<br />

SBR/GRS/Buna-S Std. I Nylon Std. II<br />

Neoprene Std. II Polyester Spc. II<br />

Buna-N/Nitrile Std. II Fiberglass/Asbestos Spc. II<br />

Hypalon Std. II Asbestos Spc. II<br />

Butyl Std. II Fiberglass Spc. II<br />

Butyl, Chloro Spc. II Kevlar Spc. II<br />

EPDM Spc. II Nomex Spc. II<br />

Viton/Fluorel Spc. II<br />

Silicone Spc. II<br />

Teflon/TFE/FEP Spc. II<br />

Maximum Service Temperature of Materials for<br />

<strong>Thorburn</strong>’s Expansion Joints and Pipe Connectors<br />

Stardard Class I - Recommended up to 180ºF<br />

Standard Class II - Recommended up to 230ºF<br />

Special Class II - Recommended for over 230ºF<br />

Rubber Acoustical Impedance Compared<br />

Sound Acoustical<br />

velocity Density impendance Relative<br />

Material (in./sec.) (lbs./in. 3 ) (lbs./in. 2 -sec.) Impendance<br />

Steel 206,500 0.283 58,400 500.0<br />

Copper 140,400 0.320 45,000 425.0<br />

Cast iron 148,800 0.260 38,700 365.0<br />

Lead 49,800 0.411 20,400 190.0<br />

Glass 216,000 0.094 20,300 190.0<br />

Concrete 198,000 0.072 14,200 134.0<br />

Water 56,400 0.036 2,030 19.0<br />

Pine 132,000 0.0145 1,910 18.0<br />

Cork 19200 0.0086 165 1.6<br />

Rubber 2,400 0.0442 106 1.0<br />

Acoustical impedance is defined as the product of material density times velocity of<br />

sound in that material. In acoustical systems low impedance corresponds to low sound<br />

transmission. Relative impedance is based on Rubber = 1.0

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

Nominal<br />

Pipe Size<br />

Exp. Jt. I.D.<br />

1<br />

1 1/4<br />

1 1/2<br />

2<br />

2 1/2<br />

3<br />

4<br />

5<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

18<br />

20<br />

22<br />

24<br />

26<br />

28<br />

30<br />

32<br />

34<br />

36<br />

40<br />

42<br />

48<br />

50<br />

54<br />

56<br />

60<br />

66<br />

72<br />

78<br />

84<br />

96<br />

108<br />

144<br />

MIGHTY SPOOL MODEL 42HP<br />

QUALITY PROTECTING EXPANSION JOINTS<br />

Note: Flange and retaining ring dimensions shown are in accordance with 125/150 pound standard drilling of: ANSI B16.1, B16.24, B16.51, MSS SP-44. Items marked with * are drilled to AWWA<br />

C207-78 Table 1 Class D, Table 3, Class E. Retaining plate thickness “G” is 3/8” for all sizes.<br />

For larger diameters, offsize diameters, special drilling, special lengths, greater movements, reducers transition connectors or other specials, call<br />

<strong>Thorburn</strong>’s flexible piping team today at 1-800-363-6613.<br />

Expansion Joint<br />

Flange<br />

Single<br />

Arch<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

8<br />

8<br />

8<br />

8<br />

8<br />

8<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

For pressure temperature and other specifications, please see page 15<br />

“Face to Face” Minimum<br />

Recommended Length<br />

Two<br />

Arch<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

16<br />

16<br />

16<br />

16<br />

16<br />

Three<br />

Arch<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

14<br />

14<br />

14<br />

16<br />

16<br />

16<br />

16<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

20<br />

20<br />

Typical 42HP<br />

Single open arch<br />

Four<br />

Arch<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

14<br />

16<br />

16<br />

16<br />

16<br />

20<br />

20<br />

20<br />

20<br />

22<br />

22<br />

22<br />

22<br />

22<br />

22<br />

22<br />

22<br />

22<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

Retaining<br />

Ring I.D.<br />

2 3/8<br />

2 5/8<br />

2 7/8<br />

3 5/8<br />

4 1/8<br />

4 5/8<br />

5 7/8<br />

6 7/8<br />

7 7/8<br />

9 7/8<br />

12 1/8<br />

14 1/2<br />

16 1/2<br />

18 1/2<br />

20 1/2<br />

22 5/8<br />

24 5/8<br />

26 5/8<br />

28 7/8<br />

30 7/8<br />

32 7/8<br />

34 7/8<br />

37<br />

39<br />

43<br />

45 1/4<br />

51 1/4<br />

53 1/4<br />

57 1/4<br />

59 1/4<br />

63 1/4<br />

69 1/4<br />

75 1/4<br />

81 1/4<br />

87 1/2<br />

99 3/8<br />

112 1/2<br />

149 1/2<br />

Standard Flange Dimensions<br />

and Drilling<br />

Flange<br />

O.D.<br />

4 1/4<br />

4 5/8<br />

5<br />

6<br />

7<br />

7 1/2<br />

9<br />

10<br />

11<br />

13 1/2<br />

16<br />

19<br />

21<br />

23 1/2<br />

25<br />

27 1/2<br />

29 1/2<br />

32<br />

34 1/4<br />

36 1/2<br />

38 3/4<br />

41 3/4<br />

43 3/4<br />

46<br />

50 3/4<br />

53<br />

59 1/2<br />

61 3/4<br />

66 1/4<br />

68 3/4<br />

73<br />

80<br />

86 1/2<br />

93<br />

99 3/4<br />

113 1/4<br />

126 3/4<br />

167 1/4<br />

Bolt<br />

Circle<br />

3 1/8<br />

3 1/2<br />

3 7/8<br />

4 3/4<br />

5 1/2<br />

6<br />

7 1/2<br />

8 1/2<br />

9 1/2<br />

11 3/4<br />

14 1/4<br />

17<br />

18 3/4<br />

21 1/4<br />

22 3/4<br />

25<br />

27 1/4<br />

29 1/2<br />

31 3/4<br />

34<br />

36<br />

38 1/2<br />

40 1/2<br />

42 3/4<br />

47 1/4<br />

49 1/2<br />

56<br />

58 1/4<br />

62 3/4<br />

65<br />

69 1/4<br />

76<br />

82 1/2<br />

89<br />

95 1/2<br />

108 1/2<br />

120 3/4<br />

158 1/4<br />

Page 16<br />

No. of<br />

Holes<br />

4<br />

4<br />

4<br />

4<br />

4<br />

4<br />

8<br />

8<br />

8<br />

8<br />

12<br />

12<br />

12<br />

16<br />

16<br />

20<br />

20<br />

20<br />

24<br />

28<br />

28<br />

28<br />

32<br />

32<br />

36<br />

36<br />

44<br />

44<br />

44<br />

48<br />

52<br />

52<br />

60<br />

64<br />

64<br />

68<br />

72<br />

84<br />

Diameter<br />

of Holes<br />

5/8<br />

5/8<br />

5/8<br />

3/4<br />

3/4<br />

3/4<br />

3/4<br />

7/8<br />

7/8<br />

7/8<br />

1<br />

1<br />

1 1/8<br />

1 1/8<br />

1 1/4<br />

1 1/4<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 5/8<br />

1 5/8<br />

1 5/8<br />

1 5/8<br />

1 5/8<br />

1 5/8<br />

1 7/8<br />

1 7/8<br />

1 7/8<br />

1 7/8<br />

1 7/8<br />

1 7/8<br />

2 1/8<br />

2 1/8<br />

2 3/8<br />

2 5/8<br />

3 3/8<br />

“A”<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

5/8<br />

3/4<br />

3/4<br />

3/4<br />

7/8<br />

7/8<br />

7/8<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 3/8<br />

FOR ORDERING DETAILS SEE PAGES 32 AND 33<br />

Retaining<br />

Ring<br />

Typical 42HP<br />

Single filled arch<br />

Typical Mighty-Spool<br />

Body Dimensions<br />

“B”<br />

1/2<br />

1/2<br />

5/8<br />

3/4<br />

7/8<br />

7/8<br />

7/8<br />

7/8<br />

7/8<br />

7/8<br />

1<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 3/8<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

1 5/8<br />

1 5/8<br />

1 5/8<br />

1 5/8<br />

1 3/4<br />

Typical 42HP<br />

Two open arches<br />

“C”<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 1/4<br />

1 1/2<br />

1 1/2<br />

1 1/2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2 1/4<br />

2 1/4<br />

2 1/4<br />

2 1/4<br />

2 1/4<br />

2 1/4<br />

2 1/4<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

2 1/2<br />

“D”<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

3/4<br />

3/4<br />

3/4<br />

3/4<br />

3/4<br />

3/4<br />

7/8<br />

7/8<br />

7/8<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

1 1/8<br />

“E”<br />

7/16<br />

7/16<br />

7/16<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

5/8<br />

11/16<br />

11/16<br />

3/4<br />

3/4<br />

3/4<br />

25/32<br />

25/32<br />

25/32<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

1 3/16<br />

29/32<br />

29/32<br />

29/32<br />

29/32<br />

29/32<br />

29/32<br />

29/32<br />

29/32<br />

1<br />

1<br />

1<br />

1<br />

1 1/8<br />

Typical 42HP<br />

Three open arches

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

MIGHTY-SPOOL MODEL 42HP<br />

MOVEMENT/FORCE/SPRING RATE WITH SINGLE OPEN ARCH DESIGN<br />

Nominal<br />

Pipe Size<br />

Exp. Jt. I.D.<br />

1<br />

1 1/4<br />

1 1/2<br />

2<br />

2 1/2<br />

3<br />

4<br />

5<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

18<br />

20<br />

22<br />

24<br />

26<br />

28<br />

30<br />

32<br />

34<br />

36<br />

40<br />

42<br />

48<br />

50<br />

54<br />

56<br />

60<br />

66<br />

72<br />

78<br />

84<br />

96<br />

108<br />

144<br />

“Face to face”<br />

minimum length<br />

<strong>Inc</strong>hes of axial<br />

compression<br />

Non-Concurrent<br />

Movement Capability<br />

<strong>Inc</strong>hes of axial<br />

extension<br />

<strong>Inc</strong>hes of lateral<br />

deflection<br />

Degrees of<br />

angular<br />

movement<br />

Total load lbs<br />

for rated<br />

compression<br />

Page 17<br />

Force Pounds<br />

Total load lbs<br />

for rated<br />

extension<br />

Total load lbs<br />

for rated<br />

lateral defl.<br />

Total load foot<br />

lbs for rated<br />

angular move.<br />

Force pounds<br />

for 1” compression<br />

mov.<br />

Spring Rate<br />

Force pounds<br />

for 1” extension<br />

mov.<br />

Force pounds<br />

for 1” lateral<br />

deflection<br />

Est. Wt (lbs)<br />

Special notes on movement capability: 1) Filled arch construction reduces above movements by 50%. 2) To calculate movement of multiple arch type for compression extension and lateral<br />

movements, take movement shown in the above table and multiply by the number of arches. 3) The degree of angular movement is based on the maximum extension shown. 4) Movement capability<br />

shown is non-concurrent percentage used in one movement position must be deducted from the other movement position so that sum of movements don’t exceed 100%. 5) Movements shown are<br />

based on proper installation practices. See <strong>Thorburn</strong> installation maintenance guide for details.<br />

Special notes on force Pounds / Spring Rates: 1) Forces required to move <strong>Thorburn</strong> Mighty-Spool Model 42HP are based on zero pressure conditions and room temperature in the pipeline. 2)<br />

These forces should be considered only as approximates, compensation must be made for more accurate forces based on materials of construction and actual service conditions. 3) Filled arch spring<br />

rates are approximately 4 times that of a single open arch. 4) Multi-arch spring rates are equal to single arch divided by number of arches.<br />

Axial<br />

Compression<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

6<br />

8<br />

8<br />

8<br />

8<br />

8<br />

8<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

10<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

12<br />

For pressure temperature and other specifications, please see page 15<br />

7/16<br />

7/16<br />

7/16<br />

7/16<br />

7/16<br />

7/16<br />

7/16<br />

7/16<br />

7/16<br />

11/16<br />

11/16<br />

11/16<br />

11/16<br />

11/16<br />

13/16<br />

13/16<br />

13/16<br />

15/16<br />

15/16<br />

15/16<br />

15/16<br />

15/16<br />

15/16<br />

15/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1 1/16<br />

1/4<br />

1/4<br />

1/4<br />

1/4<br />

1/4<br />

1/4<br />

1/4<br />

1/4<br />

1/4<br />

3/8<br />

3/8<br />

3/8<br />

3/8<br />

3/8<br />

7/16<br />

7/16<br />

7/16<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

9/16<br />

Axial<br />

Elongation<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

1/2<br />

27.5<br />

22.5<br />

18.5<br />

14.5<br />

11.5<br />

10.0<br />

7.5<br />

6.0<br />

5.0<br />

5.5<br />

4.5<br />

3.75<br />

3.25<br />

2.75<br />

2.5<br />

2.5<br />

2.25<br />

2.0<br />

2.3<br />

2.0<br />

2.0<br />

1.8<br />

1.75<br />

1.5<br />

1.5<br />

1.5<br />

1.25<br />

1.25<br />

1.25<br />

1.25<br />

1.0<br />

1.0<br />

0.9<br />

0.9<br />

0.8<br />

0.7<br />

0.62<br />

0.47<br />

103<br />

129<br />

154<br />

185<br />

232<br />

278<br />

371<br />

463<br />

556<br />

971<br />

1214<br />

1456<br />

1274<br />

1456<br />

1638<br />

2152<br />

2367<br />

2582<br />

2869<br />

3090<br />

3311<br />

3531<br />

3752<br />

3973<br />

4414<br />

4732<br />

5408<br />

5634<br />

6085<br />

6310<br />

6761<br />

7437<br />

8113<br />

8789<br />

9465<br />

10817<br />

12169<br />

16218<br />

Typical <strong>Thorburn</strong> Rubber Expansion Joints<br />

Angular Movement<br />

Bending of the centerline<br />

76<br />

96<br />

115<br />

138<br />

172<br />

207<br />

276<br />

344<br />

413<br />

689<br />

861<br />

1033<br />

904<br />

1033<br />

1163<br />

1505<br />

1656<br />

1807<br />

1990<br />

2143<br />

2297<br />

2450<br />

2603<br />

2756<br />

3062<br />

3253<br />

3717<br />

3872<br />

4182<br />

4341<br />

4651<br />

5116<br />

5581<br />

6046<br />

6511<br />

7441<br />

8372<br />

11152<br />

175<br />

219<br />

262<br />

350<br />

381<br />

412<br />

476<br />

546<br />

617<br />

753<br />

809<br />

948<br />

1117<br />

1286<br />

1420<br />

1588<br />

1648<br />

1706<br />

1829<br />

1952<br />

2075<br />

2438<br />

2801<br />

3164<br />

3338<br />

3423<br />

3866<br />

4012<br />

4303<br />

4448<br />

4736<br />

5108<br />

5477<br />

5951<br />

6425<br />

7375<br />

8325<br />

11013<br />

1<br />

2<br />

3<br />

4<br />

6<br />

8<br />

14<br />

22<br />

32<br />

70<br />

109<br />

158<br />

160<br />

209<br />

266<br />

381<br />

463<br />

549<br />

659<br />

765<br />

875<br />

1000<br />

1130<br />

1266<br />

1563<br />

1745<br />

2282<br />

2460<br />

2885<br />

3081<br />

3537<br />

4288<br />

5113<br />

6022<br />

6913<br />

9409<br />

13550<br />

20164<br />

Torsional Movement<br />

Relation about the<br />

centerline (twist)<br />

235<br />

294<br />

353<br />

423<br />

530<br />

635<br />

848<br />

1058<br />

1271<br />

1412<br />

1766<br />

2118<br />

1853<br />

2118<br />

2382<br />

2649<br />

2913<br />

3178<br />

3060<br />

3296<br />

3532<br />

3769<br />

4002<br />

4238<br />

4708<br />

4452<br />

5087<br />

5300<br />

5724<br />

5936<br />

6360<br />

6996<br />

7632<br />

8268<br />

8904<br />

10176<br />

11448<br />

15264<br />

FOR ORDERING DETAILS SEE PAGES 32 AND 33<br />

304<br />

383<br />

459<br />

552<br />

689<br />

828<br />

1104<br />

1376<br />

1652<br />

1837<br />

2296<br />

2755<br />

2411<br />

2755<br />

3101<br />

3440<br />

3785<br />

4130<br />

3980<br />

4286<br />

4594<br />

4899<br />

5602<br />

5512<br />

6124<br />

5783<br />

6608<br />

6884<br />

7435<br />

7717<br />

8268<br />

9095<br />

9922<br />

10748<br />

11575<br />

13228<br />

14883<br />

19843<br />

350<br />

438<br />

524<br />

700<br />

762<br />

824<br />

952<br />

1092<br />

1234<br />

1506<br />

1618<br />

1896<br />

2234<br />

2572<br />

2840<br />

3176<br />

3296<br />

3412<br />

3658<br />

3904<br />

4150<br />

4876<br />

5602<br />

6328<br />

6676<br />

6846<br />

7732<br />

8024<br />

8606<br />

8896<br />

9472<br />

10216<br />

10954<br />

11902<br />

12850<br />

14750<br />

16650<br />

22026<br />

Lateral Movement<br />

Shear or perpendicular<br />

to centerline<br />

Joint<br />

single arch<br />

2<br />

2.5<br />

3<br />

4<br />

4.5<br />

5.5<br />

8<br />

9<br />

11<br />

15<br />

23<br />

34<br />

40<br />

47<br />

56<br />

67<br />

70<br />

79<br />

100<br />

102<br />

117<br />

127<br />

138<br />

143<br />

173<br />

193<br />

198<br />

211<br />

265<br />

288<br />

309<br />

350<br />

385<br />

410<br />

435<br />

485<br />

650<br />

850<br />

Retaining<br />

ring set<br />

2.3<br />

2.5<br />

3<br />

4<br />

5.5<br />

6<br />

7.5<br />

8<br />

9<br />

12<br />

18<br />

22<br />

25<br />

27<br />

29<br />

35<br />

44<br />

48<br />

53<br />

58<br />

66<br />

75<br />

88<br />

91<br />

106<br />

116<br />

138<br />

154<br />

163<br />

184<br />

200<br />

246<br />

300<br />

325<br />

350<br />

432<br />

540<br />

700<br />

Absorbing<br />

Vibration

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />

MIGHTY-SPOOL<br />

MODELS 42HP-CR AND 42HP-ER CONCENTRIC AND<br />

ECCENTRIC REDUCER EXPANSION JOINTS<br />

<strong>Thorburn</strong>’s Mighty-Spool concentric and eccentric reducers were specifically developed to connect<br />

piping of unequalled diameters. These reducers were designed to replace and address the limitations<br />

found in metal reducers in a pipeline.<br />

Compare the Mighty-Spool advantages<br />

over metallic reducers:<br />

■ Absorbs pipe-wall and fluid-born noise<br />

<strong>Thorburn</strong>’s reducers are quiet operating and<br />

are designed to replace sound transmitting<br />

metal reducers. Pipe-wall sound loses energy<br />

and is absorbed as the noise carried by the<br />

piping both enters and leaves the rubber section.<br />

Fluid-born noise is absorbed by volumetric<br />

expansion (breathing) of <strong>Thorburn</strong>’s Mighty-<br />

Spool reducer. This action cushions water<br />

hammer and smooths out pumping impulses.<br />

■ Reduces system stress and strain /<br />

Compensates for misalignment<br />

Rigid attachment of piping to critical or<br />

mechanical equipment can produce excessive<br />

loading. Thermal or mechanically created<br />

strain-stress-shock are cushioned and absorbed<br />

with <strong>Thorburn</strong>’s Mighty-Spool reducers.<br />

<strong>Thorburn</strong>’s reducers add a flexible component<br />

that is automatically self correcting for<br />

misalignment created by structural movements<br />

caused by settling, expansion or ground shifts.<br />

■ Less space, lower installation cost<br />

<strong>Thorburn</strong>’s Mighty-Spool reducers replace a<br />

metal reducer and a flexible element. Thus,<br />

less space is required and installation is<br />

simplified.<br />

Page 18<br />

<strong>Thorburn</strong> 42HP-CR Concentric<br />

reducer expansion joint<br />

Control Rod Bolt Circle<br />

Control Rod Bolt Circle<br />

Flange/Retaining Ring O.D.<br />

Flange/Retaining Ring O.D.<br />

Bolt Circle<br />

Control<br />

Rod<br />

Plate Retaining<br />

Ring<br />

Optional<br />

Compression Sleeve<br />

Steel<br />

Washer<br />

<strong>Thorburn</strong> 42HP-ER Eccentric<br />

reducer expansion joint<br />

Standard<br />

Pipe<br />

Flange<br />

Nominal<br />

Pipe Size<br />

Joint I.D.<br />

<strong>Thorburn</strong> Model 42HP-CR concentric reducer rubber expansion<br />

joint<br />

Bolt Circle<br />

Control<br />

Rod<br />

Plate Retaining<br />

Ring<br />

Optional<br />

Compression Sleeve<br />

Steel<br />

Washer<br />

Standard<br />

Pipe<br />

Flange<br />

Nominal<br />

Pipe Size<br />

Joint I.D.<br />

<strong>Thorburn</strong> Model 42HP-ER eccentric reducer rubber expansion joint

THORBURN THE FLEXIBLE PIPING SPECIALIST<br />