Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LIFETIME EXCELLENCE<br />

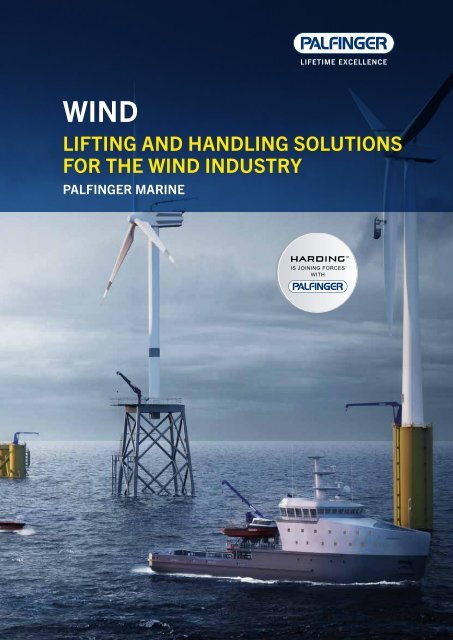

WIND<br />

LIFTING AND HANDLING SOLUTIONS<br />

FOR THE WIND INDUSTRY<br />

<strong>PALFINGER</strong> <strong>MARINE</strong>

PRODUCTS<br />

FOR<br />

WIND MILLS,<br />

TURBINE<br />

BLADES AND<br />

SUBSTATIONS

06<br />

06<br />

04<br />

03<br />

03<br />

06<br />

04<br />

06 06<br />

04<br />

03<br />

04<br />

04<br />

04<br />

04<br />

05<br />

04 03<br />

05<br />

05<br />

03<br />

07<br />

04<br />

04<br />

04<br />

04<br />

03<br />

04<br />

03<br />

03<br />

05<br />

05<br />

04<br />

03<br />

03<br />

03<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> has served the <strong>wind</strong> business for many years with a range of<br />

products for <strong>wind</strong> mills and substations in offshore <strong>wind</strong> parks. Platform, nacelle and<br />

substation cranes 03 are offered for these kinds of applications. The special fixed and stiff<br />

03 03<br />

boom cranes are typically used on platforms.<br />

The ideal choice for lifting cargo from the platform to the nacelle where space is limited.<br />

Strong and reliable – these words characterise the typical substation cranes like<br />

telescopic boom and stiff boom cranes. The optimal power-to-weight ratio allows secure<br />

handling and lifting of material and tools. Stiff boom and telescopic boom cranes are<br />

also used in the harbour area. What are known as jetty cranes are electro-hydraulically<br />

driven and the best in their class for quayside applications. For safe and efficient blade<br />

inspection and repair, <strong>PALFINGER</strong> <strong>MARINE</strong> offers a patented and innovative package<br />

solution: the <strong>PALFINGER</strong> BLADE ACCESS (PBA).<br />

This well-rounded package for the <strong>wind</strong> business is prepared for special projects<br />

under offshore conditions. <strong>PALFINGER</strong> <strong>MARINE</strong> guarantees its customers a strong and<br />

reliable partnership with excellent lifetime operation during the entire product life cycle.<br />

Product Range<br />

è Platform Cranes<br />

è Nacelle Cranes<br />

è Substation Cranes<br />

è Jetty (Harbor) Cranes<br />

è Palfinger Blade Access (PBA)

REFERENCES<br />

For years, many customers have chosen <strong>PALFINGER</strong> <strong>MARINE</strong> to deliver <strong>wind</strong> cranes for <strong>wind</strong> mills, substations,<br />

floating and accomodation platforms and deck equipment for <strong>wind</strong> farm service vessels.<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is a dependable and professional partner in every situation. Customers benefit from many<br />

years of experience and knowledge of the market.<br />

Rhyl Flats<br />

Thornton Bank phase I<br />

Norside Supply AS<br />

Pirious Singapore<br />

Van Oord<br />

North<strong>wind</strong><br />

Alpha Ventus<br />

Gemini<br />

Elhöft<br />

Dan Tysk<br />

Butendiek<br />

STX<br />

Gode Wind 01<br />

Burbo Bank<br />

Dudgeon<br />

Burbo Bank Extension<br />

Race Bank<br />

Nordergründe<br />

Nobel<strong>wind</strong><br />

Lamprell Shipyard<br />

Beatrice Demonstration<br />

Rampion<br />

Thornton Bank phase II<br />

Vestas<br />

Strategic Marine<br />

Formosa<br />

EnBW Baltic 2<br />

Gode Wind 02<br />

Ormonde<br />

Avedore Holme<br />

Walney Phase 1<br />

Walney West Cofely Fabricom<br />

Greater Gabbard<br />

Walney East<br />

Wikinger<br />

Galloper Wind Farm<br />

Pirious Vietnam<br />

Meer<strong>wind</strong> Ost/Süd<br />

Borkum Phase 1<br />

Sheringham Shoal<br />

Nordsee Ost<br />

West of Dudden Sands<br />

Global Tech I<br />

Thornton Bank phase III<br />

Bladt Industries<br />

Fred.Olsen Windcarrier AS<br />

ASM<br />

Gunfleet Sands I + II<br />

Walney Phase 2<br />

Vattenfall<br />

Siem Offshore<br />

4

ABOUT US<br />

<strong>PALFINGER</strong> GROUP<br />

Founded in 1932<br />

Employees:<br />

about 9,000<br />

Turnover 2015:<br />

1.2 Billion EUR<br />

HQ located in:<br />

Salzburg, Austria<br />

LIFETIME EXCELLENCE<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is part of the <strong>PALFINGER</strong> Group and the<br />

world's leading manufacturer of highly reliable, innovative and<br />

customised deck equipment and handling solutions for the<br />

maritime industries. LIFETIME EXCELLENCE is what we promise.<br />

For <strong>PALFINGER</strong> <strong>MARINE</strong> customers, this means excellence<br />

without compromise and reliable, economical solutions<br />

throughout the entire product life-cycle. User-friendly applications<br />

and functional design are the key benefits of the product range.<br />

Reliable equipment guarantees resistance even under the<br />

toughest conditions. A worldwide service network including<br />

spare parts supply ensures fast and professional on-site support.<br />

WIND SEGMENT PRODUCT PORTFOLIO<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> offers a wide range of products that are specially designed for the <strong>wind</strong> industry. The product<br />

portfolio for this upcoming segment includes cranes for nacelles, platforms and substation/accommodation platforms as<br />

well as lifesaving equipment, deck equipment and handling solutions for <strong>wind</strong> farm service and supply vessels. Moreover,<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> provides an innovative package for the safe inspection and effective repair of <strong>wind</strong> turbine blades.<br />

This newly developed solution for on- and offshore blade maintenance combines the crane technology of a nacelle<br />

crane and the blade-guided design of a workman basket to perform the service and repair work in a safe working zone.<br />

To meet the requirements of <strong>wind</strong> applications, <strong>PALFINGER</strong> <strong>MARINE</strong> is researching and developing its products in<br />

close cooperation with its customers. As a full-service supplier of lifting equipment, <strong>PALFINGER</strong> <strong>MARINE</strong> has been the<br />

preferred choice of many <strong>wind</strong> park operators and turbine manufacturers.<br />

SUSTAINABILITY<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is always paying attention to the economic advantages for customers and users but also taking into<br />

account ecological and social aspects.<br />

Innovation is encouraged primarily in the areas of energy efficiency during product use, alternative motors and reduction<br />

of operating supplies. Continuously lowering service costs while at the same time extending the longevity of its products<br />

remains one of <strong>PALFINGER</strong> <strong>MARINE</strong>'s first priorities.<br />

QUALITY AND HSE<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is deeply committed to providing the customer with high-quality design, equipment and services in<br />

a professional way.<br />

Experienced engineers and first-rate HSE and quality systems ensure that all requirements are fulfilled throughout the<br />

entire process from design to delivery. All phases of the supply chain are performed in compliance with ISO 9001:2008<br />

and manufacturing takes place in state-of-the-art production facilities. <strong>PALFINGER</strong> <strong>MARINE</strong> always aims to be at the<br />

forefront when it comes to meeting rules and regulations.<br />

All equipment and products are delivered in accordance with the applicable requirements specified by classification<br />

societies such as DNV GL, LR, ABS, BV, RMRS, RRR, RINA, CCS, NKK, etc., national and international regulations and<br />

standards like USCG, SOLAS, NORSOK, ISO EN 13852, API 2C to IEC Ex and ATEX directives, NEC and others as well<br />

as customers' own company standards. A range of products for the marine and offshore applications require third party<br />

certification. <strong>PALFINGER</strong> <strong>MARINE</strong> takes care of the entire process of third party verification and certification as well as<br />

the applicable documentation.<br />

NETWORK AROUND THE WORLD<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is the global player that is represented in all major maritime regions. A global network of sales and<br />

service stations and service partners offer services around the clock and around the globe.<br />

5

WIND CRANES<br />

PLATFORM CRANES<br />

FIXED BOOM CRANES<br />

PF 1100 – FULLY MANUAL OPERATION<br />

The PF 1100 platform crane can be used for easily handling loads up to 50 kg to the platform. These types of cranes are customised for unloading<br />

supply vessels fast and safely under any conditions at sea.<br />

FEATURES<br />

è Stainless steel components<br />

è Overload protection system (friction clutch)<br />

è Compliant with Machinery Directive 2006 (CE)<br />

è Surface protection: DIN EN ISO 12944<br />

C5-M high (320μm)<br />

è Bottom flange on mounting base<br />

è Manually operated rope winch<br />

• hand crank force ~ 8 kg<br />

• planetary gear type with brake system<br />

• hoisting speed ~14 m/min (1 revolution / second)<br />

• hoisting height max. 28 m<br />

• wire rope, rotation-free and galvanized<br />

è Manually operated slewing drive<br />

• slewing limitation 270°<br />

• slewing speed ~ 1 rpm<br />

• death point and slewing angle to be defined<br />

•<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

0.05 1.80 1.30 winch cargo<br />

0.20 1.70 1.00 hook-on point<br />

PF 6000 – ELECTRIC MANUAL OPERATION<br />

This fixed boom platform crane is designed for handling loads up to 700 kg from the ship or vessel to the platform. A special surface coating and<br />

the use of high-quality materials protect the crane against corrosion.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Stainless steel components<br />

Overload protection system (MOPS / AOPS)<br />

Compliant with Machinery Directive 2006 (CE)<br />

Surface protection: (spray galvanized 60 – 160μm)<br />

+ system A8.04 according to DIN EN ISO 12944<br />

C5-M high (320μm)<br />

Bottom flange on mounting base<br />

Electrically operated rope winch<br />

• planetary gear type<br />

• hoisting speeds ~10 m/min & ~20 m/min<br />

• hoisting height max. 28 m / 28 m / 26 m<br />

• 10 mm wire rope, rotation-free and galvanized<br />

Manually operated slewing drive, slewing limitation<br />

338°/ 300° / 325°, slewing speed ~ 1 rpm<br />

death point and slewing angle to be defined<br />

Electric power: 3 x 400 - 690V / 50Hz / ~ 4 to 6 kW<br />

1 x 230V / 50 Hz (standstill heating)<br />

Cable remote control system<br />

Protection class: IP56<br />

Crane weight: ~ 890 kg<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

0.70 2.40 1.70 winch cargo<br />

0.70 2.60 1.70 winch cargo<br />

2.00 2.40 / 2.60 static hook-on point<br />

6

WIND CRANES<br />

PLATFORM CRANES<br />

PF 8000 / PF 9000 – ELECTRIC MANUAL OPERATION<br />

The PF range is developed for handling loads up to 1000 kg. The light-weight fixed boom crane can be manually slewed easily in the preferred<br />

direction with ease, even in a small working space.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Stainless steel components<br />

Overload protection system (MOPS / AOPS)<br />

Compliant with Machinery Directive 2006 (CE)<br />

Surface protection: (spray galvanized 60 – 160μm)<br />

+ system A8.04 according to DIN EN ISO 12944<br />

C5-M high (320μm)<br />

Bottom flange on mounting base<br />

Electrically operated rope winch<br />

• planetary gear type<br />

• hoisting speeds ~10 m/min & ~20 m/min<br />

• hoisting height max. 26-28 m<br />

• 10 mm wire rope, rotation-free and galvanized<br />

Manually operated slewing drive,<br />

slewing limitation 300° / 325°, slewing speed ~ 1 rpm<br />

death point and slewing angle to be defined<br />

Electric power: 3 x 690V / 50Hz / ~ 6 kW<br />

1 x 230V / 50 Hz (standstill heating)<br />

Cable remote control system<br />

Protection class: IP56<br />

Crane weight: ~ 895 kg / 1,100 kg<br />

Bild fehlt noch!<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

1.00 2.90 1.75 winch cargo<br />

1.00 2.90 1.50 winch cargo<br />

2.00 2.70 static<br />

hook-on point<br />

anchor point<br />

1.00 3.40 1.50 winch cargo<br />

3.00 3.25 static<br />

hook-on point<br />

anchor point<br />

STIFF BOOM CRANES<br />

PS 15500 M – ELECTRO-HYDRAULIC OPERATION<br />

This fixed boom platform crane operates fast and cost-effectively. This is impressive, considering the slender design and the low maintenance<br />

expenditure of their class. The optimum ratio of dead weight to lift load opens up a wide range of applications.<br />

FEATURES<br />

è Stainless steel components<br />

è Overload protection system (MOPS / AOPS)<br />

è Compliant with Machinery Directive 2006 (CE)<br />

è Surface protection: DIN EN ISO 12944<br />

C5-M high (NDFT 320μm)<br />

è Bottom flange on mounting base<br />

è Hydraulically operated rope winch (multi-layer) with<br />

man-riding function<br />

• planetary gear type & 2 individual<br />

• brakes, hoisting speed max. ~26 m/min<br />

• hoisting height max. 28 m / 20 m<br />

• 15 mm wire rope, rotation-free and galvanized<br />

è Swivel hook<br />

è Hydraulically operated slewing drive with two cylinders,<br />

slewing limitation 275°/ 270°,<br />

death point and slewing angle to be defined<br />

è Electric power: 3 x 400V / 50Hz / ~ 18.5 kW (main)<br />

3 x 400V / 50Hz / ~ 2.2 kW (emerg.)<br />

1 x 230V / 50 Hz (standstill heating)<br />

è Cable or radio remote control system<br />

è Protection class: IP56<br />

è Hydraulic oil: mineral oil or biodegradable oil<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

2.40 5.00 0 winch cargo<br />

1.50 5.00 1.50 winch cargo<br />

0.50 5.00 0.50 man-riding<br />

Wind Cranes<br />

7

WIND CRANES<br />

PLATFORM CRANES<br />

STIFF BOOM CRANES<br />

PS 23500 M – ELECTRO-HYDRAULIC OPERATION<br />

The PS 23500 M is supplied according to customer requirements. The stiff boom crane can be delivered within a broad range of certifications and<br />

numerous optional features. The PS 23500 M is typically used on <strong>wind</strong> mill platforms for operating between the platform and the sea.<br />

FEATURES<br />

è Stainless steel components<br />

è Overload protection system (MOPS / AOPS)<br />

è Compliant with Machinery Directive 2006 (CE)<br />

è Surface protection: DIN EN ISO 12944<br />

C5-M high (NDFT 320μm)<br />

è Bottom flange on mounting base<br />

è Hydraulically operated rope winch (multi-layer) with<br />

man-riding function<br />

• planetary gear type & 2 individual<br />

• brakes, hoisting speed max. ~26 m/min<br />

• hoisting height max. 20 m<br />

• 15 mm wire rope, rotation-free and galvanized<br />

è Swivel hook<br />

è Hydraulically operated slewing drive with four cylinders,<br />

slewing limitation 270°, death point and slewing angle<br />

to be defined<br />

è Electric power: 3 x 400V / 50Hz / ~ 18.5 kW (main)<br />

3 x 400V / 50Hz / ~ 2.2 kW (emerg.)<br />

1 x 230V / 50 Hz (standstill heating)<br />

è Cable or radio remote control system<br />

è Protection class: IP56<br />

è Hydraulic oil: mineral oil or biodegradable oil<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

2.60 5.00 / 6.20 0 winch cargo<br />

1.30 5.00 / 6.20 1.60 winch cargo<br />

0.30 5.00 / 6.20 0.50 man-riding<br />

PSW 36000 – ELECTRO-HYDRAULIC OPERATION<br />

Efficient weight/power ratio and maintenance-friendly design, the PSW 36000 will impress with these attributes. Designed for platform<br />

applications and less working space this innovative stiff boom crane is usable for loads up to 3 tons.<br />

FEATURES<br />

è Stainless steel components<br />

è Overload protection system (MOPS / AOPS)<br />

slack wire prevention system<br />

è Compliant with Machinery Directive 2006 (CE) &<br />

DNV GL-ST-0378 (DNV 2.22)<br />

è Surface protection: DIN EN ISO 12944<br />

C5-M high (NDFT 320μm)<br />

è Bottom flange on mounting base<br />

è Electrically operated rope winch (single layer) planetary<br />

gear type, hoisting speed ~10.5 m/min & ~21 m/min<br />

hoisting height max. 27 m<br />

12 mm wire rope, rotation-free and galvanized<br />

è Boom tip lowering function for service or inspection<br />

è Hydraulically operated slewing gear, slewing limitation<br />

350°, death point and slewing angle to be defined<br />

è Electric power: 3 x 400V / 50Hz / ~ 12 kW (winch)<br />

3 x 400V / 50Hz / ~ 4 kW (hoisting & slewing)<br />

è Cable or radio remote control system<br />

è Protection class: IP66 / IP56<br />

è Hydraulic oil: ~ 25 litres of mineral oil or biodegradable oil<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

3.00 7.90 0.75 winch cargo<br />

2.00 7.90 2.00 winch cargo<br />

2.00 7.08 static anchor point<br />

8

WIND CRANES<br />

NACELLE CRANES<br />

COMPACT TELESCOPIC BOOM CRANES<br />

PC 1500 M – ELECTRO-HYDRAULIC OPERATION<br />

The PC 1500 M compact telescopic boom crane offers new solutions for customer's challenges and is mainly used in limited working space areas,<br />

especially inside the nacelles of <strong>wind</strong> turbines.<br />

FEATURES<br />

è Stainless steel components<br />

è Nickel-chromium-treated piston rods<br />

è Two hydraulic boom extensions<br />

è Radio remote control system<br />

è <strong>PALFINGER</strong> overload protection system<br />

è Optical overload warning system<br />

è Surface protection: DIN EN ISO 12944-2 C4-M (210μm)<br />

è Compliant with Machinery Directive 98/37/CE<br />

è Hydraulic rope winch with cargo function,<br />

hoisting height 7.2 m<br />

è Electric power requirements (24VDC)<br />

è Required oil flow (approx. 6 –10 l/min)<br />

è Pressure 200 bar<br />

è Slewing angle limited to 325°<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

0.40 3.15 0 cargo winch<br />

0.40 2.90 0 cargo winch<br />

0.40 3.10 0 cargo hook<br />

1.00 1.20 0 cargo hook<br />

FOLDABLE KNUCKLE BOOM CRANES<br />

PK 11001 M – ELECTRO-HYDRAULIC OPERATION<br />

Individually equipped with the right features, the PK 11001 M knuckle boom crane has a huge range of different working positions, making it<br />

perfectly adapted to its job inside and outside the nacelle.<br />

FEATURES<br />

è Stainless steel components<br />

è Nickel chrome or stainless steel piston rods<br />

è Three hydraulic boom extensions<br />

è Radio remote control system<br />

è <strong>PALFINGER</strong> overload protection system<br />

è Surface protection: DIN EN ISO 12944-2 C4-M(210μm)<br />

è Compliant with Machinery Directive 98/37/CE<br />

è Hydraulic rope winch with cargo function,<br />

hoisting height ~ 100 m<br />

è Electric power requirements (24VDC)<br />

è Required oil flow (approx. 30 l/min)<br />

è Pressure 310 bar<br />

è Slewing angle limited to 400°<br />

è Compact storage position (fully folded)<br />

Wind Cranes<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

0,50 8.6 0 cargo<br />

9

WIND CRANES<br />

NACELLE CRANES<br />

FOLDABLE KNUCKLE BOOM CRANES<br />

PK 41002 M – ELECTRO-HYDRAULIC OPERATION<br />

The PK 41002 M knuckle boom crane guarantees maximum manoeuvrability. Additional equipment extends its range of applications, also for<br />

man-riding capability. The crane enables safe and fast lifting from the platform to the nacelle between the heli-deck and the nacelle.<br />

FEATURES<br />

è Stainless steel components<br />

è Nickel-chromium or stainless steel piston rods<br />

è Five hydraulic boom extensions<br />

è Radio remote control system<br />

è <strong>PALFINGER</strong> overload protection system<br />

è Surface protection: DIN EN ISO 12944-2<br />

C4-M (280μm)<br />

è Compliant with Machinery Directive 98/37/CE<br />

è Hydraulic rope winch with cargo and man-riding<br />

function (hoisting height ~ 100 m)<br />

è Electric control cabinet (IP65)<br />

è Hydr. power pack 3 x 400V, 50Hz, ~ 22kW (IP55)<br />

oil flow (approx. 45 l/min) pressure 300 bar<br />

è Endless slewing system<br />

è Compact storage position (fully folded)<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

1.65 14.00 0 cargo<br />

3.50 6.00 0 cargo<br />

0.45 14.00 0 man-riding<br />

10

WIND CRANES<br />

SUBSTATION CRANES<br />

STIFF BOOM CRANES<br />

PSM 1800 – ELECTRO-HYDRAULIC OPERATION<br />

Guaranteed <strong>PALFINGER</strong> <strong>MARINE</strong> quality makes the PSM 1800 a reliable and well-approved piece of equipment. With its enormous outreach, this stiff<br />

boom crane covers a huge range of the platform area. Many features like the emergency power pack or lightening protection enable safe operation.<br />

FEATURES<br />

è Stainless steel components<br />

è Standstill heating for electric motor<br />

è Main & emergency power pack (IP56)<br />

main power: 3 x 400V / 50Hz / ~ 67kW<br />

emergency power: 3 x 400V / 50Hz / ~ 11kW<br />

è Radio or cable remote control system<br />

è <strong>PALFINGER</strong> overload protection system<br />

è Acoustical and optical overload warning system<br />

è Aircraft obstruction light on boom tip<br />

è Surface protection: DIN EN ISO 12944<br />

C5-M high (320μm)<br />

è Endless slewing system / limitation is also possible<br />

è Hydraulic rope winch with cargo and / or man-riding<br />

function<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

10.00 21.00 1.60 cargo<br />

7.50 21.00 2.50 cargo<br />

8.50 13.50 1.00 cargo<br />

1.00 20.00 1.00 man-riding<br />

PSM 3000 – ELECTRO-HYDRAULIC OPERATION<br />

The PSM 3000 showcases its advantage by loading and unloading heavy equipment, material and tools. Experienced staff appreciates its wide<br />

range of applications. Additional advantages like the design and easy maintenance help to save time and money.<br />

FEATURES<br />

è Stainless steel components<br />

è Ceramic coated or stainless steel piston rods<br />

è Standstill heating for electric motor<br />

è Main & emergency power pack (IP56)<br />

main power: 3 x 400V / 50Hz / ~ 110kW<br />

emergency power: 3 x 400V / 50Hz / ~ 11kW<br />

è Radio or cable remote control system<br />

è <strong>PALFINGER</strong> overload protection system<br />

è Acoustical and optical overload warning system<br />

è Aircraft obstruction light on boom tip<br />

è Working light (LED) on boom tip<br />

è Lightning protection rods<br />

è Surface protection: DIN EN ISO 12944<br />

C5-M high (320μm)<br />

è Centralised greasing system<br />

è Endless slewing system / limitation is also possible<br />

è Hydraulic rope winch with cargo and / or man-riding<br />

function<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

10.00 13.50 0.60 cargo<br />

3.00 20.00 2.00 cargo<br />

8.50 13.50 1.00 cargo<br />

1.00 20.00 1.00 man-riding<br />

Wind Cranes<br />

11

WIND CRANES<br />

SUBSTATION CRANES<br />

KNUCKLE BOOM CRANES<br />

PKM 750 – ELECTRO-HYDRAULIC OPERATION<br />

The PKM 750 is a knuckle boom crane for offshore substation applications. It can be used for man-riding and is fully class approved. A special<br />

surface coating and the use of high-quality materials protects this flexible outreach crane for the substation against corrosion.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Stainless steel components<br />

Standstill heating for electric motor<br />

Main & emergency power pack (IP56)<br />

main power: 3 x 400V / 50Hz / ~ 67kW<br />

emergency power: 3 x 400V / 50Hz / ~ 11kW<br />

Radio or cable remote control system<br />

<strong>PALFINGER</strong> overload protection system<br />

Acoustical and optical overload warning system<br />

Aircraft obstruction light on boom tip<br />

Surface protection:<br />

DIN EN ISO 12944 C5-M high (320μm)<br />

Endless slewing system / limitation is also possible<br />

Hydraulic rope winch with cargo and / or man-riding<br />

function<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

5.00 16.00 0 cargo<br />

3.80 16.00 0.50 cargo<br />

3.40 16.00 0.80 cargo<br />

2.60 16.00 1.60 cargo<br />

1.30 16.00 1.60 man-riding<br />

TELESCOPIC BOOM CRANES<br />

PTM 1800 – ELECTRO-HYDRAULIC OPERATION<br />

The PTM 1800 crane sets the tone as the strongest in its class. Uncompromising quality down to the last detail, unbeatable power-to-weight ratio and<br />

outreach up to 30 m guarantees a wide range of applications. Due to the retention possibility of the boom, less parking space is needed on the substation.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Stainless steel components<br />

Ceramic coated or stainless steel piston rods<br />

Standstill heating for electric motor<br />

Main & emergency power pack (IP55) main power:<br />

3 x 400V / 50Hz / ~ 65kW emergency power: 24VDC / ~ 3kW<br />

Radio or cable remote control system<br />

<strong>PALFINGER</strong> overload protection system<br />

Acoustical and optical overload warning system<br />

Aircraft obstruction light on boom tip<br />

Working light (LED) on boom tip<br />

Lightning protection rods<br />

Surface protection:<br />

DIN EN ISO 12944 C5-M high (320μm)<br />

Centralised greasing system<br />

Endless slewing system / limitation is also possible<br />

Hydraulic rope winch with cargo and / or man-riding<br />

function<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

3.30 30.00 1.50 cargo<br />

3.50 20.00 1.50 cargo<br />

5.00 17.50 2.50 cargo<br />

12

WIND CRANES<br />

JETTY (HARBOR) CRANES<br />

STIFF BOOM CRANES<br />

PSM 600 – ELECTRO-HYDRAULIC OPERATION<br />

Proven technology, a maintenance-friendly, robust design and high-quality workmanship. The PSM crane series satisfies all the requirements in<br />

the <strong>wind</strong> sector – without compromise. This stiff boom crane is used for jetties and harbor applications.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Stainless steel components<br />

Standstill heating for electric motor<br />

Main power pack (IP55)<br />

main power: 3 x 400V / 50Hz / ~ 37kW<br />

Radio or cable remote control system<br />

<strong>PALFINGER</strong> overload protection system<br />

Acoustical and optical overload warning system<br />

Surface protection:<br />

DIN EN ISO 12944 C5-M high (320μm)<br />

Hydraulic rope winch<br />

Working light (LED) on boom tip<br />

Endless slewing system / limitation is also possible<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

2.30 20.00 0 cargo<br />

2.60 10.00 0 cargo<br />

TELESCOPIC BOOM CRANES<br />

PTM 600 – ELECTRO-HYDRAULIC OPERATION<br />

Ecology and economy reduced to a common denominator. The PTM 600 telescopic boom crane features environmentally compatible, easy to<br />

maintain equipment. This telescopic boom crane with electro-hydraulic operation is used for jetty and harbor site applications.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Stainless steel components<br />

Standstill heating for electric motor<br />

Main power pack (IP55)<br />

main power: 3 x 400V / 50Hz / ~ 37kW<br />

Radio or cable remote control system<br />

<strong>PALFINGER</strong> overload protection system<br />

Acoustical and optical overload warning system<br />

Surface protection:<br />

DIN EN ISO 12944 C5-M high (320μm)<br />

Hydraulic rope winch<br />

Working light (LED) on boom tip<br />

Endless slewing system / also limitation is possible<br />

Wind Cranes<br />

SWL (ton) Outreach (m) SWH (m) Mode<br />

1.70 20.00 0 cargo<br />

2.56 10.00 0 cargo<br />

2.20 17.00 0 cargo<br />

13

<strong>PALFINGER</strong> BLADE ACCESS<br />

<strong>PALFINGER</strong> BLADE ACCESS (PBA) - FOR ON- AND OFFSHORE BLADE INSPECTION AND REPAIR<br />

<strong>PALFINGER</strong> BLADE ACCESS with a PK 40002 M foldable knuckle boom crane<br />

The <strong>PALFINGER</strong> BLADE ACCESS (PBA) is an innovative solution for safe blade<br />

inspection and effective repair of <strong>wind</strong> turbine blades both on- and offshore.<br />

Compared with the conventional method, <strong>PALFINGER</strong> BLADE ACCESS represents an<br />

enormous improvement with regard to service work on <strong>wind</strong> blades. Due to the stable<br />

position the working zones are more secure than before and allow direct access<br />

to electricity and maintenance tools in the workman's basket. With this DNV GL<br />

certified product innovation, maintenance and service work of <strong>wind</strong> turbine blades<br />

can be performed in a safer and more cost-efficient way.<br />

With the <strong>PALFINGER</strong> <strong>MARINE</strong> nacelle crane PK 40002 M the basket is easily lifted<br />

into operation, attached to the blade and can be stored on-site at the ground base.<br />

The time consuming handling of equipment can be reduced to a minimum. Due to<br />

the blade-guided design the service engineers follow the contours of the blade and<br />

remain at the same distance from the blade at all times.<br />

Transport and setup can be handled faster and safer than before, which allows<br />

the service team to spend more working-hours on the blade, even in bad weather<br />

conditions. The basket has enough space for two technicians and working tools and<br />

allows even complex tasks to be performed while on the blade.<br />

ADVANTAGES<br />

è On- and offshore applicatons<br />

è Space for two technicians in the basket<br />

è Blade-guided design<br />

è Designed with GPR<br />

(glass-reinforced plastic)<br />

è Low weight<br />

è Effective repair of the leading edge<br />

è Safe working environment<br />

è Fast up- and downtime<br />

è Direct access to electricity<br />

è Space for maintenance tools in the basket<br />

è Handling time for equipment is minimised<br />

Based on customer requirements, this patented package<br />

solution promises a better way to perform maintenance work<br />

on <strong>wind</strong> blades.<br />

14

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

DNV GL certified<br />

Non-corrosive fibre composite<br />

Stainless steel structure<br />

Space for two technicians and equipment in the working basket<br />

20 minutes to travel from ground level to the blade interface<br />

Designed for storage at the platform<br />

Parking on-site during service work<br />

SPECIFICATIONS<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Main dimensions:<br />

Width: 2564 mm<br />

Height: 3191 mm<br />

Depth: 889 mm<br />

Person freestanding height at 2100 mm<br />

Total net weight: 221 kg<br />

Total net weight: 495 kg incl. payload<br />

Corrosion grade: C5 high<br />

SERVICE RANGE<br />

è<br />

Leading edge and approx. 500 mm on both sides of the <strong>wind</strong> blade<br />

Wind Cranes<br />

Blade-guided design Man-riding basket for two persons Working area leading edge<br />

15

DECK EQUIPMENT<br />

FOR WIND FARM<br />

OPERATION<br />

VESSELS<br />

16

06<br />

06<br />

04<br />

03<br />

03<br />

06<br />

04<br />

06 06<br />

04<br />

03<br />

04<br />

04<br />

04<br />

04<br />

05<br />

04 03<br />

05<br />

05<br />

03<br />

07<br />

04<br />

04<br />

04<br />

04<br />

03<br />

04<br />

03<br />

03<br />

05<br />

05<br />

04<br />

03<br />

03<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> has for 03 decades been at the forefront when it comes to deck<br />

equipment and handling solutions for vessels operating in the offshore market. For<br />

vessels operating in the offshore <strong>wind</strong> segment, <strong>PALFINGER</strong> <strong>MARINE</strong> has developed<br />

03<br />

03 03<br />

specialised deck equipment and handling solutions suitable for the special needs<br />

on board service operation vessels (SOVs). The product portfolio covers cranes,<br />

winches, davit systems and boats in addition to dedicated cargo handling solutions<br />

enabling faster and safer operations when servicing the <strong>wind</strong> farms.<br />

Lifetime excellence is the promise. The entire product range is characterised by<br />

user-friendly functional design with low maintenance requirements and high-quality<br />

materials and components. The extensive <strong>PALFINGER</strong> <strong>MARINE</strong> global service<br />

network guarantees its customers effective and reliable lifetime support for all<br />

products over the entire life cycle.<br />

Product Range<br />

è Davit Systems<br />

è Boats<br />

è Winches<br />

è Lifting and Handling Equipment<br />

è Marine and Offshore Cranes<br />

17

DAVIT SYSTEMS<br />

(FAST) RESCUE BOAT DAVITS<br />

PRH-AP SERIES<br />

The PRH-AP series is a fully hydraulic pivoting anti-pendulum davit range, suitable for handling a (fast) rescue boat. The davit is equipped with a<br />

well-dimensioned “shock absorber” system to prevent overloading of the davit system in rough operation conditions. The winch is equipped with<br />

a fully hydraulic constant tension system. For proper retrieval and operation of the boat, a tried-and-tested hydraulically operated anti-pendulum<br />

docking head is mounted onto the davit top frame.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Easy to install (plug and play)<br />

Provided with self-contained HPU<br />

Trouble-free and easy to maintain<br />

Foldable davit arm for easy transportation<br />

Wave compensation system (PRH-H & AP)<br />

OPTIONS<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Paint system for marine environment<br />

Shock absorber<br />

Wave compensation (PRH-H & AP)<br />

Boat supports<br />

Ex-proof<br />

Heating system<br />

SWL (kN) Hoisting speed Operation<br />

37.5 Hydraulic, 0–48 m/min<br />

Fully hydraulically<br />

operated davit system,<br />

with integrated antipendulum<br />

docking head<br />

Configuration<br />

Pivoting:<br />

Hoisting:<br />

Hydraulic<br />

Hydraulic, 48 m/min<br />

PRHE SERIES<br />

The PRHE series is a hydraulically pivoting davit range, suitable for handling a (fast) rescue boat up to 36 kN with its full complement of persons<br />

and equipment.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Hydraulic pivoting and electric hoisting<br />

Easy to install (plug and play)<br />

Provided with self-contained stainless steel HPU<br />

Easy to maintain<br />

Foldable davit arm for easy transportation<br />

OPTIONS<br />

è<br />

è<br />

è<br />

è<br />

Paint system for marine environment<br />

Shock absorber<br />

Boat supports<br />

Heating system<br />

SWL (kN) Hoisting speed Operation<br />

20–36 Electric, 0–18 m/min<br />

Configuration<br />

Hydraulic pivoting and<br />

electric hoisting<br />

Pivoting:<br />

Hoisting:<br />

Hydraulic<br />

Electric, 18 m/min<br />

18

PRHE-H SERIES<br />

The PRHE-H series is a hydraulically pivoting davit range, suitable for handling a (fast) rescue boat weighing up to 36 kN with its full complement<br />

of persons and equipment.<br />

FEATURES<br />

è Hydraulic pivoting and hydraulic hoisting / lowering<br />

è Relatively low davit weight and reaction forces<br />

è Provided with self-contained HPU<br />

è Trouble-free and easy to maintain<br />

è Easy to operate<br />

OPTIONS<br />

è Paint system for marine environment<br />

è Shock absorber<br />

è Boat supports<br />

è Ex-proof<br />

è Heating system<br />

SWL (kN) Hoisting speed Operation<br />

27.5–36 Hydraulic, 0–18 m/min<br />

Hydraulic pivoting and<br />

hydraulic hoisting<br />

Configuration<br />

Pivoting:<br />

Hydraulic<br />

Hoisting:<br />

Hydraulic, 18 m/min<br />

PRH-H SERIES<br />

The PRH-H Series is a fully hydraulic pivoting davit range, suitable for handling a (fast) rescue boat up to 37.5 kN with its full complement of<br />

persons and equipment.<br />

FEATURES<br />

è Fully hydraulically operated davit system<br />

è Compact and proven design<br />

è Provided with self-contained HPU<br />

è Trouble-free and easy to maintain<br />

è Optionally equipped with wave compensation system<br />

OPTIONS<br />

è Paint system for marine environment<br />

è Shock absorber<br />

è Boat supports<br />

è Ex-proof<br />

è Heating system<br />

Davit Systems<br />

SWL (kN) Hoisting speed Operation<br />

27.5–37.5 Electric, 0–18 m/min<br />

Hydraulic pivoting and<br />

electric hoisting<br />

Configuration<br />

Pivoting:<br />

Hydraulic<br />

Hoisting:<br />

Hydraulic, 18 m/min or 48 m/min<br />

19

DAVIT SYSTEMS<br />

LIFE RAFT DAVITS<br />

SCM-L SERIES<br />

The SCM-L series is a manual slewing davit range, suitable for handling life raft(s) with a capacity of up to 39 persons.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Slewing davit for life rafts with up to 39 persons<br />

Standard and proven design<br />

Easy to install<br />

Low cost of ownership<br />

Easy to operate<br />

OPTIONS<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Paint system for marine environment<br />

Stainless steel automatic release hook<br />

SWL: 36 kN<br />

Pedestal<br />

Quick return unit<br />

SWL (kN)<br />

Radius /<br />

Outreach (m)<br />

Lift raft<br />

capacity<br />

Operation<br />

15–36 3.5–4.0 ≤ 39 pers. Manual slewing<br />

WORKBOAT / DAUGHTER CRAFT DAVITS<br />

PRH-AP SERIES<br />

The PRH-AP series is a fully hydraulic pivoting anti-pendulum davit range, suitable for handling a workboat / daughter craft.<br />

The range is equipped with a well-dimensioned “shock absorber” system to prevent overloading of the davit system in rough operation<br />

conditions. The winch is equipped with a fully hydraulic constant tension system.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

Hydraulic pivoting A-frame davit with<br />

anti-pendulum docking head (AP)<br />

Winch equipped with fully hydraulic<br />

constant tension system<br />

Hydraulically operated anti-pendulum docking head<br />

Increased safety for crew due to AP docking head<br />

OPTIONS<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Paint system for marine environment<br />

Shock absorber<br />

Wave compensation (PRH-H & AP)<br />

Boat supports<br />

Ex-proof<br />

Heating system<br />

SWL (kN) Hoisting speed Operation<br />

45 – 135 Hydraulic, 0 – 48 m/min<br />

Fully hydraulically<br />

operated davit system,<br />

with integrated antipendulum<br />

docking head<br />

Configuration<br />

Pivoting:<br />

Hoisting:<br />

Hydraulic<br />

Hydraulic, 48 m/min<br />

20

PFH-CT SERIES<br />

The PFH-CT series is a workboat double arm pivot davit range, suitable for handling a workboat with its full complement of persons and inventory<br />

weighing up to 220 kN.<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

Hydraulic pivoting dual-point davit<br />

Two independently operated<br />

constant tension winches<br />

Hydro-pneumatic shock absorber<br />

Stainless steel operating console<br />

OPTIONS<br />

è<br />

è<br />

è<br />

è<br />

Paint system for marine environment<br />

Shock absorber<br />

Ex-proof<br />

Heating system<br />

SWL (kN)<br />

Available versions<br />

80–220 Hydraulic pivoting dual-point davit skid-mounted or free-standing<br />

HOTT SERIES<br />

The HOTT 35 davit is a suspended roof-mounted davit consisting of a base frame, extractable davit arm, drive gear, hydraulic winch and<br />

hydraulic power pack. Suitable for handling a workboat / daughter craft with its full complement of persons and inventory up to 70 kN.<br />

FEATURES<br />

è<br />

è<br />

è<br />

Roof-mounted telescopic davit<br />

Hydraulic power pack<br />

Hydraulically operated winch<br />

OPTIONS<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Paint system for marine environment<br />

Shock absorber<br />

Wave compensation (PRH-H & AP)<br />

Ex-proof<br />

Heating system<br />

Davit Systems<br />

SWL (kN)<br />

Available versions<br />

25–75 Roof-mounted telescopic davit<br />

21

BOATS<br />

CREW TRANSFER BOATS<br />

PB 600<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

Hull and console made of seawater-resistant aluminium<br />

or glass reinforced plastic (GRP)<br />

Speed with 3 persons, no deck load >30 knots<br />

Single inboard diesel with single waterjet<br />

>550 kg bollard pull<br />

Type Dimensions (m) Capacity (max. persons @ 82.5 kg) Weight (kg incl. max. persons) Propulsion<br />

PB 600 A CREW TRANSFER BOAT SID 6.40 x 2.40 4 persons Approx. 3,000 Single waterjet<br />

PB 600 G CREW TRANSFER BOAT SID 6.40 x 2.40 4 persons Approx. 3,000 Single waterjet<br />

PB 700<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

Hull and console made out of seawater resistant aluminium<br />

Speed with 3 persons, no deck load >30 knots<br />

Bollard pull >550 kg (SID) / >1,100 kg (TID)<br />

Weight fully loaded approx. 3,300 kg (SID) / 3,800 kg (TID)<br />

Type Dimensions (m) Capacity (max. persons @ 82.5 kg) Weight (kg incl. max. persons) Propulsion<br />

PB 700 A CREW TRANSFER BOAT SID 7.14 x 2.70 4 persons 3,300 Single waterjet<br />

PB 700 A CREW TRANSFER BOAT TID 7.22 x 2.80 4 persons 3,300 Twin waterjet<br />

PB 850<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

Hull and console made out of seawater resistant aluminium<br />

Speed with 3 persons, no deck load >30 knots<br />

Bollard pull >700 kg (SID) / >1,100 kg (TID)<br />

Weight fully loaded approx. 4,600 kg (SID) / 4,800 kg (TID)<br />

Type Dimensions (m) Capacity ( max. persons @ 82.5 kg) Weight (kg incl. max. persons) Propulsion<br />

PB 850 A CREW TRANSFER BOAT SID 8.50 x 3.20 8 persons Approx. 4,600 Single waterjet<br />

PB 850 A CREW TRANSFER BOAT TID 8.50 x 3.20 8 persons Approx. 4,600 Twin waterjet<br />

22

PB 950<br />

FEATURES<br />

è Hull and console made of seawater-resistant aluminium<br />

è Twin waterjet, high manoeuvrability<br />

è Bollard pull = 3 t<br />

è Ease of maintenance, sufficient space in the engine room<br />

è Towing post integrated in hoisting arrangement<br />

è Flush working deck of 14 m²<br />

Type Dimensions (m) Capacity (max. persons @ 82.5 kg) Weight (kg incl. max. persons) Propulsion<br />

PB 950 A WORKBOAT 9.77 x 3.50 6 persons Approx. 7,540 Twin waterjet<br />

PB 1100 / 1200<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Hull and console made of seawater-resistant aluminium<br />

Speed with 8 persons, full tank 30 knots<br />

(PB 1000) / 30–35 knots (PB 1200)<br />

Twin waterjet, high manoeuvrability<br />

Bollard pull >1,300 kg<br />

Weight fully loaded approx. 7,400 kg (SID) / 8,600 kg (TID)<br />

Low maintenance on the aluminium hull<br />

Type Dimensions (m) Capacity (max. persons @ 82.5 kg) Weight (kg incl. max. persons) Propulsion<br />

PB 1100 A CREW TRANSFER BOAT 10.32 x 3.40 10 persons Approx. 7,400 Twin waterjet<br />

PB 1200 A CREW TRANSFER BOAT TID 12 x 3.40 10 persons Approx. 8,600 Twin waterjet<br />

DAUGHTER CRAFT<br />

FRSQ 1000<br />

FEATURES<br />

è<br />

è<br />

è<br />

è<br />

è<br />

è<br />

Hull and console made of seawater-resistant aluminium<br />

Bollard pull >1,300 kg<br />

Deep V-bottom construction suitable for high speeds<br />

and high stability in any offshore environment<br />

Complies with UKOAA / SOLAS regulations<br />

Delivered with design approval and certificate of inspection<br />

Excellent reachability of the engines for maintenance<br />

purposes<br />

Boats<br />

Type Dimensions (m) Capacity ( max. persons @ 82.5 kg) Weight (kg incl. max. persons) Propulsion<br />

FRSQ 1000 A DAUGHTER CRAFT 10.35 x 3.50 15 persons Approx. 7,400 Twin waterjet<br />

23

WINCHES<br />

ANCHOR WINDLASS WINCHES<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> anchor <strong>wind</strong>lass winches<br />

are offered in a variety of configurations and<br />

sizes to handle virtually any anchor application.<br />

Anchor <strong>wind</strong>lass winches by <strong>PALFINGER</strong><br />

<strong>MARINE</strong> have a rugged design including a<br />

fabricated steel construction, heavy-duty split<br />

bronze bearings, gears hardened to exceed<br />

working load requirements, clutched and<br />

braked drums and high corrosion resistance.<br />

The winch design provides easy access to all<br />

points of lubrication and inspection. Wire drum<br />

<strong>wind</strong>lass winches can be delivered (without<br />

cable lifters). Windlass winches are supplied<br />

with roller type chain stoppers suitable for<br />

withstand 80 % of the chain breaking force.<br />

FEATURES<br />

OPTIONS<br />

è Electric or hydraulic drive<br />

è Rated pull (cable lifters) according to class<br />

è Single or double configuration<br />

è Chain size from 36–160 mm<br />

è Manually operated clutch<br />

è Manually operated band brake<br />

è Local control<br />

è With or without mooring drum<br />

è Auto tension / tension control (for mooring drums)<br />

è With or without warping end<br />

è Chain length and / or speed measurement<br />

è Bridge-operated anchor drop<br />

è Hydraulically operated brake<br />

è Remote control (wireless)<br />

24

MOORING WINCHES<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> offers a range of mooring<br />

winches for all types of vessels with almost<br />

unlimited speed and line pull capacities.<br />

The rugged design is ideal for harsh and<br />

demanding offshore conditions and includes<br />

heavy-duty split bronze bearings. The operating<br />

mechanisms for brakes and clutches are<br />

designed for easy and safe manual operation<br />

but may also be remotely operated by hydraulic<br />

cylinders. The winch design provides easy<br />

access to all points for lubrication and<br />

inspection.<br />

FEATURES<br />

OPTIONS<br />

è Electric or hydraulic drive<br />

è Single- or multi-drum configuration<br />

è With or without warping end<br />

è Rated pull: 5–40 t<br />

è Manually operated clutch and band brake<br />

è Local control<br />

è Auto tension / tension control<br />

è Split drums<br />

è Hydraulically operated band brake<br />

è Hydraulically operated clutch<br />

è Light line speed<br />

è Remote control (wireless)<br />

CAPSTANS<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> offers a range of capstans for various mooring<br />

operations. Hydraulic capstans are designed with internal drive systems<br />

in order to save space on board the vessel. Electric capstans can be<br />

incorporated directly into the deck structure by means of foundation<br />

pipe pieces. The foundations are open at the bottom and make it easy to<br />

connect the motors from below deck. Electric capstans are delivered with<br />

DOL or frequency converters for variable speed.<br />

BOLLARD CAPSTANS<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> combined bollard capstans (powered bollards) have<br />

a space-saving design to make efficient use of deck space on board the<br />

vessel. They combine the features of a standard capstan (rotating part)<br />

with the features of a standard bollard (non-rotating part).<br />

FEATURES<br />

FEATURES<br />

è Electric or hydraulic drive<br />

è Rated pull: 3–15 t<br />

è Local control or remote control with cable<br />

è Electric or hydraulic drive<br />

è Rated pull: 5–10 t<br />

è Local control or remote control with cable<br />

Winches and<br />

Offshore<br />

Equipment<br />

25

LIFTING AND HANDLING EQUIPMENT<br />

CONTAINER AND PALLET HANDLING SYSTEM<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is the supplier of an automated system for safe, efficient and easy handling of containers, pallets and loose goods on<br />

board <strong>wind</strong> mill service operation vessels (SOVs).<br />

The standard CPHS system consists of:<br />

è Main rails and transverse bridge<br />

è Transverse trolley with integrated jigger winch<br />

è Adjustable container spreader with automated twist locks<br />

è Hydraulically operated pallet fork unit and 1 t auxiliary winch<br />

The system is highly adaptable and suitable for various vessel designs as well as retrofitting to existing vessels. This specialised overhead<br />

travelling crane is equipped with a telescopic container spreader for handling both 10' and 20' ISO containers.<br />

MAIN SYSTEM CONFIGURATION<br />

The CPHS can be delivered in two different main configurations:<br />

1. Container yoke for containers in longitudinal direction<br />

2. Container yoke for containers in transverse direction<br />

The key differences between the two main configurations are the free installation height required in the container store. The system can be<br />

adapted to the length and width of the container store.<br />

FEATURES<br />

OPTIONS<br />

è<br />

Rated capacity: container lifting 12–25 t<br />

è<br />

AUX winch integrated in trolley for handling loose goods<br />

è<br />

Rated capacity: pallet fork 1 t<br />

è<br />

Detachable pallet fork with quick connectors<br />

è<br />

Rated capacity: winch 1 t<br />

è<br />

Radio remote control<br />

è<br />

Container size: standard 10' and 20' ISO or PWHC containers<br />

è<br />

Pallet size: EUR pallet (1200 x 800 mm)<br />

è<br />

Local control: portable cable-based control panel<br />

26

TRANSVERSE TROLLEY SPECIFICATIONS<br />

è Electric power supply: by conductor system<br />

è Hydraulic power supply: HPU integrated in trolley<br />

è Drive type: tooth rack and pinion<br />

è Drive unit, trolley: 2 electric motors and gears<br />

è Suspension: wheels, running on girders<br />

è Container lifting: hydraulic cylinder (jigger winch)<br />

è Control: portable control panel<br />

CONTAINER SPREADER SPECIFICATIONS<br />

è Telescopic yoke: 2 hydraulic cylinders<br />

è Container gripping: hydraulically operated twist locks<br />

è Suspension: mechanical guides and wire rope<br />

è Length, extended: 6,060 mm<br />

è Length, retracted: 3,012 mm<br />

è Container size: standard 10' and 20' ISO or PWHC containers<br />

è Container lifting height: 200 mm<br />

è Control: portable control panel<br />

PALLET FORK SPECIFICATIONS<br />

è Rated capacity: 1 t<br />

è Pallet fork lifting: hydraulic cylinder<br />

è Pallet fork rotation: hydraulic motor and slewing ring<br />

è Pallet fork extender: hydraulic cylinder<br />

è Suspension: quick connect interface in spreader<br />

è Hydraulic connections: quick connect/disconnect<br />

è Vertical movement: 1,600 mm<br />

è Fork length: 1,620–2,520 mm<br />

è Fork centre distance: 450 mm<br />

è Slewing sector: 0–360°<br />

AUX. WINCH SPECIFICATIONS<br />

è Drive: 2 hydraulic motors<br />

è Pulling force: 1 t<br />

è Drum / flange diameter: 273/432 mm<br />

è Drum length: 290 mm<br />

è Wire diameter: 8 mm<br />

è Rope capacity: 20 m<br />

è FEM: M4-T5-L1<br />

è Control: portable control panel<br />

Winches and<br />

Offshore<br />

Equipment<br />

27

LIFTING AND HANDLING EQUIPMENT<br />

ONBOARD SLIPWAYS<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> supplies highly innovative on board slipway systems for stowage, launch and recovery of small crafts up to 12 m<br />

such as rescue boats and daughter crafts on board offshore vessels and <strong>wind</strong> farm service operation vessels (SOVs). The system can<br />

be delivered mounted on a hydraulic frame (with hydraulic cylinders for lifting the entire frame) or for mounting directly into the hull<br />

structure of the mother vessel. All systems are adapted according to vessel structure in addition to the length and hull shape of the small<br />

crafts. <strong>PALFINGER</strong> <strong>MARINE</strong> works closely with customers and design companies in order to find the optimal and most cost-efficient<br />

solution according to the intended usage, speed, type of craft, wave height, sea state and redundancy requirements in addition to<br />

material, weight and space constraints.<br />

One-man operation<br />

Adaptable wheel sets<br />

Safe launch and recovery<br />

28

BENEFITS<br />

Safe operations<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> slipway systems eliminate the use of hooks, painter line, or arrester wire during normal operation, reducing the risk<br />

of dangerous situations during launch and recovery operations. Embarking, disembarking and operation are designed to be safe and<br />

easy, even in harsh conditions.<br />

Faster work cycles and increased productivity<br />

The <strong>PALFINGER</strong> <strong>MARINE</strong> multi-craft slipway system enables the SOV to launch several personnel and cargo transfer boats in order<br />

to service more than one <strong>wind</strong> mill at a time. By using personnel and cargo transfer boats, the SOV does not have to wait for service<br />

personnel at the <strong>wind</strong> mill, eliminating the need for the SOV to drop off and pick up personnel and goods at each individual <strong>wind</strong> mill<br />

unit. The SOV can use gangways at easily accessible <strong>wind</strong> mills and deploy personnel and cargo transfer boats at <strong>wind</strong> mills with difficult<br />

access.<br />

Lower fuel consumption and emissions<br />

The SOV does not have to approach each and every <strong>wind</strong> mill unit to transfer personnel and cargo, saving time- and fuel-consuming<br />

manoeuvring operations at each <strong>wind</strong> mill.<br />

Lower risk of damage to <strong>wind</strong> mill installation<br />

By using personnel and cargo transfer boats, the SOV can stay at a distance during supply operations, reducing the risk of collisions<br />

between the SOV and the <strong>wind</strong> mill installations.<br />

FEATURES<br />

OPTIONS<br />

è Single or double/parallel slipways with wheels<br />

è Deck- or frame-mounted<br />

è Fixed wheel foundations<br />

è Hydraulic drive<br />

è Local control<br />

è Backup winch system for emergencies<br />

è Overrunning clutches on wheels<br />

(allow high-speed entry)<br />

è Stored power package<br />

è Different types of stern arrangement – extension of the<br />

slipway into the sea<br />

è Adjustable wheel foundations to adapt for different small<br />

craft configurations<br />

è No drive on wheels (gravity launch with small craft<br />

providing power for recovery)<br />

è Remote control<br />

è Training<br />

MULTI-CRAFT SLIPWAY SYSTEM<br />

Winches and<br />

Offshore<br />

Equipment<br />

29

<strong>MARINE</strong> AND OFFSHORE CRANES<br />

3D-COMPENSATED CRANES<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> has developed a new modular, 3D-compensation unit, for use on <strong>wind</strong> farm service operation vessels (SOVs) for<br />

increased vessel operability. Hence enabling smaller and more cost-effective vessels to be used in harsher weather conditions.<br />

Typical operations:<br />

è Offshore <strong>wind</strong> turbine supply and maintenance operations<br />

è Work towards all kind of fixed installations where elimination of ship motion is required ensure safer and improved lifting operation<br />

The 3D-compensation module is designed for mounting on <strong>PALFINGER</strong> <strong>MARINE</strong> offshore cranes - knuckle boom cranes, telescopic cranes<br />

or stiff boom cranes - on board vessels to transfer goods to and from <strong>wind</strong> mills or other fixed installations. The 3D-compensation module<br />

can be dismounted and parked in a separate cradle, allowing the crane to be used as a standard offshore crane.<br />

The 3D-compensation increases the operational safety and eases transfer and lifting/landing. It enables positioning of the cargo on the <strong>wind</strong><br />

turbine or substations/installation despite movements of the vessel due to waves and currents, as the 3D-compensation keeps the load<br />

vertically steady and the boom tip horizontally steady.<br />

The low weight which is being compensated gives an advantage, as it influences less on the ship stabilising systems and also requires less<br />

power consumption when in 3D mode.<br />

The unit has very high performance with high accuracy due to the state of the art, tailormade MRU unit located on the unit itself.<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> has put great effort into making a more user-friendly interface (HMI) from the operator cabin display and on the radio<br />

remote controllers used for smaller cranes.<br />

30

Crane compensation: HEAVE<br />

è Movements in vertical direction<br />

Crane compensation: ROLL<br />

è Rotation around longitudinal axis<br />

Crane compensation: PITCH<br />

è Rotation around transversal axis<br />

FEATURES<br />

OPTIONS<br />

è Knuckle boom jib crane<br />

è 3-axis hydraulic motion compensation system for pitch,<br />

roll and heave<br />

è 3D unit powered by crane power pack using quick<br />

connections<br />

è Motion reference unit (MRU)<br />

è MOPS - Manual Overload Protection System<br />

è AOPS - Automatic Overload Protection System<br />

è Min./max. payload in 3D-compensation mode: 1–3 t<br />

è May be fitted on any size of offshore knuckle boom jib<br />

crane<br />

è Operational <strong>wind</strong>ow up to approximately 3 m wave height,<br />

wave period 4–20 s<br />

è Compensation working range is approximately 6 m in<br />

vertical, 5.5 m in radial and +/- 1.5 m in slewing direction<br />

è Radio or cable remote control systems<br />

è Active Heave Compensation on heave can be added for<br />

increased performance<br />

è Anti-collision system mounted in the boom tip<br />

è Operator cabin (with A/C)<br />

è Centralised greasing system<br />

è Further options available upon request<br />

Offshore Cranes<br />

31

<strong>MARINE</strong> AND OFFSHORE CRANES<br />

ACTIVE HEAVE COMPENSATED (AHC) CRANES<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> delivers AHC offshore cranes ranging from smaller models for SOVs to larger models for subsea lifts, in addition<br />

to special systems for module handling deployments. All cranes are tailormade to meet customer requirements and can be delivered in<br />

various configurations. The AHC system is developed for the harsh offshore environment. The rugged design by experienced engineers,<br />

ensures trouble-free operation under the most extreme conditions.<br />

AHC CRANE DESIGN FEATURES<br />

LOW WEIGHT AND CENTRE OF GRAVITY<br />

è Low-built design<br />

è All components and the AHC winch placed as low as possible to ensure low weight and centre of gravity<br />

è High lifting capabilities compared to weight and centre of gravity maximise the cargo capacity on deck<br />

è Maximises wire capacity on the AHC winch while maintaining safe fleet angles<br />

LOW POWER CONSUMPTION<br />

è Advanced hydraulic drive system and smart system design to share the available power effectively between the different functions<br />

è Low installed power compared to AHC performance and available hoisting speeds<br />

HIGH PERFORMANCE<br />

è Capacity to reduce movement by up to 98 %<br />

è Optimised drive train for correct speed and high capacity<br />

OPERATOR EGONOMICS AND MAINTENANCE ACCESS<br />

è State-of-the-art operator cabin environment<br />

è Designed for easy access to all points of maintenance, inspection and service<br />

HYDRAULIC SYSTEM<br />

è HPU placed inside crane pedestal (no need for container system)<br />

è Zero load drop when the brake is removed, no need for tuning of the system with different loads<br />

è Load can be held in subsea mode with brake off and all safety systems active for several days if necessary without any movement<br />

of the load due to leakage in the hydraulic system<br />

32

100 T AHC CRANE 5 T AHC CRANE AHC WINCH<br />

è Low centre of gravity<br />

è Low weight<br />

è Low power consumption<br />

è Superior AHC performance<br />

è Low weight<br />

è Extended outreach for <strong>wind</strong> mill<br />

operations<br />

è Secondary controlled drive technology<br />

è Extremely high acceleration<br />

è Accurate speed and tension control<br />

è Reliable and safe<br />

FEATURES<br />

OPTIONS<br />

è Fully equipped operator cabin<br />

è Up to 3,000 m capacity wire<br />

è AOPS / MOPS / TENSIONING<br />

è Flood lights<br />

è Boom tip camera<br />

è Helicopter lights<br />

è Emergency backup control system<br />

è Design according to DNV 2.22<br />

è Tugger winches<br />

è Aux winch (with or without AHC winch)<br />

è Fibre rope solution<br />

è Pedestal adapter<br />

è Hazardous zone classification<br />

è Lift planning tool<br />

è Remote diagnostics<br />

è Winch below deck<br />

è Design according to EN 13852 / NORSOK<br />

è 3D compensation unit<br />

Offshore Cranes<br />

33

<strong>MARINE</strong> AND OFFSHORE CRANES<br />

FOLDABLE KNUCKLE BOOM CRANES<br />

PSM 400 stiff boom platform crane<br />

PK 23500 M foldable knuckle boom crane on a <strong>wind</strong> farm service vessel<br />

© by Sure Wind Marine<br />

The foldable knuckle boom range is used for loading, unloading and cargo lifting on the deck of <strong>wind</strong> farm supply and service vessels.<br />

Due to the compact construction, the cranes can easily be accommodated on every type of vessel, especially where space is limited.<br />

Adding various features and options make the foldable knuckle boom cranes a multi-functional tool.<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> foldable knuckle boom cranes can be designed in accordance with the special offshore rules and regulations.<br />

Crane type Max outreach (m) Lifting capacity (t) Total moment (kNm)<br />

Foldable knuckle boom crane PK range 3.4–21.2 0.5–26.4 45–1176<br />

Foldable knuckle boom crane PFM range 7.5–20.2 5–32 1883–4059<br />

FEATURES<br />

OPTIONS<br />

è Long-life surface treatment:<br />

corrosion protection<br />

è Low- / high-temperature operations<br />

è LeBus grooved winch drums<br />

è Return oil utilisation<br />

è Continuous slewing system<br />

è Power link system<br />

è Constant tensioning<br />

è Remote control<br />

è Standing platform<br />

è Operator cabin<br />

è Overload protection: MOPS, AOPS<br />

è Offshore control system (OCS)<br />

è Lifting of personnel – man-riding<br />

è Workman basket<br />

è External hydraulic power packs<br />

è Local control stand (FLVK)<br />

34

KNUCKLE BOOM CRANES<br />

DKF 2000<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> supplies a wide range of knuckle boom cranes for various applications. Knuckle boom cranes are designed to lift high<br />

loads with an extended jib and provide the operator with great flexibility during lifting operations. Movements of the load can be limited as<br />

the boom tip can be kept closer to the deck. A high level of control makes the crane ideal for offshore lifting operations in higher sea states.<br />

Severe weather conditions with heavy seas introduce oscillating motions to suspended loads. The range includes cranes with up to 250 t<br />

SWL lifting capacity.<br />

Crane type Max outreach (m) Lifting capacity (t) Total moment (kNm)<br />

Knuckle boom crane PKM range 8–25 1.1–9 267–2,840<br />

Knuckle boom crane DKF range 10–55 1–250 3,500–60,000<br />

FEATURES<br />

OPTIONS<br />

è Long-life surface treatment:<br />

è Tugger winches<br />

è Design in accordance with rules<br />

corrosion protection<br />

è Constant tensioning<br />

and regulations (API 2C, EN13852,<br />

è Operation from control platform on<br />

è Remote control<br />

NORSOK, etc.)<br />

crane<br />

è Operator cabin<br />

è Diesel hydraulic drive<br />

è Electro-hydraulic drive<br />

è Overload protection: MOPS, AOPS<br />

è Shock absorber<br />

è Continuous slewing<br />

è Offshore control system (OCS)<br />

è Metallising<br />

Marine Cranes<br />

è Low- / high-temperature operations<br />

è Lifting of personnel - man-riding<br />

è Aux winch<br />

è External hydraulic power packs<br />

è LeBus drum<br />

è Anti-collision system<br />

è Docking head for boat handling<br />

è Active Heave Compensation (AHC)<br />

è Pipe gripper<br />

Offshore Cranes<br />

35

<strong>MARINE</strong> AND OFFSHORE CRANES<br />

STIFF BOOM CRANES<br />

DKF 220<br />

The <strong>PALFINGER</strong> <strong>MARINE</strong> telescopic boom cranes are based on a pedestal slewing design with hydraulic cylinder luffing. The boom<br />

extension is a telescopic inner section that allows a more flexible and wider operational radius in use and leaves the crane stored in a<br />

compact position. The advantages of the telescopic boom cranes are low weight and less complex design making them maintenancefriendly.<br />

Crane type Max outreach (m) Lifting capacity (t) Total moment (kNm)<br />

Stiff boom crane PSM range 6–21 0.9–12.5 270–3,750<br />

Stiff boom crane DK range 10–55 1–200 3,500–60,000<br />

FEATURES<br />

OPTIONS<br />

è Corrosion protection<br />

è Operation from control platform<br />

on crane<br />

è Electro-hydraulic drive<br />

è Continuous slewing<br />

è Low- / high-temperature operations<br />

è Constant tensioning<br />

è Remote control<br />

è Operator cabin<br />

è Overload protection: MOPS, AOPS<br />

è Offshore control system (OCS)<br />

è Lifting of personnel - man-riding<br />

è External hydraulic power packs<br />

è Anti-collision system<br />

è Active Heave Compensation (AHC)<br />

è Design in accordance with rules<br />

and regulations (API 2C, EN13852,<br />

NORSOK, etc.)<br />

è Diesel hydraulic drive<br />

è Shock absorber<br />

è Metalling<br />

è Aux winch<br />

è LeBus drum<br />

36

AFTER SALES AND SERVICE<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> is a dependable and professional partner in every situation and offers the best available customer service – from telephone<br />

assistance to on-time delivery and instant on-site support. All products are characterised by high value retention and low maintenance. This ensures<br />

safe and economical use. A growing network of service partners specially focused on offshore <strong>wind</strong> business ensures responsive, reliable and<br />

cost efficient service. The comprehensive range of service is provided to ensure highly reliable operation during the entire product life cycle.<br />

BEST AVAILABLE SERVICE<br />

è Installation and installation support<br />

è Commissioning supervision (onshore and offshore)<br />

è Annual service and inspection/maintenance<br />

è Local technical support<br />

è Service management database for technical documentation,<br />

service history and maintenance information<br />

è Always in compliance with the latest regulations<br />

è 1 st and 2 nd level support<br />

SERVICE AGREEMENTS<br />

è Customised packages for <strong>wind</strong> farm owners<br />

and operators<br />

è Maintenance planning, original spares and<br />

service crews<br />

è Packages for inspection, support, parts<br />

management and maintenace<br />

è Local service partner networks<br />

è Local OEM support<br />

TRAINING<br />

è Operator and maintenance training<br />

è On-site training<br />

è Detailed training documents and certificates<br />

è Training on different models in the <strong>PALFINGER</strong><br />

training centre<br />

è Main components available<br />

SPARE PARTS<br />

è Global delivery<br />

è <strong>PALFINGER</strong> and OEM spare parts<br />

è Life cycle supply of spare parts<br />

è Local storage of spare parts<br />

è Customised spare parts packages<br />

After Sales<br />

and Service<br />

37

<strong>PALFINGER</strong> <strong>MARINE</strong> WORLDWIDE<br />

Harderwijk (NL)<br />

Barneveld (NL)<br />

Seattle (USA)<br />

Odense (DK)<br />

Os (NO)<br />

Bergen (NO)<br />

Houston, Texas (USA)<br />

Salzburg (AT)<br />

Gdynia (PL)<br />

Maribor (SLO)<br />

Rio Grande do Sul (BR)<br />

Rio de Janeiro (BR)<br />

SALES AND SERVICE CONTACTS<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> GMBH<br />

Salzburg, Austria<br />

Marine Cranes, Wind Cranes<br />

info-marine@palfinger.com, <strong>wind</strong>@palfinger.com<br />

Odense, Denmark<br />

Wind Cranes<br />

<strong>wind</strong>@palfinger.com<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> DO BRASIL LTDA.<br />

Rio de Janeiro, Brazil<br />

All products<br />

s.barros@palfinger.com<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> NORWAY AS<br />

Os, Norway<br />

Winches and Offshore Equipment (formerly NDM)<br />

WOE.sales@palfinger.com<br />

Bergen, Norway<br />

Offshore Cranes<br />

OC.sales@palfinger.com<br />

<strong>PALFINGER</strong> ASIA PACIFIC PTE. LTD.<br />

Singapore<br />

All products<br />

marinesales.apac@palfinger.com<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> NETHERLANDS BV<br />

Barneveld, The Netherlands<br />

Davit Systems<br />

davitsystems@palfinger.com<br />

<strong>PALFINGER</strong> BOATS BV<br />

Harderwijk, The Netherlands<br />

Boats<br />

boats@palfinger.com<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> KOREA LTD.<br />

Busan, Korea<br />

Offshore Cranes, Wind Cranes<br />

marine.korea@palfinger.com<br />

<strong>PALFINGER</strong> <strong>MARINE</strong> US OFFICES<br />

Houston, Texas, USA<br />

All products<br />

info-marine@palfinger.com<br />

Seattle, Washington, USA<br />

Marine Cranes, Offshore Cranes<br />

b.jacob@palfinger.com<br />

38

Ishimbay (RU)<br />

Singapore (SG)<br />

Hanoi (VN)<br />

(2 production sites)<br />

Busan (KR)<br />

More than 130 service stations<br />

worldwide, a network of 14 fully<br />

owned sales and service hubs,<br />

eight fully owned production<br />