Development of a novel mechatronic system for mechanical weed ...

Development of a novel mechatronic system for mechanical weed ...

Development of a novel mechatronic system for mechanical weed ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Results and discussion<br />

72<br />

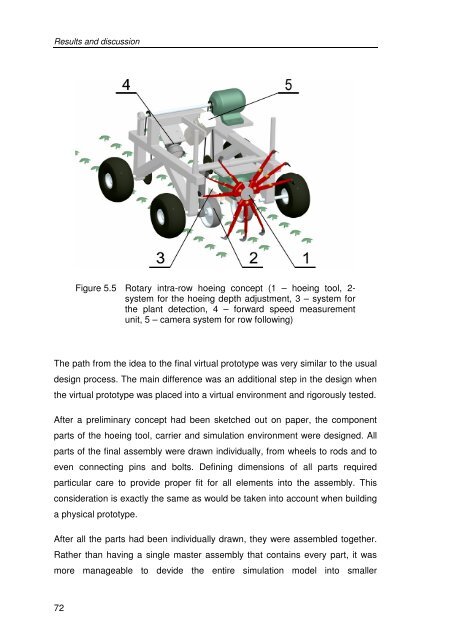

Figure 5.5 Rotary intra-row hoeing concept (1 – hoeing tool, 2-<br />

<strong>system</strong> <strong>for</strong> the hoeing depth adjustment, 3 – <strong>system</strong> <strong>for</strong><br />

the plant detection, 4 – <strong>for</strong>ward speed measurement<br />

unit, 5 – camera <strong>system</strong> <strong>for</strong> row following)<br />

The path from the idea to the final virtual prototype was very similar to the usual<br />

design process. The main difference was an additional step in the design when<br />

the virtual prototype was placed into a virtual environment and rigorously tested.<br />

After a preliminary concept had been sketched out on paper, the component<br />

parts <strong>of</strong> the hoeing tool, carrier and simulation environment were designed. All<br />

parts <strong>of</strong> the final assembly were drawn individually, from wheels to rods and to<br />

even connecting pins and bolts. Defining dimensions <strong>of</strong> all parts required<br />

particular care to provide proper fit <strong>for</strong> all elements into the assembly. This<br />

consideration is exactly the same as would be taken into account when building<br />

a physical prototype.<br />

After all the parts had been individually drawn, they were assembled together.<br />

Rather than having a single master assembly that contains every part, it was<br />

more manageable to devide the entire simulation model into smaller