iMEV - Ecobuild

iMEV - Ecobuild

iMEV - Ecobuild

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

...................<br />

...................<br />

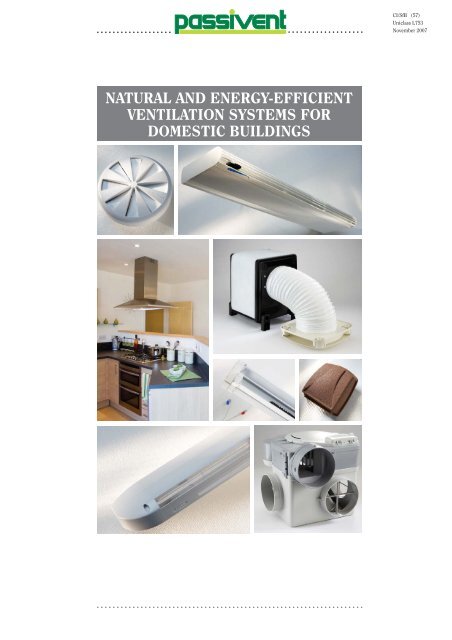

NATURAL AND ENERGY-EFFICIENT<br />

VENTILATION SYSTEMS FOR<br />

DOMESTIC BUILDINGS<br />

...................................................................<br />

CI/SfB (57)<br />

Uniclass L753<br />

November 2007

......................... ................................<br />

......................................................................<br />

CONTENTS<br />

INTRODUCTION 4-5<br />

Passivent systems, Technical context 6-8<br />

EXTRACT VENTILATION SYSTEMS 9-10<br />

Passive Stack Ventilation (PSV) 11-15<br />

PSV Whole-House 12<br />

PSV Single-Stack 13<br />

PSV Design and Installation 14-15<br />

Mechanical Extract Ventilation (MEV) 16-23<br />

Passivent MEV 18<br />

Passivent <strong>iMEV</strong> 19<br />

Passivent AV 20-21<br />

Passivent Flair 22-23<br />

Positive Input Ventilation (PIV) 24-25<br />

BACKGROUND VENTILATION 27-29<br />

Window vents 30-41<br />

Fresh wall vents 42-44<br />

ACOUSTIC VENTILATION 45<br />

Acoustic solutions: Systems 46-47<br />

Acoustic solutions: Background ventilation 48-53<br />

COMBUSTION AIR VENTILATION 54-56<br />

COMPONENTS, SERVICES 57<br />

Selected components 58-61<br />

Design and support, Services 62-63<br />

References 64<br />

.....................................................................<br />

3

4<br />

...........................................................................................<br />

PASSIVENT… the natural and energy-efficient ventilation specialists<br />

Passivent Limited are the leading<br />

specialists in natural and energy-efficient<br />

mechanical extract ventilation for domestic<br />

buildings.<br />

● Expertise<br />

Passivent have an unrivalled expertise in<br />

designing and developing ventilation<br />

solutions to meet the most up-to-date<br />

technical and regulatory requirements.<br />

● Immense experience<br />

During the last 15 years over 30 000<br />

Passivent systems have been installed in<br />

the UK alone, giving efficient and effective<br />

ventilation at all times. There is also a vast<br />

range of experience with Passivent systems<br />

over many years in Europe.<br />

● Technical and design capability<br />

We can provide authoritative technical<br />

support, advice and design services.<br />

● Comprehensive range<br />

The Passivent range provides ventilation<br />

systems and products tailored to all types<br />

of domestic applications.<br />

● Energy-efficient<br />

Passivent systems are extremely energyefficient,<br />

typically providing higher energy<br />

ratings than other forms of ventilation.<br />

They offer many advantages over other,<br />

non-responsive, systems.<br />

● Building regulations compliance<br />

Passivent systems can be used to meet<br />

building regulations requirements<br />

throughout the UK and Ireland.<br />

● Innovation<br />

We are constantly developing our<br />

ventilation systems and components to<br />

meet new requirements and further<br />

improve performance.<br />

● Quality assurance<br />

All Passivent systems and components<br />

have been designed, developed and<br />

manufactured under a BS EN ISO 9001<br />

Quality Management System.<br />

Independent auditing provides the user<br />

with assurance that the products will fulfil<br />

their intended purpose.<br />

...........................................................................................

..........................................................................................<br />

PASSIVENT SYSTEMS OVERVIEW<br />

● Passivent offer a range of passive and<br />

mechanical extract ventilation systems<br />

which meet the requirements for<br />

dwellings set out in Building Regulations<br />

Approved Document F (England and<br />

Wales), and similar requirements for the<br />

whole of the UK and the Republic of<br />

Ireland.<br />

For more details of Building Regulations<br />

requirements see page 8.<br />

● Passivent BBA Certificated PSV and MEV<br />

Whole-House systems provide the<br />

required functions of:<br />

- extract ventilation to remove pollutants,<br />

and<br />

- whole building (background) ventilation<br />

to provide a supply of fresh air<br />

These systems have major advantages over<br />

ventilation based on individual extract fans.<br />

● Passivent window/wall ventilators can<br />

provide whole-building (background)<br />

ventilation for Intermittent Fan (System1)<br />

and Continuous Mechanical Extract<br />

(System 3) systems by others.<br />

● Positive Input Ventilation (PIV) is an<br />

alternative strategy which is acceptable<br />

under Approved Document F provided<br />

compliance can be demonstrated.<br />

..........................................................................................<br />

5

6<br />

.........................<br />

.........................<br />

NATURAL AND ENERGY-EFFICIENT VENTILATION FOR DOMESTIC BUILDINGS<br />

...................................................................<br />

PASSIVENT SYSTEMS<br />

Passive Stack Ventilation (PSV) see pages 11-15<br />

(Approved Document F System 2)<br />

Applications: Public and private housing, primarily for individual<br />

houses and flats.<br />

New-build, major refurbishment<br />

Main features: Continuous demand controlled ventilation, silent operation,<br />

no energy consumed<br />

Mechanical Extract Ventilation (MEV) see pages 16-23<br />

(Approved Document F System 3)<br />

Applications: Public and private housing. Houses, flats,<br />

multi-occupancy buildings such as nursing homes,<br />

student accommodation, hotels.<br />

New-build, major or minor refurbishment<br />

Main features: Single central fan connected to multiple extracts,<br />

continuous low-level ventilation, quiet operation<br />

Positive Input Ventilation (PIV) see pages 24-25<br />

(Approved Document F paragraph 0.15)<br />

Applications: Public and private housing. Houses, flats.<br />

Major or minor refurbishment<br />

Main features: Ductless system, easy to install.<br />

Background Ventilation see pages 27-44<br />

(Approved Document F Systems 1, 2 and 3)<br />

Applications: Public and private housing. Houses, flats, multioccupancy<br />

buildings such as nursing homes,<br />

student accommodation, hotels.<br />

Major or minor refurbishment<br />

Main features: Large range of controllable window and throughwall<br />

vents.<br />

Acoustic Ventilation see pages 45-53<br />

(Approved Document F Systems 1, 2 and 3)<br />

Applications: All types of housing in areas of high noise levels<br />

Main features: PSV, MEV and background ventilation with acoustic<br />

treatment for sound reduction<br />

...................................................................

.........................<br />

.........................<br />

NATURAL AND ENERGY-EFFICIENT VENTILATION FOR DOMESTIC BUILDINGS<br />

...................................................................<br />

TECHNICAL CONTEXT<br />

Why ventilate<br />

Ventilation is essential in all buildings for<br />

the well-being and health of the occupants<br />

to:<br />

● Provide a supply of fresh air for persons<br />

using the building, creating a comfortable<br />

environment.<br />

● Extract moisture at source from areas<br />

where it is produced in significant<br />

quantities (eg kitchens and bathrooms),<br />

thereby combating condensation.<br />

● Dilute and remove pollutants including<br />

dust mites, tobacco smoke and cleaning<br />

chemicals, promoting a healthier air<br />

quality.<br />

● Aid the removal of occasional high<br />

concentrations of pollutants and water<br />

vapour.<br />

● Ventilation may also be used to improve<br />

thermal comfort and reduce overheating<br />

of buildings in summer.<br />

Energy savings<br />

Buildings are being made more and more<br />

airtight, driven by government regulations<br />

to save energy and reduce carbon emissions.<br />

Previous fortuitous ventilation routes (by<br />

natural infiltration) are being sealed,<br />

increasing the importance of an effective<br />

ventilation strategy.<br />

The need to reduce energy consumption and<br />

combat climate change means that energy<br />

savings must be made in buildings. It is<br />

therefore vital to select an effective and<br />

energy-efficient method of ventilation.<br />

Passivent systems are proven to be among<br />

the most energy-efficient.<br />

Energy efficiency and SAP<br />

Government action in response to climate<br />

change is driving the demand for increased<br />

energy efficiency. By 2016 the Government<br />

wants all new dwellings built to be ‘zerocarbon’.<br />

As part of building regulations<br />

improvements, all new housing has to be<br />

energy rated; this is achieved through the<br />

Standard Assessment Procedure (SAP).<br />

Passivent PSV with no electrical<br />

consumption and automatic operation is<br />

naturally energy-efficient.<br />

To allow flexibility and encourage<br />

innovation, energy-efficient systems can be<br />

independently tested and their actual<br />

performance used in the SAP through the<br />

‘Appendix Q’ route instead of the SAP default<br />

value.<br />

The use of energy-efficient DC fans in all<br />

Passivent MEV systems makes them more<br />

energy efficient than the SAP MEV default<br />

value.<br />

Health benefits<br />

Proper ventilation of buildings has been<br />

shown to help reduce the incidence of<br />

asthma and other allergy related problems.<br />

Controlled ventilation<br />

Traditional buildings had a considerable<br />

amount of accidental ventilation through air<br />

infiltration. In order to reduce energy loss,<br />

modern buildings (and refurbished<br />

buildings) are increasingly required to meet<br />

standards for reduced air leakage. By itself,<br />

this would lead to problems arising from<br />

lack of ventilation.<br />

A ventilation strategy is therefore required to<br />

provide good indoor air quality whilst<br />

minimising energy loss through unintended<br />

air leakage. The concept of 'build tight -<br />

ventilate right' means:<br />

- Minimising the amount of accidental and<br />

uncontrolled air leakage through the<br />

building envelope<br />

- Providing controlled ventilation to supply<br />

the required level of fresh air and expel<br />

moisture vapour and other air pollutants. In<br />

other words, ventilation where and when it<br />

is needed.<br />

................................................................... 7

8<br />

.........................<br />

.........................<br />

NATURAL AND ENERGY-EFFICIENT VENTILATION FOR DOMESTIC BUILDINGS<br />

...................................................................<br />

TECHNICAL CONTEXT<br />

Ventilation design<br />

A designed ventilation strategy should make<br />

use of the following elements:<br />

● Extract ventilation from 'wet' rooms<br />

including kitchens, bathrooms, utility<br />

rooms and WCs, to remove water vapour,<br />

together with other pollutants, directly<br />

from the rooms where it is mostly<br />

generated.<br />

● Whole building ventilation to provide a<br />

supply of fresh air from outside. This also<br />

has the function of diluting and dispersing<br />

pollutants wherever they are generated<br />

within the building.<br />

● Purge ventilation to remove high<br />

concentrations of pollutants generated by<br />

occasional activities such as painting and<br />

decorating.<br />

Building Regulations requirements<br />

The basic requirement of regulations is that<br />

there should be adequate means of<br />

ventilation for the occupants of a building.<br />

Requirements, and detailed means of<br />

satisfying them, are given in the documents<br />

listed below.<br />

Passivent Technical Services Team can also<br />

provide advice and guidance on ventilation<br />

and regulatory compliance.<br />

England and Wales<br />

Approved Document F Means of ventilation<br />

(2006).<br />

For guidance, please refer to:<br />

Scotland<br />

Building (Scotland) Regulations 2004,<br />

Technical Handbook Domestic Section 3<br />

Environment (2007).<br />

Northern Ireland<br />

Building Regulations (Northern Ireland)<br />

Technical Booklet K Ventilation (1998).<br />

Republic of Ireland<br />

Building Regulations Technical Guidance<br />

Documents, Part F Ventilation (2002).<br />

Associated regulations<br />

The building regulations for energy<br />

conservation also require control of air<br />

leakage rates through the building fabric<br />

(England and Wales Part L) and provision of<br />

an air supply for fuel-burning appliances<br />

(combustion air, England and Wales Part J).<br />

...................................................................

EXTRACT<br />

VENTILATION<br />

SYSTEMS<br />

................................<br />

Passive Stack Ventilation (PSV) 11-15<br />

PSV Whole-House 12<br />

PSV Single-Stack 13<br />

Mechanical Extract Ventilation (MEV) 16-23<br />

Passivent MEV 18<br />

Passivent <strong>iMEV</strong> 19<br />

Passivent AV 20-21<br />

Passivent Flair 22-23<br />

Positive Input Ventilation (PIV) 24-25<br />

............................... 9

10<br />

.........................<br />

EXTRACT VENTILATION SYSTEMS<br />

.........................<br />

...................................................................<br />

PASSIVENT SYSTEMS<br />

Passivent have ventilation systems tailored for all types of domestic applications and to meet<br />

the requirements of building regulations.<br />

Passive Stack Ventilation (PSV) see pages 11-15<br />

(System 2)<br />

Applications: Public and private housing, primarily for individual<br />

houses and flats.<br />

New-build, major refurbishment<br />

Main features: Continuous demand controlled ventilation, silent operation,<br />

no energy consumed<br />

Mechanical Extract Ventilation (MEV) see pages 16-23<br />

(System 3)<br />

Applications: Public and private housing. Houses, flats,<br />

multi-occupancy buildings such as nursing homes,<br />

student accommodation, hotels.<br />

New-build, major or minor refurbishment<br />

Main features: Single central fan connected to multiple extracts,<br />

continuous low-level ventilation, quiet operation<br />

Positive Input Ventilation (PIV) see pages 24-25<br />

Applications: Public and private housing. Houses, flats.<br />

Major or minor refurbishment<br />

Main features: Ductless system, easy to install.<br />

...................................................................

..........................................<br />

EXTRACT VENTILATION SYSTEMS<br />

..........................................<br />

.....................................................................................................<br />

PASSIVE STACK VENTILATION (PSV)<br />

PASSIVE STACK VENTILATION (PSV)<br />

System 2<br />

The PSV principle<br />

Passive stack ventilation (PSV) is driven<br />

primarily by the natural stack or convection<br />

effect by which warm air rises.<br />

Moisture-laden air is extracted directly from<br />

wet rooms (kitchens, bathrooms etc)<br />

through ducting up to a roof terminal where<br />

it is vented to the outside. The air inside a<br />

house is almost always warmer than that<br />

outside, and so rises up the duct by natural<br />

convection, carrying moisture with it. Wind<br />

blowing across the roof provides additional<br />

suction (the venturi effect).<br />

Warm moist air inside<br />

Colder air outside<br />

Moisture-laden warm air rises up<br />

duct and is exhausted through<br />

roof terminal<br />

................................................................................................... 11

..........................................<br />

12<br />

EXTRACT VENTILATION SYSTEMS<br />

................................................<br />

............................................................................................................<br />

PASSIVE STACK VENTILATION (PSV)<br />

PSV WHOLE-HOUSE<br />

A PSV Whole-House system ventilates all the<br />

rooms in a property effectively, using the<br />

concept of planned air routes to ensure a<br />

fresh healthy environment.<br />

Planned air routes<br />

Moisture is extracted at source from wet<br />

rooms (kitchens, bathrooms etc).<br />

Air inlets located in dry rooms (living rooms,<br />

bedrooms etc) provide a flow of replacement<br />

fresh air into the building.<br />

The siting of the inlets and extracts ensures<br />

that air always moves from dry rooms to wet<br />

rooms, so that moisture is removed and the<br />

whole house is ventilated.<br />

Applications<br />

Suitable for both new-build and<br />

refurbishment in private and social housing.<br />

Primarily designed for individual houses and<br />

low-rise flats and apartments.<br />

Demand control<br />

Ventilation is controlled by ‘intelligent’ inlets<br />

and extracts which respond automatically to<br />

changes in relative humidity, thereby<br />

modulating the ventilation rate in each<br />

room to meet demand. When humidity is<br />

low the ventilation rate is minimised,<br />

irrespective of external weather conditions,<br />

preventing unnecessary heat loss.<br />

Both inlets and extracts are operated by a set<br />

of nylon strands which respond to humidity<br />

levels and regulate the size of the air opening,<br />

giving greater ventilation when humidity is<br />

high whilst preventing unnecessary<br />

ventilation when humidity is low.<br />

Features and benefits<br />

● Natural and energy-efficient<br />

No electrical connection or power source<br />

is required, so Passivent PSV systems are<br />

naturally energy-efficient.<br />

● Continuous operation<br />

The system provides 24-hour<br />

condensation control with continuous<br />

gentle extraction. It operates all day and<br />

every day as required, combating<br />

condensation and mould growth.<br />

● Reduces requirement for background<br />

ventilation<br />

Using PSV means fewer tricklevents or<br />

wall vents are required, when compared to<br />

using intermittent fans.<br />

● No noise<br />

Passivent PSV systems are completely<br />

silent in operation.<br />

● Ideal for special needs<br />

With its automatic response and no<br />

operating controls, Passivent PSV is ideal<br />

for special-needs applications.<br />

● Minimal maintenance<br />

No mechanical components to go wrong.<br />

● BBA approved<br />

Passivent PSV Whole-House systems are<br />

covered by BBA (British Board of<br />

Agrément) Certificate No 96/3273.<br />

● Design service<br />

Passivent Limited offers a design<br />

service for PSV systems, see over.<br />

Typical PSV Whole-House ventilation system<br />

All air inlets and extracts respond automatically<br />

to relative humidity in rooms. Air movement<br />

is from dry to wet rooms.<br />

Building regulations<br />

Passivent systems can be used to satisfy<br />

building regulations requirements<br />

throughout the UK and the Republic of<br />

Ireland for extract and whole-house<br />

ventilation for domestic and domestic-type<br />

properties<br />

See also the general introduction page 8.<br />

More information is available on request.<br />

Passivent systems also meet the regulatory<br />

requirements for security, avoiding draughts<br />

and preventing rain ingress.<br />

Bedroom with air inlet<br />

Living room with air inlet<br />

Bathroom<br />

with air<br />

extract<br />

Separate roof<br />

terminal for each<br />

stack<br />

Kitchen with air extract<br />

.........................................................................................................

.........................................................................................<br />

..........................................................................................<br />

PSV SINGLE-STACK<br />

As a quiet alternative to an individual room<br />

extract fan, PSV Single-Stack systems can be<br />

installed to ventilate individual en-suites or<br />

bathrooms.<br />

They operate by the same natural stack effect<br />

as PSV Whole-House systems, and hence<br />

represent a superior alternative to a fan.<br />

They provide the same benefits of demand<br />

control, continuous operation and energy<br />

efficiency as PSV Whole-House systems, and<br />

are easy to install.<br />

Typical PSV Single-Stack system<br />

Extract responds automatically<br />

to relative humidity.<br />

Individual or<br />

en-suite bathroom<br />

with air extract<br />

Applications<br />

Suitable for both new-build and<br />

refurbishment in private and social housing.<br />

Particularly useful as a low-cost<br />

refurbishment installation in social housing.<br />

Roof terminal<br />

...........................................................................................<br />

13

..........................................<br />

14<br />

EXTRACT VENTILATION SYSTEMS<br />

................................................<br />

............................................................................................................<br />

PASSIVE STACK VENTILATION (PSV)<br />

SYSTEM DESIGN AND INSTALLATION<br />

Design of a system for an individual property<br />

is quite simple using our online design and<br />

quotation web site at www.passivent.com .<br />

Alternatively Passivent Limited offers a<br />

design service for PSV systems, based on<br />

building drawings supplied.<br />

A full installation guide is supplied with<br />

every Passivent PSV system.<br />

Typical layout (schematic)<br />

Actual installations may differ in detail. Follow the<br />

design layout if one is provided.<br />

Terminals must be no more than 0.5 metre<br />

down from the ridge.<br />

Each duct must run to a separate terminal<br />

Ducts must rise vertically or near-vertically,<br />

preferably not more than 45° from vertical<br />

with a maximum of 2 no. bends<br />

Use insulated<br />

ducting in the roof<br />

void and other unheated<br />

spaces<br />

Bedroom Bathroom<br />

Site air inlets in ‘dry’ rooms<br />

(living rooms, bedrooms etc)<br />

Site each air<br />

extract in a<br />

‘wet’ room<br />

(kitchen,<br />

bathroom)<br />

Air flow from ‘dry’ to ‘wet’ rooms<br />

Living room<br />

There is usually sufficient air flow around internal doors<br />

to provide replacement air. If this is insufficient a door<br />

undercut of 10mm or an air transfer door grille should be<br />

used.<br />

No electrical connections are required.<br />

The main features of a typical installation<br />

with the points which must be observed are<br />

shown below.<br />

For simplicity of design and ordering, a<br />

number of standard stack kits are available.<br />

Ordering<br />

To order Passivent-designed PSV systems<br />

simply state the quotation number and plot<br />

or plots required followed by the ridge or tile<br />

manufacturer, make and colour. For selfdesigned<br />

PSV systems simply quote the stack<br />

kit reference and quantity of each required,<br />

followed by the ridge or tile manufacturer,<br />

make and colour, and the inlet type and<br />

quantity required.<br />

Support<br />

flexible<br />

ducting every<br />

300mm to a wire<br />

or timber batten to<br />

prevent sagging<br />

Within the building, run circular<br />

ducting in a room corner or inside a<br />

fitted cupboard or wardrobe.<br />

Alternatively run flat channel ducting<br />

within a stud partition<br />

Kitchen<br />

System components<br />

Standard stack kits are available as shown.<br />

Where these are not suitable, alternative<br />

configurations can be supplied. Extension<br />

ducting is also available for properties over<br />

two storeys.<br />

For individual components (air inlets,<br />

terminals, ducting) see the Components<br />

section page 58.<br />

Code Description<br />

A161 Humidity-sensitive extract<br />

F12513 Uninsulated flexible ducting, 3.0m<br />

F12524 Insulated flexible ducting, 4.0m<br />

FCA3 Flat channel straight connector<br />

FCA4 Flat channel circular connector<br />

FCA6 Flat channel circular adaptor<br />

FCA10 Flat channel elbow connector<br />

FCA11 Round pipe<br />

FCD1 Flat channel ducting, 1.5m<br />

MC01 Sleeve coupling, male 125mm<br />

PRT Ridge terminal<br />

TT7 In-Line tile/slate terminal<br />

TT9 Tile terminal<br />

X332 Speed clamp<br />

..........................................................................................................

.........................................................................................<br />

...........................................................................................<br />

PSV 01 Kit<br />

Typical ground floor kitchen:<br />

Flat ducting, ridge terminal.<br />

PRT<br />

X332<br />

F12524<br />

X332<br />

FCA4<br />

FCA6<br />

FCD1<br />

FCA3<br />

FCD1<br />

FCA6<br />

A161<br />

PSV 05 Kit<br />

Typical first floor bathroom:<br />

Ridge terminal.<br />

PRT<br />

X332<br />

F12524<br />

X332<br />

A161<br />

PSV 06 Kit<br />

Typical first floor bathroom:<br />

Tile terminal.<br />

TT9<br />

X332<br />

F12524<br />

X332<br />

A161<br />

PSV 02 Kit<br />

Typical ground floor kitchen:<br />

Circular ducting, ridge terminal.<br />

PRT<br />

X332<br />

F12524<br />

A161<br />

PSV 03 Kit<br />

Typical ground floor kitchen:<br />

Circular ducting, tile terminal.<br />

X332 X332 X332<br />

MC01<br />

X332 X332<br />

F12513<br />

X332<br />

PSV 07 Kit<br />

Typical ground floor kitchen:<br />

Wall extract, flat ducting, tile<br />

terminal.<br />

TT9<br />

X332<br />

F12524<br />

X332<br />

FCA4<br />

FCA6<br />

FCD1<br />

FCA3<br />

FCD1<br />

FCA10<br />

A161<br />

FCA11<br />

TT9 PRT<br />

X332 X332<br />

F12513<br />

X332<br />

A161<br />

PSV 04 Kit<br />

F12524 F12524<br />

MC01<br />

PSV 08 Kit<br />

Typical ground floor kitchen:<br />

Flat ducting, tile terminal.<br />

TT9<br />

X332<br />

F12524<br />

X332<br />

FCA4<br />

FCA6<br />

FCD1<br />

FCA3<br />

FCD1<br />

FCA6<br />

A161<br />

Typical ground floor kitchen:<br />

Wall extract, flat ducting, ridge<br />

terminal.<br />

Specification clause<br />

Select options required,<br />

and insert information<br />

where necessary.<br />

Passivent PSV Whole-<br />

House ventilation system<br />

Provide a BBA-Certificated<br />

ventilation system<br />

complying with Building<br />

Regulations (England and<br />

Wales) Approved<br />

Document F OR Building<br />

(Scotland) Regulations<br />

Technical Handbook<br />

Domestic Section 3 OR<br />

Building Regulations<br />

(Northern Ireland)<br />

Technical Booklet K OR<br />

Building Regulations<br />

(Republic of Ireland)<br />

Technical Guidance<br />

Documents Part F, by<br />

means of a whole-house<br />

passive stack ventilation<br />

(PSV) automatic system<br />

comprising:<br />

Humidity-sensitive<br />

wall/window inlet vents<br />

operating between 47%<br />

and 65% relative humidity,<br />

sited in habitable rooms as<br />

required. Humiditysensitive<br />

ceiling extracts<br />

operating between 30%<br />

and 75% relative humidity<br />

sited in kitchen, bathroom,<br />

utility room and WC; each<br />

extract to be ducted<br />

separately to a roof<br />

terminal matching and<br />

forming an integral part of<br />

the ridge, or to pitched roof<br />

tile/slate terminals sited no<br />

lower than 0.5 metres<br />

down from the ridge.<br />

Ridge terminals to have an<br />

air flow resistance not<br />

exceeding 10Pa at an air<br />

movement rate of 100m 2 /h.<br />

Tile/slate terminals to have<br />

an air flow resistance not<br />

exceeding 5Pa at an air<br />

movement rate of<br />

100m 2 /h. All terminals to<br />

provide insect and weather<br />

protection, and be<br />

designed to ensure any<br />

condensate forming will<br />

run off on to the roof. All<br />

ducting in roof spaces and<br />

other unheated spaces to<br />

be fully insulated with<br />

25mm insulation.<br />

The system to be Passivent<br />

PSV Whole-House system<br />

covered by BBA Certificate<br />

96/3273, supplied by<br />

Passivent Limited,<br />

2 Brooklands Road, Sale,<br />

Cheshire M33 3SS.<br />

Telephone: 0161 962 7113,<br />

fax: 0161 969 5346,<br />

email: info@passivent.com.<br />

Installation to be in<br />

accordance with the<br />

manufacturer’s<br />

instructions, and to be<br />

carried out by a Passivent<br />

Mastercare trained<br />

installer holding a current<br />

certificate.<br />

Layout and installation<br />

must comply with any<br />

design recommendations<br />

supplied.<br />

..........................................................................................................<br />

FCA4<br />

FCA6<br />

FCD1<br />

FCA3<br />

FCD1<br />

FCA10<br />

A161<br />

FCA11<br />

PSV 09 Kit<br />

Typical first floor bathroom:<br />

In-Line tile/slate terminal.<br />

Not suitable for kitchens.<br />

TT7<br />

X332<br />

F12524<br />

X332<br />

A161<br />

15

..........................................<br />

16<br />

EXTRACT VENTILATION SYSTEMS<br />

................................................<br />

............................................................................................................<br />

MECHANICAL EXTRACT VENTILATION (MEV)<br />

MECHANICAL EXTRACT VENTILATION<br />

(MEV)<br />

System 3<br />

Passivent MEV systems<br />

Passivent Mechanical Extract Ventilation<br />

(MEV) systems provide continuous<br />

mechanical extraction at a low rate,<br />

boostable (manually or automatically) to<br />

extract at a higher rate when required.<br />

Whole-house systems comprise a remotely<br />

located central extract fan connected by<br />

ducting to extracts in wet rooms (kitchen,<br />

bathrooms etc), with air inlets located in dry<br />

rooms only (eg living rooms, dining rooms,<br />

bedrooms).<br />

Planned air paths<br />

Moisture is extracted at source from wet<br />

rooms. Air inlets located in dry rooms<br />

provide a flow of replacement fresh air into<br />

the building. The siting of the inlets and<br />

extracts ensures that air always moves from<br />

dry rooms to wet rooms, so that moisture<br />

and other pollutants are removed at source<br />

and the whole building is ventilated.<br />

Air extracts<br />

located in wet<br />

rooms<br />

MEV Systems<br />

Passivent has a range of MEV systems<br />

which can be matched to the intended<br />

application.<br />

Passivent MEV<br />

Continuous extract system with boost,<br />

automatic or manual, provided by extracts.<br />

Primarily individual systems for houses<br />

and apartments.<br />

Passivent <strong>iMEV</strong><br />

Continuous extract system with boost<br />

provided by automatic humidity-sensitive<br />

control of fan speed and extracts. Provides<br />

individual room control automatically.<br />

Passivent AV<br />

Continuous extract system with boost,<br />

automatic or manual, provided by extracts.<br />

Primarily multiple systems for apartments<br />

and multi-occupancy applications.<br />

Passivent Flair<br />

Continuous extract system for new-build<br />

apartments, integrating the latest design<br />

in cooker hoods.<br />

Air is exhausted<br />

through roof (or<br />

wall) terminals<br />

Low-power continuouslyrunning<br />

central extract fan located in<br />

loft space (or cupboard)<br />

Extract ducts may serve<br />

a number of rooms<br />

..........................................................................................................

..........................................................................................................<br />

........................................................................................................<br />

Applications<br />

MEV systems are suitable for a wide range of<br />

applications including houses, apartments<br />

and multi-occupancy buildings such as<br />

nursing homes, student accommodation and<br />

hotels.<br />

In flats and apartments MEV systems can be<br />

designed to ventilate either an individual<br />

apartment or several apartments<br />

simultaneously.<br />

Systems are suitable for both new build and<br />

refurbishment.<br />

Features and benefits<br />

● Tailored systems<br />

The range of extracts enables systems to<br />

be tailored specifically to suit individual<br />

room applications.<br />

● Demand control<br />

Humidity-sensitive system, with<br />

automatic boost to meet greater demand<br />

when required, provides greater comfort<br />

and energy efficiency.<br />

● Planned air movement<br />

The positions of inlets and extracts ensure<br />

that air always moves from dry rooms to<br />

wet rooms, where it is extracted.<br />

● Continuous extraction with boost<br />

Continuous gentle extraction at all times;<br />

the system operates all day and every day,<br />

boosting as required.<br />

● No noise problems<br />

The fan is normally installed in the roof<br />

space or a cupboard to avoid noise<br />

problems.<br />

● Ideal for special needs<br />

Automatic <strong>iMEV</strong> option ideal for special<br />

needs, with no manual control required.<br />

● Energy-efficient, low maintenance<br />

Fans have a low energy consumption, and<br />

minimal maintenance is required.<br />

● Simple installation<br />

Requirement for background ventilation<br />

(air inlets) is significantly reduced<br />

compared with intermittent extract fans.<br />

● Design service<br />

Passivent Limited offer a design service for<br />

MEV systems.<br />

Building Regulations and energy<br />

performance<br />

The Government’s Standard Assessment<br />

Procedure (SAP) is the method for<br />

calculating the energy rating or performance<br />

of dwellings to comply with Building<br />

Regulations. Registered SAP assessors use a<br />

computer program to calculate<br />

- the SAP rating<br />

- the Target CO2 Emission Rate (TER) based<br />

on standard values for a dwelling of the same<br />

size and shape, and<br />

- the Dwelling CO2 Emission Rate (DER),<br />

based on the performance values for the<br />

actual dwelling being assessed.<br />

For compliance, the DER must be no worse<br />

than the TER.<br />

Appendix Q of the SAP allows the use of<br />

actual performance data derived from<br />

independent assessments of systems, in place<br />

of default values. For energy efficient<br />

systems such as Passivent MEV this method<br />

can provide an enhanced SAP rating.<br />

The A151DC fan used in the Passivent MEV<br />

system is included on the Appendix Q web<br />

site.<br />

System design<br />

Passivent offer a design service for our MEV<br />

systems, based on building drawings<br />

supplied.<br />

Initially an outline proposal and estimate for<br />

a system will be prepared; following<br />

acceptance of this, a full design and costing<br />

will be prepared.<br />

System installation<br />

A full installation guide is supplied with each<br />

mechanical extract ventilation system.<br />

..........................................................................................................<br />

17

18<br />

.........................<br />

EXTRACT VENTILATION SYSTEMS<br />

.........................................<br />

....................................................................................<br />

PASSIVENT MEV<br />

Description<br />

Extraction is driven by a single low-power<br />

consumption DC fan. This is normally<br />

installed in the roof space or a cupboard and<br />

mounted to avoid noise disturbance. Fans<br />

operate efficiently at all times whether vents<br />

are fully open or virtually closed.<br />

Extraction can be boosted by a control<br />

switch, which shows the user via an LED<br />

display, the level at which the fan is<br />

operating.<br />

BBA approved<br />

Passivent MEV Whole-House systems are<br />

covered by BBA (British Board of Agrément)<br />

Certificate No 96/3273.<br />

System components<br />

Extract fan A151DC<br />

Low-wattage DC continuously-running fan,<br />

specially designed for efficient extraction of<br />

air along lengthy ducts.<br />

Extract<br />

A125 extracts located in ‘wet’ rooms.<br />

Other components<br />

For air inlets, terminals, and ducting, see the<br />

Components section on page 58.<br />

Typical MEV Whole-House ventilation systems<br />

Air movement is from ‘dry’ to ‘wet’ rooms<br />

Individual house Apartments: individual systems<br />

Bathroom<br />

Extract fan<br />

Kitchen<br />

System installation<br />

A full installation guide is supplied with each<br />

system.<br />

Extract fan<br />

Extract fan<br />

Kitchen<br />

Bathroom<br />

Kitchen Bathroom<br />

....................................................................................

.........................<br />

.........................<br />

....................................................................<br />

PASSIVENT <strong>iMEV</strong><br />

Description<br />

Innovative and intelligent, <strong>iMEV</strong> is a totally<br />

new concept in central mechanical extract<br />

ventilation. The system automatically<br />

provides, without any occupant involvement,<br />

individual room control, and is eminently<br />

suitable for both houses and apartments.<br />

The low-energy DC central extract fan<br />

incorporates a humidity sensor linked to a<br />

microprocessor that continuously monitors<br />

the relative humidity of the extracted air.<br />

The fan is linked via ducting to humidity<br />

responsive extracts located in the ‘wet’<br />

rooms. These open and close in response to<br />

relative humidity. Sensing increasing<br />

humidity the processor will progressively<br />

boost the fan.<br />

Therefore when relative humidity increases<br />

in that room:<br />

1. the extract in that room will open<br />

2. the humidity of the exhaust air will<br />

increase<br />

3. the fan speed will increase<br />

4. thus boosting the extract rate from the<br />

room containing the open extract.<br />

As humidity is reduced the extract will close<br />

and the fan will slow down to its normal<br />

running setting, until relative humidity in a<br />

wet room increases again.<br />

Typical <strong>iMEV</strong> Whole-House ventilation systems<br />

EXTRACT VENTILATION SYSTEMS<br />

System components<br />

Extract fan A151DCH<br />

Low energy central extract fan containing<br />

integral humidity sensor and<br />

microprocessor. Progressively boosts extract<br />

rate in response to increasing levels of<br />

relative humidity in the extracted air.<br />

Extracts<br />

A121 humidity<br />

sensitive extracts<br />

located in ‘wet’ rooms<br />

respond automatically<br />

to changes in relative<br />

humidity, opening and closing to meet<br />

demand, working in harmony with the fan to<br />

boost individual room extraction.<br />

Other components<br />

For air inlets, terminals, and ducting, see the<br />

Components section on page 58.<br />

System installation<br />

A full installation guide is supplied with each<br />

system.<br />

Individual house Apartments: individual systems<br />

Bathroom<br />

Extract fan<br />

Kitchen<br />

Extract fan<br />

Extract fan<br />

...................................................................<br />

Kitchen<br />

Bathroom<br />

Kitchen Bathroom<br />

19

20<br />

.........................<br />

EXTRACT VENTILATION SYSTEMS<br />

................................................<br />

...........................................................................................<br />

PASSIVENT AV<br />

Description<br />

Extraction ventilation is driven by a<br />

continuously-running central DC extract fan<br />

connected to extracts located in the ‘wet’<br />

rooms. Ventilation is boosted by the wider<br />

opening of the extracts, which can provide<br />

either automatic or manual boosts.<br />

Passivent AV is eminently suitable for<br />

apartments, where a single system can<br />

ventilate several apartments, and for student<br />

accommodation, hotels and care and nursing<br />

homes.<br />

The system is specially designed for efficient<br />

extraction of low volumes of air along<br />

lengthy ducts.<br />

The use of one system for several dwellings<br />

can reduce running costs and energy<br />

consumption per dwelling. It also minimises<br />

the number of roof penetrations required.<br />

BBA approved<br />

Passivent AV Whole-House systems are<br />

covered by BBA (British Board of Agrément)<br />

Certificate No 96/3273.<br />

System components<br />

Extract fan A151DC<br />

Low-wattage DC central extract fan for<br />

efficient extraction of air along lengthy duct<br />

runs.<br />

Extracts<br />

All extracts are for ceiling or wall-mounting<br />

in wet rooms. Boost is provided by wider<br />

opening of the vents, controlled as shown<br />

below.<br />

● Humidity-sensitive extracts respond to<br />

room humidity automatically.<br />

● Timed electrical boost is activated<br />

manually and operates for a preset time.<br />

● Constant volume extracts are selfregulating<br />

to maintain a constant extract<br />

rate.<br />

● PIR (passive infrared) boost is activated<br />

when a person is detected in the room,<br />

and operates for a preset time.<br />

The range of extracts enables the whole<br />

design and ventilation strategy to be tailored<br />

to individual room requirements and use.<br />

Other components<br />

For air inlets, terminals, ducting, see the<br />

Components section page 58.<br />

Typical AV Whole-House ventilation systems<br />

Apartments: multiple system<br />

Multi-occupancy: nursing homes, student accomodation, hotels etc<br />

Bedroom<br />

Bedroom<br />

Extract fan<br />

...........................................................................................<br />

Kitchen<br />

Bathroom<br />

Kitchen Bathroom<br />

Extract fan<br />

Ensuite<br />

bathroom<br />

Ensuite<br />

bathroom<br />

Corridor<br />

Corridor

.........................................................................................<br />

...........................................................................................<br />

...........................................................................................<br />

Specification clause<br />

Select options required,<br />

and insert information<br />

where necessary.<br />

Passivent MEV/<strong>iMEV</strong>/AV<br />

ventilation system<br />

Provide a ventilation<br />

system complying with<br />

Building Regulations<br />

(England and Wales)<br />

Approved Document F<br />

OR Building (Scotland)<br />

Regulations Technical<br />

Handbook Domestic<br />

Section 3 OR Building<br />

Regulations (Northern<br />

Ireland) Technical Booklet<br />

K OR Building Regulations<br />

(Republic of Ireland)<br />

Technical Guidance<br />

Documents Part F, by<br />

means of a mechanical<br />

extract ventilation system<br />

comprising:<br />

Humidity-sensitive<br />

wall/window inlet vents<br />

operating between 47%<br />

and 65% relative<br />

humidity, sited in<br />

habitable rooms as<br />

required.<br />

Ceiling extracts sited in<br />

kitchen, bathroom, utility<br />

room and WC … , and<br />

ducted to a central fan.<br />

Central extract fan ducted<br />

a roof terminal.<br />

All ducting in roof spaces<br />

and other unheated spaces<br />

to be fully insulated with<br />

25mm insulation.<br />

The system to be<br />

Passivent MEV/<strong>iMEV</strong>/AV<br />

ventilation system<br />

supplied by Passivent<br />

Limited,<br />

2 Brooklands Road, Sale,<br />

Cheshire M33 3SS.<br />

Telephone: 0161 962 7113,<br />

fax: 0161 969 5346,<br />

email: info@passivent.com.<br />

Installation to be in<br />

accordance with the<br />

manufacturer’s<br />

instructions, and to be<br />

carried out by a Passivent<br />

Mastercare trained<br />

installer holding a current<br />

certificate.<br />

21

Typical Flair system for<br />

an apartment<br />

22<br />

.........................<br />

EXTRACT VENTILATION SYSTEMS<br />

................................................<br />

...........................................................................................<br />

PASSIVENT FLAIR<br />

Description<br />

Passivent Flair is an innovative and<br />

extremely quiet extract ventilation system<br />

for new-build apartments. Aesthetically<br />

pleasing and discreet, it ensures a fresh,<br />

clean and healthy internal environment<br />

throughout an apartment with low energy<br />

consumption.<br />

The system ventilates the kitchen,<br />

bathrooms (which may be ensuite) and WCs.<br />

Elegant kitchen cooker hoods and discreet<br />

bathroom extracts are linked to a low-noise,<br />

low-energy central extract fan.<br />

Self-regulating extracts operate constantly to<br />

keep the bathroom and ensuite ventilation at<br />

its planned level. In the kitchen, increased<br />

extraction when cooking is provided by the<br />

boost switches on the cooker hood.<br />

Cooker hoods<br />

Features and benefits<br />

● Efficient ventilation<br />

Provides ventilation where it is most<br />

needed - kitchen and bathrooms.<br />

● Quiet and effective<br />

Quieter and more effective than individual<br />

room extract fans. Central extract fan can<br />

be located discreetly in a cupboard.<br />

● Aesthetically attractive<br />

Elegant Italian-designed cooker hoods in<br />

stainless steel, with height-adjustable duct<br />

and dishwasher-proof grease filter for easy<br />

cleaning. Attractive wall- or ceilingmounted<br />

bathroom extracts.<br />

● Single outlet<br />

Single wall or roof outlet minimises façade<br />

disruption.<br />

S2 Roma S5 Siena<br />

S7 Napoli<br />

...........................................................................................

.........................................................................................<br />

..........................................................................................<br />

Cooker hood dimensions (mm)<br />

System components<br />

Central extract fan<br />

Low-wattage continuously-running fan.<br />

S125 - spigot diameter 125mm<br />

S150 - spigot diameter 150mm<br />

Code & description Height<br />

(min - max)<br />

Width Depth<br />

S2 Roma 710 - 1130 600, 900 500<br />

S5 Siena 780 - 1130 600, 900 500<br />

S7 Napoli 710 - 1130 600, 900, 1000, 1200 500<br />

S10 Ancona 780 - 1130 600, 900 500<br />

S11 Verona 850 - 1270 900 600 width<br />

S10 Ancona S11 Verona<br />

Extracts<br />

Ceiling-mounted constant volume extracts<br />

are self-regulating to maintain a constant<br />

extract rate, and are sized to suit the<br />

bathroom or ensuite.<br />

Extract code Airflow at 80Pa<br />

SRE/15 15m3 /h (4.2 l/s)<br />

SRE/30 30m3 /h (8.4 l/s)<br />

SRE/45 45m3 /h (12.6 l/s)<br />

SRE/60 60m3 /h (16.8 l/s)<br />

SRE/90 90m3 /h (25.2 l/s)<br />

Terminals, Ducting<br />

Refer to the Components section page 58.<br />

System installation<br />

A full installation guide is supplied with each<br />

system.<br />

...........................................................................................<br />

height<br />

depth<br />

Specification clause<br />

Select options required,<br />

and insert information<br />

where necessary.<br />

Passivent Flair<br />

ventilation system<br />

Provide a ventilation<br />

system complying with<br />

Building Regulations<br />

(England and Wales)<br />

Approved Document F<br />

OR Building (Scotland)<br />

Regulations Technical<br />

Handbook Domestic<br />

Section 3 OR Building<br />

Regulations (Northern<br />

Ireland) Technical Booklet<br />

K OR Building Regulations<br />

(Republic of Ireland)<br />

Technical Guidance<br />

Documents Part F, by<br />

means of a mechanical<br />

extract ventilation system<br />

comprising:<br />

Self-regulating extracts<br />

sited in bathroom[s] and<br />

WC, ducted to a central<br />

fan<br />

Cooker hood ….. [insert<br />

code] sited in kitchen and<br />

ducted to the fan.<br />

Central extract fan …<br />

ducted to a wall/roof<br />

terminal.<br />

Continuously running<br />

central extract fan sited<br />

… and ducted to a wall<br />

terminal.<br />

All ducting in unheated<br />

spaces to be fully<br />

insulated with 25mm<br />

insulation.<br />

The system to be<br />

Passivent Flair system<br />

supplied by<br />

Passivent Limited,<br />

2 Brooklands Road, Sale,<br />

Cheshire M33 3SS.<br />

Telephone: 0161 962 7113,<br />

fax: 0161 969 5346,<br />

email: info@passivent.com.<br />

Installation to be in<br />

accordance with the<br />

manufacturer’s<br />

instructions, and to be<br />

carried out by a Passivent<br />

Mastercare trained<br />

installer holding a current<br />

certificate.<br />

23

24<br />

.........................<br />

EXTRACT VENTILATION SYSTEMS<br />

................................................<br />

...........................................................................................<br />

POSITIVE INPUT VENTILATION (PIV)<br />

Passivent PIV system<br />

Positive Input Ventilation uses air<br />

displacement to ventilate a whole dwelling,<br />

thereby improving indoor air quality and<br />

stopping or preventing condensation<br />

problems from occuring. Predominantly<br />

designed for installation in existing<br />

properties, the PIV units are very easy to<br />

install.<br />

A single fan unit mounted in the roof space<br />

(or central location for flats) supplies fresh<br />

filtered air into the dwelling via a central<br />

hallway or landing. This creates a slight<br />

positive air pressure which forces stale<br />

vapour-laden air out via fortuitous air gaps<br />

or through humidity-sensitive window vents.<br />

Whole-house system<br />

Eaves ventilation to roof space<br />

provides fresh air supply<br />

Air exhausted through<br />

window vents<br />

Continuous-running fan<br />

draws air from the roof space<br />

and supplies it to the dwelling<br />

Bedroom<br />

Living room<br />

PIV unit<br />

The PIV unit comprises a fan with connector<br />

duct and ceiling diffuser. The fan runs<br />

continuously unless the loft temperature<br />

exceeds 25ºC, when the unit will switch off.<br />

Above this temperature the hot incoming air<br />

would be uncomfortable for the occupants<br />

and the risks of condensation are somewhat<br />

reduced. When the temperature falls below<br />

25ºC the unit will automatically switch itself<br />

back on. At temperatures between 19ºC and<br />

25ºC the unit operates in heat recovery mode<br />

harnessing the benefits of solar gains,<br />

whereby the air in the loft is warmer than<br />

outside air.<br />

The ceiling diffuser has been<br />

aerodynamically designed to direct incoming<br />

air along the ceiling (coanda effect) where it<br />

mixes with warm buoyant air before recirculating<br />

downwards, thereby ensuring a<br />

more even thermal gradient between the<br />

floor and ceiling.<br />

Solar gain<br />

Bathroom<br />

...........................................................................................<br />

Kitchen

.........................................................................................<br />

...........................................................................................<br />

Applications<br />

Due to its ease of installation, PIV is<br />

designed primarily for the refurbishment of<br />

houses and flats.<br />

Features and benefits<br />

● Energy savings<br />

Supply air taken from the roof space is<br />

slightly warmer than outside air, so can<br />

provide some energy saving compared<br />

with a conventional extract system.<br />

● Simple and easy installation<br />

Requires only a single electrical<br />

connection. Does not require ducting<br />

through the interior spaces.<br />

● Low running costs<br />

With its DC fan, the PIV system is<br />

extremely energy-efficient, costing from as<br />

little as a penny a day to run.<br />

● Elapsed time meter<br />

Shows total run time, providing landlords<br />

with a foolproof check to prove usage.<br />

● Minimal maintenance<br />

Replacement of the long-life filter is only<br />

required every 5 years.<br />

● Aerodynamically designed diffuser<br />

The diffuser is designed to direct incoming<br />

air along the ceiling, thereby mixing with,<br />

re-using and re-circulating high level<br />

warm air.<br />

Quotation<br />

Passivent offer full advice and guidance for<br />

PIV systems, and will prepare an estimate<br />

and specification.<br />

System installation<br />

A full installation guide is supplied with each<br />

system.<br />

The ceiling must be as airtight as possible to<br />

minimise recirculation of air from within<br />

the dwelling.<br />

Roof space must be ventilated from outside,<br />

eg by eaves vents.<br />

Energy performance<br />

The Passivent PIV loft unit incorporates an extremely low wattage DC motor minimising<br />

energy usage.<br />

Incoming Ventilation Air volume Airflow Power Outlet noise<br />

air temp mode setting (l/s) consumption dBA at 1 metre<br />

(fan speed) (W)<br />

25ºC Comfort 1 0 0 -<br />

2 0 0 -<br />

3 0 0 -<br />

4 0 0 -<br />

..........................................................................................<br />

Specification clause<br />

PIV Unit<br />

Provide a loft mounted<br />

positive input ventilation<br />

system (Passivent<br />

PIVROOF) comprising a<br />

DC fan unit, ducting and<br />

ceiling diffuser. The fan<br />

unit to have 4 air volume<br />

settings, incorporate an<br />

elapsed time meter and<br />

have a one piece long life<br />

filter. System to switch to<br />

condensation control mode<br />

at loft temperatures below<br />

19ºC, heat recovery mode<br />

between 19ºC and 25ºC and<br />

comfort mode above 25ºC.<br />

PIV system to be supplied<br />

by Passivent Ltd,<br />

2 Brooklands Road,<br />

Sale, Cheshire M33 3SS,<br />

Telephone: 0161 962 7113<br />

Fax: 0161 905 2085<br />

Email :info@passivent.com<br />

25

26<br />

.........................<br />

.........................<br />

...................................................................

BACKGROUND<br />

VENTILATION<br />

................................<br />

Introduction 28-29<br />

Window vents 30-41<br />

Fresh wall vents 42-44<br />

.............................. 27

..........................................<br />

28<br />

BACKGROUND VENTILATION<br />

................................................<br />

............................................................................................................<br />

BACKGROUND VENTILATION<br />

Background ventilation is provided by<br />

means of a fixed performance background<br />

ventilator providing controllable ventilation<br />

to rooms or spaces at a relatively low rate.<br />

Passivent range<br />

Passivent have a comprehensive range of<br />

non-mechanical window and wall vents<br />

(Tricklevents and Fresh vents) to meet most<br />

requirements.<br />

They are purpose designed and offer the<br />

advantages of being controllable, secure, and<br />

designed to avoid draughts.<br />

A wide range of acoustic models is also<br />

available, see pages 45-53.<br />

Applications<br />

Passivent ventilators are suitable for both<br />

new-build and refurbishment in domestic<br />

applications, both private and public sector.<br />

They can be used as part of a domestic<br />

ventilation system comprising background<br />

ventilators and intermittent extract fans<br />

(Approved Document F System 1), PSV<br />

(System 2) and MEV (System 3).<br />

Features and benefits<br />

● Easily controlled<br />

Most models allow occupant control,<br />

leading to greater satisfaction with<br />

comfort levels. Automatic humiditycontrolled<br />

models are also available.<br />

● Efficient in operation<br />

Effective ventilation is provided at all<br />

times.<br />

● Protection<br />

Vents are specifically designed to provide<br />

security, adjustability, avoidance of<br />

discomfort due to cold draughts, and<br />

prevention of rain ingress.<br />

● Acoustic range<br />

Acoustic range wall vents provide good<br />

sound insulation for noisy locations (see<br />

next section).<br />

● Colour service<br />

The design requirements of architects and<br />

developers are increasing the demand for<br />

coloured window frames together with<br />

matching coloured window vents,<br />

particularly within inner city developments.<br />

Passivent are able to offer a service by<br />

which many of our plastic and aluminium<br />

window vents can be coated in any RAL<br />

colour to match windows.<br />

Building regulations requirements<br />

All ventilators can be used to meet the<br />

background ventilation requirements of<br />

building regulations throughout the UK and<br />

the Republic of Ireland, as part of a suitably<br />

designed ventilation system or strategy.<br />

For more information see Building<br />

Regulations on page 8 (general introduction)<br />

see the table opposite.<br />

Ventilation area measurement<br />

For purposes of building regulations,<br />

ventilation opening size is defined in terms<br />

of ‘equivalent area’ (England and Wales) or<br />

‘free area’ (remainder of UK and Ireland).<br />

‘Free area’ is simply the size of the<br />

ventilation aperture, whereas ‘Equivalent<br />

area’ provides a measure of the actual<br />

aerodynamic or air flow performance of a<br />

given ventilator.<br />

Equivalent area of background ventilator<br />

openings is measured by the method of<br />

BS EN 13141-1: 2004 ‘Ventilation for<br />

buildings - Performance testing of<br />

components/products for residential<br />

ventilation - Part 1: Externally and internally<br />

mounted air transfer devices’.<br />

Background ventilators for use in<br />

conjunction with continuous mechanical<br />

extracts (System 3)<br />

The need for background ventilators will<br />

depend on the air permeability of the<br />

dwelling, and this is not normally known at<br />

the design stage. Therefore, as a precaution,<br />

it is recommended that controllable<br />

background ventilators having a minimum<br />

equivalent area of 2,500mm 2 are fitted in<br />

each room, except wet rooms from which air<br />

is extracted. Where this approach causes<br />

difficulties (eg on a noisy site) please contact<br />

our technical department for advice.<br />

Replacement windows<br />

Where windows being replaced are fitted<br />

with trickle vents, then the replacement<br />

windows should also be fitted with them.<br />

However, with the reduction in fortuitous<br />

ventilation due to improved<br />

weatherstripping of new windows, it would<br />

be good practice to fit trickle vents on all<br />

replacement windows.<br />

System design<br />

Passivent offer guidance and a design service<br />

for background ventilation schemes based on<br />

the appropriate design process and<br />

information provided by the client. The<br />

design will achieve regulatory compliance,<br />

and will list the ventilation components<br />

required.<br />

However it remains the responsibility of the<br />

client or his advisor to verify the design's<br />

suitability for the project.<br />

..........................................................................................................

.........................................................................................<br />

...........................................................................................<br />

PRODUCT RANGE<br />

Passivent window and through-wall ventilators<br />

Vent type Ventilation opening (mm 2 ) Features Page<br />

free area equivalent area<br />

Window vents (Tricklevents)<br />

Through-frame<br />

Delta Vent and Grille 2000, 4000 1310, 2800 BBA Certificated 30<br />

Slimfit Vent and Grille 4000 2500 Very slim, suitable for factory fitting 31<br />

Frame Vent and Canopy Grille 2000, 4000 1400, 3120 BBA Certificated 32-33<br />

Ultra Vent and Grille 4000 3600 Slim profile, integral weatherseal 34<br />

Energy Saver Vent 4000 2760 Humidity-sensitive 35<br />

Over frame and over glass vents<br />

Streamline Overhead Vent 4000 - 8000* 2500 - 5000* BBA Certificated 36-37<br />

Overglass Vent Bars 2000 - 8000 1310 - 5930 For double or single glazing 38-39<br />

Superglaze vent 2000 - 8000* 1250 - 4390* BBA Certificated. For double glazing 40-41<br />

Wall vents (Fresh)<br />

Fresh 80 4000 2220 Dust and insect filter 42-44<br />

Fresh 90 6000 2630 Dust and insect filter 42-44<br />

Fresh 100 6000 3200 Dust and insect filter 42-44<br />

Fresh 99H 6000 3350 Humidity-sensitive, automatic 42-44<br />

Fresh TLF<br />

*depending on window width<br />

5000 2540 Dust and insect filter. Stylish new design 42-44<br />

Level of background ventilation required for use in conjunction with intermittent extract fans (System 1)<br />

Equivalent ventilator area* for dwellings (mm 2 )<br />

Number of bedrooms**<br />

Total floor area (m2 ) 1 2 3 4 5<br />

100 Add 5,000mm2 for every additional 10m2 floor area<br />

*The equivalent area should be determined at a 1Pa pressure difference using the appropriate method (BS EN 13141-1).<br />

**This is based on two occupants in the main bedroom and one occupant in all other bedrooms. For a greater level of<br />

occupancy, assume greater number of bedrooms (ie assume an extra bedroom per additional person). For more than<br />

five bedrooms, add an additional 10,000mm2 per bedroom.<br />

...........................................................................................<br />

29

Specification clause<br />

Select options required,<br />

and insert information<br />

where necessary.<br />

Provide background<br />

ventilation complying<br />

with Building<br />

Regulations (England and<br />

Wales) Approved<br />

Document F OR Building<br />

(Scotland) Regulations<br />

Technical Handbook<br />

Domestic Section 3 OR<br />

Building Regulations<br />

(Northern Ireland)<br />

Technical Booklet K OR<br />

Building Regulations<br />

(Republic of Ireland)<br />

Technical Guidance<br />

Documents Part F, by<br />

means of internal<br />

window ventilators giving<br />

*2000 / 4000mm2 free<br />

area or *1310 / 2800mm2 equivalent area of<br />

ventilation (Passivent<br />

Delta Vent *TVDV2 /<br />

TVDV4), and external<br />

grille (Passivent Delta<br />

Grille *TVDG2 / TVDG4)<br />

of injection-moulded<br />

plastic. Ventilators to<br />

provide upward<br />

directional airflow, have<br />

slide button control with<br />

‘open’ and ‘closed’<br />

indication, and optional<br />

trickle facility. Ventilators<br />

and grilles to be certified<br />

by the British Board of<br />

Agrement (BBA) and to<br />

meet or exceed the worst<br />

case requirements of<br />

BS 6375: Part 1: 2000 for<br />

resistance to water<br />

penetration.<br />

Ventilators and<br />

information available<br />

from Passivent Ltd,<br />

2 Brooklands Road, Sale,<br />

Cheshire M33 3SS,<br />

Telephone: 0161 962<br />

7113, Fax: 0161 905 2085.<br />

Email:<br />

info@passivent.com<br />

*Delete as required.<br />

30<br />

.........................<br />

....................................................................................<br />

DELTA VENT AND GRILLE<br />

CERTIFICATE No. 95/3120<br />

Controllable internal vent, with matching<br />

external grille for weather and insect<br />

protection.<br />

Can be used to meet the background<br />

ventilation requirements of building<br />

regulations throughout the UK and the<br />

Republic of Ireland, as part of a suitably<br />

designed ventilation system or strategy, and<br />

also the requirements for security, adjustability,<br />

avoidance of discomfort due to cold draughts<br />

and prevention of rain ingress.<br />

For more information see Building Regulations<br />

on page 8.<br />

Features and benefits<br />

● Directs inward air flow upwards.<br />

Avoids draughts and discomfort, thereby<br />

encouraging use.<br />

● Flush fitting slide control with positive<br />

action marked with open/closed position.<br />

Clearly indicates when vent is open/<br />

closed. No protruding flaps<br />

to break off.<br />

Easy to operate.<br />

Cord<br />

operator<br />

to special<br />

order<br />

BACKGROUND VENTILATION<br />

● Meets the worst case requirements of<br />

BS 6375: Part 1: 2000 for resistance to<br />

water penetration.<br />

Weather performance of the windows is<br />

not impaired by installing vents.<br />

● Location lugs.<br />

Ensure vents are quickly and easily<br />

mounted in the correct position.<br />

● Trickle facility (removable).<br />

Provides small amount of ventilation even<br />

when vent is closed.<br />

● Optional cord operation.<br />

For elderly and special needs,<br />

or where access<br />

is difficult.<br />

Ventilation area<br />

See table.<br />

.........................................<br />

Length see table<br />

Slide control<br />

Material<br />

Injection-moulded plastic.<br />

Colours: white or brown.<br />

Other RAL colours to special order subject<br />

to minimum quantities.<br />

Fixing<br />

By two screws each for vent and grille,<br />

concealed by cover caps.<br />

External<br />

grille<br />

Dimensions<br />

Type code Ventilation opening Trickle Length Slot size<br />

Vent & grille free area equivalent area ventilation<br />

TVDV2 & TVDG2 2000mm2 1310mm2 250mm2 190mm 148 x 15mm*<br />

TVDV4 & TVDG4 4000mm 2 2800mm 2 500mm 2 350mm 308 x 15mm**<br />

*Alternatives: 160 x 12.5mm square-ended slot with pilot holes drilled for screws; nine holes 17mm diameter.<br />

**Alternatives: 320 x 12.5mm square-ended slot with pilot holes drilled for screws; eighteen holes 17mm<br />

diameter; two slots 137 x 15mm with 40mm central blank.<br />

Depth<br />

24mm<br />

Height<br />

22mm<br />

control flap<br />

Internal<br />

vent<br />

Installed in window frame<br />

Installed on Overglass<br />

Vent Bar<br />

....................................................................................

..........................................<br />

BACKGROUND VENTILATION<br />

.........................................<br />

.....................................................................................................<br />

SLIMFIT VENT AND GRILLE<br />

Height<br />

19mm<br />

The Slimfit is an innovative, stylish, slimprofile<br />

ventilator, eminently suitable for<br />

ventilated head sections.<br />

Can be used to meet the background<br />

ventilation requirements of building<br />

regulations throughout the UK and the<br />

Republic of Ireland, as part of a suitably<br />

designed ventilation system or strategy, and<br />

also the requirements for security,<br />

adjustability, avoidance of discomfort<br />

due to cold draughts and prevention of rain<br />

ingress.<br />

For more information see Building<br />

Regulations on page 8.<br />

Length see table<br />

Height<br />

22mm<br />

Features and benefits<br />

● Slim projection of vent - only 5mm.<br />

Grille inset.<br />

Unobtrusive appearance. Suitable for<br />

factory-fitting to window frames;<br />

minimises risk of damage in transit.<br />

● Clip-fit vent and inset grille.<br />

No screws, thereby speeding up installation,<br />

reduces window production cost.<br />

● Integral flange to vent.<br />

Completely masks routed slot.<br />

Ventilation area<br />

See table.<br />

Material<br />

Vent ABS, inset grille polypropylene.<br />

Colours: white or brown.<br />

Fixing<br />

Clip-in.<br />

Slimfit inset Grille<br />

Dimensions<br />

Type code Ventilation opening Length Slot size<br />

free area equivalent area<br />

Vent TVSFV4 4000mm2 2500mm2 420mm 403 x 15mm<br />

Grille TVSFIG4 173mm *150 x 15mm<br />

*Two grilles and two slots required per vent.<br />

Slimfit Vent<br />

Specification clause<br />

Select options required,<br />

and insert information<br />

where necessary.<br />

Provide background<br />

ventilation complying<br />