C A T A L O G U E e n o l o g i c a l p r o d u c t s

160721085328

160721085328

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

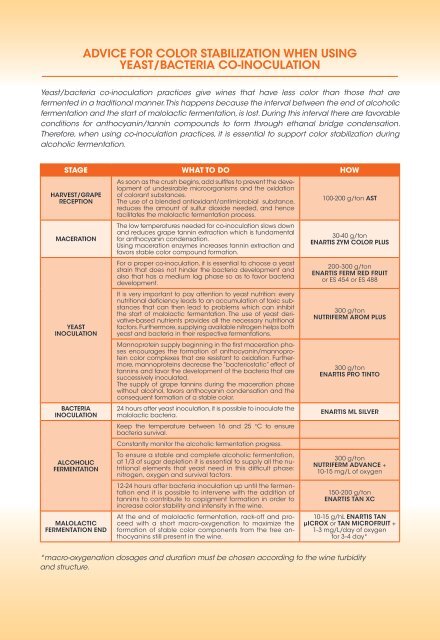

ADVICE FOR COLOR STABILIZATION WHEN USING<br />

YEAST/BACTERIA CO-INOCULATION<br />

Yeast/bacteria co-inoculation practices give wines that have less color than those that are<br />

fermented in a traditional manner. This happens because the interval between the end of alcoholic<br />

fermentation and the start of malolactic fermentation, is lost. During this interval there are favorable<br />

conditions for anthocyanin/tannin compounds to form through ethanal bridge condensation.<br />

Therefore, when using co-inoculation practices, it is essential to support color stabilization during<br />

alcoholic fermentation.<br />

STAGE WHAT TO DO HOW<br />

HARVEST/GRAPE<br />

RECEPTION<br />

MACERATION<br />

YEAST<br />

INOCULATION<br />

BACTERIA<br />

INOCULATION<br />

ALCOHOLIC<br />

FERMENTATION<br />

MALOLACTIC<br />

FERMENTATION END<br />

As soon as the crush begins, add sulfites to prevent the development<br />

of undesirable microorganisms and the oxidation<br />

of colorant substances.<br />

The use of a blended antioxidant/antimicrobial substance,<br />

reduces the amount of sulfur dioxide needed, and hence<br />

facilitates the malolactic fermentation process.<br />

The low temperatures needed for co-inoculation slows down<br />

and reduces grape tannin extraction which is fundamental<br />

for anthocyanin condensation.<br />

Using maceration enzymes increases tannin extraction and<br />

favors stable color compound formation.<br />

For a proper co-inoculation, it is essential to choose a yeast<br />

strain that does not hinder the bacteria development and<br />

also that has a medium lag phase so as to favor bacteria<br />

development.<br />

It is very important to pay attention to yeast nutrition: every<br />

nutritional deficiency leads to an accumulation of toxic substances<br />

that can then lead to problems which can inhibit<br />

the start of malolactic fermentation. The use of yeast derivative-based<br />

nutrients provides all the necessary nutritional<br />

factors. Furthermore, supplying available nitrogen helps both<br />

yeast and bacteria in their respective fermentations.<br />

Mannoprotein supply beginning in the first maceration phases<br />

encourages the formation of anthocyanin/mannoprotein<br />

color complexes that are resistant to oxidation. Furthermore,<br />

mannoproteins decrease the “bacteriostatic” effect of<br />

tannins and favor the development of the bacteria that are<br />

successively inoculated.<br />

The supply of grape tannins during the maceration phase<br />

without alcohol, favors anthocyanin condensation and the<br />

consequent formation of a stable color.<br />

24 hours after yeast inoculation, it is possible to inoculate the<br />

malolactic bacteria.<br />

Keep the temperature between 16 and 25 °C to ensure<br />

bacteria survival.<br />

Constantly monitor the alcoholic fermentation progress.<br />

To ensure a stable and complete alcoholic fermentation,<br />

at 1/3 of sugar depletion it is essential to supply all the nutritional<br />

elements that yeast need in this difficult phase:<br />

nitrogen, oxygen and survival factors.<br />

12-24 hours after bacteria inoculation up until the fermentation<br />

end it is possible to intervene with the addition of<br />

tannins to contribute to copigment formation in order to<br />

increase color stability and intensity in the wine.<br />

At the end of malolactic fermentation, rack-off and proceed<br />

with a short macro-oxygenation to maximize the<br />

formation of stable color components from the free anthocyanins<br />

still present in the wine.<br />

100-200 g/ton AST<br />

30-40 g/ton<br />

ENARTIS ZYM COLOR PLUS<br />

200-300 g/ton<br />

ENARTIS FERM RED FRUIT<br />

or ES 454 or ES 488<br />

300 g/ton<br />

NUTRIFERM AROM PLUS<br />

300 g/ton<br />

ENARTIS PRO TINTO<br />

ENARTIS ML SILVER<br />

300 g/ton<br />

NUTRIFERM ADVANCE +<br />

10-15 mg/L of oxygen<br />

150-200 g/ton<br />

ENARTIS TAN XC<br />

10-15 g/hL ENARTIS TAN<br />

μICROX or TAN MICROFRUIT +<br />

1-3 mg/L/day of oxygen<br />

for 3-4 day*<br />

*macro-oxygenation dosages and duration must be chosen according to the wine turbidity<br />

and structure.