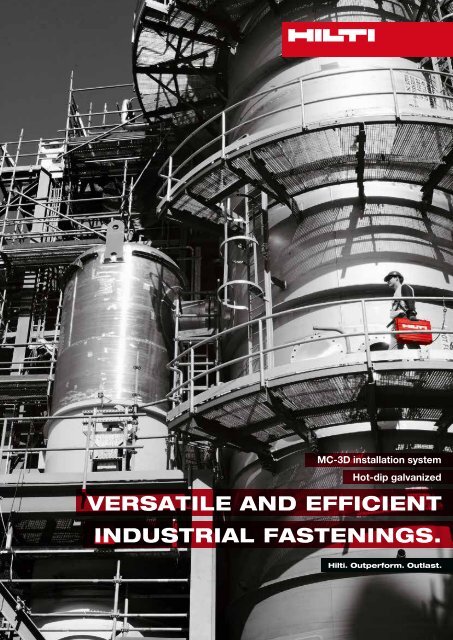

MC-3D Installation System

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MC</strong>-<strong>3D</strong> installation system<br />

Hot-dip galvanized<br />

VERSATILE AND EFFICIENT<br />

INDUSTRIAL FASTENINGS.<br />

Hilti. Outperform. Outlast.

<strong>MC</strong> Modular <strong>Installation</strong> <strong>System</strong><br />

Competence earned<br />

through experience.<br />

The daily challenges and considerable safety aspects faced in the<br />

energy sector call for trusted system solutions that always meet<br />

safety and productivity demands.<br />

Hilti’s strength of innovation is based on more than 60 years of<br />

protection. A comprehensive understanding of the technologies<br />

form the basis for a portfolio of products and services that<br />

and boost productivity in multiple applications in power generating<br />

well as supports for cable trays and instrumentation.<br />

Cable tray supports<br />

Light duty<br />

Cable tray supports<br />

Cable tray supports<br />

Medium duty<br />

Ceiling grids<br />

Instrumentation stands,<br />

junction boxes, panels<br />

Integrated floor systems<br />

2

OVERVIEW.<br />

A perfect solution for every installation application Page 4 - 5<br />

Boost your productivity in electrical<br />

and instrumentation applications Page 6 - 7<br />

<strong>MC</strong>-<strong>3D</strong> Hot-dip-galvanized Page 8 - 9<br />

Material specification and standards Page 10<br />

<strong>MC</strong> Modular <strong>Installation</strong> <strong>System</strong> Page 12 - 25<br />

Beam Clamp Page 26<br />

L-Shape Support Page 28 - 29<br />

Bracket fixed to steel Page 30 - 31<br />

U Yoke: Concrete Page 32 - 33<br />

Junction box supports<br />

Page 34 - 35<br />

Cable Tray Support with Beam Clamps Page 36 - 37<br />

Raised Floor Support Page 38 - 39<br />

3

<strong>MC</strong> Modular <strong>Installation</strong> <strong>System</strong><br />

A perfect solution for every<br />

installation application.<br />

Hilti <strong>MC</strong> is a lightweight, simple-to-install and flexible<br />

solution for integrated floor systems, cable tray and<br />

instrumentation support. Consisting of only a few different<br />

intelligently-combined parts it minimizes planning work and<br />

cuts installation costs significantly. Hilti <strong>MC</strong> is a no-welding<br />

system – and thus first choice for efficient and secure<br />

electrical and instrumentation applications.<br />

From Rough Hand Drawing To Detailed Design<br />

Hilti offers design and engineering support during the whole process<br />

Shop-drawings and BOM Software integration into plant design solutions for design &<br />

engineering (Aveva PDMS TM, Intergraph Smart TM <strong>3D</strong> for Plants)<br />

Job site support<br />

Training on site<br />

Customized logistics solutions (e.g. pre-cut, pre-kitted, etc.)<br />

Fast & easy to install support systems<br />

Adjustable & easy to manage changes<br />

Comprehensive product portfolio<br />

4

Flexibility<br />

Changes and on-site add-ons<br />

remain possible at any time, with<br />

very little planning effort.<br />

Lightweight and<br />

sustainable<br />

The modular components are up<br />

to 30% lighter than comparable<br />

solutions and can be reused in<br />

reconstruction.<br />

No welding – less risk<br />

Channels are connected by<br />

simple connectors that require no<br />

welding and which can be used<br />

in any dimension. No hot work<br />

means less risk and no need for<br />

extensive preparatory and<br />

Quick and easy<br />

Only a small number of different<br />

parts – simply bolted together<br />

during assembly – are required to<br />

support any installation need.<br />

Easy to plan<br />

Standardized components and<br />

CAD modeling using Hilti’s wellthought-out<br />

design software not<br />

only speed up the design process<br />

but also help assure maximum<br />

safety. Consulting and<br />

engineering support is provided<br />

by Hilti specialists whenever<br />

needed.<br />

5

Boost your productivity in electrical<br />

and instrumentation applications.<br />

cable tray systems or where various fastening requirements have to be met in machine control and<br />

instrumentation applications, the new Hilti <strong>MC</strong> installation system excels in every way:<br />

Self-explanatory and thus extremely easy to use<br />

system also saves time and money at the critical installation stage. The Hilti <strong>MC</strong> system consists of<br />

a few simple components that can be quickly assembled to form a support system providing<br />

exceptionally easy access, with the added advantage of quick and trouble-free extension, partial<br />

Hilti <strong>MC</strong> – for integrated floor systems<br />

structure<br />

10kN per m 2<br />

No heavy lifting equipment required<br />

Only one support system in the<br />

control room<br />

Less effort for design & engineering<br />

No hot work required<br />

Rigid and safe structure from the<br />

Adaptions & modifications on site<br />

can be done almost effortlessly<br />

Control rooms can be put in operation<br />

up to 4 times faster than before<br />

Overall total installed costs are lower<br />

with the Hilti support system<br />

6

<strong>MC</strong> modular<br />

installation system<br />

Hilti <strong>MC</strong> – for electrical cable tray routing<br />

Easiest bracing<br />

Hilti <strong>MC</strong> lets you achieve the most awkward<br />

shapes and install the most demanding seismic<br />

bracing without the need for any custom or<br />

welded parts.<br />

Lighter weight,<br />

complete system<br />

The Hilti <strong>MC</strong> modular system of lightweight<br />

components provides the complete solution for<br />

most cable tray or cable ladder sizes and weights.<br />

Ultimate flexibility<br />

Hilti <strong>MC</strong> interacts seamlessly with Hilti’s MI and<br />

MQ installation systems. Heavy-duty stands can<br />

provide maximum freedom in design and<br />

construction.<br />

Hilti <strong>MC</strong> – for instrumentation<br />

Maximum flexibility<br />

With the new <strong>MC</strong> connectors you can build <strong>3D</strong><br />

supports more easily than ever before. Only a few<br />

parts are needed to assemble and install virtually<br />

any equipment, in any environment.<br />

Fewer parts<br />

The need for expensive special parts and a huge<br />

number of different accessories when assembling<br />

<strong>3D</strong> structures becomes a thing of the past.<br />

7

Channels<br />

Brac<br />

<strong>MC</strong>-<strong>3D</strong>-41 OC-A 6m<br />

2063296<br />

<strong>MC</strong>-72 OC-A 6m<br />

2063299<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/350 OC-A<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/450 OC-A<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/650 OC-A<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/1000 OC-A<br />

2063720<br />

2063721<br />

2063722<br />

2063723<br />

Base connector<br />

Channels connector<br />

<strong>MC</strong>-CB OC-A 2061833 <strong>MC</strong>-CH OC-A 2063281 <strong>MC</strong>-CH OC-A 2063762<br />

Channels nuts<br />

Channels<br />

<strong>MC</strong>-WN-M10 OC 2063742<br />

<strong>MC</strong>-WN-<strong>3D</strong> OC 2063735<br />

<strong>MC</strong>-SI-M10 OC-A<br />

2063739<br />

Accessories<br />

M10x20-F<br />

2063241<br />

M10x65-F<br />

M12x105-F<br />

2063242<br />

2063244<br />

M10-SL-F<br />

M12-F-SL-WS 3/4"<br />

2063245<br />

382897<br />

8

<strong>Installation</strong> system<br />

<strong>MC</strong>-<strong>3D</strong> Hot-dip-galvanized<br />

kets<br />

Longitudional connector<br />

End Cap<br />

<strong>MC</strong>-BE-320 OC-A<br />

<strong>MC</strong>-BE-630 OC-A<br />

2063729<br />

2063730<br />

<strong>MC</strong>-CL OC-A<br />

2063760<br />

MQZ-E31<br />

MQZ-E41<br />

369686<br />

369685<br />

Angles<br />

<strong>MC</strong>-A-90 OC-A 2063770 <strong>MC</strong>-AH-90 OC-A 2063733 <strong>MC</strong>-AF-90 OC-A 2063740<br />

screws<br />

Channels stiffener<br />

Channels plate<br />

<strong>MC</strong>-S-M10 OC-A 2063737<br />

<strong>MC</strong>-PI OC-A 2063718<br />

<strong>MC</strong>-MI connector<br />

<strong>MC</strong>-PU OC-A 2063224<br />

MI accessories<br />

A 10,5/28-F 2063247<br />

<strong>MC</strong>-MI-AH-90 OC-A<br />

2063283<br />

MIA-EH90<br />

MIA-EH-P<br />

304887<br />

304891<br />

9

Material specification and standards<br />

Coating Category<br />

Product type<br />

Picture<br />

Product name<br />

Corrosion protection<br />

coating description<br />

Indoor<br />

Coating<br />

OC<br />

Outdoor<br />

Coating<br />

OC-A<br />

Outdoor<br />

Coating<br />

acc. ASTM<br />

channel<br />

<strong>MC</strong>-<strong>3D</strong>-41 OC-A<br />

<strong>MC</strong>-72 OC-A<br />

Hot-dip galvanized according<br />

ASTMA123, average layer<br />

thickness min. 56µm<br />

Bracket<br />

<strong>MC</strong>-BE OC-A<br />

<strong>MC</strong>-B-<strong>3D</strong>-41 OC-A<br />

<strong>MC</strong>-CB OC-A<br />

Channel<br />

connectors<br />

Channel<br />

Angles<br />

<strong>MC</strong>-CH OC-A<br />

<strong>MC</strong>-CU OC-A<br />

<strong>MC</strong>-A-90 OC-A<br />

<strong>MC</strong>-AH-90 OC-A<br />

<strong>MC</strong>-AF-90 OC-A<br />

Hot-dip galvanized according<br />

ASTMA153, average layer<br />

thickness min. 56µm<br />

Channel<br />

Accessories<br />

<strong>MC</strong>-CL OC-A<br />

<strong>MC</strong>-PU OC-A<br />

<strong>MC</strong>-PI OC-A<br />

Channel<br />

nuts<br />

<strong>MC</strong>-WN-M10 OC<br />

<strong>MC</strong>-WN-<strong>3D</strong> OC<br />

Multy-layer coated DIN 50979<br />

Channel<br />

screws<br />

<strong>MC</strong>-SI-M10 OC-A<br />

<strong>MC</strong>-S-M10 OC-A<br />

Hex, bolts, nuts and<br />

washers<br />

M10X20-F<br />

M10X65-F<br />

M10-SL-F<br />

M10,5/28-F<br />

Hot-dip galvanized according<br />

DIN EN ISO 10684, average<br />

layer thickness min. 56µm<br />

10

Hilti <strong>System</strong> <strong>MC</strong><br />

Technical Data<br />

11

<strong>Installation</strong> channel <strong>MC</strong>-<strong>3D</strong>-41 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

275 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A123,<br />

average layer thickness min 65µm<br />

Heigh<br />

Leng<br />

Material<br />

thickness<br />

Weight Designation Article number<br />

41 mm 3 m 1,6 mm 1713 g/m<br />

<strong>MC</strong>-<strong>3D</strong>-41 OC-A 3m 2063297<br />

41 mm 6 m 1,6 mm 1713 g/m<br />

<strong>MC</strong>-<strong>3D</strong>-41 OC-A 6m 2063296<br />

<strong>Installation</strong> channel <strong>MC</strong>-72 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A123,<br />

average layer thickness min 65µm<br />

Height<br />

Length<br />

Material<br />

thickness<br />

Weight<br />

Designation<br />

Article number<br />

72 mm 6 m 2,75 mm 4108 g/m <strong>MC</strong>-72 OC-A 6m 2063299<br />

12

<strong>MC</strong> modular<br />

installation system<br />

Technical data for <strong>MC</strong> and relevant MQ HDG channels<br />

Definition of axes<br />

<strong>MC</strong>-<strong>3D</strong>-41 OC-A MQ-41-F <strong>MC</strong>-72 OC-A<br />

41.3<br />

2<br />

41.3<br />

Channel wall thickness t [mm] 1.60 2.00 2.75<br />

Cross-section area A [mm²] 190.5 245.1 513.6<br />

Channel weight [kg/m] 1.71 2.13 4.11<br />

Delivered length [m] 3/6 3/6 6<br />

Material<br />

Designation according EN 10025 S275 JR S235 JR S 235 JR<br />

Permissible stress o¯<br />

perm [N/mm²] 228.9 152.6 193.2<br />

E-Modul [N/mm²] 190000 21000 210000<br />

Surface<br />

Hot-dip-galvanized according to ASTM A123, average layer<br />

thickness min 65µm<br />

x ASTM version x<br />

Cross-section values<br />

Y-axis<br />

Axis of gravity “open” 1) e 1 [mm] 21.50 21.13 36.58<br />

Axis of gravity e 2 [mm] 19.80 20.17 35.42<br />

Moment of inertia l y [cm 4 ] 4.96<br />

5.37 29.43<br />

Section modulus “open” W y1 [cm 3 ] 2.31 2.54 8.04<br />

Section modulus W y2 [cm 3 ] 2.51 2.66 8.31<br />

Radius of gyration i y [ cm]<br />

1.61<br />

1.48 2.39<br />

Permissible moment 2) M y [ Nm]<br />

529<br />

388 1554<br />

Z-axis<br />

Moment of inertia l z [cm 4 ] 5.42<br />

7.33 15.87<br />

Section modulus W z [cm 3 ] 2.63 3.55 7.68<br />

Radius of gyration i z [ cm]<br />

1.69<br />

1.73 1.76<br />

<strong>MC</strong> channel permissible stress calculated according EN 1993-1-3<br />

Channel selection table<br />

Max. span width L [cm] / deflection f [mm], max. L/200<br />

<strong>MC</strong>-<strong>3D</strong>-41 OC-A <strong>MC</strong>-72 OC-A<br />

Load F [kN] L f L f<br />

0.25 285 14 600 30<br />

0.50 208 10 486 24<br />

0.75 172 9 415 21<br />

1.00 149 7 368 18<br />

1.25 134 7 333 17<br />

1.50 122 6 306 15<br />

1.75 113 6 285 14<br />

2.00 105 5 268 13<br />

2.25 93 4 253 13<br />

2.50 84 3 241 12<br />

2.75 76 3 222 10<br />

3.00 70 2 204 9<br />

3.50 60 2 176 7<br />

4.00 52 1 154 5<br />

4.50 46

Brackets <strong>MC</strong>-B-<strong>3D</strong>-41 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength 275<br />

N/mm² for the channel, 355 N/mm² for the plate<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Pro e Length, L Weight Packaging Designation<br />

Article<br />

number<br />

<strong>MC</strong>-<strong>3D</strong>-41 350 mm 1033 g 12 pc <strong>MC</strong>-B-<strong>3D</strong>-41/350 OC-A 2063720<br />

<strong>MC</strong>-<strong>3D</strong>-41 450 mm 1242 g 12 pc <strong>MC</strong>-B-<strong>3D</strong>-41/450 OC-A 2063721<br />

<strong>MC</strong>-<strong>3D</strong>-41 650 mm 1508 g 12 pc <strong>MC</strong>-B-<strong>3D</strong>-41/650 OC-A 2063722<br />

<strong>MC</strong>-<strong>3D</strong>-41 1000 mm 2150 g 12 pc <strong>MC</strong>-B-<strong>3D</strong>-41/1000 OC-A 2063723<br />

Brackets Electrical <strong>MC</strong>-BE OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Length<br />

L<br />

Height<br />

H<br />

Dimens.<br />

A<br />

Material<br />

thick.<br />

Weight Psck. Designation<br />

Article<br />

number<br />

322 mm 97 mm 50 mm 1,5 mm 557 g 12 pc <strong>MC</strong>-BE-320 OC-A 2063729<br />

632 mm 147 mm 100 mm 1,5 mm 1138 g 12 pc <strong>MC</strong>-BE-630 OC-A 2063730<br />

14

<strong>MC</strong> modular<br />

installation system<br />

Technical data for <strong>MC</strong> and relevant MQ brackets<br />

Loading condition 1 Loading condition 2 Loading condition 3 Loading condition 4 Loading condition 5<br />

uniformly distributed load single concentrated load<br />

FZ = q · l<br />

½<br />

FZ<br />

½<br />

FZ<br />

FZ FZ<br />

1 3<br />

1 3<br />

1 3<br />

FZ FZ FZ<br />

1 4<br />

1 4<br />

1 4 1 4<br />

F1 [N] F1 [N] F1 [N] F2 [N] F3 [N]<br />

HST M12 HST M12 HST M12 HST M12 HST M12<br />

HUS-H HUS-H HUS-H HUS-H HUS-H<br />

Bracket L [mm] 10x100/15/30/40/* 10x100/15/30/40/* 10x100/15/30/40/* 10x100/15/30/40/* 10x100/15/30/40/*<br />

MQK-41/300 300 1700 1700 850 850 560<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/350 350 2320 2320 1160 1160 770<br />

MQK-41/450 450 1130 1130 560 560 370<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/450 450 1800 1800 900 900 600<br />

MQK-41/600 600 840 840 420 420 280<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/650 650 1170 1240 440 620 410<br />

MQK-41/1000 1000 490 490 210 240 160<br />

<strong>MC</strong>-B-<strong>3D</strong>-41/1000 1000 480 700 180 300 180<br />

Loading capacity calculated according EN 1993-1-3<br />

Loading capacity of bracket fastened with HST M12 or HUS-H 10x100 hef min. 70 mm.<br />

Load values are only valid for concrete ≥ C20/25<br />

The self-weight of the bracket has been taken into account.<br />

The loads apply only if the bracket fastening is away from a building component edge (fastenings at building component edges must be<br />

separately).<br />

The transfer of forces into the respective base material (steel, concrete) must be separately.<br />

The guidelines for use / application of anchors in anchor approvals must be observed. Load values according approvals status July 2012.<br />

The<br />

of L/150 was observed in all cases and measured at the point of load application.<br />

Technical data for <strong>MC</strong> Electrical Brackets<br />

Loading condition 1 Loading condition 2<br />

uniformly distributed load single concentrated load<br />

FZ = q · l<br />

½<br />

FZ<br />

½<br />

F1 [N]<br />

F1 [N]<br />

Bracket L [mm] Stiff fixation Stiff fixation<br />

<strong>MC</strong>-BE-320 320 2000 2000<br />

<strong>MC</strong>-BE-630 630 1000 1000<br />

15

Channel Longitudional connector <strong>MC</strong>-CL OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Material<br />

thickness<br />

Weight Pack. Designation Article number<br />

4,0 mm 708 g 20 pc <strong>MC</strong>-CL OC-A 2063760<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

+Fx, kN 8,1<br />

6, 5<br />

-Fx, kN 8,1<br />

6, 5<br />

My, kNcm 26,5<br />

10, 0<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use Profis installation Software.<br />

16

<strong>MC</strong> modular<br />

installation system<br />

Channel Base connector <strong>MC</strong>-CB OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Weight Pack. Designation Article number<br />

925 g 12 pc <strong>MC</strong>-CB OC-A<br />

2061833<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + M10x65+<strong>MC</strong>-PI<br />

+Fx, kN 8,1<br />

6,5<br />

13, 0<br />

-Fx, kN 8,1<br />

8,7<br />

17, 4<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use <strong>Installation</strong> Software.<br />

17

Angle 90° <strong>MC</strong>-A-90 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Weight Pack. Designation Article number<br />

324 g 10 pc<br />

<strong>MC</strong>-A-90 OC-A<br />

2063770<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

+Fz, kN 3,7<br />

1, 4<br />

-Fz, kN 4,5<br />

4, 3<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use Profis <strong>Installation</strong> Software.<br />

18

<strong>MC</strong> modular<br />

installation system<br />

Angle Height-Adjustable 90° <strong>MC</strong>-AH-90 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Weight Pack. Designation Article number<br />

174g<br />

20 pc<br />

<strong>MC</strong>-AH-90 OC-A<br />

2063733<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

+Fz, kN 2,8<br />

2, 8<br />

-Fz, kN 2,0<br />

2, 0<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use Profis <strong>Installation</strong> Software.<br />

19

Angle <strong>MC</strong>-MI Height-Adjustable 90° <strong>MC</strong>-MI-AH-90 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

For use with Weight Pack. Designation Article number<br />

MI-90 / 120<br />

MIA-EH-90 / 120<br />

MIA-EH-P<br />

223 g 10 pc <strong>MC</strong>-MI-AH-90 OC-A 2063283<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

+Fz, kN 4,5<br />

1, 4<br />

-Fz, kN 4,5<br />

1, 4<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use <strong>Installation</strong> Software.<br />

Angle Flat 90° <strong>MC</strong>-AF-90 OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Weight Pack. Designation Article number<br />

128g 20 pc <strong>MC</strong>-AF-90 OC-A 2063740<br />

Double <strong>MC</strong>-AF-90<br />

<strong>MC</strong>-<strong>3D</strong>-41 + M10x65+<strong>MC</strong>-PI<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

+Fz, kN 3,2<br />

3, 2<br />

-Fz, kN 4,5<br />

4, 5<br />

Given loads are max recommended loads for symmetrical load distribution in one<br />

direction only!<br />

For design with load combinations and assymetrical load use <strong>Installation</strong><br />

Software.<br />

20

<strong>MC</strong> modular<br />

installation system<br />

Connector Hight-Adjustable <strong>MC</strong>-CH OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Use with Weight Pack. Designation Article number<br />

<strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-S-M10<br />

710 g 20 pc <strong>MC</strong>-CH OC-A 2063281<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

+Fx, kN 8,1<br />

-Fx, kN 7,8<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use <strong>Installation</strong> Software.<br />

Connector Universal <strong>MC</strong>-CU OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Weight Pack. Designation Article number<br />

338 g 12 pc <strong>MC</strong>-CU OC-A 2063762<br />

2x M10x65 at 90<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

+Fx, kN 8,4<br />

2, 9<br />

-Fx, kN 8,4<br />

2, 9<br />

+Fz, kN 5,4<br />

3, 4<br />

-Fz, kN 5,4<br />

3, 4<br />

21

Connector Universal <strong>MC</strong>-CU OC-A<br />

1x M10x65 at 0° to 90°<br />

+/-F 90°, kN<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-WN-M10<br />

4,3<br />

<strong>MC</strong>-<strong>3D</strong>-41 + <strong>MC</strong>-SI-M10<br />

2,1<br />

+/-F 45°, kN 4,3<br />

2,1<br />

+/-F 0°, kN 4,3<br />

2,1<br />

Given loads are max recommended loads for symmetrical load distribution in one direction only!<br />

For design with load combinations and assymetrical load use <strong>Installation</strong> Software.<br />

Channel Wing-Nut <strong>MC</strong>-WN-M10 OC<br />

Technical Data<br />

Material<br />

QSTE 380 TM<br />

Coating<br />

Multi-layer coating, designed for corrosion<br />

environment category C3 according ISO 9223<br />

Connection<br />

thread<br />

Install<br />

Torque<br />

Weight Pack. Designation<br />

Article<br />

number<br />

M10 40 Nm 22 g 50 pc <strong>MC</strong>-WN-M10 OC 2063742<br />

Shear capacity, kN<br />

Tension capacity, kN<br />

<strong>MC</strong>-<strong>3D</strong>-41 4,5<br />

4,2<br />

Channel Wing-Nut 3-Dimensional <strong>MC</strong>-WN-<strong>3D</strong> OC<br />

Technical Data<br />

Material<br />

QSTE 380 TM<br />

Coating<br />

Multi-layer coating, designed for corrosion<br />

environment category C3 according ISO 9223<br />

Connection<br />

thread<br />

Install<br />

Torque<br />

Weight Pack. Designation<br />

Article<br />

number<br />

M10 40 Nm 41 g 25 pc <strong>MC</strong>-WN-<strong>3D</strong> OC 2063735<br />

22

<strong>MC</strong> modular<br />

installation system<br />

Channel Universal Plate <strong>MC</strong>-PU OC-A<br />

Technical Data<br />

Material<br />

Coating<br />

Structural steel with minimum yield strength<br />

235 N/mm 2<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Hole Diameter,<br />

D<br />

Weight Pack. Designation Article number<br />

13 mm 53 g 100 pc <strong>MC</strong>-PU OC-A 2063224<br />

Channel Insert Screw <strong>MC</strong>-SI-M10 OC-A<br />

Technical Data<br />

Material<br />

Coating<br />

Steel grade 8.8<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Connection<br />

thread<br />

Weight Pack. Designation Article number<br />

M10 17 g 100 pc <strong>MC</strong>-SI-M10 OC-A 2063739<br />

Channel Connection Screw <strong>MC</strong>-S-M10 OC-A<br />

Technical Data<br />

Material<br />

Coating<br />

Steel grade 8.8<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Connection<br />

thread<br />

Weight Pack. Designation Article number<br />

M10 47 g 100 pc <strong>MC</strong>-S-M10 OC-A 2063737<br />

23

Metric Hexagon Bolts DIN 933 HDG<br />

Technical Data<br />

Material Steel grade 8.8<br />

Coating<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Connection<br />

thread<br />

Weight Pack. Designation Article number<br />

M10 20 g 100 pc M10x20-F<br />

2063241<br />

Metric Hexagon Bolts with shenk DIN 931 HDG<br />

Technical Data<br />

Material Steel grade 8.8<br />

Coating<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Connection<br />

thread<br />

Weight Pack. Designation Article number<br />

M10 45 g 100 pc M10x65-F 2063242<br />

M12 105 g 50 pc M12x105-F 2063244<br />

Metric Hexagon Lock-nuts HDG<br />

Technical Data<br />

Material Steel grade 8<br />

Coating<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Connection<br />

thread<br />

Weight Pack. Designation Article number<br />

M10 15 g 100 pc M10-SL-F 2063245<br />

24

<strong>MC</strong> modular<br />

installation system<br />

Channel Insert Stiffener <strong>MC</strong>-PI OC-A<br />

Technical Data<br />

Material<br />

Structural steel with minimum yield strength<br />

235 N/mm²<br />

Coating Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

For use with Weight Pack. Designation Article number<br />

<strong>MC</strong>-<strong>3D</strong>-41<br />

M10x65<br />

20 g 50 pc <strong>MC</strong>-PI OC-A 2063718<br />

Flat washers HDG<br />

Technical Data<br />

Material Steel 140 HV<br />

Coating<br />

Hot-dip-galvanized according to ASTM A153,<br />

average layer thickness min 56µm<br />

Weight Pack. Designation Article number<br />

8 g 100 pc A10,5/28-F 2063247<br />

25

<strong>MC</strong> modular<br />

installation system<br />

Beam clamp<br />

Features:<br />

For connecting installation channels to steel beams<br />

withouts drilling or welding.<br />

(max. clamping thickness ≤ 23 mm).<br />

Technical Data<br />

Galvanising hot-dip galvanised, min. 56 µm<br />

MQT-F beam clamp (HDG)<br />

U-bolt: S 235 JRG-2 as per DIN EN 10025<br />

Claw plate: S 235 JR as per DIN EN 10025<br />

Nut: M8-M12-8-HDG as per DIN 934<br />

Suitable for<br />

channel height<br />

Weight<br />

each (g)<br />

Packing<br />

contents (pcs)<br />

Ordering<br />

designation<br />

Item no.<br />

MQ-21, MQ-31, MQ-41, MQ-21D 500 10 1 MQT-21-41-F 304190<br />

MQ-21, MQ-31, MQ-41, MQ-21D 650 10 2 MQT-41-82-F 304191<br />

MQ-21, MQ-31, MQ-41, MQ-21D 860 10 3 MQT-82-124-F 304192<br />

1<br />

M8<br />

92<br />

2<br />

5<br />

60<br />

95<br />

3<br />

92<br />

M10<br />

6<br />

90 140<br />

Tightening torque<br />

MD (Nm)<br />

MQT-21-41-F 10 3.0<br />

MQT-41-82-F Beam clamp<br />

20 4.5<br />

MQT-82-124-F 30 5.0<br />

Always use beam clamps in pairs.<br />

Channel loading values must be allowed for.<br />

Max. rec. load<br />

(kN)<br />

92<br />

M12<br />

8<br />

85<br />

178<br />

MQT-C-F beam clamp (HDG)<br />

Clamp: S 275 JR as per DIN EN 10 025<br />

Bolt: M12-8.8-HDG as per DIN 933<br />

Suitable for<br />

channel height<br />

Material<br />

thickness (mm)<br />

Weight<br />

each (g)<br />

Packaging<br />

contents (pcs)<br />

Outside Packaging<br />

contents (pcs)<br />

Ordering<br />

designation<br />

Item no.<br />

MQ-41 10 455 4 32<br />

1<br />

MQT-C21-F 304193<br />

MQ-41 6 170 10 80 2 MQT-C22-F 304194<br />

MQ-21, MQ-31, MQ-41 10 260 6 48 3 MQT-C23-F 304195<br />

Tightening torque<br />

MD (Nm)<br />

Beam clamp<br />

MQT-C21-F 20 4.5<br />

MQT-C22-F 5 2.5<br />

MQT-C23-F 40 2.5<br />

Always use beam clamps in pairs.<br />

Channel loading values must be allowed for.<br />

Max. rec. load<br />

(kN)<br />

26

Hilti <strong>System</strong> <strong>MC</strong><br />

Application examples<br />

Cable ladder supports<br />

Junction box supports<br />

Raised floor<br />

11

CT/2<br />

CT/2<br />

H<br />

H<br />

L/2<br />

L/2<br />

Front View<br />

B<br />

CT/2<br />

L/2<br />

C Side View<br />

CT/2<br />

L/2<br />

E<br />

Bill of Materials<br />

Item Article No.<br />

1 2063296<br />

2 2061833<br />

3 2063742<br />

4 2063247<br />

5 2063245<br />

6 2063729<br />

7 2063739<br />

8 2063245<br />

28

<strong>MC</strong> modular<br />

installation system<br />

L Shape: Cable Tray Support<br />

A Isometric View PMO ASIA TSCC<br />

Description<br />

Qty [m/pcs]<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m H<br />

Rail support <strong>MC</strong>-CB OC-A 1<br />

Wing Nut <strong>MC</strong>-WN-OC-M10 2<br />

Washer A 10.5/28-F 2<br />

Hexagon Bolt M10x20-F 2<br />

Bracket <strong>MC</strong>-BE-320-OC-A 2<br />

<strong>MC</strong> SI-M10 OC-A 4<br />

Hexagon Nut M10-F 4<br />

REV. DATE DESCRIPTION DRN CHK APP<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate<br />

in particular<br />

DIN/ EN/ ASTM standards and building/construction legislation, must be<br />

All rights including copyright reserved for HILTI AG. Duplication of this drawing,<br />

as well as utilisation and disclosure, is not permitted unless expressly agreed.<br />

Project<br />

Drawn<br />

SA<br />

Application 1 A<br />

Date 07.07.2013<br />

Description<br />

Scale<br />

-<br />

L-shape Support<br />

Sheet Format<br />

1/1 A3<br />

29

L/2 L/2<br />

H<br />

L/2<br />

L/2<br />

B<br />

Front View<br />

D<br />

Bill of Materials<br />

H<br />

Item Article No.<br />

1 2063296<br />

2 377078<br />

3 304765<br />

4 2063742<br />

5 2063247<br />

6 2063245<br />

7 2063729<br />

C<br />

Side View<br />

30

<strong>MC</strong> modular<br />

installation system<br />

Brackets Fixed to Steel:<br />

Cable Tray Support<br />

A<br />

Isometric View<br />

Description<br />

Qty [m/pcs]<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m H<br />

Threaded Stud X-BT M10 4<br />

Hexagon Nut M10-F 4<br />

Wing Nut <strong>MC</strong>-WN-OC-M10 4<br />

Washer A 10.5/28-F 8<br />

Hexagon Bolt M10x20-F 4<br />

Bracket <strong>MC</strong>-BE-320-OC-A 2<br />

REV. DATE DESCRIPTION DRN CHK APP<br />

PMO ASIA TSCC<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate<br />

in particular<br />

DIN/ EN/ ASTM standards and building/construction legislation, must be<br />

All rights including copyright reserved for HILTI AG. Duplication of this drawing,<br />

as well as utilisation and disclosure, is not permitted unless expressly agreed.<br />

Project<br />

Drawn<br />

SA<br />

Application 1B<br />

Date 07.07.2013<br />

Description<br />

Scale<br />

-<br />

Steel Fixation<br />

Sheet Format<br />

1/1 A3<br />

31

2 1<br />

W<br />

H<br />

2<br />

1<br />

H<br />

B Side View A<br />

Front View<br />

C<br />

D<br />

Isometric View<br />

Bill of Materials<br />

Item Article No.<br />

1 2063296<br />

2 2063296<br />

3 2061833<br />

4 2063742<br />

5 2063245<br />

6 2063739<br />

7 2063245<br />

8 2063770<br />

32

<strong>MC</strong> modular<br />

installation system<br />

U Yoke: Concrete<br />

Detail 1<br />

2<br />

Detail 2<br />

1<br />

2<br />

Detail 1<br />

1<br />

Detail 2<br />

Description<br />

Qty [m/pcs]<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m H<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m W X 2<br />

Rail support <strong>MC</strong>-CB OC-A 2<br />

Wing Nut <strong>MC</strong>-WN-OC-M10 8<br />

Hexagon Bolt M10x20-F 8<br />

<strong>MC</strong> SI-M10 OC-A 4<br />

Hexagon Nut M10-F 4<br />

90 degree Angle <strong>MC</strong>-A-90 OC-A 4<br />

REV. DATE DESCRIPTION DRN CHK APP<br />

PMO ASIA TSCC<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate<br />

in particular<br />

DIN/ EN/ ASTM standards and building/construction legislation, must be<br />

All rights including copyright reserved for HILTI AG. Duplication of this drawing,<br />

as well as utilisation and disclosure, is not permitted unless expressly agreed.<br />

Project<br />

Drawn<br />

SA<br />

Application 3<br />

Date 07.07.2013<br />

Description<br />

Scale<br />

-<br />

U - Yoke<br />

Sheet Format<br />

1/1 A3<br />

33

W<br />

H<br />

A<br />

Front View<br />

Scale 1:20<br />

D<br />

Bill of Materials<br />

B<br />

Side View<br />

Scale 1:20<br />

H<br />

Item Article No.<br />

1 2063296<br />

2 304799<br />

3 304827<br />

4 304887<br />

5 304891<br />

6 382897<br />

7 2063242<br />

8 -<br />

9 2063245<br />

10 2063742<br />

11 2063247<br />

12 2063241<br />

13 2063718<br />

34

<strong>MC</strong> modular<br />

installation system<br />

Junction Box Support<br />

Detail 2<br />

Detail 1<br />

Detail 1<br />

C<br />

Isometric View<br />

Detail 2<br />

Description<br />

Qty [m/pcs]<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m W<br />

Girder MI 90-6m<br />

H<br />

Base Plate MIC-90-D 2<br />

MI Toothed Bolt MIA-EH90 4<br />

Connector MIA-EH-P 4<br />

MI Hex Collar Nut M12-F 4<br />

M10X65 Bolt 4<br />

Plate <strong>MC</strong>-PU OC 4<br />

Hexagon Nut M10-F 4<br />

Wing Nut <strong>MC</strong>-WN-OC-M10 8<br />

Washer A 10.5/28-F 8<br />

Hexagon Bolt M10X20-F 4<br />

Spacer <strong>MC</strong>-PI OC-A 4<br />

REV. DATE DESCRIPTION DRN CHK APP<br />

PMO ASIA TSCC<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate<br />

in particular<br />

DIN/ EN/ ASTM standards and building/construction legislation, must be<br />

All rights including copyright reserved for HILTI AG. Duplication of this drawing,<br />

as well as utilisation and disclosure, is not permitted unless expressly agreed.<br />

Project<br />

Drawn<br />

SA<br />

Application 2<br />

Date 07.07.2013<br />

Description<br />

Scale<br />

-<br />

Junction Box Support<br />

Sheet Format<br />

1/1 A3<br />

35

Function Box Support<br />

Front View<br />

Side View<br />

BOO:<br />

PMO ASIA TSCC<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate specifications, in<br />

particular DIN standards and building/construction legislation, must<br />

be observed as seen fit at ones own responsibility.<br />

All rights including copyright reserved for<br />

HILTI AG. Duplication of this drawing, as<br />

well as utilisation and disclosure, is not<br />

permitted unless expressly agreed.<br />

36

<strong>MC</strong> modular<br />

installation system<br />

Cable Tray Support<br />

with Beam Clamps<br />

PMO ASIA TSCC<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate specifications, in<br />

particular DIN standards and building/construction legislation, must<br />

be observed as seen fit at ones own responsibility.<br />

All rights including copyright reserved for<br />

HILTI AG. Duplication of this drawing, as<br />

well as utilisation and disclosure, is not<br />

permitted unless expressly agreed.<br />

37

Item Article No.<br />

1 304799<br />

2 304799<br />

3 304825<br />

4 304803<br />

5 304882<br />

6 304100<br />

7 2063296<br />

8 2063296<br />

9 2063296<br />

10 2061833<br />

11 2063762<br />

12 2063281<br />

13 2063283<br />

14 2063733<br />

15 2063742<br />

16 2063735<br />

17 2063739<br />

18 2063245<br />

19 2063245<br />

20 382897<br />

21 304887<br />

22 304891<br />

38

<strong>MC</strong> modular<br />

installation system<br />

Raised Floor Support<br />

Description<br />

Qty [m/pcs]<br />

Girder MI-90 H X 2<br />

Girder MI-90<br />

L1<br />

Connector concrete MIC-C90-AA 2<br />

Connector MIC-90-U 2<br />

MI/MQ connector MIC-MI/MQ-M8 2<br />

Install. channel MQ-41-F 6m 0.5<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m H2 X 4<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m L2 X 2<br />

Install. channel <strong>MC</strong>-<strong>3D</strong> 41 OC-A 6m 0.3<br />

Rail support <strong>MC</strong>-CB OC-A 4<br />

Universal connector <strong>MC</strong>-CU OC-A 1<br />

Height connector <strong>MC</strong>-CH OC-A 5<br />

MI/<strong>MC</strong> connector <strong>MC</strong>-MI-AH-90 OC-A 1<br />

Angle <strong>MC</strong>-AH-90 OC-A 1<br />

Wing Nut <strong>MC</strong>-WN-OC-M10 19<br />

Wing Nut <strong>3D</strong> <strong>MC</strong>-WN-<strong>3D</strong> OC 2<br />

Screw <strong>MC</strong> SI-M10 OC-A 10<br />

Hexagon Bolt M10x20-F 14<br />

Hexagon Nut M10-F 10<br />

Hexagon Nut M12-F-SL 1<br />

Elementary screw MIA-EH90 1<br />

Counter plate MIA-EH-P 1<br />

REV. DATE DESCRIPTION DRN CHK APP<br />

PMO ASIA TSCC<br />

701-704 & 708B | 7/F | Tower A I Manulife Financial Centre<br />

223 Wai Yip Street Kwun Tong | Kowloon | Hong Kong<br />

www.hilti.com<br />

The data and results must be checked for agreement with the actual<br />

circumstances and for plausibility. The appropriate<br />

in particular<br />

DIN/ EN/ ASTM standards and building/construction legislation, must be<br />

All rights including copyright reserved for HILTI AG. Duplication of this drawing,<br />

as well as utilisation and disclosure, is not permitted unless expressly agreed.<br />

Project<br />

Drawn<br />

SA<br />

Application 4<br />

Date 07.07.2013<br />

Description<br />

Scale<br />

-<br />

Raised Floor<br />

Sheet Format<br />

1/1 A3<br />

39

Hilti = registered trademark of Hilti Corp., Schaan | Printed in Singapore | April 2016 | © 2016| Right of technical and programme changes reserved S. E. & O.<br />

Hilti. Outperform. Outlast.<br />

Customer Service 6777-7887<br />

Hilti Far East Pte Ltd | 20 Harbour Drive, #06-06 PSA Vista, Singapore 117612 | T 6777-7887 | F 6777-3057<br />

www.hilti.com.sg