Machinery World - October 2016

Machinery World was launched in 1982 to serve the machinery & production engineering market.

Editorially Machinery World is a news and information source that gives direct contact with the provider of innovative services and equipment. Editorial is available both online and in hard copy.

Machinery World carries news, views, projects, invites opinions and is a source of information readily available online and by smartphone.

Machinery World was launched in 1982 to serve the machinery & production engineering market.

Editorially Machinery World is a news and information source that gives direct contact with the provider of innovative services and equipment. Editorial is available both online and in hard copy.

Machinery World carries news, views, projects, invites opinions and is a source of information readily available online and by smartphone.

OCTOBER 2016 The No.1 International Machine Tool Journal Join us on @MachineryW www.machineryworld-online.com

- Page 2: Special Steels & Alloys

- Page 5 and 6: Laser metrology, machine tool, CMM

- Page 8 and 9: NEWS NEWS NEWS SUBCONTRACT MACHINE

- Page 10 and 11: NEWS NEWS NEWS TORNOS ANNOUNCE OPEN

- Page 12 and 13: EUROBLECH HANOVER 25-29TH OCTOBER M

- Page 14 and 15: NEWS NEWS NEWS TURNING TECHNOLOGY S

- Page 16 and 17: NEWS NEWS NEWS ETG CELEBRATES 20 YE

- Page 18: NEWS NEWS NEWS THE ORACLE TM HAS LA

- Page 21 and 22: MACHINE TOOL ACCESSORIES Fast and p

- Page 23 and 24: See the new Surtronic at GTMA Measu

- Page 25 and 26: IndySoft www.indysoft.co.uk Tel: +4

- Page 27 and 28: The UK’s largest meeting place fo

- Page 29 and 30: JOIN THE REVOLUTION EUROBLECH HALL

- Page 31 and 32: The Latest in Grinding Technology..

- Page 33 and 34: Still innovating! The HPSAW 310 ZER

- Page 35 and 36: PSupplying the World’s Finest Mac

- Page 37 and 38: Suppliers of Quality Used Machine T

- Page 39 and 40: Permat Machines Ltd. Station Road C

- Page 41 and 42: SubconDrillingLtd Gundrilling - Hon

- Page 44: THREE YEARS WARRANTY ON ALL NEW HYD

- Page 47 and 48: SERVICES DIRECTORY ASSOCIATIONS THE

- Page 49 and 50: SERVICES DIRECTORY HONING CONTINUED

- Page 51: DO YOU OFFER A SPECIALISED SERVICE?

OCTOBER <strong>2016</strong><br />

The No.1 International<br />

Machine Tool Journal<br />

Join us on @<strong>Machinery</strong>W www.machineryworld-online.com

Special Steels & Alloys

You make it,<br />

We simulate it<br />

CONTENTS<br />

OCTOBER ISSUE<br />

MANAGING DIRECTOR:<br />

Carole Titmuss<br />

NEWS EDITOR:<br />

Pat Fairfax<br />

FEATURES EDITOR:<br />

Danielle Titmuss MSc<br />

SALES:<br />

Tracy Chamberlain<br />

PRODUCTION:<br />

William Brunt Ian Purves<br />

SUBSCRIPTIONS:<br />

Wendy Burnett<br />

PUBLISHERS:<br />

Carole Titmuss Tony Prior<br />

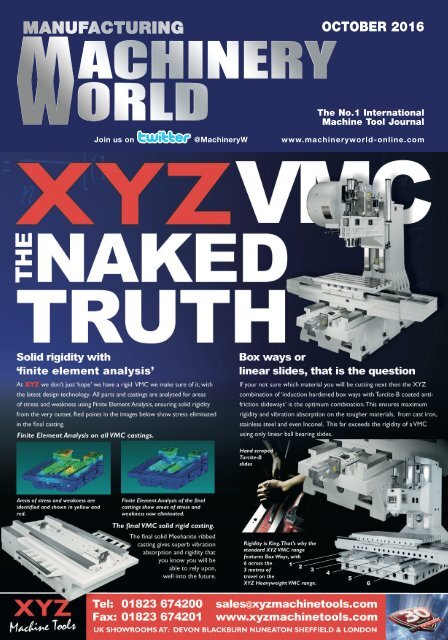

Front Cover:<br />

XYZ Machine Tools<br />

AUCTIONS 55-57<br />

FEATURES 22-27<br />

Measurement, Inspection & Quality Control<br />

NEW PRODUCTS 46<br />

Multi-Axis Milling<br />

Machining Centres<br />

Machine Simulation for:<br />

Mill/Turn Centres<br />

WaterJet Cutting<br />

SERVICES DIRECTORY 47-50<br />

Our comprehensive quide to Products & Service Providers to the<br />

manufacturing industry.<br />

THIS MONTH’S EXHIBITIONS<br />

Make Measurement Matter, 13 <strong>October</strong> <strong>2016</strong>.<br />

Euroblech, Hanover, 25th-29th <strong>October</strong> <strong>2016</strong>.<br />

Advanced Engineering Show, 2nd-3rd November <strong>2016</strong>.<br />

NEXT MONTH’S FEATURES<br />

Grinding & Abrasives.<br />

Medical Report.<br />

VERICUT is the world’s leading CNC simulation,<br />

verification and optimisation software. Used in all<br />

industry sectors, it can be integrated with all<br />

manufacturing software systems and machine tools.<br />

Right First Time with VERICUT.<br />

Visit cgtech.co.uk to learn more.<br />

Curtis House, 34 Third Avenue, Hove, East Sussex, BN3 2PD, England<br />

Phone: +44 (0) 1273-773538 info.uk@cgtech.co.uk<br />

.co.uk<br />

This journal includes editorial photographs provided and paid for by suppliers.<br />

<strong>Machinery</strong> <strong>World</strong> is available on subscription annual rate:<br />

UK £40, Europe £64, Overseas £88<br />

Single Copies £3.50 UK £6 Overseas<br />

Published by: SHEEN PUBLISHING LTD,<br />

50 QUEENS ROAD, BUCKHURST HILL, ESSEX IG9 5DD<br />

Telephone: 020 8504 5912 / 020 8504 1661<br />

International: +44 20 8504 1661<br />

Facsimile: 020 8505 4336<br />

International: +44 20 8505 4336<br />

Web: www.machineryworld-online.com<br />

Email: machinery@sheenpublishing.co.uk<br />

ISSN 1745-5898<br />

MACHINERY WORLD is published monthly and is circulated to senior personnel who<br />

influence the buying and selling of new and used metal working machinery worldwide.<br />

©Sheen Publishing Ltd. All rights reserved. No part of this<br />

publication may be reproduced or transmitted in any form or<br />

by any means, including photocopying and recording,<br />

without the written permission of the publishers. Such<br />

written permission must also be obtained before any part of<br />

this publication is stored in a retrieval system of any nature.<br />

www.machineryworld-online.com<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

Laser metrology, machine tool, CMM and robotic performance<br />

Themes<br />

Novel Manufacturing Technologies<br />

& Machine Tools<br />

New Developments in Measurement<br />

Techniques<br />

Performance Evaluation for Machine<br />

Tools and CMMs<br />

Roughness and Machine Tool<br />

Standards<br />

Lamdamap<br />

12th International Conference & Exhibition<br />

15 th - 16 th March 2017<br />

Renishaw Innovation Centre,<br />

Wotton-under-Edge, UK<br />

Key dates<br />

Metrology in New Fabrication<br />

Techniques<br />

22nd Aug <strong>2016</strong> Call for abstracts<br />

14th Oct <strong>2016</strong><br />

Online abstract submission deadline<br />

Please visit our website for further information<br />

info@euspen.eu<br />

www.euspen.eu

‘Always Excel’<br />

Working in Partnership with<br />

The OPTIMUM in quality, price-performance and service<br />

Working in Partnership with<br />

The OPTIMUM in quality, price-performance and service<br />

CNC<br />

‘Always Excel’<br />

Working in<br />

partnership with<br />

‘Always Excel’<br />

Working in partnership with<br />

Working in partnership with<br />

MAIN CATALOGUE 2015 / <strong>2016</strong><br />

Superior Quality Professional Machine Tools<br />

Magnetic drilling machines<br />

Belt grinding machines<br />

Surface grinding machines<br />

Sheet metal shears<br />

Notching machines<br />

Hole punchers<br />

Ring bending machines<br />

Round bending machines<br />

Swivel bending machines<br />

Folding presses<br />

Shop presses<br />

Circular metal saws<br />

Roller conveyors<br />

Metal band saws<br />

Accessories<br />

Metal working machines<br />

CNC milling machines<br />

CNC lathes<br />

Automation<br />

CNC software<br />

Accessories<br />

mill ®<br />

turn ®<br />

CNC metal working machines<br />

Bench drilling machines<br />

Upright drilling machines<br />

Gear drilling machines<br />

Lathes<br />

Milling machines<br />

Metal band saws<br />

Metal circular saws<br />

Grinding machines<br />

Polishing machines<br />

Drill bit grinder<br />

Sheet metal processing<br />

Arbor presses<br />

Measuring tools<br />

CNC add-on kit´s<br />

Metal working machines<br />

‘Always Excel’<br />

Scissor-type lifting tables<br />

Pallet trucks<br />

Pallet stackers<br />

Handcarts<br />

Transport rollers and chassis<br />

Trolley jacks<br />

Body straightening kits<br />

Lifting gear<br />

Load handling equipment<br />

Chain hoists<br />

Rope winches<br />

Machine jacks<br />

Workshop presses<br />

Lifting and workshop technology<br />

‘Always Excel’<br />

Belt saws<br />

Wood working machines<br />

Wet-dry grinder<br />

for do-it-yourselfers and craftsmen<br />

Belt and disk sander<br />

Edge sanding machines<br />

Cylinder sanding machines<br />

Circular table & Scroll saws<br />

Surface planing machines<br />

Wood turning lathes<br />

Suction plants<br />

Material stand<br />

Joiner’s benches<br />

Long hole drills<br />

Edge banders<br />

Power grinders<br />

Workshop equipment<br />

Accessories<br />

CNC MACHINES | GRINDERS | LATHES | SHEARS<br />

DRILLS | MILLS | GUILLOTINES | SAWS | SHAPERS<br />

PLATE BENDING ROLLS | PRESS BRAKES | LOTS MORE!<br />

WWW.EXCELMACHINETOOLS.CO.UK<br />

CNC main catalogue 2015/16<br />

Main catalogue 2015/16<br />

Your search for the right machine is top of our priority at Excel<br />

machine tools we guarantee to provide a personal service with<br />

continuous support and assistance.<br />

WHAT IS NEW AT EXCEL MACHINE TOOLS<br />

NEW RANGE OF PRODUCTS<br />

Due to working in partnership with a number of companies, In<br />

May <strong>2016</strong> we extended our range of high quality machines,<br />

which now comprise of additional Metalworking/CNC machines,<br />

a new range of Woodworking products, Lifting/Workshop<br />

Technology and Welding Equipment. All the new range of<br />

products feature in our digital catalogues online our website<br />

NEW WEBSITE LAUNCH<br />

In April <strong>2016</strong> we launched a new website with a fresh new<br />

design and easy navigation setup. This features our extensive<br />

range of stock. Find what machine you are looking for by clicking<br />

on our quick links which is divided in the following categories<br />

CNC, Metalworking, Fabrication, Accessories<br />

and Woodworking. Alternatively all our catalogues can be<br />

viewed/downloaded on the products page . You can order<br />

a printed version of our main catalogue call us on<br />

024 7636 5255 or email sales@excelmachinetools.co.uk<br />

Our new website is kept up to date regularly look out for new<br />

features on the homepage which will include special<br />

<br />

giveaway competitions and customer reviews. Keep up to date<br />

by joining Excel’s social networks online our website. Twitter,<br />

Instagram, Facebook, YouTube, LinkedIn & Google Plus<br />

WHAT OUR CUSTOMERS SAY<br />

Excels products are reviewed and are scored out of ten - on the<br />

quality of the machine, quality of the work produced, safety<br />

features, the operational manual and also the customer com-<br />

<br />

these product reviews below please visit our website.<br />

CURRENT REVIEWS ONLINE:<br />

D420x1000 Manual Lathe PRODUCT REVIEW<br />

B26PRO DRILL 3PH PRODUCT REVIEW<br />

CALL EXCEL ON: 024 7636 5255<br />

website www.excelmachinetools.co.uk<br />

EMAIL: sales@excelmachinetools.co.uk

NEWS NEWS NEWS<br />

SUBCONTRACT MACHINE SHOP BUYS FIRST CNC VMC…<br />

FROM FANUC<br />

When James Camden Engineering Ltd had<br />

an issue machining some complicated<br />

aerospace parts, it turned to FANUC and its<br />

renowned ROBODRILL vertical machining<br />

centre for a solution. The Warwick based<br />

subcontractor conducted a comprehensive<br />

review of the CNC machine tool market and<br />

concluded that FANUC offered the best<br />

combination of cost, performance, precision,<br />

technology and service.<br />

With a plant list that includes EDM,<br />

manual milling and lathes, the company was<br />

having difficulty completing certain parts<br />

and it was the expertise of the FANUC team<br />

that swung the purchasing decision. As<br />

Jordan Coles, a Tool Room Machinist at<br />

James Camden Engineering says: "We looked<br />

at lots of suppliers and their respective<br />

machines, but it was the FANUC sales<br />

engineer that was more focused upon our<br />

needs. To this end, FANUC looked at our<br />

components, the type of regular work and<br />

the quantities we produce and accordingly<br />

recommended the FANUC ROBODRILL<br />

D21MiA5 High Power Version machining<br />

centre."<br />

For the small subcontractor it was a<br />

paradigm shift in moving to its first CNC<br />

VMC and FANUC were only too aware of<br />

this. As Mr Coles continues: "There is often a<br />

perception, like the one we had, that VMC's<br />

and FANUC machines in particular, are<br />

aimed at higher volume production and that<br />

FANUC is a premium brand with a higher<br />

price tag. However, FANUC blew such<br />

perceptions away and delivered a solution to<br />

our problems."<br />

As the first CNC machining centre for the<br />

company, the 3-axis ROBODRILL was sold<br />

as an application solution to the prototype<br />

and small batch manufacturer. "We haven't<br />

just bought this machine for production<br />

machining; it's been brought in for<br />

machining extremely accurate small batch<br />

parts. When we looked at the market, we<br />

wanted a super accurate machine that could<br />

work to high tolerances and would be very<br />

precise and very consistent in its<br />

performance," continues Mr Coles.<br />

For giving James Camden Engineering<br />

the edge from a productivity perspective, the<br />

FANUC ROBODRILL has a 30m/min feed<br />

rate and a maximum spindle speed of<br />

10,000rpm that is derived from a 11kW<br />

spindle motor. This combination of speed<br />

and power is ideally suited to the demands of<br />

the Warwick Company. Concluding on this,<br />

Mr Coles says: "From a service perspective,<br />

we couldn't ask for more. The sales team<br />

were attentive to our needs and understood<br />

our business and our goals. After the<br />

purchase, the application engineers have<br />

proven to be great guys that frequently pop-<br />

OPEN MIND ANNOUNCE 5-AXIS EVENT<br />

AT HURCO<br />

Processing speed on the shop floor is more<br />

crucial than ever these days. This is why<br />

OPEN MIND Technologies has developed<br />

hyperMILL MAXX Machining, the<br />

comprehensive high-performance CAM<br />

solution for roughing, finishing and drilling<br />

that generates machining time savings of up<br />

to 90%. The latest version of this ground<br />

breaking CAM software will be on show at<br />

the Hurco UK headquarters in High<br />

Wycombe on the 4th of <strong>October</strong>. At the event,<br />

manufacturers will have an opportunity to<br />

witness all the latest 5-axis machine tool<br />

technology from Hurco with live<br />

demonstrations on a VMX42 SRTI machining<br />

centre.<br />

The demo day will highlight the synergy<br />

and the remarkable potential of combining 5-<br />

axis machine tools with new tooling concepts<br />

such as circle segment end-mills from<br />

Quickgrind; and of course the latest<br />

hyperMILL® MAXX Machining module.<br />

This performance package offers end users<br />

three powerful modules for roughing,<br />

finishing and drilling.<br />

The event will start at 9am on the 4th<br />

<strong>October</strong> and will run through to 2pm with<br />

comprehensive 'live' demos, a Q&A session<br />

and also the opportunity to talk to engineers<br />

from Hurco, OPEN MIND and Quickgrind<br />

on how the synergy between machine tool,<br />

CAM and tooling can really open up new<br />

avenues for your business.<br />

For further details or to register for the<br />

event, please visit http:/ / www.openmindtech.com/<br />

news/ upcoming-events.html<br />

in to check on us and our machine; they give<br />

us regular advice and see how we are getting<br />

on. In comparison, we've had other machine<br />

tool vendors that sell us a machine, drop it<br />

off, do the training and we don't hear from<br />

them again. So, the service from FANUC has<br />

genuinely been beyond all expectations."<br />

Tel: 02476639669<br />

Email: info@fanuc.co.uk<br />

A 50%–60%<br />

INCREASE IN<br />

PRODUCTIVITY AT<br />

GR CONTRACTS<br />

When G R Contracts, a leading supplier of<br />

structural steelwork for the construction<br />

industry, were looking to invest in new steel<br />

processing machinery to increase<br />

productivity and reduce production costs,<br />

they never envisaged that it would have such<br />

a radical impact on their business.<br />

After investing time and effort into<br />

evaluating machines from several<br />

manufacturers they choose the Endeavour -<br />

FICEP’s fastest ever automatic CNC line for<br />

drilling, milling and marking for beams<br />

channels and flats.<br />

Not only have G R Contracts seen<br />

substantial increases productivity, the<br />

scribing facility on the machine has<br />

substantially reduced the the fit up time for<br />

the fabricators. This has resulted in the<br />

fabricators finding that time has reduced<br />

significantly with the new Endeavour<br />

because they usually had to mark out and<br />

mag drill then fabricate the steel. As now<br />

they just have to fabricate the steel, the<br />

company decided to run the machine on 2<br />

shifts which meant they doubled output with<br />

the same number of fabricators.<br />

Robert Savage, Director of G R Contracts,<br />

said: “We have now seen benefits of between<br />

20-30% more pieces produced on one shift<br />

compared to the previous methods which<br />

using a saw on two shifts. When we have<br />

moved to 2 shifts on the Endeavour we are<br />

seeing a further 20-30% increase which<br />

equates to an overall 50-60% increase in<br />

pieces / productivity from the new machine.<br />

This is a result that has far out exceeded our<br />

expectations.<br />

Tel: 01924 223530<br />

Email: info@ficep.co.uk<br />

Web: www.ficep.co.uk<br />

8 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

FANUC Fiber Laser<br />

Fast, reliable and efficient<br />

industrial sheet separation<br />

Sample of thin material cut using FANUC Fiber Laser<br />

Your advantages:<br />

Micro<br />

Joints<br />

Minute<br />

Control<br />

• 1 to 6 kW<br />

• compatible operation with CO 2 Laser<br />

• efficient machine development thanks to a flexible,<br />

encapsulated fiber optic cable<br />

• very high-speed cutting up to 6 mm<br />

• cuts extremely fine contours<br />

• cuts non-ferrous metals<br />

• easy 3D thin metal cutting<br />

• replacing the process fiber is easy<br />

Power<br />

Control<br />

WWW.FANUC.EU<br />

marketing@fanuc.co.uk<br />

MW1016<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong> 9

NEWS NEWS NEWS<br />

TORNOS<br />

ANNOUNCE OPEN<br />

HOUSE DATES<br />

For manufacturers looking for the latest<br />

turning innovations, Tornos UK has now<br />

announced that it will be hosting its <strong>2016</strong><br />

Open House event from the 11th to 13th<br />

<strong>October</strong> at its Coalville headquarters. The<br />

event will see the established SwissNano,<br />

GT26 and ST26 turning centres appearing<br />

alongside the new DT26, which will be<br />

making its UK debut at the event.<br />

As well as cutting edge machine tool<br />

innovations, manufacturers of small turned<br />

parts will have the opportunity to investigate<br />

the latest cutting tool innovations from Floyd<br />

Automatic Tooling, Rainford Precision, Arno<br />

Werzeuge and Iscar. Complimentary<br />

technology will also be demonstrated by PSL<br />

Datatrack, Wogaard and many more.<br />

From a machine tool perspective, visitors<br />

will get an opportunity to see the brand new<br />

Swiss DT26, which will be shown in the UK<br />

for the first time. The extremely sturdy and<br />

powerful Swiss DT26 machine has a<br />

kinematic design that promotes swarf<br />

evacuation and rigidity whilst being an<br />

extraordinarily flexible machine.<br />

Alongside the DT26 will be the<br />

established and extremely popular Swiss<br />

ST26.<br />

Both machines will be accompanied by<br />

the new Swiss GT26 that was launched at<br />

EMO last autumn. The new version of the<br />

market leading Swiss GT26 turning centre<br />

now includes a B-axis to increase the already<br />

impressive flexibility credentials of this<br />

machine.<br />

Finishing the complement of machine<br />

tools is the unique SwissNano.<br />

Working in synergy with its machine tool<br />

range is the Tornos TISIS 2.0 programming<br />

and machine management software that will<br />

comprehensively be demonstrated at the<br />

Open House Event. Designed for all Tornos<br />

products working in ISO mode, TISIS has<br />

been continuously expanded to provide the<br />

users with a steadily increasing number of<br />

features such as Industry 4.0 and parametric<br />

programming that will simplify<br />

programming and prevent errors.<br />

Tel: 01530 513100<br />

Email: sales@tornos.co.uk<br />

Web: www.tornos.com<br />

When Sheffield based Special Quality Alloys<br />

chose to bring the sawing of large diameter<br />

nickel-based superalloys in-house, they<br />

naturally turned to Prosaw for advice on<br />

processing these extremely tough materials.<br />

The decision to discontinue the use of<br />

sub-contractors for this purpose was made<br />

all the easier since Prosaw had already<br />

provided three Danobat bandsaws to Special<br />

Quality Alloys. The first of these machines<br />

was installed twelve years ago and although<br />

all three have been used for sawing slightly<br />

smaller diameter billets they have performed<br />

remarkably reliably.<br />

The fact that these machines have<br />

functioned so consistently over such a long<br />

period of time has inevitably resulted in the<br />

operators becoming comfortable with the<br />

Danobat saws. In addition, the operators did<br />

not require any further training as they were<br />

of course familiar with the Danobat control<br />

systems.<br />

This time however, billets of up to 800mm<br />

diameter were required to be cut in an<br />

automated continuous process, so a Danobat<br />

CP800A Auto-bandsaw was specified and<br />

duly purchased by the company.<br />

Jonathan Gillet, Works Manager of<br />

Special Quality Alloys explained the thinking<br />

behind the decision: “Bringing the<br />

processing of the larger diameter billets inhouse<br />

has meant a good deal less handling<br />

for us, resulting in faster turnaround times,<br />

since we are no longer reliant on transport<br />

contractors.”<br />

VALUE FOR MONEY<br />

“This has benefited the company in the<br />

form of lower costs and has brought the<br />

whole process entirely under our own<br />

control. Even though these products are<br />

notoriously difficult to cut, we have complete<br />

confidence that when we put a large<br />

diameter billet onto the Danobat machine it’s<br />

going to be cut.”<br />

“From our recent experiences we believe<br />

that Danobat machines represent real value<br />

for money.”<br />

Tel: 01536 410999<br />

Email: sales@prosaw.co.uk<br />

Web: www.prosaw.co.uk<br />

GUHRING DRILL IS THE TOP PRIZE FOR<br />

ROBOT WAR WARRIORS<br />

Over the summer months Robot Wars has been back on our TV screens with 40 distinct<br />

combat robots battling it out for the prestigious accolade of being crowned the <strong>2016</strong> champion.<br />

Self-built by the competitors and fighting in a purpose-built arena, the six-episode series has<br />

been watched by over 2 million people each week.<br />

The Grand Final was won by Apollo, a robot captained and driven by Dave Young. As one<br />

of the House Robots that featured in the Series, Sir Killalot is a 740kg robot with a 2.5tonne<br />

pincer grip and a top speed of 10mph. On one arm is a 300kg arm lift that outweighs all<br />

competitors and on the other arm is a 2inch taper shank drill from Guhring.<br />

The Guhring 245 Series Taper Shank Drill has been used throughout the series as a tactical<br />

feature in battles with contestants. Manufactured by Robo Challenge, a Birmingham based<br />

company of enthusiastic, creative and downright whacky engineers, Sir Killalot is just one of<br />

many prestigious projects that Robo Challenge has delivered.<br />

As well as featuring<br />

heavily in the hit TV<br />

show with Sir Killalot,<br />

Robo Challenge was also<br />

tasked with designing<br />

and manufacturing the<br />

coveted trophy. A<br />

trophy that has another<br />

iconic masterpiece at its<br />

centre, the Guhring 245<br />

Series Drill.<br />

Tel: 0121 7495544<br />

Email:<br />

info@guhring.co.uk<br />

Web:<br />

www.guhring.co.uk<br />

10 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

METROL<br />

High accuracy sensors.<br />

Used on CNC lathes,<br />

Machining centres and<br />

Grinders.<br />

Supplied by<br />

CNC Systems Ltd UK<br />

and European distributer.<br />

EuroBLECH <strong>2016</strong><br />

<br />

<br />

<br />

Tel No: 01932 830492<br />

Email: offices@cncsystemsltd.co.uk<br />

Web: www.cncsystemsltd.co.uk<br />

THE TOOLING SPECIALISTS FOR PRECISION COMPONENT MACHINING<br />

24 <br />

<br />

Coolant pressure in excess of 50 bar, for all types of machines!<br />

SWISS MADE ADJUSTABLE LOCKABLE<br />

STAINLESS STEEL COOLANT NOZZLES<br />

Wide choice of nozzle types to achieve correct flow pattern.<br />

Visit our website to get more details or Youtube channel to<br />

see nozzle flow demonstrations.<br />

Contact our specialist team for help and advice or to request a<br />

catalogue Alternatively scan QR code to download direct from<br />

our website.<br />

Sheet metal, Tube, Sections Handling Forming<br />

Separation, Cutting Joining, Welding R&D<br />

Finished products, Parts, Assemblies Tools, Dies<br />

Flexible sheet metal working Machine elements<br />

Tube/Section working Additive Manufacturing<br />

Surface treatment Composites Safety at work<br />

Data capture/processing CAD/CAM/CIM systems<br />

Controlling, Regulating, Measuring, Inspection<br />

Factory and warehouse equipment<br />

<br />

HANOVER, GERMANY<br />

www.euroblech.com<br />

Organisers: Mack Brooks Exhibitions Ltd<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong> 11

EUROBLECH HANOVER 25-29TH OCTOBER<br />

MAZAK PLANS LASER REVOLUTION<br />

Hall 11, Stand D26<br />

Yamazaki Mazak is planning a revolution at<br />

EuroBLECH <strong>2016</strong> with new laser machines<br />

and automation systems making their world<br />

debuts.<br />

Taking pride of place is the new SUPER<br />

TURBO-X 3015 Fiber series, the latest<br />

generation of the highly popular SUPER<br />

TURBO-X series of CO2 laser machines, that<br />

have sold more than 4,000 units across<br />

Europe since 1990.<br />

The new fibre machine, which is available<br />

in both 2kW and 3kW versions, has been<br />

specifically developed for laser users who<br />

require optimum productivity allied to<br />

reduced running costs, lower maintenance<br />

costs and the ability to cut highly reflective<br />

materials, such as copper, brass and<br />

galvanised sheet.<br />

The SUPER TURBO-X 3015 Fiber series<br />

also boasts a best-in-class reduced floorspace<br />

of 2,900mm x 7,400mm, which is unmatched<br />

by competitor fibre machines, and crucially<br />

can be fitted with Mazak’s existing FMS laser<br />

VERNET BEHRINGER will exhibit for the<br />

first time in Hanover the HD-S 412 compact<br />

drilling-milling machine for profiles and the<br />

FGEVO 1000, latest development in plate<br />

processing.<br />

The HD-S model has been inspired by the<br />

HD-XEVO drilling-milling machine<br />

launched during Euroblech in 2014. It<br />

became immediately THE reference in this<br />

category and will be positioned as an entry<br />

level, particularly dedicated to<br />

small/medium-sized steel fabricators<br />

looking for a versatile machine with compact<br />

footprint or bigger companies requiring an<br />

additional line for lighter profiles, with 400 x<br />

300 mm capacity.<br />

The HD-S is a 3-spindle machine that can<br />

drill simultaneously the web and both<br />

flanges of H-beams, but also process<br />

channels, angles, flats as well as right hollow<br />

sections. Jansen steel profiles for windows<br />

and doors can also be machined thanks to an<br />

optional adaptation kit.<br />

The machine offers a unique clamping<br />

system with CNC controlled x-axis with 150<br />

automation systems, which enables an easy<br />

upgrade to fibre cutting for existing ST-X<br />

CO2 laser machine users.<br />

Mazak is also introducing two new<br />

automation systems at EuroBLECH <strong>2016</strong>. An<br />

OPTIPLEX NEXUS 3015 4kW laser machine<br />

will be equipped with the latest version of<br />

Mazak’s flexible automation technology.<br />

QUICK CELL, which has been designed by<br />

famed Japanese industrial designer Ken<br />

Okuyama, is available in three different<br />

specifications, 6-stocker, 10-stocker and 14-<br />

stocker versions.<br />

Mazak will also be exhibiting the new<br />

LaserFlex 2.0 materials handling solution<br />

which is fitted to an OPTIPLEX 3015 Fiber<br />

6kW laser cutting machine. LaserFlex is a<br />

compact, easy-to-use laser automation<br />

solution that enables the fast handling of raw<br />

plates, with a process time for the exchange<br />

of raw and cut plates of less than 75 seconds<br />

when teamed with the OPTIPLEX machine.<br />

Mazak will also introduce its new laser<br />

CNC, MAZATROL PreviewG, the world’s<br />

fastest CNC. PreviewG combines intuitive<br />

touchscreen operations, similar to<br />

smartphones and tablets, with new machine<br />

hardware and servo systems, which together<br />

can dramatically reduce programming and<br />

processing time.<br />

Alongside, Mazak will also exhibit an<br />

innovative laser technology, which will be<br />

making its world debut at EuroBLECH <strong>2016</strong>.<br />

Tel: 01905 755755<br />

Email: sales@mazak.co.uk<br />

Web: www.mazakeu.co.uk<br />

LATEST DEVELOPMENT IN PLATE<br />

PROCESSING<br />

Hall 12, Stand F85<br />

mm stroke which ensures:<br />

• High productivity when carbide drilling,<br />

as there is no time lost for<br />

clamping/unclamping operation between<br />

holes (within 150 mm window), in<br />

combination with high-end energy<br />

efficient Siemens spindle motors.<br />

• Vibration-free milling operations on<br />

profiles (long holes, openings etc.)<br />

• Fast and precise part identification and<br />

layout marking with Vernet Behringer’s<br />

exclusive V-scoring system<br />

• Low running costs thanks to extended<br />

tool life and easy maintenance<br />

The range comprises the HD-S 612, 912<br />

and 1012 with respectively 600, 900 and 1000<br />

x 300 mm capacity.<br />

It is available with a wide range of<br />

infeed/outfeed loading and transport<br />

systems and can be installed in line with a<br />

high performances BEHRINGER band<br />

sawing machine for straight and mitre cuts.<br />

Tel: 0129 666 8259<br />

Email:<br />

simon.smith@behringerltd.co.uk<br />

THE ENTIRE<br />

PRODUCTION<br />

PROCESS WITH<br />

AMADA<br />

Hall 12, Stands D06 and F06<br />

Productivity is the key to the competitiveness<br />

for every company. Production technologies<br />

are the source for innovation, differentiation,<br />

ensuring the final clients’ loyalty and<br />

facilitating the capacity to acquire new clients<br />

for our customers. AMADA not only creates<br />

machines but also answers specific needs by<br />

delivering “tailor-made” solutions. We’re<br />

proud to say that, at EuroBLECH <strong>2016</strong> and<br />

worldwide, we strive to help our customers<br />

face their economic challenges.<br />

Our main concept at EuroBLECH <strong>2016</strong><br />

will be “Creating the customers value using<br />

AMADA’s latest machines and processing<br />

technologies.” We will introduce fiber lasercutting<br />

and -welding machines, a<br />

combination machine, press brakes, and the<br />

new VPSS 3i software, the sheet-metal<br />

engineering system, which can simulate all<br />

the processing operations at once. In addition,<br />

we will show some sample workpieces with<br />

accumulated know-how of processing<br />

technology.<br />

AMADA will be showcasing more<br />

innovations than ever before at the industry’s<br />

flagship trade fair EuroBLECH. Also on<br />

display will be an overview of AMADA’s IoT,<br />

“V-factory” which is being shown as a ‘Smart<br />

Factory’ concept. 8 latest technology AMADA<br />

machines and AMADA MIYACHI products<br />

will be on show in live operation over an area<br />

of some 2,000 square meters. All the machines<br />

on view will, of course, be production-ready.<br />

And every one of them represents a further<br />

development to an existing solution or a<br />

completely new innovation.<br />

During EuroBLECH <strong>2016</strong>, experts will be<br />

present on the stand to discuss the benefits of<br />

fibre laser welding, laser ablation and<br />

resistance welding for applications in the<br />

Automotive, Electronics & Solar cells, IT &<br />

Multimedia, Medical, Aerospace and Defense<br />

industries.<br />

In addition, the MIYACHI EAPRO Jupiter<br />

fibre laser welding system, the MIYACHI<br />

EAPRO Laser Ablation System and the<br />

MIYACHI PECO AWS3 Active welding<br />

system 3, an integrated resistance welding<br />

solution, will be on display on the stand.<br />

Tel: 01562749500<br />

Email: cathryn.morris@amada.co.uk<br />

Web: www.amada.co.uk<br />

12 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

<strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong> 13

NEWS NEWS NEWS<br />

TURNING<br />

TECHNOLOGY<br />

SHOWCASE AT<br />

CITIZEN’S ANNUAL<br />

OPEN HOUSE<br />

Central to Citizen’s <strong>2016</strong> Open House<br />

between 11 and 13 <strong>October</strong> will be the first<br />

UK demonstration of a key breakthrough in<br />

machining technology that is not only able to<br />

increase cutting performance, but also create<br />

gains through improved and controlled chip<br />

flow, extended tool life and help maintain<br />

better levels of surface finish.<br />

The demonstration of Low Frequency<br />

Vibration (LFV) cutting on Citizen’s latest<br />

L20-VIII CNC sliding head turn-mill centre<br />

will be amongst a host of high performance<br />

cutting demonstrations. A Citizen L12 will<br />

be featured with automatic loading of precut<br />

bar lengths to aid increased productivity<br />

when shorter lengths of bar are supplied and<br />

further applications will include hard<br />

turning and camshaft machining carried out<br />

on the12 turn-mill centres that will be under<br />

power at the Bushey, Watford, headquarters.<br />

Representing the wide spectrum of<br />

Citizen Cincom sliding head machines and<br />

Miyano fixed head, turn mill-centres will be<br />

the latest generation of the international top<br />

selling, modular build, L-Series which now<br />

has a 25 mm bar size option for the 20 mm<br />

capacity machine. While the 5-axis L20-VIII<br />

version is to demonstrate LFV, a L20-XII will<br />

show the advantages of a B- and Y- axis,<br />

alongside the larger capacity L32-XII and<br />

L32-VIII variants. There will also be under<br />

power the top-of-the-range M32-VIII<br />

demonstrating B-axis contouring and 4-axis<br />

simultaneous control.<br />

Visitors that attended the MACH <strong>2016</strong><br />

exhibition Citizen stand at the NEC in<br />

Birmingham and who bring along their token<br />

given on the stand will be able to take part in<br />

a competition to win an Orange mountain<br />

bike worth some £6,000. Lunch will be<br />

provided each day and, of course on<br />

Wednesday 13 <strong>October</strong> the Open House will<br />

be extending its visitor hours of 09.00 to 17.00<br />

until 21.30 when all are welcome to the<br />

traditional highly sociable, Citizen Curry<br />

Evening.<br />

While Citizen has an open invitation to all,<br />

in order to help with catering, those wishing<br />

to attend are able to register online at<br />

www.citizenmachinery.co.uk or call 01923<br />

691 500.<br />

STARRAG DEVELOPMENTS OPEN UP<br />

HIGH-SPEED ALUMINIUM CUTTING<br />

Starrag has expanded its range of five-axis<br />

horizontal machining centres targeted at<br />

aluminium cutting with a host of<br />

developments to satisfy all machining needs<br />

in companies of every size. Starrag has<br />

announced an uprated 83 kW range, added a<br />

30,000 revs/min model and launched 150 kW<br />

spindle variants for larger workpieces.<br />

These developments not only present a<br />

range of smaller yet competitively-priced<br />

and high-speed (rapid traverse rates of 65<br />

metres/min) five-axis machines to subcontract<br />

machinists, but they also further<br />

enhance Starrag’s impressive array of<br />

aluminium cutting machines for OEMs and<br />

tier one and two suppliers.<br />

Available from Starrag UK, the portfolio<br />

now also includes 150 kW variants for the<br />

Scharmann Ecospeed and Ecospeed F models<br />

(complementing 120 kW units), that are<br />

capable of handling components from three<br />

to 20 metres long, while the new Starrag STC<br />

800X features a 120 kW spindle and the threemachine<br />

Heckert HEC X5 range has been<br />

uprated with 83 kW spindles.<br />

Indeed, the new 150 kW spindles have the<br />

potential to reduce machining times by a<br />

further 15-20 per cent on typical aerospace<br />

structural parts.<br />

In all cases, the machines boast metal<br />

removal rates that out-perform ‘like-for-like’<br />

competitor models, Starrag UK claims.<br />

triflex R, the energy chain solution from igus<br />

designed to deal with the three-dimensional<br />

movement needed by industrial robots, and<br />

the new compact universal triflex RS<br />

dresspack module.<br />

As well as electrical and pneumatic lines,<br />

industrial robots often require feed hoses for<br />

bolts, rivets or screws. When robotic arms are<br />

moving at high speeds, tight bends or<br />

hanging loops can sometimes cause<br />

problems; if the energy chain falls below the<br />

Indeed, the STC 800X can remove aluminium<br />

at the rate of up to 10 litres a minute.<br />

Featuring NC-controlled rotary table, the<br />

trio of HEC 500 X5, HEC 630 X5 and HEC 800<br />

X5 five-axis machining centres have X, Y and<br />

Z axis travels that extend from 1,000 mm by<br />

800 mm by 1,000 mm to 1,450 mm by 1,100<br />

mm by 1,000 mm and are capable of<br />

accommodating loads of 1,200 kgs.<br />

In all cases the 83 kW main spindle motor<br />

produces speed ranges up to 15,000<br />

revs/min and torque up to 1,500 Nm, plus<br />

rapid traverse rates of 65 metres/min.<br />

This reinforces Starrag’s customerfocused<br />

policy of ‘Engineering precisely<br />

what you value’ by, for example, reducing<br />

production times and unit costs by offering<br />

complete machining in a single set-up.<br />

Tel: 0121 3593637<br />

Web: www.starrag.com<br />

IGUS TRIFLEX RS DRESSPACK UNIVERSAL<br />

MODULE FOR MULTI-AXIS INDUSTRIAL<br />

minimum permissible bending radius of the<br />

supply hoses, the worst case scenario is that a<br />

rivet or screw may get stuck, which can then<br />

lead to plant downtime.<br />

To tackle this issue, igus developed triflex<br />

R, a multi-axis cable management and energy<br />

supply system specifically for sophisticated<br />

6-axis robotic applications in harsh industrial<br />

environments. With over 100 modular<br />

components, triflex R avoids looping of the<br />

energy chain as it moves, preventing tube<br />

blockages from occurring which might<br />

otherwise ultimately lead to unplanned and<br />

costly machine downtime.<br />

The new triflex RS dresspack is a very<br />

compact universal module that is mounted<br />

directly on the robot, with space-saving low<br />

installation height to deal with extremely<br />

narrow installation space. It includes an<br />

integrated pull-back spring to prevent loop<br />

formation and there are also pneumatic,<br />

elastic and linear alternatives for lightweight<br />

and effective retraction systems.<br />

See triflex RS in action at:<br />

www.igus.co.uk/ triflexrssystems<br />

For more information on igus products and<br />

to request free product samples, please<br />

contact us on 01604 677240.<br />

For regular updates, follow us on<br />

www.twitter.com/ igusUK<br />

14 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

The Universal Hydraulic Expansion<br />

Toolholder<br />

A Class of its Own!<br />

The ultimate<br />

for volume cutting<br />

For every application,<br />

for every cutting tool!<br />

< 0.003 mm<br />

Run-out and repeat accuracy<br />

ensures best surface qualities<br />

High radial rigidity<br />

for a better part geometry accuracy.<br />

A robust base body avoids lateral<br />

deflection during metal cutting.<br />

Up to 300% higher<br />

tool life<br />

Verified in a study by the wbk<br />

Institute for Production Technology<br />

at the Karlsruhe Institute of<br />

Technology (KIT)<br />

Best surface qualities<br />

due to excellent vibration damping for<br />

best surfaces without chatter marks.<br />

HSC/HPC machining<br />

At a balancing grade of G2.5<br />

at 25,000 rpm suitable for high<br />

torques.<br />

Excellent vibration<br />

damping<br />

The hydraulic system ensures best<br />

surface qualities, prevents the machine<br />

spindle from damage, increases tool life,<br />

and reduces costs.<br />

Made in Germany<br />

In the city of Lauffen,<br />

home of Friedrich Hölderlin<br />

Highest torques –<br />

now up to 2,000 Nm<br />

at Ø 32 mm with dry<br />

clamping conditions,<br />

900 Nm in oily conditions<br />

Tool change<br />

within seconds<br />

micron precise without peripheral<br />

equipment. Easy turned to stop<br />

Maintenance-free<br />

Completely enclosed system.<br />

Maintenance-free and long<br />

service life<br />

www.gb.schunk.com/tendo-e-compact<br />

© <strong>2016</strong> SCHUNK GmbH & Co. KG

NEWS NEWS NEWS<br />

ETG CELEBRATES 20 YEARS<br />

REPRESENTING CHIRON<br />

Twenty years after setting up Chiron Werke<br />

UK Limited and selling their first Chiron FZ<br />

series machining centre, the company - now<br />

trading as the Engineering Technology<br />

Group - has sold many hundreds of Chiron<br />

machines into the UK in the ensuing years.<br />

It has been 20 years that have seen ground<br />

breaking moves forward in machine designs,<br />

computerised technology and control,<br />

turnkey and automation capabilities as the<br />

industry in general has developed and<br />

Chiron in particular has pioneered new<br />

developments and machining concepts.<br />

Machining centres and turnkey solutions<br />

“Made by Chiron” are the now world’s first<br />

choice across a spectrum of metalworking<br />

industries in small, medium and large-sized<br />

engineering and manufacturing<br />

environments.<br />

Areas where Chiron has developed<br />

unsurpassed capabilities are its high speed<br />

From an introduction by Mollart Engineering<br />

of its Elliott roller burnishing tool range to a<br />

customer, it has been able to replace separate<br />

time consuming OD finish grinding and<br />

unpredictable manual polishing operations<br />

on steel forming rolls to now create a<br />

controlled and automated consistently high<br />

surface finish over a 300 mm length of the 150<br />

mm diameter 36NiCrMo4 alloy steel<br />

customers workpieces.<br />

The change in processing strategy to<br />

introduce the Elliott S2327 single roll OD<br />

burnishing tool allows the roll shaft to be<br />

turned and then finish burnished in a single<br />

operation which is now maintaining a<br />

surface texture that is now half the specified<br />

tolerance. Running at the same 450 revs/min<br />

speed as the finish turning, the burnishing<br />

tool setting includes a feed rate of 0.1 mm per<br />

rev. Indeed, such is the margin of quality<br />

being maintained from part-to-part, that the<br />

process is repeating a finish within 0.4 Ra<br />

that is half the drawing specification.<br />

Said Mollart Sales Manager Mark Dore:<br />

“The customer elected to change processes<br />

due to problems of inconsistency from the<br />

manual polishing process and the time taken<br />

to achieve the specified finish. We were then<br />

able to add the bonus of eliminating the<br />

tool changing systems with tool-to-tool times<br />

of 0.5 seconds and the development of linear<br />

motor based high speed axis travels<br />

combined with accuracy, stability and<br />

reliability. These qualities make Chiron<br />

machine tools well suited to high volume<br />

applications, automated cells and turn-key<br />

installations where maximum productivity is<br />

a primary consideration.<br />

Today the Chiron range of vertical<br />

machining centres offer exceptional<br />

productivity and a wide choice of 5 axis<br />

options including swivel head and two axis<br />

rotary table options.<br />

However, in the early days of Chiron<br />

Werke in the UK, performance standards<br />

were more modest yet, for the period, still<br />

impressive.<br />

Ian Howlett, now Operations Commercial<br />

Director at ETG, joined the fledgling<br />

company as Service Manager a few months<br />

after founder Paul Rhodes established the<br />

business and he recalls the very first<br />

installation.<br />

“We sold a FZ 28L into Longclose<br />

Engineering in Leeds soon followed by an FZ<br />

22W machine to O.L.D. Engineering in<br />

Hinckley – a machine they still use to this<br />

day. Automotive was the predominant<br />

sector for Chiron – between 80 and 90% of<br />

sales were into the sector - but over the years<br />

this has broadened considerably.”<br />

Tel: 01926 298128<br />

Web: www.engtechgroup.com<br />

ROLLER BURNISHING ELIMINATES<br />

GRINDING AND POLISHING TASKS<br />

grinding process plus the logistics of moving<br />

components around the workshop.”<br />

The Elliott single roll OD burnishing tool<br />

is suitable for use in both manual or CNC<br />

controlled lathes and machining centres to<br />

create a controlled finish on diameters,<br />

angles, radii and faces. The contact roll can<br />

be supplied with a selection of radii to suit<br />

the application between 0.8 mm and 3 mm.<br />

As the roll is made from carbide this means<br />

production life is extended and the roll can<br />

be easily replaced or refurbished. In order to<br />

set operational speeds and feeds, these<br />

normally bear a close relationship to those<br />

applied in the finished pre-sizing cutting<br />

operations and the toolpath replicates the<br />

finish machining operation.<br />

Tel: 0208 391 2282<br />

Email: mark.dore@mollart.co.uk<br />

METAL REMOVAL<br />

RATES INCREASED<br />

BY 500%<br />

Manufacturers attending VISI’s recent user<br />

days at DMG Mori and Nikken, saw how the<br />

new Waveform Roughing Strategy in the<br />

latest release of the software improves<br />

material removal rates by up to 500 per cent.<br />

Live demonstrations of waveform, on a<br />

DMG Mori ecomill 600v, using Seco Tools<br />

UK’s new 5542C cutter – part of their solid<br />

square range – showed a Material Removal<br />

Rate above 65 cm3 a minute.<br />

Paul Bown, Seco’s UK Product Manager,<br />

says the new tool is ideal for VISI’s waveform<br />

roughing strategy. “It’s particularly strong<br />

and has a tapered core, along with<br />

considerable clearance on the bottom for<br />

helical interpolation to get into cuts without<br />

the need to drill holes.” The demonstration<br />

tool was 8 mm and used the full 20 mm depth<br />

of cut, with 20 per cent side engagement, and<br />

running at 200 metres a minute.<br />

“This is a 4 flute tool, and we’ve got a 5<br />

flute version coming later in the year along<br />

with a 6 flute tool for these strategies on<br />

titanium.”<br />

And Steve Finn, DMG Mori UK Managing<br />

Director, says it showed three premium<br />

products working in harmony. “Combining<br />

DMG Mori machine tools, Seco cutting tools<br />

and VISI CAD/CAM from Vero Software,<br />

improves efficiency and productivity for the<br />

customer.”<br />

According to John Cockerill, VISI’s UK<br />

Support Manager, the new Waveform<br />

Roughing Strategy in VISI <strong>2016</strong> R2 increases<br />

material removal rates by a minimum of 100<br />

per cent, and up to 500 per cent, compared to<br />

conventional toolpaths.<br />

“These strategies utilise the full depth of<br />

the tool with smaller step overs, meaning<br />

speeds and feeds can be considerably ramped<br />

up, giving significant productivity<br />

improvements.”<br />

Vero’s ERP/MRP production control<br />

system, Javelin, was also on display over the<br />

three days, along with demonstrations of the<br />

Hexagon Romer Arm. Steven Whalley,<br />

Hexagon Manufacturing Intelligence Product<br />

Specialist, showed how the system laser scans<br />

a model to produce a 3D point cloud. “An STL<br />

file is produced from that point cloud and<br />

imported into VISI where a surface is created,<br />

and the tool paths generated to cut the metal.<br />

Without this, you’d have to go in with a hard<br />

touch probe and take individual hits, which<br />

would take several hours, to do what laser<br />

scanning does in minutes.”<br />

Tel: 01189 56084<br />

Email: marketing@verosoftware.com<br />

16 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

Laser metrology, machine tool, CMM and robotic performance<br />

Themes<br />

Novel Manufacturing Technologies<br />

& Machine Tools<br />

New Developments in Measurement<br />

Techniques<br />

Performance Evaluation for Machine<br />

Tools and CMMs<br />

Roughness and Machine Tool<br />

Standards<br />

Lamdamap<br />

12th International Conference & Exhibition<br />

15 th - 16 th March 2017<br />

Renishaw Innovation Centre,<br />

Wotton-under-Edge, UK<br />

Key dates<br />

Metrology in New Fabrication<br />

Techniques<br />

22nd Aug <strong>2016</strong> Call for abstracts<br />

14th Oct <strong>2016</strong><br />

Online abstract submission deadline<br />

Please visit our website for further information<br />

info@euspen.eu<br />

www.euspen.eu

NEWS NEWS NEWS<br />

THE ORACLE TM HAS LANDED<br />

Innovative ‘Factory of the Future’ technology<br />

launched by Jemtech at its Advanced Metal<br />

Working Fluid Management Conference<br />

pulls in the crowds.<br />

Jemtech, the UK’s leading cutting fluid<br />

solutions provider and supplier of Blaser<br />

Swisslube metal working fluids to UK and<br />

Irish component manufacturers, has reported<br />

that its Advanced Metal Working Fluid<br />

Management Conference held at the<br />

Manufacturing Technology Centre (MTC) in<br />

Coventry on 23rd August <strong>2016</strong>, was a huge<br />

success.<br />

The event attracted over 140 VIP visitors<br />

and, according to Jemtech’s CEO Steve Coull,<br />

“provided the perfect venue” to launch<br />

Oracle, the company’s new, intelligent and<br />

fully-automated metal working fluid<br />

management system into the market and one<br />

of the main highlights of the Conference.<br />

The Advanced Metal Working Fluid<br />

Management event provided attendees with<br />

ample food for thought focusing on the bestpractice<br />

use, application and maintenance of<br />

metal working fluids in the machining<br />

process.<br />

Following an opening scene-setting<br />

presentation from Mr Craig Stevens, Head of<br />

Industrial Sectors at the MTC, on the purpose<br />

and the role of the MTC (the MTC was<br />

strategically involved in the Oracle TM<br />

system’s two year development programme),<br />

Mr Coull took centre stage and delivered a<br />

typically passionate address on the<br />

importance of metal working fluids.<br />

As well as creating the context for the<br />

Oracle launch, the introduction also<br />

provided the ideal platform to present and<br />

explain LiquidTool - Blaser Swisslube’s (and<br />

Jemtech’s) unique and proven approach to<br />

metal working fluid management.<br />

Billed as a ‘Factory of the Future’<br />

technology - Oracle, used in conjunction<br />

with Blaser Swisslube fluids, is a real gamechanger<br />

and is aimed at (and, as a<br />

consequence, will appeal to) precision<br />

component manufacturers looking to<br />

increase their productivity, improve their<br />

performance, reduce their operational costs<br />

and increase their competitive advantage.<br />

Developed in partnership with the MTC<br />

over the last two years, Oracle provides<br />

customers’ individual machine tools with a<br />

constant supply of accurately mixed cutting<br />

fluid and captures live data relating to the<br />

real time condition of metal working fluids in<br />

a machine tool’s sump, as part of the process.<br />

Oracle advanced metal working fluid<br />

system will be showcased at DMG Mori’s<br />

Technology Days event taking place 11th-<br />

13th <strong>October</strong> at DMG Mori’s facility in<br />

Coventry and Citizen <strong>Machinery</strong> UK<br />

Openhouse event 11th-13th <strong>October</strong> - UK<br />

Headquarters Hertfordshire.<br />

Tel: 01825 767640<br />

HAINBUCH PUBLISHES AEROSPACE<br />

WORKHOLDING BROCHURE<br />

As one of the leading innovator in the workholding sector, HAINBUCH has now published a<br />

new eight page brochure for the aerospace industry. The new brochure is packed with new<br />

technology that has been developed specifically for manufacturers in this technically<br />

demanding industry sector.<br />

HAINBUCH is all too aware of the challenges from an industry that is driven by time<br />

constraints, exacting component and material specifications and the geometric complexity of<br />

the parts machined. As experts in workholding, HAINBUCH has published its aerospace<br />

brochure to demonstrate the durability, accuracy and versatility for customer demands in this<br />

ever evolving industry.<br />

The new brochure has detailed information on product lines such as the double<br />

independent I.D clamping system, the segmented bushing chuck, the segmented T213<br />

mandrel and the extremely popular TOPlus pull back chucks. In each instance, HAINBUCH<br />

demonstrates common aerospace components and their respective machining problems;<br />

providing a resolution to all your aerospace machining issues.<br />

Web: www.hainbuch.com<br />

TWO NEW PILLAR<br />

DRILLS HAVE JUST<br />

JOINED THE<br />

AXMINSTER<br />

ENGINEER SERIES.<br />

Weighing in at 48kg, the M-360 is a very<br />

precise, small pillar drill best suited for small<br />

production batch work. It uses the ER16<br />

collet system, which in turn uses collets with<br />

a closure of 1mm; for example, a 7mm collet<br />

will close down to 6mm. Collets have long<br />

been recognised as the most accurate tool<br />

holding system, so perfect concentricity is<br />

assured. The drill shank capacity is 0.5-<br />

10mm. The machine, although compact in<br />

size, is heavily built in cast iron. The column<br />

features a rack and pinion system to control<br />

the height of the headstock. The headstock<br />

itself has an exceptionally deep quill housing,<br />

ensuring accuracy even with the quill fully<br />

extended. There is a threaded depth stop,<br />

which can be locked to ensure a constant<br />

drilling depth. A 3-speed belt drive system is<br />

fitted, driven by a smooth running induction<br />

motor. The base has a work table surface<br />

machined into it with 14mm T-slots for work<br />

clamping. The drill is fitted with an<br />

interlocked chuck guard, LED work light and<br />

locking “E” stop switch. Please note collets<br />

are not supplied with the drill but can be<br />

purchased separately.<br />

At the other end of the spectrum, the SB-<br />

250 floor pillar drill is an extremely robust<br />

25mm (max. capacity in steel) drill with a<br />

weight of 210kg. It is designed for large<br />

engineering and production tasks and is<br />

capable of being used for prolonged periods.<br />

Very heavily built and manufactured to<br />

extremely accurate tolerances, this pillar drill<br />

will stand up to hard work every day. The<br />

headstock has been machined to precisely<br />

match the quill housing, virtually eliminating<br />

any spindle run-out, even at full quill<br />

extension. Because the column is surface<br />

ground, the table rise and fall is super<br />

smooth in operation, making table height<br />

adjustment a light task. The high torque<br />

1,500W motor drives the spindle via a 6-<br />

speed belt drive, with machined steel pulleys<br />

eliminating vibration. This machine is also<br />

fitted with a quill down feed system,<br />

controlling the down feed speed in relation to<br />

the spindle speed selected.<br />

Tel: 01297 630032<br />

Email: jacqueline.hunt@axminster.co.uk<br />

Web: www.axminster.co.uk<br />

18 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

NEWS NEWS NEWS<br />

DOOSAN LATHES ARE CHOSEN<br />

Tufcot, one of the leading specialist<br />

manufacturers of composites materials, had<br />

its fifth Doosan machine delivered to its<br />

facility in Sheffield.<br />

The machine, a new Doosan Puma 3100<br />

lathe supplied by Mills CNC, joined the four<br />

previously-purchased Doosan lathes<br />

acquired by the company since 2007. The<br />

new Puma is being used to manufacture,<br />

using ‘dry’ machining strategies and<br />

techniques, high-precision finished and<br />

semi-finished Tufcot® components that<br />

include spherical bearings, bushes, flanged<br />

bushes, washers, wear pads and hydraulic<br />

wear rings for Tufcot’s diverse and growing<br />

domestic and international customer base.<br />

According to Tufcot’s Managing Director,<br />

Greg Majchrzak, this latest Doosan machine<br />

acquisition (like those that preceded it), “will<br />

help Tufcot achieve future growth and<br />

maintain its competitive edge.”<br />

Explains Greg Majchrzak:<br />

“We are continually improving and<br />

igus, the motion plastics specialist, will be<br />

exhibiting its solutions for demanding<br />

moving applications at this year’s Advanced<br />

Engineering Show, 2-3rd November <strong>2016</strong>,<br />

NEC Birmingham.<br />

Whether in the aerospace or automotive<br />

industry, when it comes to weight savings,<br />

design engineers increasingly rely on carbon<br />

fibre. To meet the demands in this field, igus<br />

developed a carbon fibre drylin W rail, which<br />

will be on display at The NEC, stand H41.<br />

Visitors to the stand will also be able to<br />

see new Industry 4.0-enabled technologies<br />

and their applications. Smart<br />

plastics are an evolution of proven<br />

igus cable, energy chain and linear<br />

bearing products. Adding<br />

embedded intelligence to its<br />

motion plastics via the addition of<br />

sensing, monitoring and<br />

communications, smart plastics<br />

allow customers to maximise<br />

uptime and reduce costs through<br />

condition monitoring and<br />

predictive maintenance.<br />

In addition to the above, igus<br />

refining our products and services to<br />

customers. An integral part of this companywide<br />

Continuous Improvement Programme<br />

involves investing in the latest and most<br />

advanced CNC machine tool technologies.<br />

“We have a long-established relationship<br />

with Mills CNC and, during this time, have<br />

made Doosan lathes our preferred ‘turning<br />

technology’ choice. Doosan machines<br />

combined with the back-up, service and<br />

technical assistance provided by Mills CNC<br />

help us reduce lead times and ensure we are<br />

able to manufacture high-quality and highprecision<br />

products.”<br />

Tufcot has invested in five Doosan lathes<br />

- all equipped with Fanuc controls.<br />

The most recent investments made<br />

include a 12” chuck Puma 3100M with<br />

7.8kW/5000rpm driven tooling capability<br />

(acquired in 2014); a 12” chuck (standard)<br />

Puma 3100 purchased in <strong>2016</strong>; a Puma<br />

400MC large-capacity turning centre with<br />

large bore capability and a Lynx 220LM<br />

(long-bed lathe with driven tools) purchased<br />

in 2012 and 2007 respectively.<br />

All Doosan lathes are powerful and have<br />

a rigid build and construction thereby<br />

enabling Tufcot to achieve rapid cycle times<br />

as well as high part accuracies and superior<br />

surface finishes.<br />

Because Tufcot only machines composite<br />

materials - all Doosan machines at its facility<br />

are equipped with additional seals and<br />

extraction systems to prevent particle and<br />

dust ingress.<br />

Tel: 01926 736736<br />

Email: sales@millscnc.co.uk<br />

IGUS TO DEMONSTRATE INDUSTRY 4.0<br />

SOLUTIONS AT ADVANCED<br />

ENGINEERING SHOW<br />

will also be exhibiting a comprehensive<br />

range of lightweight, maintenance and<br />

corrosion-free robotic solutions, including<br />

robolink multi-axis joints for robots.<br />

Members of the igus team will be<br />

available on stand H41 to answer questions<br />

and demonstrate the potential applications of<br />

its bearing products and cable management<br />

systems, as well as provide insight into the<br />

full range of igus products suitable for their<br />

industry and application.<br />

For more information, please visit:<br />

http:/ / www.igus.co.uk/ industry<br />

TMB PATTERNS<br />

MAKES MAJOR<br />

GRINDING<br />

INVESTMENT<br />

Bridgwater-based TMB Patterns, a leading<br />

supplier of tooling for the thermo-moulding<br />

industry has ordered a surface grinder from<br />

RK International Machine Tools on the back<br />

of positive business outlook, increased work<br />

from its customers in the thermo-forming<br />

sector and a diversification into sub-contract<br />

machining for the nuclear and aerospace<br />

sectors. The surface grinding machine Perfect<br />

PFG120-200AHD double column-type<br />

machine (1200 mm by 2000 mm maximum<br />

grinding surface), is one of the largest<br />

machines of its type sold by RK International<br />

Machine Tools in the UK.<br />

“While concentrating on the metal-cutting<br />

side of our operation we had taken our eye<br />

off the pressure on our grinding section. The<br />

old machines we had were working 16 hours<br />

per day and are obviously an important<br />

element of our business. However, they were<br />

old and becoming less reliable so the time<br />

was right to invest in the latest technology.<br />

Our thermo-forming work tends to be<br />

seasonal, so we took the decision some time<br />

ago to maximise the skills we have available<br />

to us and the two areas of nuclear and<br />

aerospace were an ideal fit for our business<br />

and the people we have working here. By<br />

bringing in the Perfect grinding machine, we<br />

will improve productivity and be well placed<br />

to handle the increase in work that we are<br />

seeing from nuclear and aerospace<br />

customers. In addition, since the EU<br />

referendum we are also seeing increased<br />

activity in our export markets, which<br />

represents 20 per cent of our turnover,” says<br />

Martin Baker, Managing Director TMB<br />

Patterns.<br />

The Perfect grinding machine ordered in<br />

September <strong>2016</strong>, will be delivered in January<br />

2017.<br />

“TMB Patterns is a superb example of a<br />

business looking to build on its success it has<br />

proven that investment in modern<br />

manufacturing technology is the way<br />

forward and it is continuing along that path<br />

with the purchase of this surface grinding<br />

machine from Perfect,” says Dick Aldrich,<br />

Sales Director, RK International Machine<br />

Tools.<br />

Tel: 01322 447611<br />

Email: simonrood@rk-int.com<br />

Web: www.rk-int.com<br />

20 <strong>Machinery</strong> <strong>World</strong>, <strong>October</strong> <strong>2016</strong>

MACHINE TOOL ACCESSORIES<br />

Fast and precise<br />

component<br />

workholding?<br />

The answer’s<br />

YES<br />

Chick from 1st MTA. The UK’s leading<br />

machining accessory supplier.<br />

St<br />

Email: enquiries@1mta.com Freephone: 0800 783 0510<br />

Fax: 0800 783 0517 www.1mta.com<br />

MTA

METROLOGY, INSPECTION, QUALITY CONTROL<br />

SHOWTIME FOR METROLOGY<br />

INNOVATIONS<br />

The Advanced Engineering <strong>2016</strong> exhibition<br />

(NEC, 2-3 November), provides an annual<br />

platform for OEMs and tier 1 manufacturers<br />

to meet and do business with all levels of the<br />

engineering supply chain. Prominent at this<br />

year’s show will be a number of high profile<br />

metrology companies keen to demonstrate<br />

their latest measurement, inspection and<br />

quality control innovations.<br />

For instance, Zoller will use the show to<br />

launch its ‘Turning Advisor’ software<br />

function, which allows the user to define a<br />

variety of tool positions on turn-mill<br />

machines. This eliminates the need for<br />

adaptors to be set up on the machine, thus<br />

improving efficiency during turning and<br />

milling machining operations.<br />

Another feature of the stand will be ‘Get<br />

to Know Industry 4.0’, where Zoller will<br />

discuss total connectivity solutions that<br />

involve cyber-physical processes safely<br />

transferring data between machines in order<br />

to eliminate manpower and increase<br />

production.<br />

Also on stand L2 will be Zoller’s most<br />

popular universal measuring machine, the<br />

Venturion Smartcheck system. Using the<br />

Venturion Smartcheck, visitors will be able to<br />

carry out an interactive demonstration of the<br />

machine and its tool presetting capabilities,<br />

alongside an introduction to TMS (tool<br />

management solutions).<br />

Over on stand K9, OGP UK will be<br />

holding the first demonstration of its new<br />

Zone3 metrology software, which is used in<br />

conjunction with the company’s SmartScope<br />

multi-sensor measurement systems.<br />

According to OGP, Zone3 allows users to<br />

acquire faster measurements and futureproof<br />

capabilities. It incorporates full 3D CAD<br />

programming, interactive reporting with live<br />

data and graphs, multi-sensor auto-path<br />

creation and live kinematic model simulation<br />

of the machine with DRF and GD&T<br />

animation.<br />

OGP will also exhibit a SmartScope CNC<br />

200 multi-sensor measurement system, which<br />

will feature TTL (through-the-lens) laser and<br />

touch probe sensors. These sensors will be<br />

used to demonstrate the system’s<br />

metrological capabilities and speed using a<br />

selection of both metal and plastic<br />

components through laser scanning and<br />

optical measurement.<br />

Faro Technologies, on stand O60, says its<br />

staff will be demonstrating how the<br />

company’s range of portable 3D<br />

measurement equipment can save time and<br />

improve quality. On show will be products<br />

such as the Faro Laser ScanArm, with a light<br />

laser line probe for non-contact<br />

measurements, and the Faro Laser Tracker for<br />

large volume measurements.<br />

Also on display will be a relatively new<br />

addition to the Faro range, the Array Imager,<br />

a metrology-grade non-contact scanner which<br />

utilises blue light technology to capture<br />

millions of high resolution 3D co-ordinate<br />

measurements in seconds.<br />

Visitors to stand C41 will see Blum<br />

Novotest show how reliable and consistent<br />

measurement can be conducted on machine<br />

tools, despite the presence of coolant, which<br />

the company says is an underestimated<br />

source of errors. This is credit to predeflection<br />

technology and an increased<br />

measuring force that ensure coolant has no<br />

impact on the actual measurement, even at a<br />

measuring speed of 5 m/min. In addition to a<br />

pushing measurement, the bi-directional<br />

TC61 touch probe system enables pulling<br />

measurements in the Z+ direction.<br />

A further Blum innovation in the spotlight<br />

will be the new TC63-RG and TC64-RG<br />

Digilog surface roughness gauges, which can<br />

evaluate the surface roughness of a part while<br />

it remains clamped in the machine tool. Using<br />

the TC64-RG Blum says that measurements<br />

can be carried out up to 20 times faster when<br />

it comes to detecting machining errors in the<br />

micron range. For the end user, the benefits<br />

are immediate. Reject parts are reduced by<br />

enabling immediate reworking while the part<br />

is still clamped in the machining or turning<br />

centre.<br />

Supporting these products will be the<br />

latest RG 2.0 software that now allows<br />

parameters such as waviness, skew or contact<br />

area ratio to be presented for the measured<br />

surface, in addition to the calculated<br />

roughness values. This system can be<br />

integrated with the Digilog software in the<br />

control systems of machine tools.<br />

Elsewhere at the exhibition, Alicona<br />

(stand B31) says it will be promoting newly<br />

developed collaborative systems created from<br />

a combination of the company’s optical<br />