AIR CONDITIONING LABORATORY UNIT - Solution Engineering

AIR CONDITIONING LABORATORY UNIT - Solution Engineering

AIR CONDITIONING LABORATORY UNIT - Solution Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SOLTEQ ® Equipment for <strong>Engineering</strong> Education & Research<br />

T<br />

<strong>AIR</strong> <strong>CONDITIONING</strong> <strong>LABORATORY</strong><br />

<strong>UNIT</strong><br />

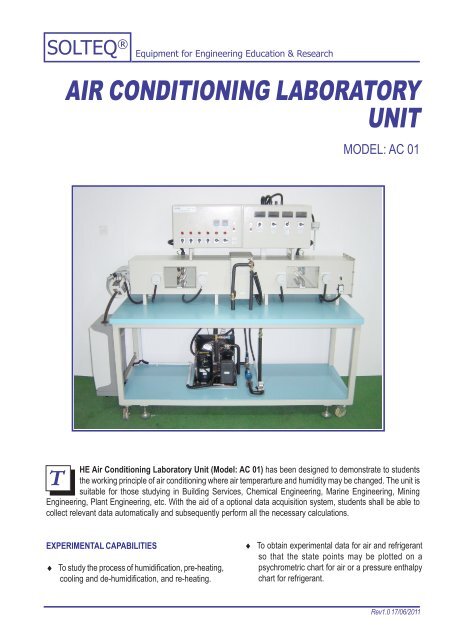

MODEL: AC 01<br />

HE Air Conditioning Laboratory Unit (Model: AC 01) has been designed to demonstrate to students<br />

the working principle of air conditioning where air temperarture and humidity may be changed. The unit is<br />

suitable for those studying in Building Services, Chemical <strong>Engineering</strong>, Marine <strong>Engineering</strong>, Mining<br />

<strong>Engineering</strong>, Plant <strong>Engineering</strong>, etc. With the aid of a optional data acquisition system, students shall be able to<br />

collect relevant data automatically and subsequently perform all the necessary calculations.<br />

EXPERIMENTAL CAPABILITIES<br />

♦ To study the process of humidification, pre-heating,<br />

cooling and de-humidification, and re-heating.<br />

♦ To obtain experimental data for air and refrigerant<br />

so that the state points may be plotted on a<br />

psychrometric chart for air or a pressure enthalpy<br />

chart for refrigerant.<br />

Rev1.0 17/06/2011

SOLTEQ ®<br />

♦ To determine the thermodynamic properties (e.g.<br />

specific enthalpy, specific volume, specific humidity,<br />

etc.)<br />

♦ To compare the enthalpy change of the air during the<br />

above processes with the heat transfer at the boiler,<br />

the heat transfer at the pre-heater, the enthalpy<br />

change of the refrigerant, and the heat transfer at<br />

the re-heater.<br />

♦ To compare the change of the specific humidity of<br />

the air during cooling with the condensate formed.<br />

DESCRIPTION<br />

This self-contained unit consists of several components<br />

joined by ducting through which the air flows. These<br />

components, commonly found in an industrial or<br />

commercial air conditioning unit, include a fan, a heater,<br />

a cooler, a humidifier, a de-humidifier (may be in<br />

conjunction with cooler) and a filter. The ducting and the<br />

components are supported on a steel frame with lockable<br />

castors.<br />

The unit comes with a pressure boiler (for humidification)<br />

and refrigeration plant (for cooling and de-humidification)<br />

which are housed in the lower part of the frame.<br />

The ducting through which the air flows has a crosssectional<br />

area of about 0.9 m 2 . Air from the atmosphere<br />

enters a variable speed centrifugal fan before going into<br />

the ducting. While the air is entering the fan, steam can<br />

be injected to increase the moisture contents so that a<br />

homogenous mixture of air and steam flows into the duct.<br />

Upon leaving the fan the air passes over two 1 kW<br />

externally finned electric elements (pre-heating) which<br />

may be individually switched. The warmed air then enters<br />

a stabilising section where its condition is determined by<br />

humidity or temperature sensor. Next the air flows through<br />

the evaporator of the refrigeration unit where it may be<br />

cooled and will deposit some of its moisture content as<br />

liquid. The cool and drier air passes into another<br />

stabilising section with humidity or temperature sensor<br />

Equipment for <strong>Engineering</strong> Education & Research<br />

before passing over two individually switched 0.5<br />

kW re-heating elements. The condition of the reheated<br />

air is determined and it then passes back to<br />

the atmosphere through an air flowmeter.<br />

SOLTEQ<br />

The boiler which supplies the steam for<br />

humidification is controlled by a steam generation<br />

controller so that the rate of steam production rate<br />

may be varied. An electronic level switch is installed<br />

in the boiler so that, in conjuction with a solenoid<br />

valve, the water level can be maintained.<br />

The refrigeration circuit is charged with refrigerant<br />

R134a. During the proces vapour formed in the<br />

evaporator is drawn into a hermetic compressor<br />

which discharges into an air cooled condenser. The<br />

R134a liquid then passes through a flowmeter and<br />

thermostatically controlled expansion valve to the<br />

evaporator. Temperature and pressure measuring<br />

points are provided in the refrigeration circuit.<br />

The fan speed may be varied by a thyristor mounted<br />

on the control panel switches and indicators are<br />

mounted on the control panel.<br />

SPECIFICATIONS<br />

Air Throughput: 0.14 m 3 s -1 (max.)<br />

Fan: Centrifugal (variable speed)<br />

Pre-heater: Two extended fin electric heating<br />

elements, each 1.0 kW, individually switched<br />

Cooler: Direct expansion, finned coil. Cooling rate<br />

approximately 2.0 kW but varies with conditions<br />

Re-heater: Two extended fin electric heating<br />

elements, each 0.5 kW, individually switched<br />

Boiler: Electrically heated, Fitted with level switch<br />

and solenoid valve to maintain level. Variable steam<br />

generation controller<br />

Refrigerator: Hermetic compressor with air cooled<br />

condenser. Refrigerant R134a.<br />

Duct cross section: 30.0 cm x 30.0 cm<br />

Rev1.0 17/06/2011

SOLTEQ ® Equipment for <strong>Engineering</strong> Education & Research<br />

SAFETY<br />

Refrigerator : High pressure and low pressure cut-out<br />

.<br />

Boiler : All heaters protected by temperature<br />

controller. Water level is maintained by<br />

means of level switch and solenoid<br />

valve.<br />

OPTIONAL ITEMS<br />

-EI<br />

DIGITAL INSTRUMENTATIONS<br />

i) 4 units of Digital Indicators<br />

ii) 6 units of temperature sensor c/w transmitter<br />

iii) 1 unit of refrigerant flowmeter<br />

iv) 1 unit of air flowmeter<br />

v) 5 units of temperature/humidity sensor c/w<br />

transmitter<br />

vi) 2 units of pressure transmitter<br />

-DAS<br />

SOLDAS DATA ACQUISITION SYSTEM<br />

i) A PC with latest Pentium Processor<br />

ii) An electronic signal conditioning system<br />

iii) Stand alone data acquisition modules<br />

iv) Windows based software<br />

♦ Data Logging<br />

♦ Signal Analysis<br />

♦ Process Control<br />

♦ Real-Time Display<br />

♦ Tabulated Results<br />

♦ Graph of Experiment Results<br />

SOLTEQ<br />

- CAL<br />

SOLCAL COMPUTER AIDED LEARNING<br />

SOFTWARE<br />

i) Interactive multimedia features<br />

ii) Graphical simulation<br />

iii) Experiment results samples<br />

iv) Full experiment manuals<br />

REQUIREMENT<br />

Electrical : 10 kW 380-415 VAC/3-Phase/50Hz<br />

Water : 10 litre per hour at 10 m head minimum.<br />

OVERALL DIMENSIONS<br />

Height : 1.130 m<br />

Width : 2.230 m<br />

Depth : 0.500 m<br />

MANUAL<br />

The unit is supplied with Operating and Experiment<br />

Manuals in English giving full descriptions of the unit,<br />

summary of theory, experimental procedures and<br />

typical experimental results.<br />

Rev1.0 17/06/2011

SOLTEQ ®<br />

SOFTWARE & E - LEARNING<br />

Our range of teaching equipment can be complemented with our<br />

SOLDAS and SOLCAL software.<br />

SOLDAS TM - Supervisory Control & Data Acquisition<br />

- Data Logging<br />

- Signal Analysis<br />

- Process Control<br />

- Real-Time Display<br />

- Tabulated Results<br />

- Graph of Experimental Results<br />

SOLCAL TM - Computer Aided Learning<br />

- Multimedia Features<br />

- Interactive<br />

- Graphic Simulation<br />

- Experiment Result Samples<br />

- Full Experiment Manuals<br />

Contact us for a catalog CD<br />

SOLUTION ENGINEERING SDN. BHD.<br />

(Co. No. 174876-M)<br />

Sales Office :<br />

No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara,<br />

47100 Puchong, Selangor Darul Ehsan, Malaysia.<br />

Tel. No. : +(603) 80758000<br />

Fax.No.: +(603) 80755784<br />

R&D Office :<br />

G-2A, Incubator 3, Technology Park Malaysia,<br />

Bukit Jalil, 57000 Kuala Lumpur, Malaysia.<br />

Tel. No. : +(603) 8996 0023<br />

Email : solution@solution.com.my<br />

Web site : http//www.solution.com.my/<br />

Equipment for <strong>Engineering</strong> Education & Research<br />

AGENT:<br />

BUATAN MALAYSIA<br />

MSC- Status<br />

Company<br />

Rev1.0 17/06/2011