Guarantees optimum moulding sand at the moulding ... - Michenfelder

Guarantees optimum moulding sand at the moulding ... - Michenfelder

Guarantees optimum moulding sand at the moulding ... - Michenfelder

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FoMaSys<br />

The Moulding Sand-Management-System<br />

GIFA 2011 - Preview<br />

Every foundry strives to achieve high product quality <strong>at</strong> <strong>the</strong> best possible<br />

price. In <strong>the</strong> past, however, <strong>the</strong> motives for investing in <strong>moulding</strong> <strong>sand</strong><br />

prepar<strong>at</strong>ion changed rapidly. Where once <strong>the</strong> focus was on making savings<br />

on labour costs by autom<strong>at</strong>ing processes, <strong>the</strong>se days it is on reducing<br />

<strong>moulding</strong> <strong>sand</strong>-rel<strong>at</strong>ed waste in <strong>the</strong> fully autom<strong>at</strong>ed prepar<strong>at</strong>ion process.<br />

Casting models and casting products are becoming increasingly complex.<br />

All <strong>the</strong> more important it is to achieve a consistent <strong>moulding</strong> <strong>sand</strong> quality for<br />

<strong>the</strong> specific cast product <strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine directly. The objective<br />

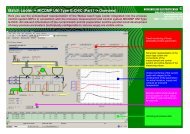

must be to reduce <strong>sand</strong>-rel<strong>at</strong>ed waste to close to zero. Measuring <strong>sand</strong><br />

moisture in tenths or regul<strong>at</strong>ing <strong>the</strong> compactability of <strong>the</strong> <strong>sand</strong> <strong>at</strong> <strong>the</strong> mixer<br />

with a vari<strong>at</strong>ion of ±3% is no longer enough by any manner of means. It will<br />

only work if changes in moisture content are registered in hundredths and<br />

compactability can be kept constant <strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine with a<br />

vari<strong>at</strong>ion of no more than ±0.8 – 1.3% (1 st standard devi<strong>at</strong>ion).<br />

More and more foundries and foundry suppliers throughout <strong>the</strong> world are<br />

<strong>the</strong>refore relying on <strong>the</strong> <strong>moulding</strong> <strong>sand</strong> management system FoMaSys.<br />

FoMaSys is <strong>the</strong> first choice for <strong>the</strong> required reduction in <strong>sand</strong>-rel<strong>at</strong>ed<br />

waste. In practical use, no o<strong>the</strong>r system achieves lower compactability<br />

vari<strong>at</strong>ions <strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine directly. Wherever individual FoMaSys<br />

modules are used, <strong>the</strong>y quickly become an indispensable part of <strong>moulding</strong><br />

<strong>sand</strong> prepar<strong>at</strong>ion.<br />

Major focus points are continuous moisture measurement and control in<br />

mixers, coolers and b<strong>at</strong>ch coolers (MICOMP UNI), consistent<br />

compactability <strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine directly (VEDIMAT) in addition to<br />

<strong>the</strong> control, monitoring and analysis from a central loc<strong>at</strong>ion (MiPro) of <strong>the</strong><br />

control systems used and of <strong>the</strong> relevant process parameters.<br />

<strong>Michenfelder</strong> will be using GIFA 2011 as an opportunity to present <strong>the</strong><br />

individual FoMaSys modules in detail and to explain <strong>the</strong> technical processrel<strong>at</strong>ed<br />

fe<strong>at</strong>ures and benefits and <strong>the</strong>ir interaction to interested fair visitors.<br />

Page 1/2<br />

<strong>Guarantees</strong><br />

<strong>optimum</strong> <strong>moulding</strong> <strong>sand</strong><br />

<strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine<br />

Hall 16<br />

Booth A32<br />

M <strong>Michenfelder</strong><br />

E<br />

Form<strong>sand</strong>- und Betonaufbereitung mit System<br />

<strong>Michenfelder</strong> Elektrotechnik GmbH & Co. KG<br />

An der Fahrt 4, D-55124 Mainz/Germany<br />

www.michenfelder.com<br />

info@michenfelder.com<br />

TEL.: +49-(0)6131-91017-0 / FAX: -17

<strong>Michenfelder</strong> is very pleased to note <strong>the</strong> first <strong>at</strong>tempts <strong>at</strong> imit<strong>at</strong>ion by<br />

manufacturers who for years were critical of <strong>the</strong> technology of continuous<br />

in-mixer measurement. They are both an incentive and an endorsement.<br />

But <strong>the</strong>y also show th<strong>at</strong> <strong>the</strong> development direction adopted by <strong>Michenfelder</strong><br />

decades ago was certainly <strong>the</strong> right one. With approx. 3000 machines<br />

installed throughout <strong>the</strong> world in various industrial sectors, and around 50<br />

years of personal experience in <strong>the</strong> field on <strong>the</strong> part of <strong>the</strong> company's<br />

founder, <strong>Michenfelder</strong> has valuable and crucial experience, knowledge and<br />

a technological advantage in this field. This competitive advantage is<br />

developed and maintained through continuous improvement.<br />

<strong>Michenfelder</strong> is making <strong>the</strong> MICOMP UNI-series fit for future requirements<br />

and will be presenting <strong>the</strong> new gener<strong>at</strong>ion <strong>at</strong> GIFA 2011. Precision will<br />

continue to be <strong>the</strong> outstanding and decisive fe<strong>at</strong>ure of <strong>Michenfelder</strong><br />

systems. In order to improve <strong>the</strong>m even fur<strong>the</strong>r and to make <strong>the</strong> systems<br />

even more reliable and efficient, <strong>the</strong> measuring circuit component will in<br />

future be moved to <strong>the</strong> mixer/cooler and connected to <strong>the</strong> process<br />

computer through a field bus. The malfunction frequency and <strong>the</strong> amount of<br />

cabling used will be reduced, and thanks to <strong>the</strong> bus systems, <strong>the</strong><br />

connectivity will become much more flexible.<br />

In <strong>the</strong> meantime, <strong>Michenfelder</strong> is also striving to implement concepts and<br />

ideas aimed <strong>at</strong> keeping <strong>the</strong> m<strong>at</strong>erial composition of <strong>the</strong> <strong>moulding</strong> <strong>sand</strong><br />

directly <strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine constant as regards <strong>the</strong> components<br />

percentage. Even in modern foundries, <strong>the</strong> very opposite is frequently <strong>the</strong><br />

case and expected losses due to burn-out and thinning are compens<strong>at</strong>ed<br />

for as a precautionary measure. This means th<strong>at</strong> composition and<br />

properties fluctu<strong>at</strong>e in <strong>the</strong> very moment in which <strong>the</strong>y actually need to be<br />

kept most consistent. <strong>Michenfelder</strong> wants to point out altern<strong>at</strong>ive solutions<br />

and options of action.<br />

We are looking forward to meeting you <strong>at</strong> our booth.<br />

<strong>Michenfelder</strong> Elektrotechnik<br />

GmbH & Co. KG<br />

FoMaSys<br />

The Moulding Sand-Management-System<br />

Page 2/2<br />

<strong>Guarantees</strong><br />

<strong>optimum</strong> <strong>moulding</strong> <strong>sand</strong><br />

<strong>at</strong> <strong>the</strong> <strong>moulding</strong> machine<br />

Hall 16<br />

Booth A32<br />

M <strong>Michenfelder</strong><br />

E<br />

Form<strong>sand</strong>- und Betonaufbereitung mit System<br />

<strong>Michenfelder</strong> Elektrotechnik GmbH & Co. KG<br />

An der Fahrt 4, D-55124 Mainz/Germany<br />

www.michenfelder.com<br />

info@michenfelder.com<br />

TEL.: +49-(0)6131-91017-0 / FAX: -17