combined small

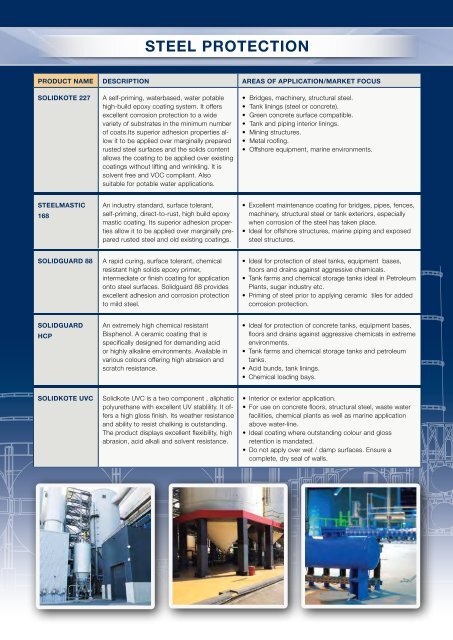

STEEL PROTECTION PRODUCT NAME DESCRIPTION AREAS OF APPLICATION/MARKET FOCUS SOLIDKOTE 227 A self-priming, waterbased, water potable high-build epoxy coating system. It offers excellent corrosion protection to a wide variety of substrates in the minimum number of coats.Its superior adhesion properties allow it to be applied over marginally prepared rusted steel surfaces and the solids content allows the coating to be applied over existing coatings without lifting and wrinkling. It is solvent free and VOC compliant. Also suitable for potable water applications. • Bridges, machinery, structural steel. • Tank linings (steel or concrete). • Green concrete surface compatible. • Tank and piping interior linings. • Mining structures. • Metal roofing. • Offshore equipment, marine environments. STEELMASTIC 168 An industry standard, surface tolerant, self-priming, direct-to-rust, high build epoxy mastic coating. Its superior adhesion properties allow it to be applied over marginally prepared rusted steel and old existing coatings. • Excellent maintenance coating for bridges, pipes, fences, machinery, structural steel or tank exteriors, especially when corrosion of the steel has taken place. • Ideal for offshore structures, marine piping and exposed steel structures. SOLIDGUARD 88 A rapid curing, surface tolerant, chemical resistant high solids epoxy primer, intermediate or finish coating for application onto steel surfaces. Solidguard 88 provides excellent adhesion and corrosion protection to mild steel. • Ideal for protection of steel tanks, equipment bases, floors and drains against aggressive chemicals. • Tank farms and chemical storage tanks ideal in Petroleum Plants, sugar industry etc. • Priming of steel prior to applying ceramic tiles for added corrosion protection. SOLIDGUARD HCP An extremely high chemical resistant Bisphenol. A ceramic coating that is specifically designed for demanding acid or highly alkaline environments. Available in various colours offering high abrasion and scratch resistance. • Ideal for protection of concrete tanks, equipment bases, floors and drains against aggressive chemicals in extreme environments. • Tank farms and chemical storage tanks and petroleum tanks. • Acid bunds, tank linings. • Chemical loading bays. SOLIDKOTE UVC Solidkote UVC is a two component , aliphatic polyurethane with excellent UV stablility. It offers a high gloss finish. Its weather resistance and ability to resist chalking is outstanding. The product displays excellent flexibility, high abrasion, acid alkali and solvent resistance. • Interior or exterior application. • For use on concrete floors, structural steel, waste water facilities, chemical plants as well as marine application above water-line. • Ideal coating where outstanding colour and gloss retention is mandated. • Do not apply over wet / damp surfaces. Ensure a complete, dry seal of walls.

PRODUCT GROUP CONCENTRATION % TEMPERATURE 0 C A b C D E Acetic Acid 10 60 NR NR NR NR VG 30 20 NR NR E NR VG blood – – E E E E E Calcium Chloride – – E E E E E Calcium Hydroxide 30 – E E E E E Citric Acid 30 20 E F E E E Copper Sulphate 30 20 E E E E E Formic Acid 30 20 NR NR E NR E 98 20 NR NR F NR F Petrol – – E E E E E Hydrofluoric Acid 48 20 NR NR E NR E Hydrogen Peroxide 100 20 G F E E E Lactic Acid 90 20 NR NR E NR E Nitric Acid 30 20 NR NR E NR E 69 20 NR NR NR NR NR Abbreviations Phosphoric Acid 5 20 E NR E VG E 50 20 E NR E E E Skydrol A500 – – E NR E E E Sodium Hydroxide 50 20 E E E E E 50 60 NR NR NR NR VG 5 20 E NR E F E Sulphuric Acid 30 20 G NR G NR G 98 20 NR NR NR NR NR Potassium Hydroxide 10 100 E E E E E 50 20 E E E E E

- Page 1: Corrosion ProteCtion P O L Y S C R

- Page 6 and 7: P O L Y S C R E E D Corrolam solidg

- Page 8 and 9: Mining Products INDEX Technical Fin

- Page 10 and 11: TECHNICAL DATA SHEET SOLIDGUARD 88

- Page 12 and 13: TECHNICAL DATA SHEET Eposhield HCP

- Page 14 and 15: TECHNICAL DATA SHEET Eposhield ST 1

- Page 16 and 17: TECHNICAL DATA SHEET Corrolam VEP G

- Page 18 and 19: TECHNICAL DATA SHEET SOLIDGUARD LV

- Page 20 and 21: TECHNICAL DATA SHEET SOLIDFIX FS WE

- Page 22 and 23: TECHNICAL DATA SHEET SOLIDWEAR HP 1

- Page 24 and 25: TECHNICAL DATA SHEET SOLIDWEAR HP 5

- Page 26 and 27: TECHNICAL DATA SHEET SOLIDWEAR HP 8

- Page 28 and 29: TECHNICAL DATA SHEET SOLIDBOND QSP

- Page 30 and 31: TECHNICAL DATA SHEET SOLIDBACK HP 1

- Page 32 and 33: TECHNICAL DATA SHEET SOLIDBACK ST 1

- Page 34 and 35: MATERIAL SAFETY DATA SHEET SOLIDGUA

- Page 36 and 37: MATERIAL SAFETY DATA SHEET SOLIDGUA

- Page 38 and 39: MATERIAL SAFETY DATA SHEET 5 Progre

- Page 40 and 41: MATERIAL SAFETY DATA SHEET SOLIDGUA

- Page 42 and 43: MATERIAL SAFETY DATA SHEET SOLIDWEA

- Page 44 and 45: MATERIAL SAFETY DATA SHEET SOLIDWEA

- Page 46 and 47: MATERIAL SAFETY DATA SHEET 41 Circu

- Page 48 and 49: MATERIAL SAFETY DATA SHEET SOLIDWEA

- Page 50 and 51: MATERIAL SAFETY DATA SHEET SOLIDWEA

- Page 52 and 53: MATERIAL SAFETY DATA SHEET SOLIDWEA

STEEL PROTECTION<br />

PRODUCT NAME DESCRIPTION AREAS OF APPLICATION/MARKET FOCUS<br />

SOLIDKOTE 227<br />

A self-priming, waterbased, water potable<br />

high-build epoxy coating system. It offers<br />

excellent corrosion protection to a wide<br />

variety of substrates in the minimum number<br />

of coats.Its superior adhesion properties allow<br />

it to be applied over marginally prepared<br />

rusted steel surfaces and the solids content<br />

allows the coating to be applied over existing<br />

coatings without lifting and wrinkling. It is<br />

solvent free and VOC compliant. Also<br />

suitable for potable water applications.<br />

• Bridges, machinery, structural steel.<br />

• Tank linings (steel or concrete).<br />

• Green concrete surface compatible.<br />

• Tank and piping interior linings.<br />

• Mining structures.<br />

• Metal roofing.<br />

• Offshore equipment, marine environments.<br />

STEELMASTIC<br />

168<br />

An industry standard, surface tolerant,<br />

self-priming, direct-to-rust, high build epoxy<br />

mastic coating. Its superior adhesion properties<br />

allow it to be applied over marginally prepared<br />

rusted steel and old existing coatings.<br />

• Excellent maintenance coating for bridges, pipes, fences,<br />

machinery, structural steel or tank exteriors, especially<br />

when corrosion of the steel has taken place.<br />

• Ideal for offshore structures, marine piping and exposed<br />

steel structures.<br />

SOLIDGUARD 88<br />

A rapid curing, surface tolerant, chemical<br />

resistant high solids epoxy primer,<br />

intermediate or finish coating for application<br />

onto steel surfaces. Solidguard 88 provides<br />

excellent adhesion and corrosion protection<br />

to mild steel.<br />

• Ideal for protection of steel tanks, equipment bases,<br />

floors and drains against aggressive chemicals.<br />

• Tank farms and chemical storage tanks ideal in Petroleum<br />

Plants, sugar industry etc.<br />

• Priming of steel prior to applying ceramic tiles for added<br />

corrosion protection.<br />

SOLIDGUARD<br />

HCP<br />

An extremely high chemical resistant<br />

Bisphenol. A ceramic coating that is<br />

specifically designed for demanding acid<br />

or highly alkaline environments. Available in<br />

various colours offering high abrasion and<br />

scratch resistance.<br />

• Ideal for protection of concrete tanks, equipment bases,<br />

floors and drains against aggressive chemicals in extreme<br />

environments.<br />

• Tank farms and chemical storage tanks and petroleum<br />

tanks.<br />

• Acid bunds, tank linings.<br />

• Chemical loading bays.<br />

SOLIDKOTE UVC<br />

Solidkote UVC is a two component , aliphatic<br />

polyurethane with excellent UV stablility. It offers<br />

a high gloss finish. Its weather resistance<br />

and ability to resist chalking is outstanding.<br />

The product displays excellent flexibility, high<br />

abrasion, acid alkali and solvent resistance.<br />

• Interior or exterior application.<br />

• For use on concrete floors, structural steel, waste water<br />

facilities, chemical plants as well as marine application<br />

above water-line.<br />

• Ideal coating where outstanding colour and gloss<br />

retention is mandated.<br />

• Do not apply over wet / damp surfaces. Ensure a<br />

complete, dry seal of walls.