Special Edition - Deutsche Molkerei Zeitung

Special Edition - Deutsche Molkerei Zeitung

Special Edition - Deutsche Molkerei Zeitung

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

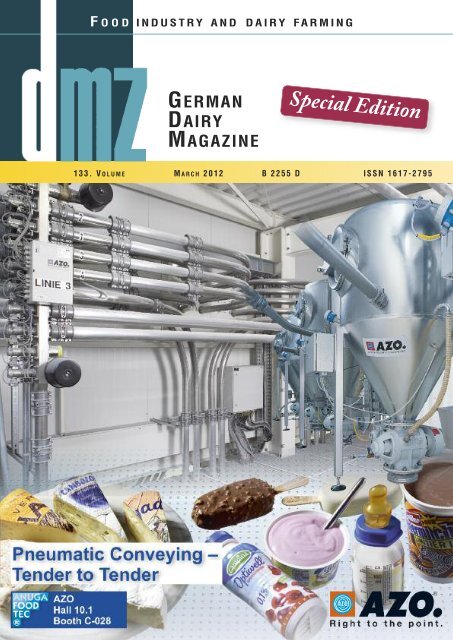

F O O D<br />

I N D U S T R Y A N D D A I R Y FA R M I N G<br />

GERMAN<br />

DAIRY<br />

MAGAZINE<br />

<strong>Special</strong> <strong>Edition</strong><br />

133. VOLUME MA R C H 2012 B 2255 D ISSN 1617-2795

Got a cheese challenge?<br />

We got it covered.<br />

When it comes to cheese, there’s a whole world out there. Whether<br />

you are a global player or regional producer, DSM can help you<br />

produce the perfect cheese. Across eight key cheese types, our<br />

enzymes and cultures are proven to accelerate production, increase<br />

output, cut costs and carbon emissions, boost flavor and texture,<br />

and maximize consistency.<br />

We’ll help you optimize every step of the cheese making process<br />

with our expert technical knowledge – the result of several decades’<br />

experience.<br />

From rich indulgent cheeses to healthy, low fat varieties and value<br />

ranges, you can trust our synergistic portfolio to deliver the solution<br />

to any cheese challenge. Plus, we o� er technical support across<br />

every continent and a global distribution network. Active in all<br />

dairy segments including enzymes, cultures and food protection<br />

solutions, think of us as your experienced, sustainable partner.<br />

info.food@dsm.com | www.dsm.com

Appropriate technical concepts<br />

for practical use<br />

The availability of safe and high-quality<br />

food is an essential need of societies today.<br />

The taste of various foods must satisfy our<br />

individual expectations and health requirements,<br />

but that's not all. Today's consumer<br />

also expects food producers to deal sparingly<br />

with the environmental and economic resources<br />

available to them. Minimizing the<br />

energy consumed during food production<br />

of course plays a special role, as this not<br />

only benefits the environment but also reduces<br />

production costs over the long term.<br />

Companies whose production processes<br />

comply with these standards certainly have<br />

a tremendous market advantage as they<br />

compete for the consumers' favour.<br />

Peter Grothues,<br />

Kölnmesse GmbH<br />

In this context, Anuga FoodTec plays a prominent role, because its visitors<br />

– in other words, food and beverage producers – expect to find integrated<br />

and flexibly usable technology concepts there rather than partial solutions.<br />

These are expectations that Anuga FoodTec fulfils in general and<br />

by contrast to food and beverage technology trade fairs that are oriented<br />

towards a specific sector only. Thanks to its process-oriented, cross-sector<br />

approach, which encompasses all raw ingredients, Anuga FoodTec offers<br />

its participants an overview of the technologies used for the entire course<br />

of processing at all stages of food and beverage production. The sixth<br />

Anuga FoodTec will take place from 27th to 30th March 2012 presenting all<br />

the relevant themes of food production to the international food business<br />

on the basis of the three major pillars Processing, Packaging and Food<br />

Safety.<br />

Approximately 1,300 exhibitors from 35 countries will present their<br />

technical innovations and cutting-edge solutions in Cologne – a new<br />

record turnout for Anuga FoodTec. Over 50 per cent of the exhibiting companies<br />

will come from abroad. The majority of these participants come from<br />

Italy, the Netherlands, Denmark, France, Great Britain and Sweden, followed<br />

by Spain, Austria, Turkey and the United States. Almost all of the key<br />

international players will be represented in Cologne, including the world<br />

market leader, TetraPak. In addition, Anuga FoodTec will feature more than<br />

400 first-time exhibitors.<br />

Publisher AVA Agrar-Verlag Allgäu GmbH<br />

Porschestraße 2, D-87437 Kempten/Allgäu<br />

phone +49 831 57142-0 fax +49 831 79008<br />

Internet: www.deutsche-molkerei-zeitung.de<br />

Managing<br />

Shareholder Dipl.-Ing. (FH) Wolfgang Kühnle<br />

Publishing<br />

Director Dr. Harald Ströhlein<br />

Advertisements Karl Nagenrauft<br />

e-mail: anzeigen.dmz@ava-verlag.de<br />

Ines Schilling<br />

e-mail: i.schilling@ava-verlag.de<br />

From the content<br />

<strong>Special</strong> <strong>Edition</strong><br />

Anuga FoodTec set to expand 4<br />

Chilled Food: 10<br />

Tasty fresh products are very popular with consumes<br />

Less effort, greater benefits 12<br />

Packing in flux: At the interface 14<br />

the real und digital worlds<br />

Efficient and versatile model systems 16<br />

Softdrinks – a paradigm shift 22<br />

Company News 24<br />

This growth in exhibitor turnout is also reflected in the size of the exhibition<br />

area. In addition to the large number of new exhibitors, many regular<br />

exhibitors have signed up for significantly larger stand areas. As a<br />

result, Anuga FoodTec will not only occupy Halls 4.1, 5.1, 6, 7, 8, 9 and<br />

10.1, as in 2009, but will also integrate Hall 5.2 for the first time, thus creating<br />

a gross exhibition space of 127,000 square metres — a gross increase<br />

of 10,000 square metres.<br />

As food and beverage producers, visitors to Anuga FoodTec can expect<br />

integrated and flexibly usable technology concepts ranging across all technologies<br />

of the entire production process and covering all stages of food<br />

and beverage production. The following sectors will be represented: process<br />

technology, packaging technology (including filling technology),<br />

automation, data processing, control and regulation technology, food safety<br />

and quality management, environmental technology, bio-engineering,<br />

operating materials, air conditioning and cooling technology, conveying,<br />

transport and storage installations, logistics, technological process materials,<br />

ingredients, components, assemblies, surface technology, equipment<br />

and services.<br />

Innovations are often the result of worldwide research and the exploitation<br />

of international technological know-how in relation to the optimisation<br />

of production processes and resource utilisation. In addition to the exhibitor<br />

presentations, Anuga FoodTec will therefore also feature a diverse, topquality<br />

supporting programme that will provide answers to specific questions<br />

and include special shows of innovative concepts.<br />

Editors Susanne Behm, Dr. Harald Ströhlein,<br />

phone: +49 831 57142-41<br />

e-mail: redaktion@ava-verlag.de<br />

Print KKW-Druck GmbH,<br />

Heisinger Str. 17,<br />

D-587437 Kempten/Allgäu<br />

Place of jurisdiction is Kempten (Allgäu).<br />

FLAG<br />

All rights reserved. Reproduction and photomechanical showing of parts of the<br />

magazine or whole only in written form from the publisher in prior. Articles from authors<br />

do not describe the opinion of the editors. ©2012<br />

dmz 6/2012 | 3

<strong>Special</strong> <strong>Edition</strong><br />

Anuga FoodTec 2012 set to expand:<br />

record exhibitors and exhibition space<br />

About 1,300 suppliers from 35 countries will showcase innovations –<br />

Comprehensive supporting programme for all product sectors<br />

The sixth Anuga FoodTec will present all the relevant themes of food production.<br />

From 27th to 30th March 2012 the<br />

international food technology sector will<br />

once again meet at Anuga FoodTec in<br />

Cologne. Anuga FoodTec offers the<br />

international food business an information<br />

and purchasing platform that covers<br />

the entire spectrum of technology and investment<br />

requirements for production in<br />

all segments of the food industry. With almost<br />

1,300 exhibitors from 35 countries,<br />

Anuga FoodTec will be setting a new record<br />

turnout. What’s more, the trade fair<br />

is also set to expand in terms of exhibition<br />

space. Anuga FoodTec is jointly organized<br />

by Koelnmesse GmbH and the<br />

German Agricultural Society (DLG).<br />

The sixth Anuga FoodTec will present<br />

all the relevant themes of food production<br />

to the international food business on<br />

the basis of the three pillars Food<br />

Processing, Food Packaging and Food<br />

Safety. Approximately 1,300 exhibitors<br />

from 35 countries will present their technical<br />

innovations and cutting-edge solutions<br />

in Cologne. Compared to the previous<br />

event, the trade fair is set to ex-<br />

4 |dmz 6/2012<br />

pand its participation figures by more<br />

than 16 per cent this year. Over 50 per<br />

cent of the exhibiting companies will come<br />

from abroad. The majority of these<br />

participants come from Italy, the Netherlands,<br />

Denmark, France, Great Britain<br />

and Sweden, followed by Spain, Austria,<br />

Turkey and the United States. In addition<br />

to the world market leader TetraPak, numerous<br />

key players will participate, including<br />

Albert Handtmann, Alco-Food-<br />

Machines, Alpma, Baader Nordischer<br />

Maschinenbau, Bizerba, Ecolab, Fuji<br />

Packaging, GEA, Grundfos, Grundwald,<br />

Heinen Freezing, Henckert Engineering,<br />

Inauen, Indag, IMA Industries Unipersonale,<br />

Ishida, Kawasaki Robotics, Kiremko,<br />

Komet Maschinenfabrik, Kronen<br />

Nahrungsmitteltechnik, Krones, Linde<br />

Gas, Maja Maschinenfabrik, Maschinenfabrik<br />

Seydelmann, Mespack, Mettler<br />

Toledo, Meypack Verpackungstechnik,<br />

Multivac, Provisur Technologies Formax,<br />

Reepack, Robert Bosch, SACMI,<br />

Schwarte Jansky, Sidel, Siemens Industry<br />

Sector, SPX Flow Technology, Tipper<br />

Tie Alpina, Treif, Trepko, Vemag Maschinenbau<br />

and Weber Maschinenbau. Also<br />

taking part will be many new companies<br />

from Germany and abroad that are exhibiting<br />

at Anuga FoodTec for the first time<br />

in 2012. More than 400 new exhibitors<br />

have registered for Anuga FoodTec so<br />

far.<br />

This growth in exhibitor turnout is also<br />

reflected in the size of the exhibition<br />

area. In addition to the large number of<br />

new exhibitors, many regular exhibitors<br />

have signed up for significantly larger<br />

stand areas. As a result, Anuga FoodTec<br />

will not only occupy Halls 4.1, 5.1, 6, 7,<br />

8, 9 and 10.1, as in 2009, but will also integrate<br />

Hall 5.2 for the first time, thus<br />

creating a gross exhibition space of<br />

127,000 square metres — a gross increase<br />

of 10,000 square metres.<br />

As food and beverage producers,<br />

visitors to Anuga FoodTec can expect integrated<br />

and flexibly usable technology<br />

concepts ranging across all technologies<br />

of the entire production process and<br />

covering all stages of food and beverage<br />

production. The following sectors<br />

will be represented: process technology,<br />

packaging technology (including filling<br />

technology), automation, data processing,<br />

control and regulation technology,<br />

food safety and quality management,<br />

environmental technology, bioengineering,<br />

operating materials, air conditioning<br />

and cooling technology, conveying,<br />

transport and storage installations, logistics,<br />

technological process materials, ingredients,<br />

components, assemblies,<br />

surface technology, equipment and services.<br />

In addition to the exhibitor presentations,<br />

Anuga FoodTec will therefore also<br />

feature a diverse, top-quality supporting<br />

programme that will provide answers to<br />

specific questions and include special<br />

shows of innovative concepts.<br />

Continued on page 6

Cream of the crop.<br />

We never settle for less than the best<br />

to satisfy our dairy partners.<br />

In fac a t, since 1893, ZENTIS has<br />

searched the world for onl nl nly y th the e mo most s t<br />

delectable fruit used in our ur fru ru r it<br />

preparations. Our r pr p ep epar ar a at ation pr proces e s<br />

be b gi g ns even before the h fru ruit is pick cked ed ed.<br />

We ensur ure su supe peri rior o qua ua u li l ty t by y fi rst<br />

ap appl pl plyi yi ying ng a rig ig igorou ous se s le l ct ctio io ion pr p oc o es ess<br />

in the he h field ld. Then we test for or flavo vor, r,<br />

fi rmness and acidity before proces esss<br />

in ing. g This way, when our fruit – the<br />

cream of the cro rop p – is added to your<br />

cream, the taste exper erie i nce is nothing<br />

short of extraordinary ry.<br />

ZENTIS – the partner for your success.<br />

Zentis GmbH & Co. KG � Postfach 10 16 37 � 52016 Aachen � Deutschland � Tel. +49 (0) 2 41/47 60-0 � Fa x +49 (0) 2 41/47 60 -3 69 � www.zentis.de � info@zentis.de

<strong>Special</strong> <strong>Edition</strong><br />

Under the direction of the DLG, 27<br />

specialist forums will address topics and<br />

questions of current interest to the sector,<br />

with presentations by leading<br />

research institutes and associations.<br />

The programme will consist of the following<br />

elements: emulsifying technology,<br />

process-structure-function-relations in<br />

food, the use of ultrasound in food tech-<br />

6 |dmz 6/2012<br />

nology, energy efficiency, coating and<br />

capsules, sensor technology, nanotechnology,<br />

controlled-temperature logistics,<br />

meat technology, cooling and freezing,<br />

KIN forum on the subject ”Successful<br />

Strategies for Chilled Ready Meals”, the<br />

HighTech Europe Innovation & Technology<br />

Transfer Workshop, dosing and<br />

weighing technology, seals, nozzles and<br />

pumps, IT solutions for the food industry,<br />

the future of food technology, the use<br />

of robots in baked goods production,<br />

pack-aging technology, extruder technology,<br />

modified atmosphere packaging,<br />

”Inside Food”, maintaining the global<br />

food supply, the High Tech Europe<br />

Continued on page 8

New generation of<br />

GRUNWALD rotary-type machines<br />

GRUNWALD is going to show the latest developments of<br />

their cup filling machines and bucket lines at their stand no.<br />

B-030 in hall 7.1.<br />

This is the first time the new generation of rotary-type machines<br />

will be featured. To introduce this new design of rotarytype<br />

machines, we will be exhibiting a 2-lane ROTARY 6.000<br />

which is designed for filling spreadable butter. With Grunwald’s<br />

ongoing development of their rotary-type machines, they have<br />

been optimised in a user-friendly way with regard to the machine<br />

operation, modular drive technology and hygienic<br />

design. This new design applies to all our rotary-type machines<br />

and as a result we can achieve production speeds up to 18,000<br />

cups/h.<br />

Flexible inline machines: The Grunwald engineering company<br />

from the Allgäu excites the industry by offering the most<br />

flexible cup filling machines with regard to filling spreadable<br />

butter. With their 6-lane FOODLINER 20.000 GRUNWALD demonstrates<br />

its up to the minute design technology with a<br />

machine which has maximum format flexibility. This inline machine<br />

is designed to handle 7 different cup sizes with a production<br />

speed of 18,000 cups/h. The quick format changeover<br />

is achieved with minimum change over times without the need<br />

for tools. With maximum flexibility and high filling accuracy this<br />

will be interesting criteria for many companies.<br />

Bucket line FLEXLINER XL with ”One touch quick-change<br />

system”: This 1-lane machine will be the ideal solution for customers<br />

who need a flexible bucket line with short changeover<br />

times. The FLEXLINER XL is suitable for filling and lidding<br />

buckets from 1 kg up to 20 kg using weigh filling technology for<br />

accurate results. This machine is equipped with the unique<br />

Company News<br />

The GRUNWALD<br />

fair stand: designed in<br />

the style of a typical<br />

Allgäu mountain pasture.<br />

”One touch quick-change system”. This system allows a fullyautomatic<br />

changeover without the need for tools and makes it<br />

possible within a very short time. As an option, this machine<br />

can be equipped with sealing from the reel and can include a<br />

leak test station.<br />

In addition, this bucket line, together with all GRUNWALD machines,<br />

can be equipped with a packing material sterilisation system<br />

as well as with a laminar cabin or sterile air cabin for ultra<br />

clean applications which are needed for the dairy industry.<br />

The 2-lane compact rotary-type machine GRUNWALD-<br />

HITTPAC AKH-019SE filling stirred yoghurt and set yoghurt<br />

makes the range of exhibition machines perfect. This cup filler<br />

is equipped with quick format change system and will be handling<br />

two different round 500 grs cups. The filling station in CIP<br />

design has a high filling accuracy. As with all GRUNWALD<br />

machinery, they are well engineered with compact design, together<br />

with competitive pricing making this an interesting feature<br />

of this machine.<br />

As major suppliers to the dairy industry and other areas of the<br />

food industry, GRUNWALD excel with their highly-flexible cup<br />

and bucket filling machines. This is being achieved by their special<br />

features, in particular quick format and product changeover.<br />

For the year 2012 based on constant growth and a full order<br />

book, has resulted in the company making an investment of<br />

5 million euros in their location at Wangen im Allgäu to further<br />

extend and improve the company’s offices and manufacturing<br />

facility. The completion of this building works is scheduled for<br />

the middle of this year. GRUNWALD currently employ 120 people<br />

and this is expected to grow throughout 2012.<br />

www.grunwald-wangen.de<br />

dmz 6/2012 | 7

<strong>Special</strong> <strong>Edition</strong><br />

Stakeholder event ”Future of Food Processing”,<br />

foreign object detection, halal<br />

food production, fresh convenience, clean<br />

room technology and allergy management.<br />

Anuga FoodTec 2012 will also be<br />

accompanied by top-class conferences.<br />

The congress organized by the European<br />

Federation of Food Science and<br />

Technology (EFFoST) will show the latest<br />

developments in the production of<br />

chilled food, with a particular focus on<br />

fresh-cut products. The symposium by<br />

the European Hygienic Engineering &<br />

Design Group (EHEDG) will share comprehensive<br />

know-how on the role of hygiene<br />

technology in the production of undamaged<br />

and healthy food. A particular<br />

focus will be on hygienic design and<br />

guidelines for hygienic processing. Once<br />

again Anuga FoodTec will be hosting<br />

International Fruit World (IFW). Under<br />

the title ”An Opportunity for Fruit Juice?”,<br />

the congress will focus on several cutting-edge<br />

topics, including markets and<br />

trends, quality assurance, process technology<br />

and the raw materials procurement<br />

market. Experts from the worlds of<br />

business, industry, science and research<br />

will give a series of talks underlining the<br />

strategic importance of sustainable management.<br />

For the second time now, the Nova Institute<br />

will organize a conference on<br />

”Sustainable Packaging – SusPack” at<br />

Anuga FoodTec. Over the course of two<br />

conference days, presentations and discussions<br />

will analyse the current challenges<br />

and solutions in the field of sustainable<br />

packaging. One focus will be on<br />

organically based pack-aging and the<br />

questions it raises: Where and how has<br />

organically based packaging already<br />

8 |dmz 6/2012<br />

Presentations and<br />

discussions will<br />

analyse the current<br />

challenges and<br />

solutions in the<br />

food technology.<br />

Photograph:<br />

Koelnmesse<br />

been successfully established? What<br />

advantages does it offer, and what do we<br />

need to know about its use? And finally,<br />

which innovations, trends and potentials<br />

can be predicted? At a joint event with<br />

Anuga FoodTec, nova-Institut GmbH will<br />

for the first time issue the ”SusPack-<br />

Award” for the most innovative and most<br />

sustainable packaging solution introduced<br />

on the market in 2011/2012.<br />

Following a pre-selection round, a panel<br />

of judges will choose the overall winner<br />

on the first day of the conference. The<br />

prize will be awarded in a special evening<br />

event on 29th March 2012. <br />

New international challenges, guidelines<br />

and procedures as well as packaging<br />

trends for the meat industry will be<br />

the subject of the half-day conference of<br />

the online publication FoodProduction-<br />

Daily.com, which will take place on 28th<br />

March 2012.<br />

World-premiere presentation<br />

In addition, this year’s trade fair will<br />

host a world-premiere live presentation<br />

of the Robotic Pack Line, which cannot<br />

be seen in this form anywhere else and<br />

will demonstrate new possibilities for the<br />

sector. This time, the show will demonstrate<br />

the hygienic handling of real fresh<br />

meat. In a complete production line, robots<br />

will automatically take E2 boxes<br />

from pallets and check the fresh meat<br />

contained in the boxes.<br />

A robot equipped with a hygienic gripper<br />

will take the pieces of meat out of the<br />

boxes and place them in a piece of primary<br />

packaging (a tray), which it then<br />

seals. After the seams of the seal have<br />

been checked and the product labelled,<br />

a Scara robot will lay the finished pieces<br />

of primary packaging in the cleaned<br />

E2 boxes, which are then automatically<br />

placed onto the palette. Another section<br />

of the Robotic Pack Line will demonstrate<br />

a high-performance secondary<br />

packaging process. Here, the trays are<br />

automatically removed, checked, labelled<br />

and put into boxes. The trays are<br />

then labelled as well and placed onto<br />

pallets.<br />

For the first time, Anuga FoodTec will<br />

stage a Careers Day this year. This initiative<br />

will enable closer contact between<br />

the exhibitors at Anuga FoodTec<br />

and students and graduates of related<br />

subjects, thus strengthening the sector’s<br />

recruitment strategies. Careers Day will<br />

take place on Friday, 30th March 2012,<br />

from 9:00 a.m. to 6:00 p.m.<br />

An overview of the entire supporting<br />

programme, including detailed information<br />

on the topics, speakers, places and<br />

times, can be found on the Anuga Food-<br />

Tec website at www.anugafoodtec.de or<br />

www.anugafoodtec. com.<br />

Anuga FoodTec will take place from<br />

Tuesday, 27th to Friday, 30th March<br />

2012. For four days it will offer a concentrated<br />

overview of machines and<br />

equipment as well as services for the<br />

food and beverage production industry.<br />

The trade fair is open to trade visitors<br />

only. Anuga FoodTec will be open daily<br />

from 9:00 a.m. to 6:00 p.m.<br />

Exhibitors can make all the necessary<br />

preparations for their visit on the<br />

Anuga FoodTec website, www.anugafoodtec.com.<br />

In addition to online visitor<br />

registration, the website provides<br />

affordable and time-saving assistance<br />

with travel and hotel arrangements. The<br />

”Matchmaking” online tool also enables<br />

trade visitors to research various exhibitors<br />

and product segments before the<br />

trade fair and to contact exhibitors<br />

directly.<br />

Admission fees: a day ticket costs<br />

€ 40 (€ 24 in advance), a two-day ticket<br />

costs € 50 (€ 34 in advance), and<br />

a season ticket costs € 80 (€ 54 in advance).<br />

Admission for food technology<br />

students is € 14. The catalogue costs €<br />

25. The admission ticket entitles the bearer<br />

to travel free of charge on buses,<br />

trams and trains (second class only) of<br />

the Cologne Municipal Transport Authority<br />

(KVB) and the Rhein-Sieg Transport<br />

Authority (VRS).<br />

To find out all about Anuga FoodTec,<br />

visit: www.anugafoodtec.com

Here’s a renewable product: certifi ed,<br />

traceable back to source and the produce<br />

of responsibly managed cultivation<br />

Here’s a glass of milk<br />

Renewable, certifi ed, and the product of responsibly managed cultivation. What goes without<br />

saying for many of their valuable contents, also applies for our beverage cartons.<br />

It is nice when product and packaging go together so perfectly. Take our beverage cartons –<br />

to make them, we use only wood fi bres originating from forests that are managed to the<br />

highest standards and from other controlled sources. To guarantee this, we have had all our<br />

facilities around the globe certifi ed in accordance with the rigorous, internationally binding<br />

criteria of the Forest Stewardship Council (FSC) ® for a continuous product chain of custody.<br />

For the sake of the environment, and the contents of our carton packs.<br />

Visit www.sig.biz for more information.

<strong>Special</strong> <strong>Edition</strong><br />

Chilled Food: Tasty fresh products are<br />

very popular with consumers<br />

The relatively new convenience product segment known as chilled food involves food that is<br />

freshly made, freshly processed and freshly cooled.<br />

The fair will also provide informations about<br />

innovative trends in the convenientsegment.<br />

Photograph: Koelnmesse<br />

In addition to complete ready-meals,<br />

this segment primarily encompasses<br />

fresh pizza and pasta that only need to<br />

be baked or cooked, as well as kitchenready<br />

cleaned vegetables and salad<br />

preparations or complete, ready-to-eat<br />

salads to which only dressing needs to<br />

be added. Other examples of chilled<br />

food include sandwiches, cut and<br />

portioned fruit and even plates of sushi.<br />

Chilled beverage products include<br />

smoothies and freshly pressed juices.<br />

What all of these products have in common<br />

is that they aren't preserved thermally<br />

and don't contain preservatives.<br />

They are all sold in a chilled state and<br />

can be eaten after only minimal preparation.<br />

Chilled products enable food companies<br />

to create more value than is the<br />

case with conventional ready-meals or<br />

refrigerated products. They also offer<br />

consumers the opportunity to enjoy<br />

freshly prepared food without needing<br />

special skills or having to spend much time<br />

preparing meals. However, these miraculously<br />

fresh products do require a<br />

certain amount of processing. In addition<br />

to needing an effectively uninterrupted<br />

cold chain, hygienic and germ-free con-<br />

10 |dmz 6/2012<br />

ditions are needed during the production<br />

and packaging of chilled food. The focus<br />

is therefore on the germ count of the<br />

raw materials, packaging materials,<br />

processing areas and finished products.<br />

Clean surroundings are<br />

essential for combating germs<br />

A clean and nearly germ-free production<br />

environment is the primary precondition<br />

for ensuring that preservatives<br />

and heat treatment are not needed to<br />

manufacture refrigerated fresh products.<br />

In addition to strict hygiene on the part of<br />

personnel and the regular cleaning of all<br />

surfaces, machines and operating materials,<br />

such an environment can best be<br />

attained through the use of an appropriate<br />

air management system. As a result,<br />

clean rooms are slowly being increasingly<br />

used in food production. However,<br />

targeted measures can also be employed<br />

to ensure that airborne germs do<br />

not get anywhere near chilled food in<br />

normal production facilities. For example,<br />

UV-C modules can be integrated into<br />

air conditioning and ventilation systems.<br />

These modules irradiate the air<br />

channelled into the room so that airborne<br />

germs are effectively exterminated.<br />

Air is also effectively sterilized by atomising<br />

special aerosols in the production<br />

areas. The effective components of these<br />

aerosols are substances such as<br />

benzoic acid, lactic acid or hydrogen peroxide.<br />

These substances can even be<br />

used for the production of organic products<br />

and they also are effective on the<br />

food's surface. Although they eliminate<br />

almost all of the germs that cause spoilage,<br />

they are harmless for human<br />

beings and do not damage the product.<br />

Everything is under control<br />

in the packaging as well<br />

Chilled food can be shrink-wrapped,<br />

which is particularly suited for pasta and<br />

fully prepared meals. By contrast, sandwiches,<br />

sushi and salad preparations<br />

would be damaged by such packaging<br />

or lose their fresh appearance. That's<br />

why Modified Atmosphere Packaging<br />

(MAP) on trays is frequently used for<br />

such products. MAPs replace preservatives<br />

with a germ-free gas atmosphere<br />

that is tailored to the food in question in<br />

order to keep cut fruit, salads and vegetables<br />

fresh. But tray packaging is also<br />

useful for other applications. The merger<br />

of freshness and convenience is made<br />

perfect by all-new plastic wrapping that<br />

allows kitchen-ready chilled products to<br />

be cooked or baked in the microwave<br />

directly on the tray.<br />

Creating clean conditions<br />

with high pressure<br />

High Pressure Preservation (HPP) is<br />

a non-thermal method for preserving<br />

food. This method, which has recently<br />

become generally available, reduces the<br />

number of undesirable micro-organisms<br />

in food in a manner that preserves the<br />

product's properties. HPP helps to meet<br />

the increasing demand for very highquality<br />

food products lacking additives.<br />

The system offered by the Anuga Food-<br />

Tec exhibitor Multivac consists of one or<br />

more HPP chambers and a pressure<br />

booster. High Pressure Preservation of<br />

food is generally performed at a pressure<br />

of up to 6,000 bars, which destroys<br />

any harmful micro-organisms that the<br />

products may contain. The high-pressure<br />

treatment is employed on primary<br />

packaged food. The process causes<br />

negligible thermal stress and hardly<br />

changes the food's structure, its taste or<br />

the valuable nutrients it contains. Protective<br />

gas packaging that is especially<br />

adapted to high pressures is used as the<br />

primary packaging to ensure that product<br />

quality remains unchanged during<br />

the food's shelf life.

GEA Westfalia Separator Group at Anuga FoodTec 2012<br />

Outstanding centrifugal separation technology<br />

The new ecoclear of GEA Westfalia<br />

Separator Group is ideal for bacteria<br />

removal in the production of highgrade<br />

dairy products and is also suitable<br />

for producing cheese-making milk.<br />

Cologne<br />

27.03. – 30.03.2012<br />

Hall 4.1<br />

Stand A031-D038<br />

GEA Westfalia Separator Group is presenting a new separator<br />

generation for milk skimming at Anuga FoodTec from 27. to<br />

30. March 2012 in Cologne. For the first time in a medium<br />

capacity range, the new milk skimming separator MSI 140<br />

with integrated direct drive will be presented. This separator<br />

will be combined with a standomat MC for automatic fat<br />

content regulation of cream and milk at the fair.<br />

The new GEA Westfalia Separator ecoclear has likewise been<br />

developed for small and medium flow rates in the dairy<br />

technology sector – combinable for the first time in this capacity<br />

class with proplus. The proplus system enables extending the<br />

ejection intervals and consequently a reduction of the solids<br />

discharge. The ecoclear separator is optimal for bacteria<br />

removal from high-grade dairy products and is suitable for producing<br />

cheese-making milk. Thanks to the self-cleaning bowl,<br />

the machine is suitable for fully automated cleaning-in-place.<br />

The GEA Westfalia Separator ecoforce decanter series in 2phase<br />

and 3-phase design with integrated summationdrive<br />

stands for high performance efficiency and absolute reliability. It<br />

is used specifically in beverage technology, in the processing of<br />

renewable resources and in dairy technology. In addition, GEA<br />

Westfalia Separator Group will be showing its range of ceramic<br />

membrane elements for microfiltration and ultrafiltration which<br />

complements the mechanical separation technology perfectly.<br />

A completely new service concept is also having its premiere<br />

at Anuga FoodTec: serv&care for permanently high availability,<br />

process efficiency and budget security. With this whole bundle<br />

of new developments, GEA Westfalia Separator Group is<br />

emphatically underlining its claim to innovate.<br />

GEA Mechanical Equipment<br />

GEA Westfalia Separator Group GmbH<br />

Werner-Habig-Straße 1, 59302 Oelde<br />

www.westfalia-separator.com<br />

engineering for a better world

<strong>Special</strong> <strong>Edition</strong><br />

Less effort, greater benefits<br />

Creating products with economical processes and efficient plant concepts<br />

In the future, hygiene will remain the overarching topic for processing facilities.<br />

Photograph: Koelnmesse<br />

The latest generation of food production<br />

plants enables operators to conserve<br />

resources and minimize costs by optimising<br />

processes, boosting flexibility and<br />

improving products. By integrating appropriate<br />

design criteria and cutting-edge<br />

automation components, operators can<br />

produce top-quality products that benefit<br />

manufacturers, consumers and the environment<br />

alike.<br />

Hygiene will remain the overarching<br />

topic for processing facilities in the future.<br />

The systematic use of hygienic design criteria<br />

to improve plant hygiene has a positive<br />

impact on a wide range of different<br />

factors. The focus is on minimizing hygiene-related<br />

and health-related risks,<br />

which can damage a company's image,<br />

cause product losses and lead to damage<br />

claims. Processing facilities that are<br />

easier to clean also create substantial<br />

cost savings in practice, because they<br />

can be cleaned more rapidly with the use<br />

of less water, energy, cleaning agents<br />

and disinfectants. This not only saves money<br />

but also improves the company's environmental<br />

performance. Now that the<br />

key hygienic design criteria for processing<br />

plants have been formulated and implemented<br />

with increasing success, researchers<br />

have begun to examine the issue<br />

in more detail. In the years ahead,<br />

close examination of the properties of<br />

12 |dmz 6/2012<br />

material surfaces and their interaction<br />

with dirt and micro-organisms will provide<br />

new insights that will be used to create<br />

new cleaning strategies. These include<br />

strategies for combating harmful biofilms,<br />

which have been largely disregarded up<br />

until now, as well as systems for the biomonitoring<br />

of plant cleanliness and hygienic<br />

conditions.<br />

Things are happening<br />

on the surface<br />

Stainless steel is an outstanding material<br />

with regard to durability and hygiene.<br />

To date, it has always been the key<br />

material for ensuring that processing<br />

facilities are easy to clean. However, alternatives<br />

are now being increasingly<br />

used for exterior surfaces, largely because<br />

of the greatly increased prices of raw<br />

materials. These alternatives consist of<br />

materials and coatings that offer a range<br />

of advantages. Bosch Rexroth, for example,<br />

is using special plastics for its successful<br />

CL03 valve terminal system. These<br />

plastics can withstand a wide variety of<br />

cleaning chemicals so that the terminal<br />

system achieves protection class IP69K,<br />

which means it can be used directly on<br />

the machinery without requiring a switching<br />

cabinet. Innovative surface coatings<br />

are already being used in washdown drives,<br />

automation components and robots.<br />

Their low percentage of stainless steel<br />

and the possibility of using other materials<br />

underneath the surface coating makes<br />

these systems less expensive and<br />

lighter than those made of stainless steel.<br />

Thus, it is possible to reduce the material<br />

costs of servo motors by around 30 per<br />

cent if two-part coatings are used. The<br />

protective coat meets the IP67 protection<br />

class and enables the wet cleaning of the<br />

machinery with cleaning agents and chemicals.<br />

This new generation of robust, hygienic<br />

surfaces is represented by the tried<br />

and tested VLT series from Danfoss and<br />

by Stäubli's He robot series. It allows exterior<br />

surfaces to achieve the same level<br />

of durability and cleanability as stainless<br />

steel without containing this material.<br />

Stainless steel remains the preferred material<br />

for processing plant interiors and is<br />

difficult to replace. Nevertheless, the rising<br />

cost of this material will almost certainly<br />

lead to the development of alternatives<br />

in the medium term. Nanoscience<br />

will surely contribute to the development<br />

of suitable coatings for the targeted modification<br />

of surface properties and generating<br />

new ideas for hygienic plant design.<br />

Modular systems for improving<br />

plants and efficiency<br />

Plant manufacturers are continuously<br />

improving their products in order to approach<br />

maximum efficiency at all levels.<br />

Modular designs for flexible expansion,<br />

retooling and upgrades, as well as flexible<br />

application possibilities, are now almost<br />

mandatory features in this regard.<br />

One example of this is the optimised version<br />

of the Tetra Albrix module for dissolving<br />

sugar. Thanks to its high operating efficiency<br />

and modular design, this system<br />

cuts costs, increases environmental<br />

compatibility and simplifies upgrading. A<br />

range of innovations makes these savings<br />

possible compared to predecessor<br />

models. The module is fitted with an advanced<br />

control system for the brix setpoint<br />

value that enables companies to<br />

continuously adjust the dosage and<br />

maintain the temperature at an optimal le-

vel for the respective amount of sugar,<br />

thus reducing energy consumption. Energy<br />

consumption is also cut by a new<br />

cross-flow filter, which enables the manufacturer<br />

to determine the size of the sugar<br />

crystals and minimizes the dissolution<br />

tempera-ture. Heating costs are 42 per<br />

cent lower than those of the predecessor<br />

version, and the costs for cooling energy<br />

are even 55 per cent lower. Including the<br />

demand for cooling energy, electricity<br />

consumption amounts to only 4 kWh per<br />

1,000 litres of the product, while the<br />

amount of heating energy needed totals<br />

14.5 kWh per 1,000 litres. Other advantages<br />

include time savings resulting from<br />

process acceleration and reduced raw<br />

material costs due to the use of less expensive<br />

sugar. Depending on requirements,<br />

the dissolver can be modularly expanded<br />

to include a pasteuriser and a decoloriser.<br />

Local designs<br />

for global benefits<br />

This example combines a number of<br />

trends, some of which the manufacturers<br />

of processing facilities have been addressing<br />

for a long time, but which will not<br />

become less important in the future. One<br />

of these trends is the increasingly modularised<br />

design of the facilities and the individual<br />

components, which makes it possible<br />

to customise the assembly and expansion<br />

of plants and components as<br />

well as of complete modular systems.<br />

The resulting cost savings in production<br />

and parts stocking benefit manufacturers<br />

and customers alike.<br />

Another trend involves splitting processing<br />

facilities into modules, components<br />

and parts, but at the same time holistically<br />

examining the effects of changes<br />

so that time, raw mat-erial and energy savings<br />

can contribute to substantial cost<br />

reductions.<br />

However, one of the most important<br />

trends for the production flow involves the<br />

sensor sys-tems. Increasing process integration<br />

and new developments in online<br />

and inline analyses open up new possibilities<br />

for measuring and controlling<br />

technology as well as for the automation<br />

of processes.<br />

For example, there are methods for<br />

the inline determination of production parameters<br />

that go far beyond simple density,<br />

guide value and opacity measurements<br />

and enable optimal processing<br />

through the immediate influencing of pro-<br />

<strong>Special</strong> <strong>Edition</strong><br />

cess parameters before any defects can<br />

occur in the product. This development<br />

will continue in the future and might eventually<br />

include the use of biosensors.<br />

Presenting the numbers<br />

Manufacturers will also increasingly<br />

examine all of the lifecycle costs of machines<br />

and plants, from their purchase all<br />

the way to their disassembly and disposal.<br />

They will do this because it enables investors<br />

(including those from outside the<br />

food industry) to plan the costs that will accrue<br />

during the system's use. On the one<br />

hand, this enables operators to evaluate<br />

the sustainability of their investments; on<br />

the other, they can then achieve planning<br />

security that prevents high follow-up costs<br />

from arising after the system is put into<br />

operation. Thanks to this examination of lifecycle<br />

costs, the suppliers of processing<br />

facilities can convincingly demonstrate<br />

that an investment will pay off for the customer<br />

over the long run due to the system's<br />

increased energy efficiency and reduced<br />

resource use. The efficient use of all<br />

types of resources – from energy and raw<br />

materials to additives and the processing<br />

facilities themselves – will remain a key topic<br />

in the future.<br />

From milk supply to ripened cheese.<br />

We create added value for you, your products and<br />

your customers.<br />

Kalt Maschinenbau AG<br />

Dairy supplies and cheese making equipment<br />

Letziwiesstrasse 8, CH-9604 Lütisburg<br />

Phone +41 (0)71 932 53 53<br />

info@kalt-ag.ch<br />

www.kalt-ag.ch<br />

Meet us at the ANUGA<br />

hall 4.1, aisle B<br />

stand no. 069a

<strong>Special</strong> <strong>Edition</strong><br />

Packing in Flux: At the interface<br />

between the real and digital worlds<br />

The days are gone when packaging was used for nothing more than protecting<br />

the product andensuring an attractive presentation at the point of sale. These days,<br />

packaging has to do a lot more.<br />

The packaging technology is strongly represented at the fair. Photograph: Koelnmesse<br />

It has to be intelligent and interactive,<br />

and it is supposed to track goods<br />

along the entire supply chain, to expose<br />

counterfeits, to test whether a<br />

package has already been opened, or<br />

to indicate whether a cold chain has<br />

been interrupted. Finally, it is supposed<br />

to make it possible to pursue<br />

new methods of brand communication<br />

and to interact with the consumer.<br />

QR codes are spreading very rapidly<br />

at the moment: in magazines, on<br />

placards, and on packaging too. More<br />

and more merchants and manufacturers<br />

of branded products are making<br />

use of these two-dimensional „quick<br />

response” codes. If the consumer has<br />

a cell phone with a built-in camera or a<br />

smartphone, it can be used to scan in<br />

the code printed on the packaging.<br />

The phones have an app that decrypts<br />

the code and navigates the user directly<br />

to the corresponding website of<br />

the manufacturer, where consumers<br />

can find more information. This way,<br />

14 |dmz 6/2012<br />

the limited analogue space on the<br />

packaging can be expanded virtually.<br />

For example, the stated goal of<br />

Frosta, a producer of frozen foods, is<br />

to ”remove cooking obstacles”. The<br />

company prints a QR code on many<br />

frozen vegetable packages. With a<br />

smartphone, the consumer can then<br />

use the code to navigate to a microsite<br />

that presents recipe ideas, for<br />

example. Any ingredients that are still<br />

needed can then conveniently be<br />

bought during the same shopping trip.<br />

But that's not all: In keeping with the<br />

trend towards interactivity and networking,<br />

users can also enter their<br />

own recipe ideas and use interfaces to<br />

social media networks like Facebook<br />

and Twitter.<br />

Coca-Cola has its sights on a different<br />

target group. Together with the can<br />

manufacturer Ball Packaging Europe,<br />

the beverage maker wants to use beverage<br />

cans as a link between music<br />

and refreshment. A consumer with a<br />

cell phone uses the QR code printed on<br />

the can to connect directly to the Coke<br />

Music Portal. „This way, the beverage<br />

can appeal to several of the customer's<br />

senses at once – taste, hearing, sight –<br />

and therefore turns into an interactive,<br />

multimedia amplifier of the customer's<br />

enjoyment of the product,” says Gerlof<br />

Toenhake, Director of Marketing at Ball<br />

Packaging Europe.<br />

Protection<br />

against product piracy<br />

QR codes are used for more than<br />

just brand communication, however.<br />

The printing press manufacturer Heidelberg<br />

has developed a technology<br />

that protects against product piracy.<br />

The products are equipped with security<br />

tags. These consist of a pattern<br />

randomly generated from copper<br />

threads and an associated, unique<br />

QR code. The combination of these<br />

two elements on the product itself or<br />

its packaging ensures a high degree<br />

of protection against counterfeits and<br />

generates a unique identity comparable<br />

to a human fingerprint for each individual<br />

product. With a special app<br />

that runs on mobile devices like smartphones,<br />

it is easy for the final customer<br />

to check the authenticity of the<br />

products labelled in this way.<br />

The QR code is used not only by<br />

manufacturers of branded products<br />

but also by merchants. For example,<br />

the discount supermarket chain Netto<br />

is currently expanding QR coding for<br />

its products. Now that all the packaged<br />

fruit and vegetable products have<br />

been labelled, fresh meat is being<br />

tagged with the QR code too. Via<br />

smartphone, the customer can obtain<br />

information about the origin, quality<br />

and nutritional value of the product, in

addition to recipes. The spread of QR codes has gained more<br />

momentum as a result of the recent E. coli scare and other<br />

food scandals. This shows how quickly a technology<br />

can become established if it is relatively simple and inexpensive<br />

to use.<br />

Because of their cost, RFID (radio frequency identification)<br />

tags are not yet suitable for the mass market. If prices<br />

fall, this could change quickly, however, because RFID<br />

technology has the potential to replace the bar code. Radio<br />

frequency technology enables non-contact identification,<br />

management and tracking of as many products as is desired,<br />

throughout the entire value chain and from production<br />

to the consumer. The packaging used for high-priced products<br />

is already being made with integrated RFID tags as<br />

protection against product piracy and theft.<br />

New development: RFID plus sensor<br />

The Fraunhofer Institute for Physical Measurement<br />

Techniques IPM, Freiburg, is going one step further: It has<br />

developed special RFID tags in which sensors are integrated<br />

into the label. This means temperature sensors can be<br />

used to check whether a cold chain has been maintained,<br />

for example. In a different variant, gas sensors measure the<br />

concentration of the gas ethylene, which allows inferences<br />

to be made about the degree of ripeness of many types of<br />

fruit.<br />

As the examples show, packaging is taking on a multimedia<br />

character and linking manufacturers, the trade and<br />

consumers. There is a downside, however: This brave new<br />

world of packaging doesn't yet seem to be fully mature and<br />

functionally stable. A study carried out by GS 1 (an international<br />

organization that formulates global standards to improve<br />

the value chain) and the consultancy GapGemini<br />

shows that the product information often is not valid. Over<br />

90 per cent of the information that British market researchers<br />

obtained via mobile bar code scanning was incorrect<br />

or incomplete. And how will customers react?<br />

Thirty-eight per cent of those surveyed said they wouldn't<br />

buy the product if they can't trust the data they get via their<br />

smartphones. So there is still some work to be done in this<br />

regard.<br />

Health consciousness<br />

provides impetus for developments<br />

Despite the fact that there are sometimes still problems<br />

with the technology and some ”teething troubles” that have<br />

to be cured, these difficulties won't impede the growth in intelligent<br />

packaging. Organic and printed electronics in particular<br />

have considerable potential to change the world of<br />

packaging. The U.S. market research firm MarketsandMarkets<br />

estimates that between 2010 and 2015, global sales of<br />

intelligent packaging will grow by 8.2 per cent per year to<br />

approximately US$24 billion. With a market share of 35 per<br />

cent, North America is set to become the largest buyer of<br />

active and intelligent packaging. The health-conscious consumer<br />

is applying ever higher standards to food safety. This<br />

is likely to add more impetus to the spread of intelligent packaging,<br />

particularly in the fields of dairy products, meat,<br />

poultry and ready-cooked meals.<br />

Impressive Variety for<br />

individual requirements<br />

Whatever you may need, ILLIG can<br />

offer it. We provide a full spectrum<br />

of future-oriented, high-quality<br />

thermoforming and packaging<br />

machines as well as suitable<br />

tools: Cost-effective, long-lasting,<br />

world-wide available and suitable<br />

for your requirements. In addition,<br />

we offer a comprehensive service<br />

kit to ensure utmost production<br />

reliability for decades. Buy now –<br />

and get lasting benefit.<br />

ILLIG Maschinenbau GmbH & Co. KG<br />

Robert-Bosch-Strasse 10<br />

74081 Heilbronn I Germany<br />

Tel. +49 7131 505-0<br />

Fax. +49 7131 505-303<br />

Tradition forms future<br />

Thermoforming<br />

Packing technology<br />

Tooling<br />

E-Mail: info@illig.de<br />

Internet: www.illig.de

<strong>Special</strong> <strong>Edition</strong><br />

Efficient and versatile model systems<br />

for innovations in cheese<br />

Dr. Wim Engels, Dr. Lucie Hazelwood, Dr. Eva-Maria Düsterhöft,<br />

Divisions of Flavour & Texture and Health, NIZO food<br />

research, Ede, The Netherlands<br />

The key to the acceptance of cheese by the consumer is the flavor and texture quality. The current<br />

trends towards low fat and low salt cheeses require time and cost effective screening models for<br />

maintaining optimal quality. Such cheese screening models are available at NIZO food research to<br />

better understand, improve and tailor many aspects of cheese making and ripening. This article<br />

exemplifies exciting possibilities that are offered by our efficient and versatile model systems.<br />

Figure1: Close-up of MicroCheeser apparatus. Inset: microcheese. Photos: NIZO<br />

In recent years the demand for improvement,<br />

diversification and tailoring<br />

of the quality of cheeses has increased.<br />

The consumer’s awareness<br />

on healthy diet choices has triggered<br />

a trend towards low fat and low salt<br />

cheeses. For producers, implementation<br />

of improved methods for producing<br />

high quality low fat and low salt<br />

products, but also for e.g. acceleration<br />

of ripening, are important aspects.<br />

These developments touch on a variety<br />

of aspects of cheese making,<br />

especially those focusing on the improvement<br />

of cheese flavour and texture,<br />

but also on ensuring optimal pre-<br />

16 |dmz 6/2012<br />

servation of the fermented product.<br />

The aspects include culture selection,<br />

optimization of processing and ripening<br />

and the use of novel ingredients.<br />

The key to the consumer acceptability<br />

and thus the success of e.g. lowsalt<br />

and low-fat varieties of cheese,<br />

though, is the flavour quality. For optimising<br />

cheese quality, (detailed)<br />

knowledge of flavour attributes is essential<br />

as well as understanding of the<br />

physiology of starter cultures and<br />

(bio)chemistry of flavour compound<br />

formation. Effective and targeted improvement<br />

of flavour (and texture) requires,<br />

in addition to basic research,<br />

extensive systematic screening of<br />

cultures and processing conditions<br />

during real cheese-making. This generally<br />

is a lengthy and costly process.To<br />

reduce screening costs and<br />

to enable production and testing of<br />

many variables in parallel, models<br />

were developed to down-size the<br />

cheese manufacturing process. Dedicated<br />

and effective, real cheese,<br />

screening systems were for a long time<br />

however not available for this purpose.<br />

NIZO food research developed<br />

the MicroCheese and ScreenCheese<br />

models available for tailoring flavour<br />

and texture formation. These models<br />

offer tremendous possibilities to study<br />

many aspects of cheese production<br />

e.g. the screening of microbial culture<br />

collections for desired fermentative<br />

capacities, screening of bacterial mutant<br />

libraries, variation of processing<br />

conditions and assessment of health<br />

or safety related aspects. Rapid enzymatic,<br />

microbial, compositional<br />

and, for ScreenCheese, sensory analysis<br />

methods can be applied on the<br />

model cheeses.<br />

The real cheese screening models<br />

offer new possibilities to study many<br />

aspects of cheese production and flavour<br />

formation by cultures and culture<br />

combinations under varying processing<br />

conditions. Such screening not<br />

only accelerates product development<br />

but also allows a more systematic<br />

approach to better understand the<br />

complex process of cheese making<br />

and ripening.

Figure 2: Key aroma compound formation in Gouda MicroCheese with (engineered) adjuncts<br />

and control strains.<br />

Cheese models<br />

at various scales<br />

The MicroCheese model<br />

NIZO has developed a protocol for<br />

the high-throughput manufacturing of<br />

cheese by employing a standard 96<br />

deep-well microplate as an array of<br />

cheese vats. In this system, up to 600<br />

individual cheeses can be manufactured<br />

per day. Each ”vat” can contain<br />

1.7 ml of milk and can be addressed<br />

separately with substrate, ingredients<br />

or cultures yielding cheeses of 170<br />

mg. Protocols for the production of miniaturized<br />

Gouda, Cheddar and<br />

Swiss-type cheeses have been developed<br />

and the resulting cheeses closely<br />

resemble conventionally produced<br />

cheese in terms of acidification profiles,<br />

moisture and salt contents, proteolysis,<br />

flavor profiles and micro structure.<br />

The MicroCheese platform can<br />

be used for the rapid screening of cultures,<br />

adjuncts or even enzymes in<br />

the cheese environment. All required<br />

analyses can be performed such as<br />

viable cell counts, flavour profiles, enzyme<br />

activities, microstructure and<br />

composition. The MicroCheese is also<br />

suitable for safety studies to monitor<br />

survival of pathogens or spoilage<br />

organisms in cheeses. For example,<br />

reduction of salt in cheese inevitably<br />

leads to safety issues where new strategies<br />

for cheese preservation must<br />

be considered. The MicroCheese is a<br />

well suited model to assess survival<br />

and possible outgrowth of spoilage<br />

and/or pathogenic microorganisms<br />

under various processing conditions<br />

or in the presence of preservatives.<br />

The manufacturing process<br />

A custom-made automated apparatus<br />

has been developed (see Figure<br />

1). Cutting of the curds is performed<br />

by computer-controlled movement of<br />

a stirring device through the curds.<br />

Centrifugation of the microplates is a<br />

<strong>Special</strong> <strong>Edition</strong><br />

key element for performing washing<br />

and pressing of the MicroCheeses. After<br />

completion of acidification, a brine<br />

solution is added to each well, which<br />

results in the desired salt percentage<br />

in the cheese. For ripening, the plates<br />

are sealed in an atmosphere of nitrogen<br />

and placed at the desired temperature<br />

for up to three months before<br />

further analysis.<br />

Testing of adjunct cultures for new<br />

flavor profiles<br />

To investigate the starter culture<br />

screening potential offered by the MicroCheese<br />

model, we have evaluated<br />

the impact of the addition of selected<br />

adjunct starter cultures in the Goudatype<br />

MicroCheese [1]. To this end,<br />

three strains were applied as adjunct<br />

cultures in Gouda-type Micro<br />

Cheeses. The strain B1157 is known<br />

to express high levels of the α-keto<br />

acid decarboxylase (BcKAD) enzyme,<br />

which is known to be involved in the<br />

formation of certain aldehydes impor-<br />

dmz 6/2012 | 17

<strong>Special</strong> <strong>Edition</strong><br />

Figure 3: Top panel: Outgrowth of C. tyrobutyricum in Gouda cheese as a function of salt<br />

content after 6 weeks ripening at 17 °C. Results are expressed as gene copy number/g cheese.<br />

Lower panel: Butyric acid production in Gouda cheese contaminated with 0, 5 or 25 spores/ml<br />

of C. tyrobutyricum as a function of salt content after 6 weeks ripening at 17 °C.<br />

Figure 4: Schematic representation of ScreenCheese production.<br />

tant for flavour in cheese, such as 3methyl-butanal<br />

[2]. In addition, Micro-<br />

Cheeses were manufactured containing<br />

adjunct culture B2083, a B1157<br />

derivative in which the gene for BKAD<br />

has been inactivated, and a strain<br />

NZ9000+ in which BcKAD is expressed<br />

at a high level. After 41 days of<br />

cheese ripening MicroCheeses produced<br />

with strains B1157 and<br />

NZ9000+ cultures respectively contained<br />

7.6- and 5.3-fold increased 3methylbutanal<br />

levels as compared to<br />

the control MicroCheeses (Figure 2),<br />

while the strain B2083 produced low<br />

levels. These findings demonstrate<br />

18 |dmz 6/2012<br />

that the MicroCheese model allows<br />

the accurate prediction of the flavorprofile<br />

impact of modulation of a single<br />

enzyme in the (adjunct) starter culture.The<br />

advantage of the Micro-<br />

Cheese model in comparison to liquid<br />

culture screening is the increased predictive<br />

value.<br />

Risk and safety assessment<br />

upon salt reduction<br />

In the context of an EU-funded project,<br />

entitled DREAM, the Micro<br />

Cheese model has been further developed<br />

to generate a representative<br />

model for monitoring growth of spoilage<br />

bacteria during cheese ripening. In<br />

the project, cheese milk was deliberately<br />

contaminated with Clostridium tyrobutyricum,<br />

a relevant spoilage bacterium<br />

for cheese, and a potential<br />

threat when e.g. salt in cheese is lowered<br />

[3, 4]. C. tyrobutyricum causes<br />

excessive gas formation (the late blowing<br />

effect) and flavour defects in<br />

cheese. The outgrowth of C. tyrobutyricum<br />

was monitored during cheese ripening<br />

in cheeses of different salt<br />

contents by quantitative PCR (qPCR)<br />

of a unique DNA sequence from the<br />

microorganism. The results obtained<br />

confirmed that salt reduction may result<br />

in higher outgrowth of C. tyrobutyricum.<br />

The increased levels of butyric<br />

acid in the various low salt Micro-<br />

Cheeses were in agreement with outgrowth<br />

of C. tyrobutyricum (Figure 3).<br />

The MicroCheese model is thus a suitable<br />

tool for risk assessment upon<br />

salt reduction.<br />

The ScreenCheese model<br />

A second versatile and cost-effective<br />

small scale cheese model system<br />

developed and successfully applied<br />

by NIZO food research is Screen-<br />

Cheese. ScreenCheese allows the<br />

testing of up to 30 variables per day<br />

where a normal cheese pilot plant can<br />

only handle 4 to 5 vats. The screening<br />

system is perfectly suited to evaluate<br />

the effect of different starters, adjunct<br />

cultures/microbial strains, enzymes,<br />

other ingredients and also the influence<br />

of compositional parameters,<br />

e.g. different salt or fat contents, on<br />

primarily cheese flavour and on texture.<br />

Per variant, several small cheeses<br />

of ca. 300 g to 1 kg are produced. This<br />

size allows assessment by sensory<br />

grading as well as instrumental analysis,<br />

such as the formation of flavour<br />

compounds and textural properties<br />

during the course of the ripening<br />

period.<br />

The production process<br />

Basically the ScreenCheese protocol<br />

consists of production of a large<br />

batch of curd (e.g. from 200L of cheese<br />

milk) and dividing this curd into portions<br />

of typically 2 to 3 kg. The ingredients<br />

and/or cultures that are to be<br />

tested are blended into the predrained<br />

curd and subsequently moulding,<br />

Continued on page 20

Company News<br />

The TIGER System from BARTEC BENKE<br />

World class in milk Measurement and sampling technology<br />

The customer performance requirements placed upon this<br />

BARTEC BENKE Milk-Tiger System were quickly and precisely<br />

formulated. Quick in the milk uptake, exact and light was the<br />

requirement consensus, with a stable milk density and volume<br />

measurement.<br />

Demanded by dairies, trucking companies and producers,<br />

the BARTEC BENKE Milk Tiger System represents the latest<br />

milk measurement technology on collection vehicles.<br />

The TIGER is unmatched in its stability of reproducing milk<br />

density, measurement precision, speed and light weight. Working<br />

without an air separator, the TIGER literally measures air via<br />

its patented bubble sensors and calculates the exact amount<br />

of milk drawn in from the produces. It does this across the entire<br />

spectrum up to 1.350 l/min. The reaction time of the bubble<br />

sensors is in the millisecond range.<br />

Due to the high resolution and the nature of the measurement<br />

principle, the sensor can be used directly to control the<br />

pump. With a weight of less than 200kg, it is currently the lightest<br />

system in the market.<br />

The system conforms to all regulatory guidelines of the food<br />

processing industry for the handling and measurement of milk.<br />

The system is MID-certified and available in 3” piping throughout.<br />

The advantages in short:<br />

n exact and consistent density and volume measurement<br />

for the robust daily environment<br />

n compact foot print weighing less than 200 kg,<br />

air-separator is not necessary<br />

n optimized milk uptake volume across the entire<br />

suction spectrum<br />

n simultaneous sampling<br />

n caring treatment of the milk retaining its quality<br />

n fully electronic<br />

n no constraints or constrictions on the suction side<br />

n remote update and off-site error diagnosis<br />

n simple operation coupled with high performance<br />

The high customer acceptance of the BARTEC BENKE Milk<br />

Tiger System is a confirmation for BARTEC BENKE that they have<br />

come full circle from a component supplier to a systems supplier.<br />

Lutz Reiprich, Manager of the BARTEC BENKE FOOD Division<br />

describes it the following way: ”It was a real pleasure to<br />

have seen the cooperation of our employees, working together<br />

with customers in an effort to bring this product to market. It was<br />

a very unique experience to develop a product under the watchful<br />

eyes of dairy personnel, truckers and milk producers. The<br />

”real-life“ proximity of these customers has helped us immensely<br />

to make the product robust for the day-to-day business of<br />

collecting milk. On top of the list of requirements: the consistent<br />

and constant delivery of exact density and volume data.“<br />

The exact determination of the milk volume drawn in at the<br />

producers is the economic common denominator in the milk<br />

procurement chain. Here, the BARTEC BENKE Milk Tiger System<br />

goes the extra mile. ”Throughout the development process,<br />

we were always conscious of the responsibility placed<br />

upon us to deliver the most exact measurement possible.“ Not<br />

needing an air separation system brings with itself considerable<br />

weight reductions, but also excellent measurement results<br />

due to the bubble-sensor based active volume measurement of<br />

the air-in-milk inclusion. The BARTEC BENKE Milk Tiger System<br />

calculates these values out of the equation. Thus measuring<br />

milk…not air, which is fair.<br />

BARTEC BENKE at the ANUGA FoodTec 2012: Hall 4.1, Booth A080<br />

dmz 6/2012 | 19

<strong>Special</strong> <strong>Edition</strong><br />

Table 1: Typical bacterial counts and compositional data of ScreenCheeses. Mesophilic<br />

starters (Mesoph.) and thermophilic adjunct cultures (Lb.) were counted (n.d. =not detected,<br />

i.d.m.=in dry matter).<br />

Figure 5: Sensory profile of ScreenCheeses produced with different starters (DL-, O-) and<br />

adjunct culture (LH-B01). Scale 0 (none) – 4 (very high).<br />

Figure 6: Efficient screening: the key to fast strain selection and product development.<br />

20 |dmz 6/2012<br />

pressing, brining (alternatively drysalting)<br />

and foil-ripening at appropriate<br />

conditions take place (Figure 4).<br />

Protocols for Gouda-type, Cheddartype<br />

and Swiss type cheeses are<br />

available. Fat and salt content can be<br />

adapted as desired.<br />

ScreenCheese performance<br />

The small cheeses produced resemble<br />

their large scale counterparts<br />

in every respect: starter cultures grow<br />

to typical numbers, composition, texture<br />

(Table 1) and characteristic flavour<br />

profiles develop in comparable<br />

ripening periods (up to 16 weeks). The<br />

differentiating power of this screening<br />

system is illustrated in Figure 5: A<br />

ScreenCheese produced with a thermophilic<br />

adjunct culture (LH-B01) was<br />

clearly distinguished from control<br />

ScreenCheeses by an in-house panel<br />

due to its flavor profile which was<br />

characterized by a higher flavour intensity,<br />

more sweetness and the absence<br />

of any bitterness. The wellstandardized<br />

and specifically adapted<br />

cheese-making protocols guarantee<br />

excellent reproducibility and low variations<br />

in moisture content (comparable<br />

to industrial cheese production).<br />

ScreenCheese’s superior translatability<br />

to large scale cheeses has been<br />

proven in many projects for cheese<br />

and ingredient manufacturers.<br />

New possibilities<br />

The processes involved in flavour<br />

and texture formation in cheese, during<br />

cheese ripening, are complex but<br />

essentially comprise of a series of<br />

(bio)chemical processes in which the<br />

starter cultures provide the enzymes.<br />

The natural biodiversity which exists<br />

in starter microorganisms, e.g. Lactococcus<br />

lactis, offers exciting possibilities<br />

when explored and applied in<br />

practice. Various real cheese model<br />

systems for directed screening for flavour<br />

producing (starter) organisms<br />

are now available enabling successful<br />

selection of strains. These tools will<br />

make the rational design of improved<br />

tailor-made industrial cultures for<br />

cheeses with attractive flavour and<br />

texture properties possible. Their sequential<br />

usage, ultimately combined<br />

with evaluation on pilot-scale, creates<br />

a unique methodology for selection of<br />

cultures (Figure 6). In addition, the

cheese models facilitate screening for<br />

processing conditions and/or ingredients,<br />

e.g. rennets or other enzymes,<br />

that improve and accelerate flavour or<br />

texture formation. Also, possibilities<br />

for preventing or controlling growth of<br />

undesired micro-organisms in cheese<br />

can be evaluated much more efficiently<br />

using cheese screening models.<br />

Ultimately, this means acceleration<br />

of product development and reduction<br />

of costs.<br />

DREAM (Design and development<br />

of realistic food models with well characterized<br />

micro- and macro-structure<br />

AAmpack<br />

mpack<br />

AAmmann<br />

mmann<br />

G<br />

GmbH mbH<br />

&<br />

CCo.<br />

o.<br />

KG G<br />

AAbfüll-<br />