CompAir- Rotary Screw Compressor-Cyclon.pdf

www.atlaspart.co

www.atlaspart.co

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cyclon</strong> <strong>Rotary</strong> <strong>Screw</strong> <strong>Compressor</strong>s - 5.5-75kW<br />

Compressed air delivered<br />

simply and reliably

Compressed air,<br />

delivered simply<br />

and reliably<br />

123<br />

<strong>Cyclon</strong> 475 (75kW)<br />

<strong>Cyclon</strong> 345 (45kW)<br />

<strong>Cyclon</strong> 222 (22kW)<br />

<strong>Cyclon</strong> 105 (5.5kW)<br />

R e m a r k a b l y

4&<br />

CYCLON<br />

COMPRESSION ELEMENT<br />

Designed and manufactured by<br />

<strong>CompAir</strong> BroomWade to deliver compressed<br />

air reliably and efficiently day in, day out.<br />

HIGH EFFICIENCY DRIVE MOTOR<br />

Totally enclosed IP54 rated motor delivers high<br />

efficiency and reliability as well as<br />

maximum protection.<br />

HIGH QUALITY AIR<br />

For efficient air/oil separation system<br />

and optimum cooling.<br />

LOW NOISE LEVELS<br />

Eliminates the need for a separate<br />

compressor house.<br />

45 0 C AMBIENT CAPABILITY<br />

Ensures reliability and stress free<br />

operation in high ambient temperatures.<br />

SIMPLE SERVICING<br />

All major service items grouped in one<br />

area reducing downtime and maintenance costs.<br />

SIMPLE INSTALLATION<br />

A small footprint, lifting slots and versatile air discharge<br />

allow maximum flexibility when choosing a location.<br />

AUTOMATIC BELT TENSIONING<br />

Belts are kept at optimum tension for long life<br />

and maximum transmission efficiency<br />

– no adjustments necessary.<br />

SURESCAN ELECTRONIC CONTROL SYSTEM<br />

The simple Surescan control panel provides you<br />

with reliability and efficiency.<br />

FACTORY FILLED WITH COMPAIR LUBRICANT<br />

Specially formulated to provide maximum<br />

protection for the compressor.<br />

PRESSURE TRANSDUCER<br />

For reliable and accurate pressure control.<br />

24 VOLT CONTROLS<br />

For safe operation.<br />

R e l i a b l e

123<br />

●13<br />

●10<br />

●14<br />

●3<br />

●1<br />

●2<br />

●3<br />

●4<br />

●5<br />

●6<br />

●7<br />

●8<br />

●9<br />

●12<br />

Key to Diagram<br />

Intake Filter<br />

Suction Regulator<br />

BroomWade <strong>Cyclon</strong> Compression Element<br />

Primary Oil Separation<br />

Spin-On Air/Oil Separation Element<br />

Scavenge Line<br />

Minimum Pressure Valve<br />

Aftercooler<br />

Compressed Air Discharge<br />

●10 Oil Cooler with<br />

Thermostatic Bypass<br />

●11 Spin-On Oil Filter<br />

●12 Enclosure Filter<br />

●8<br />

●13 Vertical/Horizontal<br />

Cooling Air Discharge<br />

●14 Automatic Belt Tensioner<br />

●15 High Efficiency Drive<br />

Motor<br />

8<br />

9<br />

▼<br />

1<br />

●5<br />

●15<br />

AIR/OIL FLOW DIAGRAM<br />

10<br />

7<br />

11<br />

5<br />

6<br />

4<br />

2<br />

3<br />

Oil<br />

Air/Oil Mixture<br />

Compressed air Discharge<br />

Simplicity of Operation<br />

Operation of the <strong>Cyclon</strong><br />

compressors could not be<br />

simpler. The proven<br />

Surescan electronic control<br />

system takes care of every<br />

thing. All you need to do is<br />

press the start and stop<br />

buttons. The control system<br />

protects your investment by<br />

continuously monitoring<br />

operational parameters as<br />

well as providing the<br />

following features:<br />

S i m p l i c i t y o

4<br />

&<br />

●7<br />

●4<br />

●12<br />

●11<br />

●3<br />

●15<br />

• Discharge pressure<br />

display<br />

●14<br />

• Air/oil temperature<br />

display<br />

• Hours run display<br />

●8<br />

• Service due indication<br />

• Fault indication<br />

• Remote start/stop<br />

• Remote load/unload<br />

• Group fault output<br />

• Automatic restart on<br />

power failure<br />

10<br />

11<br />

9<br />

12<br />

AIR/OIL FLOW DIAGRAM<br />

1<br />

2<br />

13<br />

3<br />

●1<br />

●2<br />

●3<br />

●4<br />

●5<br />

●6<br />

●7<br />

●8<br />

●9<br />

Key to diagram<br />

Intake Filter<br />

Suction Regulator<br />

BroomWade <strong>Cyclon</strong><br />

Compression Element<br />

Fan<br />

Oil Filter<br />

Thermostatic Mixing<br />

Valve<br />

Oil Cooler<br />

Primary Oil Separator<br />

Minimum Pressure/NRV<br />

8<br />

●10 Delivery Air Outlet<br />

●11 Aftercooler<br />

●12 Oil Separation Element<br />

7<br />

6<br />

5 4<br />

●13 Scavenge Line<br />

●14 Automatic Belt Tensioner<br />

Oil<br />

●15 High Efficiency Drive<br />

Motor<br />

Air/Oil Mixture<br />

Compressed Air Discharge<br />

f O p e r a t i o n

The Inside Story<br />

Our prime objective<br />

in developing the<br />

<strong>Cyclon</strong> rotary screw<br />

compressors was to<br />

provide a range of<br />

compressors from<br />

5.5kW to 75kW<br />

that combined<br />

high performance,<br />

low operating costs<br />

and reliability with<br />

ease of installation<br />

and servicing.<br />

Sound engineering<br />

principles allied to<br />

innovative design has<br />

resulted in a range<br />

of compressors that<br />

exceeds these<br />

objectives.<br />

Reliability<br />

The slow running<br />

compression element is<br />

supported on precision<br />

taper and parallel roller<br />

bearings for long troublefree<br />

life with vee-belt life and<br />

drive efficiency enhanced by<br />

automatic belt tensioning.<br />

The enclosure filter<br />

maintains internal<br />

cleanliness and ensures<br />

coolers operate at maximum<br />

efficiency. A fully EMC<br />

(Electro Magnetic<br />

Compatibility) tested<br />

electronic control system<br />

housed in an IP 54<br />

enclosure together with high<br />

quality pressure tranducers<br />

and temperature sensor<br />

further safeguards<br />

operational reliability.<br />

High Performance<br />

and Efficiency<br />

The <strong>CompAir</strong> BroomWade<br />

designed, developed and<br />

manufactured <strong>Cyclon</strong> profile<br />

compression element<br />

delivers high air output<br />

for minimum power<br />

consumption. When teamed<br />

with the high efficiency drive<br />

motor the result is an<br />

energy-efficient high<br />

performance package.<br />

Installation Flexibility<br />

A small installation footprint,<br />

lifting slots and versatile<br />

compressed air discharge<br />

simplify installation while low<br />

noise levels and resilient<br />

mounts allow siting without<br />

disturbance to nearby<br />

personnel or equipment.<br />

<strong>Cyclon</strong> 105 to 222 models<br />

are designed to pass<br />

through a standard doorway<br />

for ease of positioning.<br />

The <strong>Cyclon</strong> 4 offers a<br />

vertical air discharge whilst<br />

the <strong>Cyclon</strong> 1-3 has a unique<br />

reversible cooling air outlet<br />

grille enabling either<br />

horizontal or vertical<br />

discharge depending on<br />

installation requirements.<br />

Simple Servicing<br />

All major service<br />

components are grouped<br />

in one area. Servicing is<br />

simple, quick and<br />

economical.<br />

23<br />

1 &<br />

A modern V-belt tensioner<br />

reliably carries out your<br />

maintenance. The tension<br />

will always be set at the<br />

correct level. This means<br />

no slip and absolutely<br />

maintenance free.<br />

The air intake filter, oil fill<br />

point, spin on/off, air/oil<br />

separators and oil filter are<br />

conveniently located behind<br />

easy removable panels or<br />

wide hinged doors, thereby<br />

minimising your<br />

maintenance time and<br />

costs.<br />

Quality Air<br />

<strong>Cyclon</strong> Series compressors<br />

deliver high quality cool<br />

compressed air, ideal for<br />

your production process.<br />

An air/oil separation system<br />

incorporating centrifugal,<br />

gravity and filtered<br />

separation ensures very low<br />

oil carryover (2-3mg/m 3 ).<br />

A pressure transducer<br />

enables the discharge<br />

pressure to be controlled<br />

within a 0.1 bar band<br />

minimising system pressure<br />

fluctuations.<br />

Quality In-built<br />

An ISO 9001 certified design<br />

and manufacturing process,<br />

continuously audited by both<br />

our internal auditors and<br />

Lloyd’s Register ensures a<br />

high quality and reliable<br />

product.<br />

Every compressor is tested<br />

for operation and<br />

performance in accordance<br />

with our own stringent<br />

specifications and those of<br />

the industry standard,<br />

PNEUROP/CAGI PN2CPTC2<br />

code.<br />

E f f i c i e n c y

4<br />

Free Air Delivered at Working Pressure Stated**<br />

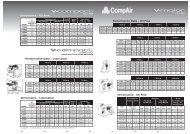

TECHNICAL DATA PERFORMANCE DATA – 60Hz PERFORMANCE DATA – 50Hz<br />

Model<br />

Drive Motor*<br />

kW<br />

hp<br />

<strong>Cyclon</strong> 105 5.5 7.5<br />

<strong>Cyclon</strong> 107 7.5 10.0<br />

<strong>Cyclon</strong> 111 11.0 15.0<br />

<strong>Cyclon</strong> 215 15.0 20.0<br />

<strong>Cyclon</strong> 218 18.5 25.0<br />

<strong>Cyclon</strong> 222 22.0 30.0<br />

<strong>Cyclon</strong> 330 30.0 40.0<br />

<strong>Cyclon</strong> 337 37.0 50.0<br />

<strong>Cyclon</strong> 345 45.0 60.0<br />

<strong>Cyclon</strong> 455 55.0 75.0<br />

<strong>Cyclon</strong> 475 75.0 100<br />

Note: performance data for the C455/C475<br />

includes air and watercooled versions<br />

Model<br />

Drive Motor*<br />

kW<br />

hp<br />

<strong>Cyclon</strong> 105 5.5 7.5<br />

<strong>Cyclon</strong> 107 7.5 10.0<br />

<strong>Cyclon</strong> 111 11.0 15.0<br />

<strong>Cyclon</strong> 215 15.0 20.0<br />

<strong>Cyclon</strong> 218 18.5 25.0<br />

<strong>Cyclon</strong> 222 22.0 30.0<br />

<strong>Cyclon</strong> 330 30.0 40.0<br />

<strong>Cyclon</strong> 337 37.0 50.0<br />

<strong>Cyclon</strong> 345 45.0 60.0<br />

<strong>Cyclon</strong> 455 55.0 75.0<br />

<strong>Cyclon</strong> 475 75.0 100<br />

Note: performance data for the C455/C475 includes air and watercooled versions<br />

Model Weight Dimensions mm<br />

kg lbs A B C<br />

bar g psi.g bar g psi.g bar g psi.g bar g psi.g bar g psi.g<br />

7.5 109 8.2 119 10 145 13 188 14 203<br />

m 3 /min cfm m 3 /min cfm m 3 /min cfm m 3 /min cfm m 3 /min cfm<br />

0.87 30.6 0.80 28.4 0.70 24.7 0.51 18.1 0.50 17.8<br />

1.24 43.8 1.14 40.4 1.04 36.7 0.78 27.6 0.77 27.3<br />

1.77 62.5 1.67 59.1 1.49 52.7 1.26 44.5 1.19 42.0<br />

2.56 90.4 2.55 90.1 2.24 78.8 1.65 58.2 1.63 57.5<br />

3.30 116.7 3.10 109.5 2.69 94.5 2.18 77.0 2.15 76.0<br />

3.68 130.0 3.49 122.8 3.25 114.6 2.84 100.4 2.65 93.6<br />

4.90 173.0 4.64 164.0 4.25 150.0 3.46 122.0 — —<br />

6.20 219.0 5.72 202.0 5.27 186.0 4.33 153.0 — —<br />

7.42 262.0 6.74 238.0 6.26 221.0 5.10 180.0 — —<br />

9.35 330.2 8.84 312.2 8.16 288.1 7.08 249.9 — —<br />

11.45 404.4 10.77 380.5 10.2 359 8.56 302.33 — —<br />

Free Air Delivered at Working Pressure Stated**<br />

bar g psi.g bar g psi.g bar g psi.g bar g psi.g bar g psi.g<br />

7.5 109 8.2 119 10 145 13 188 14 203<br />

m 3 /min cfm m 3 /min cfm m 3 /min cfm m 3 /min cfm m 3 /min cfm<br />

0.86 30.37 0.81 28.61 0.71 25.07 0.51 18.1 0.50 17.66<br />

1.25 44.14 1.16 40.97 1.10 38.85 0.78 27.55 0.77 27.19<br />

1.76 62.15 1.70 60.04 1.50 52.97 1.24 43.79 1.17 41.32<br />

2.59 91.47 2.40 84.76 2.23 78.75 1.72 60.74 1.61 56.86<br />

3.25 114.77 3.02 106.65 2.63 92.88 2.06 72.75 2.04 72.04<br />

3.68 129.26 3.45 121.84 3.18 112.3 2.75 97.12 2.60 91.82<br />

4.85 171.28 4.65 164.21 4.22 149.03 3.29 116.19 — —<br />

6.16 217.54 5.83 205.89 5.10 180.11 4.28 151.15 — —<br />

7.42 262.04 6.83 241.20 6.26 221.07 5.20 183.64 — —<br />

9.31 328.6 8.84 312.2 7.92 279.8 7.00 247.2 — —<br />

11.30 398.8 10.81 381.88 9.87 348.5 8.56 302.2 — —<br />

Average<br />

Noise Level<br />

dB(A)†<br />

<strong>Cyclon</strong> 105 286 629 710 760 925 66 G 3 ⁄ 4<br />

<strong>Cyclon</strong> 107 292 642 710 760 925 67 G 3 ⁄ 4<br />

<strong>Cyclon</strong> 111 351 772 710 1000 925 68 G 3 ⁄ 4<br />

<strong>Cyclon</strong> 215 489 1076 710 1165 1252 68 G1 1 ⁄ 4<br />

<strong>Cyclon</strong> 218 504 1109 710 1165 1252 69 G1 1 ⁄ 4<br />

<strong>Cyclon</strong> 222 517 1137 710 1165 1252 69 G1 1 ⁄ 4<br />

<strong>Cyclon</strong> 330 939 2070 990 1420 1650 68 Rp1 1 ⁄ 2<br />

<strong>Cyclon</strong> 337 945 2083 990 1420 1650 69 Rp1 1 ⁄ 2<br />

<strong>Cyclon</strong> 345 1043 2299 990 1420 1650 70 Rp1 1 ⁄ 2<br />

<strong>Cyclon</strong> 455 1370 3014 1800 1200 1650 74 (73)* RP2<br />

<strong>Cyclon</strong> 475 1370 3014 1800 1200 1650 75 (74)* RP2<br />

† ±3dB(A) according to PNEUROP/CAGI test code. *(Watercooled option shown in brackets)<br />

Air<br />

Outlet<br />

Conn<br />

C<br />

B<br />

* 50/60Hz motor speeds:<br />

105-222 – 2960/3550rpm,<br />

330-345 – 2970/3570rpm,<br />

455-475-2970/8570rpm<br />

** Unit performance measured in<br />

accordance with PNEUROP/CAGI<br />

PN2CPTC2<br />

A

The Global Player<br />

Where our customers are<br />

concerned quality is not<br />

just a word but reality.<br />

From the early planning<br />

stage to start-up and<br />

after-sales service, we<br />

can provide the answers<br />

where compressed air is<br />

concerned – worldwide<br />

Complete capability – compressed air to suit all applications<br />

Lubricated <strong>Compressor</strong>s<br />

(0.1 to 43 m 3 /min,<br />

.75 to 250 kW)<br />

● Single Stage<br />

<strong>Screw</strong> <strong>Compressor</strong>s<br />

● Speed Regulated<br />

<strong>Screw</strong> <strong>Compressor</strong>s<br />

● Piston <strong>Compressor</strong>s<br />

Oil Free <strong>Compressor</strong>s<br />

(0.1 to 43 m 3 /min,<br />

.75 to 250 kW)<br />

● Two Stage<br />

<strong>Screw</strong> <strong>Compressor</strong>s<br />

● Piston <strong>Compressor</strong>s<br />

● Water Sealed<br />

<strong>Screw</strong> <strong>Compressor</strong>s<br />

Complete Accessories<br />

Programme<br />

● Filters and Dryers<br />

● Cooling Systems<br />

● Heat Recovery<br />

● Condensate Management<br />

● Air Receivers<br />

● Multi Set Controllers<br />

● <strong>Compressor</strong> Lubricants<br />

Complete Service<br />

for Compressed Air<br />

Technology<br />

● Engineering of Complete<br />

<strong>Compressor</strong> Stations<br />

● Computer Assisted<br />

Demand Analysis<br />

● Local Service Centres<br />

● Guaranteed Parts<br />

Availability<br />

www.compair.com<br />

<strong>CompAir</strong> policy is one of continuous improvement and we therefore reserve<br />

the right to alter specifications and prices without prior notice.<br />

All products are sold subject to the Company's conditions of sale.<br />

Brochure re-order ref: G3 31E Print ref: AGB/AGB/5.00 Printed in England