Sputter and multi-source - caburn-mdc europe

Sputter and multi-source - caburn-mdc europe Sputter and multi-source - caburn-mdc europe

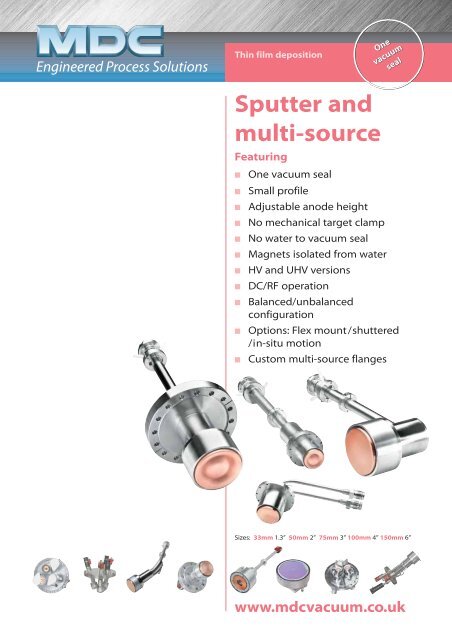

Thin film deposition Sputter and multi-source Featuring One One vacuum vacuum seal ■ One vacuum seal ■ Small profile ■ Adjustable anode height ■ No mechanical target clamp ■ No water to vacuum seal ■ Magnets isolated from water ■ HV and UHV versions ■ DC/RF operation ■ Balanced/unbalanced configuration ■ Options: Flex mount/shuttered /in-situ motion ■ Custom multi-source flanges Sizes: 33mm 1.3” 50mm 2” 75mm 3” 100mm 4” 150mm 6” www.mdcvacuum.co.uk

- Page 2 and 3: 3 The history of MAK ® Sputter sou

- Page 4 and 5: 2 MAK ® Sputter sources The sputte

- Page 6 and 7: 4 Sputter source Introduction MAK

- Page 8 and 9: 6 A N G S T R Angstroms O M S Worki

- Page 10 and 11: 8 A N G S T R Angstroms O M S Worki

- Page 12 and 13: 10 MAK ® Flex mount Options The fl

- Page 14 and 15: 12 Features ■ UHV Compatible ■

- Page 16: Sputter and multi-source www.mdcvac

Thin film deposition<br />

<strong>Sputter</strong> <strong>and</strong><br />

<strong>multi</strong>-<strong>source</strong><br />

Featuring<br />

One One<br />

vacuum vacuum<br />

seal<br />

■ One vacuum seal<br />

■ Small profile<br />

■ Adjustable anode height<br />

■ No mechanical target clamp<br />

■ No water to vacuum seal<br />

■ Magnets isolated from water<br />

■ HV <strong>and</strong> UHV versions<br />

■ DC/RF operation<br />

■ Balanced/unbalanced<br />

configuration<br />

■ Options: Flex mount/shuttered<br />

/in-situ motion<br />

■ Custom <strong>multi</strong>-<strong>source</strong> flanges<br />

Sizes: 33mm 1.3” 50mm 2” 75mm 3” 100mm 4” 150mm 6”<br />

www.<strong>mdc</strong>vacuum.co.uk

3<br />

The history of MAK ® <strong>Sputter</strong> <strong>source</strong>s<br />

Since the 1980’s MeiVac’s US<br />

Components Division has<br />

acquired <strong>multi</strong>ple exclusive<br />

manufacturing <strong>and</strong> distribution<br />

licenses for patented planar<br />

magnetron sputter <strong>source</strong>s from two<br />

prominent Silicon Valley research<br />

laboratories.<br />

With over 6,000 of these <strong>source</strong>s<br />

delivered worldwide, the US<br />

Components Division has become<br />

known as a leading manufacturer of<br />

sputter deposition <strong>source</strong>s, substrate<br />

heaters <strong>and</strong> <strong>and</strong> associated<br />

hardware. Introduced in the 1990’s,<br />

one of the <strong>source</strong>s, the MAK®, rapidly<br />

became a st<strong>and</strong>ard in the industry.<br />

Noted for its simplicity, ease of use<br />

<strong>and</strong> resulting high reliability, the<br />

MAK® <strong>source</strong> has been designed to<br />

present the smallest profile possible<br />

<strong>and</strong> deliver higher deposition rates<br />

than comparable sputter <strong>source</strong>s.<br />

Because of its popularity, the<br />

MAK® <strong>source</strong> has been used in<br />

the development of many of<br />

today’s thin film processes.<br />

The MAK® <strong>source</strong> is produced at<br />

MeiVac’s San Jose, California,<br />

USA facility.

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Uniformity distribution 2-3<br />

<strong>Sputter</strong> <strong>source</strong> technical features 4<br />

33mm 1.3” MAK ® 5<br />

50mm 2” MAK ® 6<br />

75mm 3” MAK ® 7<br />

100mm 4” MAK ® 8<br />

150mm 6” MAK ® 9<br />

Flex mount 10<br />

Multi-<strong>source</strong> 11<br />

Substrate heaters 12-13<br />

United MDC Vacuum Limited France MDC Vacuum Products Sarl Germany Tel: +49 (0)2305 947 508<br />

Kingdom Tel: +44 (0)1825 280 450 Tel: +33 (0)437 65 17 50 Tel: +49 (0)2305 947 508<br />

Fax: +44 (0)1825 280 440 Fax: +33 (0)437 65 17 55 Fax: +49 (0)2305 947 510<br />

sales@<strong>mdc</strong>vacuum.co.uk info@<strong>mdc</strong>vacuum.fr sales@<strong>mdc</strong>vacuum.de<br />

Italy Kenosistec Srl Holl<strong>and</strong> Evatec Process Systems BV Russian MSH Technology Limited<br />

Tel: +39 02 9055200 Tel: +31 343 595 470 Federation Tel: +7 (495) 543 60 25<br />

Fax: +31 343 592 294 Fax: +31 343 592 294 Fax: +7 (495) 722 12 90<br />

info<strong>caburn</strong>@kenosistec.it sales@<strong>mdc</strong>vacuum.nl shive@msht.ru

2<br />

MAK ® <strong>Sputter</strong> <strong>source</strong>s<br />

The sputtering process<br />

<strong>Sputter</strong>ing, which is a physical<br />

vapour deposition (PVD)<br />

coating technique, is a<br />

common method of<br />

depositing both metal layers<br />

<strong>and</strong> insulating layers on a<br />

substrate. The layers being<br />

deposited can be elements<br />

such as Cu, Au, etc., alloys such<br />

as AlCu, NiFe, etc. or insulators<br />

such as SiO2, TiN, etc.<br />

Principles of<br />

sputtering<br />

Ions<br />

Electrons<br />

Target atoms<br />

Argon atoms<br />

Growing<br />

film<br />

Typically, a substrate (the item<br />

to be coated) is placed in a<br />

vacuum chamber opposite a target (made of the<br />

material being sputtered). The chamber is<br />

evacuated <strong>and</strong> then backfilled with a process<br />

gas (argon). The gas is ionized with a<br />

positive charge which creates plasma.<br />

Resulting ions are strongly attracted<br />

to the target, which carries a<br />

negative charge. The effect is<br />

a physical process similar to<br />

the interaction of billiard balls<br />

in a confined space. As the relatively large<br />

argon ions impact on the target,<br />

atoms/molecules of target material<br />

are physically removed from the<br />

target. Due to its close<br />

proximity, a majority of the<br />

sputtered atoms/molecules<br />

l<strong>and</strong> on the target. The intent<br />

is for this material to arrive at<br />

the substrate with enough<br />

energy to form a thin,<br />

strongly attracted<br />

film, one<br />

monolayer at<br />

a time.<br />

Uniformity<br />

Uniformity is<br />

heavily dependant on<br />

<strong>source</strong> to substrate<br />

distance <strong>and</strong> the<br />

relationship between<br />

<strong>source</strong> <strong>and</strong> substrate<br />

diameters<br />

All dimensions are nominal in millimetres unless specified.<br />

B Field<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

E Field<br />

Legend<br />

Material removed by<br />

ion bombardment<br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Target (cathode)<br />

negative high voltage<br />

Planar magnetron<br />

sputtering<br />

In conventional diode<br />

sputtering, electrons are<br />

created that escape the<br />

effective plasma area near the<br />

target. Some fly around the<br />

chamber creating undesirable<br />

side effects, such as heating<br />

the tooling. A magnetron<br />

sputtering <strong>source</strong> addresses<br />

the electron problem by<br />

placing magnets behind, <strong>and</strong><br />

sometimes at the sides of the<br />

target. These magnets capture<br />

the escaping electrons <strong>and</strong><br />

confine them to the<br />

immediate vicinity of the<br />

target. This increases the ion current (density of<br />

ionized argon atoms hitting the target) by a factor of 10 over<br />

conventional diode targets, resulting in faster deposition rates<br />

at lower pressures, which help to produce cleaner films.<br />

Film properties<br />

Magnetic<br />

field lines<br />

Captured<br />

electrons<br />

Deposition rate, film structure <strong>and</strong> layer uniformity<br />

of deposition materials are highly dependent on:<br />

■ <strong>Sputter</strong> efficiency of the material<br />

■ Deposition power level<br />

■ Source of substrate distance<br />

■ Process gas<br />

■ Substrate temperature<br />

■ Target erosion<br />

■ Position of anode<br />

■ Process pressure<br />

■ Power type (RF or DC)<br />

■ Angle of incidence<br />

■ Target magnetic permeability<br />

■ Configuration of <strong>source</strong><br />

■ Balance of magnetic fields<br />

Source to Rate Wafer Wafer Cu Watts<br />

MAK ® substrate Å/min diameter Typical diameter Typical target @<br />

model distance copper mm uniformity mm uniformity thickness 5 mTorr<br />

33<br />

50<br />

75<br />

100<br />

150<br />

Cross section of a planar magnetron<br />

Details of typical rates <strong>and</strong> uniformity performances<br />

50.8 1,750<br />

±7%<br />

±20%<br />

50.8<br />

76.2<br />

76.2 975 ±5% ±12%<br />

50.8 6,200<br />

±6%<br />

±16%<br />

50.8<br />

76.2<br />

76.2 2,800 ±3% ±10%<br />

76.2 10,000<br />

±5%<br />

±15%<br />

50.8<br />

101.6<br />

101.6 5,600 ±3% ±10%<br />

101.6 6,470<br />

±5%<br />

±7%<br />

76.2<br />

101.6<br />

152.4 2,900 ±2% ±3%<br />

101.6 12,900<br />

±4%<br />

±12%<br />

101.6<br />

152.4<br />

152.4 5,800 ±2% ±7%<br />

4.7 200<br />

6.35 500<br />

12.7 1000<br />

12.7 2000<br />

12.7 3000

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Uniformity of sputtered materials across the<br />

diameter of a substrate as a function of target<br />

Uniformity distribution<br />

Relative rates Cu = 1.0<br />

size <strong>and</strong> <strong>source</strong> to substrate distance. Under identical power <strong>and</strong> geometric conditions<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

Working distance<br />

50.8<br />

76.2<br />

1,510<br />

1,180<br />

760<br />

Working distance<br />

50.8<br />

76.2<br />

5,550<br />

4,445<br />

2,295<br />

Working distance<br />

76.2<br />

101.6<br />

9,100<br />

7,300<br />

4,650<br />

Working distance<br />

101.6<br />

152.4<br />

6,070<br />

5,840<br />

2,750<br />

Working distance<br />

101.6<br />

152.4<br />

12,200<br />

10,225<br />

5000<br />

885<br />

2,620<br />

5,230<br />

2,780<br />

5500<br />

1,750<br />

76.2 25.4<br />

0<br />

25.4 38.1<br />

MAK<br />

mm<br />

® 1.3” Source<br />

38.1 25.4<br />

0<br />

25.4 38.1<br />

MAK<br />

mm<br />

® 2” Source<br />

50.8 25.4<br />

0<br />

25.4 50.8<br />

MAK<br />

mm<br />

® 3” Source<br />

6,470<br />

50.8 38.1<br />

0<br />

38.1 50.8<br />

MAK<br />

mm<br />

® 4” Source<br />

12,900<br />

5800<br />

6,090<br />

12,180<br />

5520<br />

5,830<br />

10,150<br />

5050<br />

76.2 50.8<br />

0<br />

50.8 76.2<br />

MAK<br />

mm<br />

® 6” Source<br />

975<br />

6,200<br />

2,800<br />

10,000<br />

5,600<br />

2,900<br />

1.520<br />

890<br />

5,580<br />

2,630<br />

9,135<br />

5,210<br />

2,780<br />

1,195<br />

720<br />

4,475<br />

2,270<br />

7,320<br />

4,620<br />

2,715<br />

target materials will sputter at different rates.<br />

The table provides relative rates for common<br />

elements <strong>and</strong> compounds where copper is 1.00.<br />

Ag 2.06<br />

Al 0.73<br />

Al203 0.15<br />

Au 1.76<br />

Be 0.22<br />

Bi 10.00<br />

C 0.05<br />

CdS1010 2.39<br />

CdTe 0.64<br />

Co 0.58<br />

Cr 0.60<br />

Cu 1.00<br />

Dy 1.18<br />

Er 1.00<br />

Fe 0.56<br />

GaAs(110) 1.70<br />

Gd 1.17<br />

Ge 1.05<br />

Glass 0.23<br />

Hf 0.67<br />

Ir 0.61<br />

Mg 0.26<br />

Mgf 0.03<br />

Mn 0.99<br />

Mo 0.53<br />

Nb 0.44<br />

Ni 0.65<br />

Os 0.5<br />

Pb 3.52<br />

Pd 1.31<br />

Pt 0.9<br />

Rb 4.55<br />

Re 0.53<br />

Rh 0.74<br />

Ru 0.66<br />

Sb 3.68<br />

Si 0.39<br />

SiC 0.36<br />

SiO 0.27<br />

SiO2 0.45<br />

Sm 1.14<br />

Sn 1.38<br />

Ta 0.43<br />

Th 0.84<br />

Ti 0.38<br />

U 0.73<br />

V 0.38<br />

W 0.39<br />

Y 0.95<br />

Zr 0.65<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

3

4<br />

<strong>Sputter</strong> <strong>source</strong><br />

Introduction<br />

MAK ® <strong>Sputter</strong> <strong>source</strong>s<br />

Target is retained by the magnet structure with a simple<br />

keeper. Target exchange is accomplished in moments<br />

without disassembly.<br />

MAK ® <strong>source</strong>s are designed to overcome limitations<br />

commonly found in other <strong>source</strong>s:<br />

Features<br />

■ Water channel is not part of the high voltage path<br />

■ Magnets are not in the water channel<br />

■ Target change does not require <strong>source</strong> disassembly<br />

■ Only one vacuum seal <strong>and</strong> no water to vacuum seals<br />

■ Target requires no clamping or bonding to cathode<br />

■ Magnetic materials may be sputtered with the st<strong>and</strong>ard<br />

magnetic assembly in most applications<br />

■ Operates in DC or RF modes<br />

■ Process pressures 0.5 – 600 m Torr<br />

■ Adjustable anode, improves uniformity, prevents build up<br />

<strong>and</strong> shadowing<br />

■ HV or UHV designs<br />

Magnetron configuration<br />

MDC Vacuum Limited offers a number of options to assist in<br />

achieving desired results. The st<strong>and</strong>ard model MAK ® <strong>source</strong> is<br />

mounted on a 300mm (12˝) long support with a position<br />

clamp included. Water <strong>and</strong> power are contained at<br />

atmospheric pressure within this support. A 19mm/0.75˝<br />

quick coupler vacuum feedthrough is required to integrate<br />

the <strong>source</strong> in the vacuum system <strong>and</strong> position it at the<br />

correct <strong>source</strong> to substrate distance.<br />

St<strong>and</strong>ard mount<br />

101.6 with<br />

manual linear<br />

adjustment<br />

Right angle<br />

50.8 –<br />

manually<br />

adjustable<br />

Flex mount angular<br />

50.8 – manually<br />

adjustable<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

50mm<br />

Flange<br />

mounted<br />

Target<br />

Cathode<br />

(cooling<br />

surface)<br />

Magnet<br />

return<br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Cathode<br />

Water line<br />

Optional <strong>source</strong>s <strong>and</strong> features<br />

AIN<br />

insulator<br />

Cooling<br />

block<br />

Keeper<br />

Magnets<br />

Anode<br />

Power feedthrough<br />

■ Gas injection, to deliver process gas directly to the area of<br />

the target, reducing residual gas interaction with the<br />

sputtering process<br />

■ Right angle flex mount, 0-45 degree angular adjustment<br />

■ Low profile, through wall<br />

■ Externally adjustable ‘in-situ’ angular <strong>and</strong> linear <strong>source</strong>s<br />

■ RF <strong>and</strong> DC power supplies <strong>and</strong> RF matching networks<br />

■ Custom tailored flange mounted packages<br />

■ Flange type <strong>and</strong> mount geometry specified by customer<br />

■ Shutters <strong>and</strong> shielding<br />

■ Rotary motion feedthrough

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Specifications<br />

Source dimensions 33mm (1.3”) MAK ®<br />

Vertical size 113mm<br />

Outside diameter 38mm<br />

Mounting<br />

Flange DN63CF / 4.5 OD” (min)<br />

Feedthrough 19mm quick coupler<br />

Target specifications<br />

Target diameter 33mm<br />

Target thickness (maximum) 5.7mm<br />

Target mounting Magnetic<br />

Magnetic materials Yes<br />

Magnet design<br />

Type Nd/Fe B<br />

Configuration Balanced<br />

Operation specifications<br />

DC Max power 350W<br />

RF Max power 200W<br />

Cathode voltage (volts) 200-1000V<br />

Discharge current (max amps) 1.00A<br />

Operating pressure (mtorr) 0.5-600<br />

Cooling water<br />

Flow rate 0.6 gpm<br />

Conductivity No requirement<br />

33mm 1.3” typical rates <strong>and</strong> uniformity performance<br />

Working Uniformity<br />

distance Rate A/min 50.8 dia. 76.2 dia.<br />

50.8 1,750 ±7% ±20%<br />

76.2 975 ±5% ±12%<br />

33.0mm diameter 4.7 thick Cu target 3000W @ 5 mTorr<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

Working distance<br />

50.8<br />

76.2<br />

1,510<br />

1,180<br />

760<br />

885<br />

1,750<br />

975<br />

1.520<br />

1,195<br />

76.2 25.4<br />

0<br />

mm<br />

25.4 38.1<br />

890<br />

720<br />

33mm 1.3” MAK ®<br />

Description<br />

Source<br />

Vertical<br />

Horizontal<br />

Options<br />

33mm 1.3” MAK ®<br />

113.0<br />

Flange mounting options<br />

DN100CF<br />

DN160CF<br />

Accessories<br />

Ø19.1<br />

UHV<br />

Flex mount<br />

Non-st<strong>and</strong>ard mounting tube length*<br />

38.1<br />

Thermal paste (15gm)<br />

Quick disconnect for 25.4 (1”) baseplate<br />

Quick disconnect for DN40KF<br />

Quick disconnect for DN40CF<br />

Quick coupler feedthrough on DN63CF<br />

Quick coupler feedthrough on DN100CF<br />

* Please advise tube length<br />

Reference<br />

Fixed<br />

anode<br />

Ø56.8<br />

305mm<br />

st<strong>and</strong>ard<br />

custom<br />

lengths<br />

available<br />

MAK-130-V<br />

MAK-130-H<br />

UHV<br />

FM2<br />

NSL<br />

CF100KIT<br />

CF160KIT<br />

TP-832<br />

DBF-75<br />

K40XDS-75<br />

FDS-75<br />

QC-833-450<br />

QC-833-600<br />

HN<br />

connector<br />

Part<br />

number €<br />

2701000<br />

2701001<br />

-331<br />

-332<br />

-333<br />

2701105<br />

2701104<br />

2700600<br />

650005<br />

734027<br />

412008<br />

2703100<br />

27003101<br />

2627<br />

2801<br />

3234<br />

2945<br />

POA<br />

POA<br />

POA<br />

72<br />

294<br />

90<br />

116<br />

488<br />

565<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

5

6<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

Working distance<br />

50.8<br />

76.2<br />

5,550<br />

4,445<br />

2,295<br />

50mm 2” MAK ®<br />

Specifications<br />

Source dimensions 50mm (2”) MAK ®<br />

Vertical size 99mm<br />

Outside diameter 59mm<br />

Mounting<br />

Flange DN63CF / 4.5” OD (min)<br />

Feedthrough 19 quick coupler<br />

Target specifications<br />

Target diameter 51mm<br />

Target thickness (maximum) 7.9mm<br />

Target mounting Magnetic<br />

Magnetic materials Yes<br />

Magnet design<br />

Type Nd/Fe B<br />

Configuration Balanced/Unbalanced<br />

Operation specifications<br />

DC Max power 1000W<br />

RF Max power 400W<br />

Cathode voltage (volts) 200-1000V<br />

Discharge current (max amps) 3A<br />

Operating pressure (mtorr) 0.5-600<br />

Cooling water<br />

Flow rate 0.8 gpm<br />

Conductivity No requirement<br />

50mm 2” typical rates <strong>and</strong> uniformity performance<br />

Working Uniformity<br />

distance Rate A/min 50.8 dia. 76.2 dia.<br />

50.8 6200 ±6% ±16%<br />

76 2800 ±3% ±10%<br />

50.8mm diameter 6.35 thick Cu target 3000W @ 5 mTorr<br />

2,620<br />

6,200<br />

2,800<br />

5,580<br />

2,630<br />

38.1 25.4<br />

0<br />

mm<br />

25.4 38.1<br />

All dimensions are nominal in millimetres unless specified.<br />

4,475<br />

2,270<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

50mm 2” MAK ®<br />

Description<br />

Source<br />

Vertical<br />

Horizontal<br />

Options<br />

Accessories<br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

99.3<br />

Ø19.1<br />

UHV<br />

Flex mount<br />

Non-st<strong>and</strong>ard mounting tube length*<br />

Ø59.2<br />

Thermal paste (15gm)<br />

Quick disconnect for 25.4 (1”) baseplate<br />

Quick disconnect for DN40KF<br />

Quick disconnect for DN40CF<br />

Quick coupler feedthrough on DN63CF<br />

Quick coupler feedthrough on DN100CF<br />

* Please advise tube length<br />

Reference<br />

Anode height<br />

adjustable to<br />

target thickness<br />

Ø38.1<br />

305mm<br />

st<strong>and</strong>ard<br />

custom<br />

lengths<br />

available<br />

MAK-200-V<br />

MAK-200-H<br />

UHV<br />

FM2<br />

NSL<br />

TP-832<br />

DBF-75<br />

K40XDS-75<br />

FDS-75<br />

QC-833-450<br />

QC-833-600<br />

HN<br />

connector<br />

Part<br />

number €<br />

2701002<br />

2701003<br />

-331<br />

-332<br />

-333<br />

2700600<br />

650005<br />

734027<br />

412008<br />

2703100<br />

27003101<br />

2627<br />

2801<br />

3234<br />

2945<br />

POA<br />

72<br />

294<br />

90<br />

116<br />

488<br />

565

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Specifications<br />

Source dimensions 75mm (3”) MAK ®<br />

Vertical size 110mm<br />

Outside diameter 86mm<br />

Mounting<br />

Flange DN100CF / 6” OD (min)<br />

Feedthrough 19mm quick coupler<br />

Target specifications<br />

Target diameter 76.2mm<br />

Target thickness (maximum) 15.9mm<br />

Target mounting Magnetic<br />

Magnetic materials Yes<br />

Magnet design<br />

Type Nd/Fe B<br />

Configuration Balanced/Unbalanced<br />

Operation specifications<br />

DC Max power 2000W<br />

RF Max power 750W<br />

Cathode voltage (volts) 200-1000V<br />

Discharge current (max amps) 5A<br />

Operating pressure (mtorr) 0.5-600<br />

Cooling water<br />

Flow rate 0.8 gpm<br />

Conductivity No requirement<br />

75mm 3” typical rates <strong>and</strong> uniformity performance<br />

Working Uniformity<br />

distance Rate A/min 50.8 dia. 101.6 dia.<br />

76.2 10,000 ±5% ±15%<br />

101.6 5,600 ±3% ±10%<br />

76.2mm diameter 12.7 thick Cu target 3000W @ 5 mTorr<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

Working distance<br />

76.2<br />

101.6<br />

9,100<br />

7,300<br />

4,650<br />

5,230<br />

10,000<br />

5,600<br />

9,135<br />

5,210<br />

7,320<br />

4,620<br />

50.8 25.4<br />

0<br />

mm<br />

25.4 50.8<br />

75mm 3” MAK ®<br />

110.5<br />

75mm 3” MAK ®<br />

Description<br />

Source<br />

Vertical<br />

Horizontal<br />

Options<br />

Accessories<br />

Ø19.1<br />

UHV<br />

Flex mount<br />

Non-st<strong>and</strong>ard mounting tube length*<br />

Ø85.9<br />

Thermal paste (15gm)<br />

Quick disconnect for 25.4 (1”) baseplate<br />

Quick disconnect for DN40KF<br />

Quick disconnect for DN40CF<br />

Quick coupler feedthrough on DN63CF<br />

Quick coupler feedthrough on DN100CF<br />

* Please advise tube length<br />

Reference<br />

MAK-300-V<br />

MAK-300-H<br />

UHV<br />

FM2<br />

NSL<br />

TP-832<br />

DBF-75<br />

K40XDS-75<br />

FDS-75<br />

QC-833-450<br />

QC-833-600<br />

Anode height<br />

adjustable to<br />

target thickness<br />

Ø57.2<br />

305mm<br />

st<strong>and</strong>ard<br />

custom<br />

lengths<br />

available<br />

HN<br />

connector<br />

Part<br />

number €<br />

2703000<br />

2703001<br />

-331<br />

-332<br />

-333<br />

2700600<br />

650005<br />

734027<br />

412008<br />

2703100<br />

27003101<br />

3133<br />

3422<br />

3802<br />

3560<br />

POA<br />

72<br />

294<br />

90<br />

116<br />

488<br />

565<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

7

8<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

Working distance<br />

101.6<br />

152.4<br />

6,070<br />

5,840<br />

2,750<br />

101mm 4” MAK ®<br />

Specifications<br />

Source dimensions 100mm (4”) MAK ®<br />

Vertical size 117mm<br />

Outside diameter 113mm<br />

Mounting<br />

Flange DN160CF / 8” OD (min)<br />

Feedthrough 19mm quick coupler<br />

Target specifications<br />

Target diameter 102mm<br />

Target thickness (maximum) 19.1mm<br />

Target mounting Magnetic<br />

Magnetic materials Yes<br />

Magnet design<br />

Type Nd/Fe B<br />

Configuration Balanced/Unbalanced<br />

Operation specifications<br />

DC Max power 3000W<br />

RF Max power 1200W<br />

Cathode voltage (volts) 200-1000V<br />

Discharge current (max amps) 7A<br />

Operating pressure (mtorr) 0.5-600<br />

Cooling water<br />

Flow rate 1.0 gpm<br />

Conductivity No requirement<br />

100mm 4” typical rates <strong>and</strong> uniformity performance<br />

Working Uniformity<br />

distance Rate A/min 76.2 dia. 101.6 dia.<br />

101.6 6,480 ±5% ±7%<br />

152.4 2,900 ±2% ±3%<br />

101.6mm diameter 12.7 thick Cu target 3000W @ 5 mTorr<br />

2,780<br />

6,470<br />

2,900<br />

6,090<br />

2,780<br />

50.8 38.1<br />

0<br />

mm<br />

38.1 50.8<br />

All dimensions are nominal in millimetres unless specified.<br />

5,830<br />

2,715<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

116.8<br />

75mm 4” MAK ®<br />

Description<br />

Source<br />

Vertical<br />

Horizontal<br />

Options<br />

Accessories<br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Ø19.1<br />

UHV<br />

Flex mount<br />

Non-st<strong>and</strong>ard mounting tube length*<br />

113.0<br />

Thermal paste (15gm)<br />

Quick disconnect for 25.4 (1”) baseplate<br />

Quick disconnect for DN40KF<br />

Quick disconnect for DN40CF<br />

Quick coupler feedthrough on DN63CF<br />

Quick coupler feedthrough on DN100CF<br />

* Please advise tube length<br />

Reference<br />

MAK-400-V<br />

MAK-400-H<br />

UHV<br />

FM2<br />

NSL<br />

TP-832<br />

DBF-75<br />

K40XDS-75<br />

FDS-75<br />

QC-833-450<br />

QC-833-600<br />

305mm<br />

st<strong>and</strong>ard<br />

custom<br />

lengths<br />

available<br />

Anode<br />

height<br />

adjustable<br />

to target<br />

thickness<br />

Ø57.2<br />

HN<br />

connector<br />

Part<br />

number €<br />

2703005<br />

2703006<br />

-331<br />

-332<br />

-333<br />

2700600<br />

650005<br />

734027<br />

412008<br />

2703100<br />

27003101<br />

4043<br />

4523<br />

4764<br />

4523<br />

POA<br />

72<br />

294<br />

90<br />

116<br />

488<br />

565

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Specifications<br />

Source dimensions 152mm (6”) MAK ®<br />

Vertical size 171mm<br />

Outside diameter 166mm<br />

Mounting<br />

Flange DN200CF / 10” OD (min)<br />

Feedthrough 32mm quick coupler<br />

Target specifications<br />

Target diameter 152.4mm<br />

Target thickness (maximum) 25.4mm<br />

Target mounting Magnetic<br />

Magnetic materials Yes<br />

Magnet design<br />

Type Nd/Fe B<br />

Configuration Balanced/Unbalanced<br />

Operation specifications<br />

DC Max power 6000W<br />

RF Max power 2000W<br />

Cathode voltage (volts) 200-1000V<br />

Discharge current (max amps) 10A<br />

Operating pressure (mtorr) 0.5-600<br />

Cooling water<br />

Flow rate 2.0 gpm<br />

Conductivity No requirement<br />

150mm 6” typical rates <strong>and</strong> uniformity performance<br />

Working Uniformity<br />

distance Rate A/min 101.6 dia. 152.4 dia.<br />

101.6 13,000 ±4% ±12%<br />

152.4 5,800 ±2% ±7%<br />

152.4mm diameter 12.7 thick Cu target 3000W @ 5 mTorr<br />

A<br />

N<br />

G<br />

S<br />

T<br />

R<br />

Angstroms<br />

O<br />

M<br />

S<br />

Working distance<br />

101.6<br />

152.4<br />

12,200<br />

10,225<br />

5000<br />

5500<br />

12,900<br />

5800<br />

12,180<br />

5520<br />

10,150<br />

5050<br />

76.2 50.8<br />

0<br />

mm<br />

50.8 76.2<br />

171.5<br />

152mm 6” MAK ®<br />

Ø114.3<br />

150mm 6” MAK ®<br />

Description<br />

Source<br />

Vertical<br />

Options<br />

Accessories<br />

Ø19.1<br />

UHV<br />

Flex mount<br />

Non-st<strong>and</strong>ard mounting tube length*<br />

166.4<br />

Thermal paste (15gm)<br />

Quick disconnect for 25.4 (1”) baseplate<br />

Quick disconnect for DN40KF<br />

Quick disconnect for DN40CF<br />

Quick coupler feedthrough on DN63CF<br />

Quick coupler feedthrough on DN100CF<br />

* Please advise tube length<br />

Reference<br />

MAK-600-V<br />

UHV<br />

FM2<br />

NSL<br />

TP-832<br />

DBF-75<br />

K40XDS-75<br />

FDS-75<br />

QC-833-450<br />

QC-833-600<br />

305mm<br />

st<strong>and</strong>ard<br />

custom<br />

lengths<br />

available<br />

HN<br />

connector<br />

Anode<br />

height<br />

adjustable<br />

to target<br />

thickness<br />

Part<br />

number €<br />

2703004 6728<br />

-331<br />

-332<br />

-333<br />

2700600<br />

650005<br />

734027<br />

412008<br />

2703100<br />

27003101<br />

7690<br />

POA<br />

POA<br />

72<br />

294<br />

90<br />

116<br />

488<br />

565<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

9

10<br />

MAK ® Flex mount<br />

Options<br />

The flex mount feedthrough allows for angular adjustment to<br />

the MAK’s sputtering attitude. Use of a welded formed<br />

bellows <strong>and</strong> special support bracket, any angle from 0 to 30°<br />

is firmly held in place. Power is applied thru a coaxial cable;<br />

thus assuring RF continuity.<br />

In-situ linear movement features<br />

■ Provides target to substrate distance change without<br />

breaking vacuum<br />

■ Adaptable to 33mm (1.3”) thru 102mm (4”) MAK ®<br />

■ 25 – 152mm linear travel<br />

■ Welded bellows<br />

■ Bakeable to 120°C<br />

■ UHV Compatible<br />

203.2 CF<br />

85.7 CF<br />

Bellows<br />

50.8 <strong>source</strong><br />

Ø19.1<br />

Ø19.1 quick couple<br />

for support only<br />

152.4 extension<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

Magnet array<br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

View<br />

rotated 90°<br />

157<br />

218<br />

305mm st<strong>and</strong>ard<br />

custom lengths<br />

available<br />

Performance adaptability<br />

The single piece cathode assembly permits change of the<br />

magnetic structure without disassembly of the MAK ® .<br />

Performance requirements from excellent uniformity, with<br />

good target utilization to – high rates, with maximum target<br />

thickness is achieved. The magnetic array is field changeable.<br />

Magnetic material sputtering<br />

Direct attachment to the active cathode, without use of a<br />

magnetic housing, provides a small free space between<br />

target <strong>and</strong> magnets. This places a stronger magnetic flux at<br />

the target surface allowing sputtering of magnetic material<br />

as st<strong>and</strong>ard.<br />

In-situ, externally<br />

adjustable (under vacuum)<br />

linear 76mm or angular<br />

76mm

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Multi-<strong>source</strong> design examples<br />

Project/process specific<br />

custom packages including<br />

■ Sources:<br />

■ St<strong>and</strong>ard with linear adjustment<br />

■ Flexmount internally adjustable<br />

angular<br />

■ In-situ externally adjustable linear<br />

■ In-situ externally adjustable angular<br />

■ Shutters<br />

■ Shields<br />

■ Gas injection<br />

■ 33.0, 50.8, 76.2, 101.6, 152.4 <strong>source</strong>s<br />

(1.3” 2” 3” 4” 6”)<br />

■ Two or more guns on a flange<br />

■ 203.2 – 609.6 (8”–24”) CF, ISO, ANSI<br />

Custom <strong>multi</strong>-<strong>source</strong><br />

assembly with shutters<br />

■ 3 x 50.8 sputtering <strong>source</strong>s<br />

■ Shown with fixed flange to target<br />

distance<br />

■ Customer specified <strong>source</strong> angle<br />

■ Shown mounted on metal seal<br />

ConFlat ® DN160CF flange<br />

■ 2 x <strong>source</strong>s shown with targets <strong>and</strong><br />

one without target<br />

■ With optional non-cross deposition<br />

shields<br />

■ Includes shutters<br />

RF Power supplies,<br />

matching networks<br />

■ 300W, 600W, 1000W RF<br />

■ CE marked<br />

■ Programmable<br />

■ Air cooled<br />

■ RS-232 / 485<br />

■ RF DC voltage control<br />

Multi-<strong>source</strong><br />

DC Power supplies<br />

■ 500W, 1KW, 1.5KW, 2.5KW, 5KW<br />

■ Pulsed DC available with 5KW<br />

■ Arc suppression circuitry<br />

■ Some CE marked configurations<br />

available<br />

■ Regulation in power, voltage, <strong>and</strong><br />

current modes<br />

Custom <strong>multi</strong>-<strong>source</strong> assembly with shutters<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

11

12<br />

Features<br />

■ UHV Compatible<br />

■ 0 2 Compatible<br />

■ Electrical bias capability<br />

Substrate heaters<br />

SU-400-NC wafer heater block<br />

Heaters are configured for two general types of<br />

application, samples <strong>and</strong> wafers<br />

■ Sample blocks may be drilled <strong>and</strong> tapped for sample holding clips<br />

Note this per customer specification at an additional charge<br />

■ Sample blocks are made of Haynes metal <strong>and</strong> must be prebaked at<br />

atmosphere by the customer at or exceeding the desired operating<br />

temperature prior to use<br />

■ Haynes metal heater blocks are compatible with silver thermal paste, which<br />

is sold as an accessory<br />

■ Wafer blocks are Inconel metal <strong>and</strong> are wafer size specific<br />

■ Wafer pockets are machined into the surface of the heater<br />

■ Inconel is not compatible with silver thermal paste.<br />

■ Unprecedented temperature uniformity<br />

Applications<br />

■ <strong>Sputter</strong>ing<br />

■ Laser ablation<br />

■ Ion beam deposition<br />

■ ERC, MOCVD <strong>and</strong> others<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

SU-300-HH sample heater block<br />

Optional accessories<br />

Deluxe feedthrough <strong>and</strong> mounting st<strong>and</strong><br />

■ Adjustable mounting bracket with X, Y, Z<br />

movement<br />

■ 2 x type S thermocouple leads<br />

■ 2 x power pins<br />

■ Mounted on a DN40CF, DN63CF or<br />

DN100CF rotatable<br />

Hook-up kit<br />

■ Type S thermocouple 457mm leadwire<br />

■ 2 x 1.27mm OFHC copper power leads<br />

457mm long<br />

■ Ceramic tubes <strong>and</strong> beads for insulation<br />

<strong>and</strong> protection from plasma

<strong>Sputter</strong> <strong>source</strong>s <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

Part number<br />

Reference<br />

Stage type<br />

Size in mm<br />

Dimensions in mm<br />

A<br />

B<br />

C<br />

D<br />

E<br />

Maximum temperature<br />

Temperature uniformity<br />

Area of uniformity<br />

Temperature reliability<br />

Ramp time to 950°C<br />

Cool down time<br />

Maximum current<br />

Maximum voltage<br />

Input power<br />

Heater resistance<br />

Heater material<br />

A<br />

D<br />

B<br />

E<br />

C<br />

Substrate heaters<br />

Description<br />

Details<br />

Substrate heaters<br />

See details of typical rates /uniformity performances below<br />

See details of typical rates/uniformity performances below<br />

See details of typical rates/uniformity performances below<br />

See details of typical rates/uniformity performances below<br />

See details of typical rates/uniformity performances below<br />

Tapped hole<br />

Reference<br />

SU-200HH<br />

SU-200IH<br />

SU-300HH<br />

SU-400IH<br />

SU-600IH<br />

Part<br />

number<br />

2706002<br />

2706003<br />

2706004<br />

2706005<br />

2706006<br />

See details of typical rates/uniformity performances below TH<br />

-335<br />

Accessories<br />

Mounting feedthrough DN40CF<br />

Mounting feedthrough DN63CF<br />

Mounting feedthrough DN100CF<br />

Hook up kit ‘K’ TC wire<br />

Hook up kit ‘S’ TC wire<br />

Deluxe mounting feedthrough DN40CF<br />

Deluxe mounting feedthrough DN63CF<br />

Deluxe mounting feedthrough DN100CF<br />

Details of typical rates <strong>and</strong> uniformity performances<br />

SU-905-C40<br />

SU-905-C63<br />

SU-905-C100<br />

SU-918-K<br />

SU-918-S<br />

SU-925-C40<br />

SU-925-C63<br />

SU-925-C100<br />

2706103<br />

2706104<br />

2706105<br />

2706108<br />

2706109<br />

2706111<br />

2706112<br />

2706113<br />

2706002 2706003 2706004 2706005 2706006<br />

SU-200HH SU-200IH SU-300HH SU-400IH SU-600IH<br />

Sample Wafer Sample Wafer Wafer<br />

50.8 50.8 76.2 101.6 152.4<br />

Refer to sketches Refer to sketches Refer to sketches Refer to sketches Refer to sketches<br />

63.5 76.2 88.9 127 171.5<br />

84.6 88.4 97.3 142.2 187.5<br />

60.2 60.2 60.2 83.8 83.8<br />

53.8 66.5 66.5 76.2 76.2<br />

35.1 35.1 35.1 58.4 58.4<br />

950°C 950°C 950°C 950°C 950°C<br />

+/–1% +/–1% +/–1% +/–2% +/–2%<br />

Centre 31.8 dia. 50.8 dia. Centre 57.2 dia. 101.6 dia. 152.4 dia.<br />

12°C 12°C 12°C 13°C 13°C<br />

12 minutes 12 minutes 13 minutes 22 minutes 30 minutes<br />

35 minutes 35 minutes 40 minutes 3 hours 4 hours<br />

10A 10A 9A 14A 14A<br />

45V 45V 85V 85V 135V<br />

AC/DC AC/DC AC/DC AC/DC AC/DC<br />

5 ohms 5 ohms 10 ohms 6 ohms 10 ohms<br />

Haynes Inconel Haynes Inconel Inconel<br />

All dimensions are nominal in millimetres unless specified.<br />

Telephone +44 (0)1825 280 450 www.<strong>mdc</strong>vacuum.co.uk<br />

€<br />

3003<br />

3003<br />

3794<br />

7182<br />

9235<br />

308<br />

508<br />

950<br />

1022<br />

164<br />

452<br />

1817<br />

1817<br />

1858<br />

13

<strong>Sputter</strong> <strong>and</strong> <strong>multi</strong>-<strong>source</strong><br />

www.<strong>mdc</strong>vacuum.co.uk<br />

United Kingdom<br />

MDC Vacuum Limited<br />

Tel: +44 (0)1825 280 450<br />

Fax: +44 (0)1825 280 440<br />

sales@<strong>mdc</strong>vacuum.co.uk<br />

France<br />

MDC Vacuum Products Sarl<br />

Tel: +33 (0)437 65 17 50<br />

Fax: +33 (0)437 65 17 55<br />

info@<strong>mdc</strong>vacuum.fr<br />

Germany<br />

Tel: +49 (0)2305 947 508<br />

Tel: +49 (0)4931 930 5245<br />

Fax: +49 (0)2305 947 510<br />

sales@<strong>mdc</strong>vacuum.de<br />

Holl<strong>and</strong><br />

Evatec Process Systems BV<br />

Tel: +31 343 595 470<br />

Fax: +31 343 592 294<br />

sales@<strong>mdc</strong>vacuum.nl<br />

Italy<br />

Kenosistec Srl<br />

Tel: +39 02 9055200<br />

Fax: +39 02 9052984<br />

info<strong>caburn</strong>@kenosistec.it<br />

Thin film deposition<br />

■ Flanges <strong>and</strong> fittings<br />

■ Gate, inline <strong>and</strong><br />

angle valves<br />

■ Roughing<br />

components<br />

■ Vacuum<br />

measurement<br />

■ Viewports <strong>and</strong><br />

glass components<br />

■ Feedthroughs:<br />

electrical <strong>and</strong><br />

optical<br />

■ Motion <strong>and</strong><br />

manipulation<br />

■ Thin film<br />

deposition<br />

■ Chambers<br />

■ Custom<br />

engineering<br />

Reserve your copy of our<br />

extensive vacuum components<br />

catalogue on our website.<br />

Russian Federation<br />

MSH Technology Limited<br />

Tel: +7 (495) 543 60 25<br />

Fax: +7 (495) 722 12 90<br />

shive@msht.ru