Measuring where it really matters - Michenfelder

Measuring where it really matters - Michenfelder

Measuring where it really matters - Michenfelder

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

draft report for trade press publication in the magazine GIESSEREI ERFAHRUNGSAUSTAUSCH 11/2008<br />

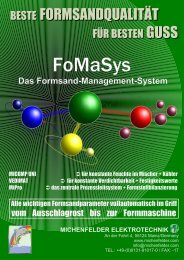

FoMaSys<br />

Module 1<br />

Module 2<br />

Module 3 Moisture Control<br />

Systems for<br />

Mixers<br />

Moisture Control<br />

Systems for<br />

Coolers<br />

Online Sand Testing System VEDIMAT<br />

Material taking from con-<br />

veyor belt by elevating un<strong>it</strong><br />

test of compactabil<strong>it</strong>y<br />

charging of test cylinder<br />

test of compressive strength<br />

Fig_3:<br />

By controlling compactabil<strong>it</strong>y at the moulding line directly, any<br />

subtle changes are detected and compensated for through<br />

feedback to the moisture control system. That means<br />

compactabil<strong>it</strong>y is automatically kept very constant.<br />

The idea behind FoMaSys<br />

The idea behind FoMaSys is to create<br />

a network of intelligent measurement,<br />

control and testing systems, while at<br />

the same time trying to combat the<br />

effects of dehomogenisation and<br />

change by the application of process<br />

technology. Looking at add<strong>it</strong>ives and<br />

superfines, the motto is: What comes<br />

out should be the same as what goes<br />

in – i.e. <strong>it</strong> should be as consistent as<br />

possible concerning times and<br />

quant<strong>it</strong>ies. Measurement and control<br />

technology ensures that first of all, the<br />

sand is accurately pre-wetted (to at<br />

least 2%) in the used sand bunker, and<br />

secondly, that <strong>it</strong> reaches the moulding<br />

line w<strong>it</strong>h consistently optimal<br />

mechanical properties (flowable).This<br />

ensures the reliabil<strong>it</strong>y of the tried and<br />

trusted moisture measuring and control<br />

systems that are networked and<br />

mon<strong>it</strong>ored centrally. The high level of<br />

automation also produces<br />

rationalisation effects. Precision and<br />

reliabil<strong>it</strong>y reduce scrap, and continuous<br />

control ensures a sand cond<strong>it</strong>ioning<br />

process that is cost-effective and that<br />

consistently conserves resources.<br />

Constant compactabil<strong>it</strong>y <strong>where</strong> <strong>it</strong><br />

<strong>really</strong> <strong>matters</strong> – directly at the<br />

moulding line<br />

As a relevant factor for sand qual<strong>it</strong>y,<br />

online control of compactabil<strong>it</strong>y is<br />

essential. Automatically controlling<br />

compactabil<strong>it</strong>y through the add<strong>it</strong>ion of<br />

water during production has become<br />

an established trend. In order to obtain<br />

Module 4<br />

Process Control<br />

System MiPro<br />

installation example<br />

Moisture Control<br />

Systems for<br />

Mixers<br />

or expand the relevant expertise,<br />

compet<strong>it</strong>ors have now responded by<br />

entering into joint ventures and<br />

acquis<strong>it</strong>ions. In the case of some<br />

manufacturers, this expertise has<br />

been developed in-house over several<br />

years – one-stop system solutions, as<br />

demonstrated so convincingly by the<br />

FoMaSys are a matter of course.<br />

More and more im<strong>it</strong>ators are coming<br />

to the realisation that continuous<br />

measurement in the mixing equipment<br />

(i.e. in the mixer or cooler) is essential<br />

for a precise sand moisture control. In<br />

relation to this major issue, FoMaSys<br />

manufacturer <strong>Michenfelder</strong> can rely on<br />

a head start of 40 years of knowledge.<br />

Success factors<br />

1.) The sand moisture is kept<br />

constant w<strong>it</strong>hin a tight tolerance<br />

of 2% at the cooler outlet.<br />

2.) The incomparable precision of<br />

moisture measurement and mois-<br />

ture control achieved thanks to<br />

the accurate in-mixer and incooler<br />

measurement technology<br />

(incl. the patented mixing<br />

dynamics mon<strong>it</strong>oring system)<br />

3.) The special installation location of<br />

the online sand testing system<br />

VEDIMAT on the conveyor belt<br />

directly before the moulding machine.<br />

Module 1<br />

Module 2<br />

Module 3<br />

Moisture Control<br />

Systems for<br />

Coolers<br />

FoMaSys<br />

Module 4<br />

Process Control<br />

and Qual<strong>it</strong>y Assurance System MiPro<br />

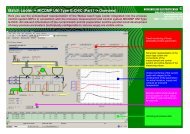

Total plant view<br />

Materialaufnahme vom<br />

Förderband per Aufzug<br />

On-line Sand<br />

Testing System<br />

VEDIMAT<br />

Process data analysis, evaluation<br />

Einbaubeispiel<br />

and archiving<br />

Mon<strong>it</strong>oring of single modules remote control in 1-to-1-view<br />

Fig_4:<br />

W<strong>it</strong>h MiPro moulding sand qual<strong>it</strong>y control comes into your office.<br />

Analyse the trends and evaluate production data – online or from<br />

archived database. Make relationships and developments in the<br />

sand cycle transparent comprehensible in an easy way.<br />

By combining FoMaSys modules 1 and<br />

3, <strong>it</strong> is possible to reliably record and<br />

compensate for any negative factors<br />

influencing the moulding sand on <strong>it</strong>s<br />

way from the mixer to the moulding<br />

machine that could have a long-term<br />

detrimental impact on compactabil<strong>it</strong>y<br />

(e.g. different benton<strong>it</strong>e saturation<br />

levels due to unstable in<strong>it</strong>ial moisture<br />

in the mixer, or moisture changes due<br />

to differences in temperature, and<br />

evaporation or mechanical changes<br />

caused by aeration or material transfer<br />

stations). None of these influences are<br />

identified or taken into account when<br />

compactabil<strong>it</strong>y is measured in the<br />

mixer. Variations of ±0.1% in moisture<br />

levels in the mixer result in<br />

compactabil<strong>it</strong>y fluctuations of up to ±2-<br />

3% in the moulding machine. There<br />

are some foundries <strong>where</strong> fluctuations<br />

of up to 10-12% in compactabil<strong>it</strong>y<br />

between the mixer and the moulding<br />

machine have been shown to occur –<br />

particularly when there is no sand<br />

cooler at all or <strong>where</strong> there is a sand<br />

cooler in which sand moisture is poorly<br />

regulated.<br />

From a well-nursed prejudice to<br />

technological head start<br />

However, there is one preconception<br />

that needs to be eliminated: contrary to<br />

what many people believe or claim to<br />

be the case, measuring compactabil<strong>it</strong>y<br />

just before the moulding machine is by<br />

no means too late. Since <strong>it</strong> is well<br />

known that there is a correlation<br />

between moisture and compactabil<strong>it</strong>y,