Australia's junior explorers - The ASIA Miner

Australia's junior explorers - The ASIA Miner

Australia's junior explorers - The ASIA Miner

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

July/August 2012 | Volume 9 | Issue 4 | Industry Technical Information | 矿业技术信息<br />

STRENGTH IN MINING 开采强度<br />

Focus on the Philippines Australian <strong>junior</strong> <strong>explorers</strong> Grinding mills 聚焦菲律宾 澳大利亚小型勘探企业 磨矿机

FEATURES<br />

Australian <strong>junior</strong> <strong>explorers</strong> Australia’s <strong>junior</strong> mining companies are at the forefront of the global mining industry<br />

owing to the fact that they ar e not only seeking to locate and pr ove new deposits in Australia but<br />

their reach extends to Asia, Africa, South America and other parts of the world. Australia’ s <strong>junior</strong>s face<br />

many challenges, not the least of which is securing capital in unpr edictable economic times. This special<br />

feature looks at the work of a number of these <strong>junior</strong>s. ...................................................... From page 46<br />

Paste thickening Operators, suppliers and researchers continue to pursue higher efficiency and reliability<br />

in paste thickening applications. ..........................................................................................................59<br />

Grinding mills Leading manufacturers offer perspectives on the market, evolving technology and the<br />

future. ..................................................................................................................................................61<br />

LEADING DEVELOPMENTS<br />

Asian Intelligence On the surface it is difficult to see what benefits Indonesia’s new tax on unprocessed<br />

ore exports can bring to the global mining industry. However, nickel may be one of the minerals that benefits<br />

on a worldwide scale as it may boost depressed prices and increase pressure on supply. ..............5<br />

Philippines Intex Resources has signed a Project Management Contract with China’s MCC8 Group<br />

covering its Mindoro Nickel Project. MCC8 is now responsible for managing the formation of a consortium<br />

to develop the project. ...........................................................................................................................7<br />

Exploration Six new targets identified by a survey at Paramount Mining’s Gunung Rosa project are being<br />

prepared for detailed exploration. ........................................................................................................72<br />

AROUND THE REGION<br />

Philippines Toledo Mining is assessing ways to extend its DSO shipping period. ...................................8<br />

China Drilling at the Beiya project has extended the gold-silver and base metal zone. .........................16<br />

Mongolia A pre-feasibility study has confirmed the Ovoot coal project is financially robust. ..................26<br />

Indonesia <strong>The</strong> start of production at G-Resources’ Martabe Gold-Silver project is imminent. ..............28<br />

Australia Nickel technology will be piloted at the Lucky Break project in Queensland. .........................32<br />

Cambodia OZ <strong>Miner</strong>als has sold its Cambodian gold assets to Renaissance <strong>Miner</strong>als. ........................35<br />

Papua New Guinea <strong>The</strong> maiden nickel estimate at Mambare has exceeded expectations. ..................36<br />

Central Asia Premier Gold has started a new exploration program at the Cholokkaindy project. ..........38<br />

Malaysia Exploration at the Sokor Gold Project has led to a 35% increase in resources. .....................40<br />

India NSL Consolidated has sold its first iron ore ex-gate into the domestic market. ............................43<br />

South Pacific Lion One Metals confirms exploration upside at Tuvatu Gold Project. ............................72<br />

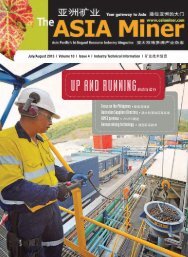

Despite global economic uncertainty, the mining industry<br />

throughout Asia is strong, with the Philippines<br />

a leading light. CGA Mining’s Masbate Gold Project<br />

is one of the island nation’s success stories with production<br />

through the pictured mill reaching record<br />

levels and exploration continuing to boost resources,<br />

thus replenishing mined ounces. <strong>The</strong> plant with 4<br />

million tonne annual capacity was constructed by<br />

Leighton Contractors Asia and CGA aims to increase<br />

throughput to 6.5 million tonnes.<br />

DEPARTMENTS<br />

Photo courtesy CGA Mining.<br />

Advertisers’ Index ......................................70<br />

Calendar of Events ....................................44<br />

From the Editor ............................................2<br />

Product News ............................................64<br />

Subscription Form ......................................70<br />

Supplier News ............................................66<br />

ENK focuses on Acoje .........................................6 Spotted Quoll performs well ................................32 Increase in Yandera resource ................................37<br />

July/August 2012 | <strong>ASIA</strong> <strong>Miner</strong> | 1

From <strong>The</strong> Editor<br />

Philippines mining finally ‘coming of age’<br />

With foreign investment increasing, exploration providing impressive results,<br />

several mining projects forging ahead, the economy expanding and<br />

a number of its neighbours ‘shooting themselves in the feet’ with new<br />

mining laws, the Philippines is starting to demonstrate the mining potential<br />

it has been threatening to reveal for years. However, there is still work<br />

to be done if the industry is to reach its full potential.<br />

Good signs are there as the country recorded strong growth of 6.4% in<br />

the first quarter, up from 4.9% in the corr esponding period of 2011. This<br />

strong performance prompted an upward revision to the growth forecast by<br />

By John Miller /Editor<br />

Moody’s, which lifted 2012 forecasts for the Philippines to 4.7% fr om 4%.<br />

Foreign direct investment is also reported to have increased by almost 154% to US$850 million in<br />

the first two months of 2012. <strong>The</strong> W orld Economic Forum has also recognized the impact of key<br />

reforms in its Global Enabling T rade Report, which indicated that the Philippines has made substantial<br />

improvements in trade access, jumping 50 places to 14th out of 132 nations.<br />

To reach the potential that has been talked about for years, some changes need to be implemented,<br />

important decisions made at a government level and work done by the mining industry<br />

to better sell itself to all Filipinos. <strong>The</strong> impasse with the Tampakan project needs to be resolved<br />

as it does not promote investor confidence in the nation as a whole. Another hindrance is the<br />

moratorium on new mines in place since January 2011 while the gover nment has also been<br />

talking about following Australia’s ‘example’ and imposing further mining taxes.<br />

<strong>The</strong>re is some light at the end of the tunnel in the form of a systematic government review of<br />

mining policy. According to Gavan Collery, the chairman of Indophil Resources, one of the partners<br />

in Tampakan, the framework of the review is contained within six points - sustainable development;<br />

best practice and gover nance; protection of the environment; primacy of national<br />

law; sharing of benefits; and sound mining sector management.<br />

“As a somewhat obvious observation,” he says, “this framework – save for implying r estoration<br />

of investor confidence – is the basis for the type of responsible practice that one would care<br />

to see applied in any jurisdiction in the world. <strong>The</strong> framework is one we support, and one we will<br />

continue to advocate within the industry and all levels of government. Hopefully, its carriage and<br />

adoption will see the Philippines’ mining industry contributing to a sound economic future; a future<br />

that can in part be underpinned by development of Tampakan.<br />

“While being cautious based on past experiences, it appears that mining policy in the Philippines<br />

is coming of age, and will be based on sound process and system. A robust and invigorated<br />

national mining policy will deliver nation-building benefit to the people and reward those who<br />

embark on the considerable risk of minerals exploration and development.”<br />

National resources development fund has merit<br />

An emerging cash crisis for Australia’s <strong>junior</strong> <strong>explorers</strong> is threatening the long-term sustainability<br />

of the country’s ‘mining boom’ as well as in other ar eas in which the <strong>junior</strong>s play a vital r ole<br />

in identifying and proving new deposits, such as Asia, Africa and South America. A national resources<br />

development fund paid for by a modest levy on established and pr ofitable mining operations,<br />

and proposed by the managing director of Minotaur Exploration, Andrew Woskett, is<br />

worthy of further investigation by decision makers. At the heart of the pr oposal is providing an<br />

innovative source of access to capital exclusively for the backbone of Australia’s mining future<br />

– the cash-starved <strong>junior</strong> end of the resources spectrum.<br />

“<strong>The</strong>re is nothing more serious right now confronting <strong>junior</strong>s than the complete absence of risk<br />

capital available for <strong>explorers</strong> and small cap pr oject developers,” Andrew Woskett says. “<strong>The</strong><br />

consequences of capital starvation to the overall well-being of our so-called booming resources<br />

sector is intensely serious and with negative global equities sentiment as it is, we need to be<br />

more unconventional in resolving how we alleviate this funding gap. A national resources development<br />

fund can fill that gap.”<br />

2 | <strong>ASIA</strong> <strong>Miner</strong> | July/August 2012<br />

WWW.<strong>ASIA</strong>MINER.COM<br />

<strong>The</strong> <strong>ASIA</strong> <strong>Miner</strong>®<br />

Suite 9, 880 Canterbury Road,<br />

Box Hill, Melbourne,Victoria, 3128 Australia<br />

Phone: +61 3 9899 2981 Mobile: + 61 417 517 863<br />

Editor —John Miller, john@asiaminer.com<br />

Graphic Designer—Christine Hensley, chensley@mining-media.com<br />

Editorial Director—Steve Fiscor, sfiscor@mining-media.com<br />

Europe—Simon Walker, simon.iets@btinternet.com<br />

North America—Russ Carter, russ.carter.emj@gmail.com<br />

Latin America—Oscar Martinez,martin1@ctcinternet.cl<br />

South Africa—Antonio Ruffini,antonior@webafrica.org.za<br />

SALES<br />

Publisher—Lanita Idrus, lanita@asiaminer.com<br />

Sales Account Manager —Rashi Mujoo, rashi@asiaminer.com<br />

North America—Victor Matteucci, vmatteucci@mining-media.com<br />

Latin America—Mauricio Godoy, mgodoy@mining-media.com<br />

Germany, Austria, Switzerland— Gerd Strasmann<br />

strasmannmedia@t-online.de<br />

Rest of Europe—Colm Barry, colm.barry@telia.com<br />

Jeff Draycott, jeff.draycott@WOMPint.com<br />

Japan—Masao Ishiguro, Ishiguro@irm.jp<br />

Indonesia—Dimas Abdillah, dimas@lagunagroup.net<br />

Mining Media International<br />

8751 East Hampden Ave, Suite B-1<br />

Denver, Colorado 80231, U.S.A.<br />

Phone: +1 303-283-0640 Fax: +1 303-283-0641<br />

President—Peter Johnson, pjohnson@mining-media.com<br />

Subscriptions: $120/year—Tanna Holzer,<br />

tholzer@mining-media.com<br />

Accounting—Lorraine Mestas, lmestas@mining-media.com<br />

<strong>The</strong> <strong>ASIA</strong> <strong>Miner</strong>® is published six times per year by Mining Media<br />

International. Every endeavour is made to ensure that the contents<br />

are correct at time of publication. <strong>The</strong> Publisher and Editors do not<br />

endorse the opinions expressed in the magazine. Editorial advice<br />

is non-specific and readers are advised to seek pr ofessional advice<br />

for specific issues. Images and written material submitted for<br />

publication are sent at the owners risk and while every car e is<br />

taken, <strong>The</strong> <strong>ASIA</strong> <strong>Miner</strong>® does not accept liability for loss or damage.<br />

<strong>The</strong> <strong>ASIA</strong> <strong>Miner</strong>® reserves the right to modify editorial and advertisement<br />

content. <strong>The</strong> contents may not be reproduced in whole<br />

or in part without the written permission of the publisher.<br />

Copyright 2011 Mining Media International Pty Ltd<br />

ISSN: 1832-7966

Asian Intelligence<br />

4 | <strong>ASIA</strong> <strong>Miner</strong> | July/August 2012

AN interesting recent development for the<br />

sluggish nickel industry has come in the form<br />

of the Indonesian gover nment’s new tax on<br />

unprocessed mineral ore exports, which may<br />

boost prices and increase pressure on supply.<br />

<strong>The</strong> new tax on the export of 14 types of<br />

unprocessed minerals came into ef fect on<br />

May 6 and has been intr oduced in a bid to<br />

boost value-added products.<br />

<strong>The</strong> minerals affected are gold, silver, platinum,<br />

copper, lead, nickel, zinc, ir on ore<br />

and sand iron, manganese, chromium, molybdenum,<br />

bauxite and antimony. <strong>The</strong>re has<br />

been mixed response within Indonesia and<br />

further afield with concern expressed that it<br />

will affect miners’ revenue and significantly<br />

affect profit margins.<br />

<strong>The</strong>re have certainly been mixed messages<br />

about the impact on nickel with some companies<br />

to benefit and others to be impacted<br />

negatively. <strong>The</strong> government has made exceptions<br />

for miners that alr eady have or plan to<br />

New Indonesian tax may benefit nickel<br />

build smelters. <strong>The</strong>y will be taxed at an average<br />

of 20% on ore exports.<br />

Companies like Vale Indonesia, the country’s<br />

biggest nickel miner, won’t be affected<br />

because they process ore into refined products.<br />

But other companies will be impacted,<br />

including state-controlled Antam, which<br />

obtains about 30% of its r evenue from ore<br />

shipments. To process raw nickel, Antam<br />

plans to build a $1.6 billion ferronickel smelter<br />

in East Halmahera.<br />

Some companies may end up holding back<br />

ore shipments if the new levy makes mining<br />

unprofitable and might focus on building<br />

smelters instead. This could, in turn, lift nickel<br />

prices and put pressure on supply. Kim Eng<br />

Securities in Jakarta said in a note to clients<br />

that the imposition of an export duty on mineral<br />

ores would curb cheap nickel ore supply<br />

and, in turn, stoke a nickel price rally.<br />

China International Capital Corp also for ecasts<br />

a boost in nickel prices but says large<br />

EPA recommends approval for Wiluna<br />

THE Western Australian Environmental Protection<br />

Authority (EPA) has r ecommended<br />

approval for Toro Energy’s Wiluna Uranium<br />

Project. <strong>The</strong> EPA has presented a report and<br />

recommendations to Western Australia’s Minister<br />

for Environment. Toro is awaiting the<br />

Minister’s decision following review of any appeals<br />

that are raised.<br />

<strong>The</strong> project was referred for assessment to<br />

the Western Australian and Federal gover nments<br />

in October 2009. An Environmental Review<br />

and Management Program was exhibited<br />

for public consultation over 14 weeks from July<br />

2011 with 48 submissions made to the EP A.<br />

Toro has provided comprehensive responses<br />

to all submissions to enable the EPA to finalize<br />

its assessment. A Federal Gover nment decision<br />

on its assessment is anticipated after the<br />

Western Australian process is finalized. Toro’s<br />

Board will then target a final investment decision<br />

by the end of 2012, subject to final market<br />

and economic considerations.<br />

“<strong>The</strong> EPA recommendation is an important<br />

milestone for Toro and for the W estern Australian<br />

uranium industry,” Toro’s managing<br />

director Greg Hall says. “While the Toro team<br />

members have significant experience within<br />

other uranium and mining operations, Wiluna<br />

is Toro’s first project and the first uranium project<br />

to receive a positive EPA recommendation<br />

in Western Australia since the change of<br />

government in 2008. Toro is confident that its<br />

extensive technical and environmental study<br />

work and the rigorous assessment undertaken<br />

by the EPA will ensure a safe and sustainable<br />

mining operation. This project is one of<br />

the few in the world potentially capable of<br />

commencing production in the critical<br />

2014/15 period when the nuclear industry will<br />

be seeking additional supplies.”<br />

Toro’s Wiluna project is about 520km north of Kalgoorlie<br />

in central Western Australia. It comprises uranium in the<br />

Centipede and Lake Way deposits.<br />

Asian Intelligence<br />

By <strong>The</strong> <strong>ASIA</strong> <strong>Miner</strong> editor, John Miller<br />

stockpiles in China will limit short-term impacts<br />

of any supply shortfall. It says the tax<br />

is expected to add 7.5% to average production<br />

costs of nickel pig ir on in China, improving<br />

incentives to use refined nickel at current<br />

price levels. About 60% of China’ s pig iron<br />

output, which accounts for 60% of the nation’s<br />

nickel production, relied on Indonesian<br />

laterite ores last year.<br />

In a research note, analysts at Citi said the<br />

outlook for nickel was ‘significantly mor e<br />

positive’ thanks to Indonesia’s moves. “Expectations<br />

of reductions in exports range<br />

from 20% per cent to 75% by the fourth<br />

quarter of 2012.<br />

<strong>The</strong> Philippines might also pick up any<br />

slack in shipments caused by the ban. A<br />

Mines and Geosciences Bureau official said<br />

recently that nickel-ore production and exports<br />

from the Philippines may rise this year,<br />

benefiting from Indonesia’s ban. Australia is<br />

another country that could benefit.<br />

Lynas has LAMP appeal dismissed<br />

AN appeal lodged under the Atomic Energy<br />

Licensing Act in relation to the decision<br />

of the Malaysian Atomic Energy<br />

Licensing Board to approve the issuance<br />

of a temporary operating licence (TOL) for<br />

the Lynas Advanced Materials Plant<br />

(LAMP), has been dismissed.<br />

In dismissing the appeal, the Minister of<br />

Innovation, Science and Technology, YB<br />

Dato’ Seri Panglima Dr Maximus Johnity<br />

Ongkil affirmed the February 1, 2012 decision<br />

of the Boar d to appr ove the issuance<br />

of the TOL. L ynas has r eadily<br />

available solutions to satisfy the new conditions<br />

announced by the Minister . <strong>The</strong><br />

next step will be the tabling and debate of<br />

the Parliamentary Select Committee’s Report.<br />

Lynas looks forward to completion of<br />

the regulatory and political pr ocesses in<br />

Malaysia as soon as possible.<br />

“<strong>The</strong> decision by the Minister is the<br />

latest in a long line of rulings and approvals<br />

where Lynas has been assessed<br />

and judged to have complied<br />

with Malaysian and international regulatory<br />

standards,” says Lynas executive<br />

chairman Nicholas Curtis.<br />

July/August 2012 | <strong>ASIA</strong> <strong>Miner</strong> | 5

Philippines<br />

ENK focuses entirely on Acoje project<br />

Laterite direct shipping ore (DSO) mining operations at ENK’s Acoje Nickel Project on Luzon.<br />

RATIONALIZATION of its portfolio during the<br />

last 12 months has put nickel gr oup ENK in<br />

a strong position to advance its flagship<br />

Acoje Nickel Project on Luzon island. <strong>The</strong><br />

sales of a number of pr ojects in Turkey and<br />

the Philippines and the repayment of loans by<br />

its local partner has put ENK in a str ong financial<br />

position as Acoje moves into the key<br />

stages of development.<br />

<strong>The</strong> company expects to publish a bankable<br />

MARCVENTURES Holdings expects to more<br />

than double nickel shipments from its project<br />

in Surigao del Sur on Mindanao this year compared<br />

to 2011. A study by First Metro Investment<br />

Corp says the company can make 18<br />

shipments or 1 million wet metric tons (WMT)<br />

of combined low-grade (1% per tonne of or e<br />

with iron content of 48%) and high grade nikkel<br />

ore (1.8% per tonne of ore) this year.<br />

It is estimated that in 2011 Marcventures, a<br />

holding company listed on the Philippine<br />

Stock Exchange, shipped mor e than<br />

550,000 WMT of pr edominantly low-grade<br />

nickel ore, which was the first to be extracted<br />

based on the company’s mining strategy over<br />

an open pit mine of 15 hectares. It is involved<br />

in nickel mining operations through its subsi-<br />

6 | <strong>ASIA</strong> <strong>Miner</strong> |July/August 2012<br />

feasibility study for the pr oject in September,<br />

which is expected to lead to ear nest discussions<br />

about how to move Acoje fr om development<br />

into pr oduction. ENK is hopeful of<br />

beginning production in late 2013 or early 2014.<br />

Last year ENK sold its Caldag pr oject in<br />

Turkey for US$40 million and this year has<br />

sold its interest in Berong Nickel Corporation<br />

and Toledo Mining Corporation, both with<br />

Philippines projects, for US$7.25 million.<br />

Marcventures increases nickel shipments<br />

diary - Marcventures Mining & Development<br />

Corporation (MMDC).<br />

<strong>The</strong> area covered by MMDC’s <strong>Miner</strong>al Production<br />

Sharing Agreement is at Cantilan in<br />

the Diwata mountain range of Surigao del Sur<br />

and covers 4799 hectar es. <strong>The</strong> company<br />

started mining last year and is undertaking<br />

ongoing exploration activities adjacent to the<br />

open pit and in other parts of the licence<br />

area. Shipments to China are made from the<br />

company’s causeway at Carrascal.<br />

<strong>The</strong> operating mine is part of an area of just<br />

120 hectares that has been explored with resource<br />

and reserve estimates of 22.6 million<br />

WMT and 11.6 million WMT, respectively, and<br />

with nickel ore average grade of 1.5%, compliant<br />

with the Philippine standards.<br />

ENK’s local partner Montemina Resour ces<br />

will also be paying back its loans totalling<br />

US$11 million through the sale of a 60% interest<br />

to Golden Harvest Global Corporation.<br />

Acoje is expected to be developed over<br />

two stages with a focus on the higher grade<br />

ore first to reduce the upfront capital costs.<br />

<strong>The</strong> first stage will see annual thr oughput of<br />

1.5 million tonnes of or e, producing about<br />

15,000 tonnes of nickel. Production schedules<br />

in early years will also be optimized to take<br />

advantage of higher nickel feed grades to<br />

realize higher revenues.<br />

<strong>The</strong> proposed sulphuric acid plant will only<br />

be built during stage two, greatly reducing initial<br />

project capital requirements. In year five,<br />

the plant will be expanded to an annual rate<br />

of 24,000 tonnes over a 20 year life of mine,<br />

making ENK a sizeable global producer.<br />

ENK has already decided to use tank leaching<br />

rather than traditional heap leaching to<br />

process the ore. Costings for this process will<br />

be keenly scrutinized by the nickel industry as<br />

ENK will be one of the first miners to use atmospheric<br />

leaching at a nickel laterite project.<br />

ENK’s managing director Rob Gregory says<br />

traditional heap leaching would have worked,<br />

but because of the heavy rainfall in the Philippines<br />

it would have been mor e difficult to<br />

manage. He says the equatorial laterites that<br />

make up the or e at Acoje ar e also better<br />

suited to tank leaching.<br />

First Metro Investment Corp said earlier this<br />

year that company’s 2012 earnings growth<br />

would be driven by higher daily tonnage, likely<br />

to be 6600 WMT over 150 days of operations<br />

in 2012, and a slight revival in LME nickel prices<br />

to around $21,500 per tonne or an equivalent<br />

selling price of $56 per tonne for<br />

Marcventures under its 3-year, 3 million tonne<br />

nickel ore forward sales contract with Dun<br />

Feng International. Dun Feng is one of the largest<br />

buyers of nickel ore in China.<br />

In an industry report about nickel, a global<br />

financial services consultancy firm says that<br />

nickel pig iron (NPI), a Chinese invention, has<br />

gained wide acceptability as a substitute for<br />

primary nickel as a raw material for stainless<br />

steel manufacturers.

Intex is involved in the provision of water around the<br />

Mindoro Nickel Project.<br />

INTEX Resources has signed a Pr oject Management<br />

Contract (PMC) with China’s MCC8<br />

Group Co Ltd covering its Mindoro Nickel Project.<br />

<strong>The</strong> contract means that MCC8 is responsible<br />

for managing the formation of a<br />

consortium to develop the project, including arranging<br />

project financing, identifying pr oject<br />

operator, evaluating EPCM contract options<br />

and, if appropriate, bringing in off-takers.<br />

An MoU was originally signed in January and<br />

this was converted to a PMC in May. Since January,<br />

Intex and MCC8 have worked diligently<br />

to identify potential investors, financiers, of-takers<br />

and operators. One of the results was that<br />

on April 17 Intex, thr ough the introduction of<br />

MCC8, received a proposal from CITIC-GEM<br />

Fund offering 800 million Norwegian kr one in<br />

equity financing, which is assumed to be the<br />

major part, or all of the equity needed for the<br />

realization of phase one of the project.<br />

CITIC-GEM Fund is a part of the CITIC<br />

MINDORO Resources is restructuring its Philippines<br />

assets so that it can concentrate on the<br />

Agata Nickel Project. <strong>The</strong> company is spinning<br />

out its key gold and copper-gold assets - the<br />

Batangas gold pr ojects including Ar changel<br />

and Lobo, and the Tapian San Francisco (TSF)<br />

copper-gold properties near Surigao - into<br />

ASX-listed Red Mountain Mining.<br />

<strong>The</strong> consideration for the sale is shar es in<br />

Red Mountain payable to Mindor o in two<br />

tranches. <strong>The</strong> first tranche involves 100 million<br />

initially non-voting shar es at Aus$0.10<br />

per share on completion of the transaction<br />

and the second involves 50 million ‘perfor -<br />

mance shares’ at Aus$0.10 per share to convert<br />

to non-voting shar es based on<br />

Intex signs contract for Mindoro management<br />

An Intex employee plants an acacia seedling as part of<br />

the CSR program.<br />

Group Corporation, a leading China Stateowned<br />

multinational conglomerate. Its financial<br />

business covers a full range of services<br />

including commercial banking, investment<br />

banking, trust, insurance, fund management<br />

and asset management.<br />

MCC8 is a major Chinese state-contr olled<br />

engineering and construction company, and<br />

is a former part of China’s largest nickel producer,<br />

Jinchuan Group. <strong>The</strong> company develops,<br />

and forms Chinese consortia that<br />

undertake project finance, plant engineering<br />

and construction (EPCM), mine operation<br />

and equity investments. MCC8 possess a<br />

50-year history of construction and completion<br />

of more than 80 non-ferrous metallurgical<br />

plants, including the construction of China’ s<br />

Nickel City in Jinchang.<br />

Intex says planning of the amended feasibility<br />

study for a staged development of Mindoro is<br />

expected to be completed by the end of the<br />

Philippines<br />

Intex employees and local community members involved<br />

in environmental work.<br />

year and the initial financing under the PMC to<br />

cover the DFS costs is expected to be in place<br />

within the same period. It is understood that<br />

MCC8’s deep understanding of nickel production<br />

operations could reduce the CAPEX of MN<br />

significantly. MCC8 will modify the feasibility<br />

studies and undertake preliminary design with<br />

the assistance of Intex.<br />

Intex believes MCC8’s experience in numerous<br />

mining and envir onmental projects in<br />

Asia; Europe and Africa will provide credibility<br />

in coordinating the political, financial and<br />

technical aspects of the pr oject into a streamlined<br />

development strategy.<br />

Under the PCM the consortium will have<br />

the first right of r efusal/option to buy up to<br />

90% of Mindoro Nickel in a staged pr ocess<br />

for US$296 million linked to specific milestones.<br />

Full payment of the US$296 million will<br />

take place befor e construction can start.<br />

Construction is estimated to start in 2015.<br />

Mindoro to spin out copper-gold assets<br />

upgrading the Batangas indicated r esource<br />

to 600,000 ounces of gold and completing a<br />

scoping study that demonstrates a viable<br />

gold project based on more than 50% of the<br />

indicated resource within 12 months of completing<br />

the transaction.<br />

Mindoro’s president and CEO Jon Dugdale<br />

says, “<strong>The</strong> separation of the key gold<br />

and copper-gold assets of the company<br />

from the advanced Agata Nickel Project provides<br />

the opportunity for optimal value recognition<br />

of these assets in today’ s equity<br />

marketplace. This is why the Board and management<br />

of Mindoro supports this proposed<br />

spin-out of the Batangas and TSF gold<br />

and copper-gold projects into the gold mi-<br />

ning and exploration focused Red Mountain.<br />

Red Mountain’s mining expertise and funding<br />

with the Mindor o team’s exploration<br />

and community engagement track r ecord,<br />

is a great combination.”<br />

As part of the transaction Red Mountain will<br />

provide a secured draw-down facility for up<br />

to Aus$1 million to enable Mindor o to commence<br />

drilling, focused on delineating the<br />

high-grade feeder structures below the Kay<br />

Tanda resource at Archangel, Batangas.<br />

Agata includes a 42 million tonne @ 1.01%<br />

nickel measured and indicated resource for<br />

430,000 tonnes of nickel, and a 35.4 million<br />

tonne @ 1.03% nickel pr oved and probable<br />

reserve for 365,000 tonnes.<br />

July/August 2012 | <strong>ASIA</strong> <strong>Miner</strong> | 7

Philippines<br />

Toledo assesses Berong improvements<br />

TOLEDO Mining Corporation is investigating<br />

ways to extend the curr ently restrained shipping<br />

period of its direct shipping ore (DSO) nikkel<br />

from the Berong joint venture project on<br />

Palawan, is assessing a possible value-added<br />

strategy and is improving the port area. <strong>The</strong>se<br />

measures are aimed at improving revenue at<br />

a time when the JV is targeting annual production<br />

of 750,000 wet metric tons (WMT) @<br />

1.8% nickel from the end of this year.<br />

An engineering company is evaluating the<br />

constraints of the shipping window which<br />

sees shipments halted during the monsoon<br />

season. AIM-listed Toledo hopes to extend<br />

the shipping window and increase annual capacity<br />

to 1 million WMT. If this is not possible<br />

the company believes the non-shipping period<br />

presents an opportunity to build a stockpile<br />

of ‘r eady-to-go’ 1.8% or e. At pr esent<br />

Toledo ships its ore to China but also believes<br />

it may be prudent to investigate value-added<br />

opportunities to find the most suitable pr ocess<br />

for the ore, generating more cashflow.<br />

At its port, Toledo plans to extend the causeway<br />

to achieve better ship loading ef ficiency<br />

with the first phase of the extension<br />

agreed at a budget of US$314,000. This will<br />

extend the existing pier by about 30 metr es<br />

seaward, creating a deeper loading draft<br />

which should provide more stable barge-loading<br />

conditions even during moderate swell.<br />

While the pier extension may not necessarily<br />

prolong the shipping period, it will greatly en-<br />

METALS Exploration is making steady pr ogress<br />

on development of the Runruno Gold<br />

Project with the early works pr ogram reaching<br />

design activity levels and work under<br />

way on multiple facets of the pr oject. <strong>The</strong><br />

company is also making progress with a debt<br />

funding package to support the full development<br />

of Runruno with legal documentation<br />

advanced and finalization expected shortly.<br />

<strong>The</strong> earthworks are at an advanced stage<br />

with the camp site, batch plant and lay-down<br />

area completed, two causeways established<br />

across the Sulong River to facilitate access to<br />

the processing plant site and the pr ocessing<br />

plant earthworks nearing completion. Work is<br />

continuing on construction of the camp and of-<br />

8 | <strong>ASIA</strong> <strong>Miner</strong> |July/August 2012<br />

hance the loading throughput.<br />

Berong has a JORC-compliant resource of<br />

9.13 million tonnes @ 1.55% nickel and a potential<br />

resource of 120 million tonnes @<br />

1.34% nickel. <strong>The</strong> nearby Long Point and<br />

Moorsom projects have a potential resource<br />

of 120 million tonnes @ 1.27% nickel. During<br />

the first quarter of 2012 production of run-ofmine<br />

ore from Berong was 183,000 WMT at<br />

an average grade of 1.88%. DSO operations<br />

resumed in early Mar ch when the shipping<br />

window reopened with shipments of 48,700<br />

WMT @ 1.82% and 54,000 WMT @ 1.63%<br />

carried out during March. Another three shipments<br />

of 55,603, 48,315 and 40,845 WMT<br />

were made in subsequent weeks.<br />

<strong>The</strong> Berong operation is held by Ber ong<br />

Nickel Corporation, a joint ventur e between<br />

Toledo, Atlas Consolidated Mining and Deve-<br />

fice complexes, and on the pioneering work to<br />

establish the road into the pit with the material<br />

extracted being used as fill on both the laydown<br />

and processing plant site areas.<br />

Leighton Contractors Asia have been contracted<br />

to design and construct the pr ocessing<br />

plant at a guaranteed maximum of<br />

US$91.5 million out of a total capital cost for<br />

the entire project of US$167.8 million.<br />

Leighton reports that it is pr oceeding well<br />

with the processing plant detailed engineering<br />

program.<br />

Other aspects of the early stage works program<br />

include provision of construction power,<br />

provision of potable water, erection of a concrete<br />

batching plant and acquisition of selec-<br />

lopment and World Fund Pte Ltd, which r ecently<br />

purchased ENK’s 18.7% stake.<br />

Owing to a delay in the granting of a new<br />

tree cutting permit, the Berong mine has a limited<br />

mining area which is impacting on the<br />

amount of high grade ore that can be produced.<br />

This forced the joint venture to revise the<br />

ore sales plan from a single 1.8% grade to a<br />

combination of 1.8%, 1.6% and 1.5% grade<br />

shipments in order to maximize revenue until<br />

a new permit is granted.<br />

Toledo is also seeking other potential buyers<br />

for its 40% stake in the Ipilan nickel operation<br />

after it received a draft share purchase<br />

agreement from Chinese gr oup Jinchuan,<br />

which contained terms that the company ,<br />

along with its JV partners, thought wer e<br />

wholly unacceptable. <strong>The</strong> exclusivity granted<br />

to Jinchuan in the MoU has expired.<br />

Loading direct shipping ore from Toledo Mining’s Berong Nickel Project on Palawan island.<br />

Steady progress on early Runruno development<br />

ted units of the mobile fleet.<br />

Metals Ex executive chairman Ian Holzberger<br />

says, “It is very satisfying to see the progress<br />

being made on the ground at Runruno<br />

as the early works program ramps up and the<br />

work commences on multiple facets of the<br />

project. This work demonstrates the company’s<br />

capacity to implement the Runruno project<br />

and is crystallising the size and scope of<br />

the project to its stakeholders. Equally it is<br />

pleasing to see the pr ogress made with the<br />

processing plant detailed engineering pakkage<br />

under Leighton’s management. This<br />

work will support the early commencement<br />

of the processing plant construction once full<br />

funding is available.”

Philippines<br />

10 | <strong>ASIA</strong> <strong>Miner</strong> |July/August 2012

DRILLING by CGA Mining has resulted in an<br />

updated resource and reserve estimate that<br />

replaces all ounces mined at Masbate Gold<br />

Project. Total measured and indicated resources<br />

have increased contained gold by 12.7%<br />

to 5.13 million ounces compar ed with 4.55<br />

million ounces reported in the last release of<br />

a NI 43-101 compliant r esource. After allowing<br />

for ounces depleted from mining since<br />

the last resource release, this represents an<br />

increase of 1.06 million ounces or 23.3%.<br />

<strong>The</strong> deposit also contains an estimated in -<br />

ferred mineral resource containing 2.83 million<br />

ounces compared with 3.22 million ounces reported<br />

in the last resource release. <strong>The</strong> reduction<br />

is associated with mining depletion and<br />

conversion to the measured and indicated categories.<br />

<strong>The</strong> updated estimates are based on<br />

drilling completed to the end of June 2011,<br />

which represents only the addition of about<br />

42,000 metres of new drilling. Drilling continues<br />

within and adjacent to the current mineralization,<br />

with intercepts subsequent to the<br />

preparation of this model showing potential to<br />

upgrade mineral classification and further increase<br />

the total resources.<br />

<strong>The</strong> update covers a geographic ar ea<br />

slightly larger than the earlier estimate and includes<br />

resources for the Old Lady deposit reported<br />

for the first time. It does not include<br />

resources for the Pajo prospect as drilling at<br />

this location commenced after the cut-of f<br />

date for inclusion in the updated estimate.<br />

As of October 31, 2011, the total pr oven<br />

and probable reserves estimation has increased<br />

to contain 3.097 million ounces compared<br />

to 3.02 million ounces r eported in the<br />

BROKER Fairfax has increased its price target<br />

for Medusa Mining and says that the curr ent<br />

market represents a golden opportunity to buy<br />

into the stock. It has impr oved its forecasts<br />

owing to an expected reduction in cash costs<br />

at Medusa’s flagship Co-O Gold Project as well<br />

as an increase in production during 2012.<br />

Fairfax analyst John Meyer says exploration<br />

at the Co-O mine continues to pr ogress and<br />

that the JORC resource should continue to expand<br />

to replace ounces that have been unearthed<br />

and to extend the overall resource to more<br />

than 2 million ounces, up from 1.96 million. He<br />

says the r ecent Bananghilig gold discovery ,<br />

where production is targeted for 2016, should<br />

also extend to more than 1 million ounces although<br />

mine planning will be for a potential<br />

200,000 ounce per annum operation for a five<br />

year mine life at a $550 per ounce cash cost.<br />

In terms of copper, John Meyer says the<br />

Medusa team is working to pr ove up a significant<br />

body of mineralization with a view<br />

to selling its copper portfolio.<br />

“Medusa is a relatively safe gold stock with<br />

Philippines<br />

CGA replaces ounces mined at Masbate<br />

previous reserve estimate. This represents an<br />

overall increase of 455,000 ounces or 17.2%<br />

from the previous estimate after allowing for<br />

production of 378,000 ounces.<br />

Since the drilling cut-off date a further 60,600<br />

metres of exploration drilling has been completed.<br />

Further updates to the r eserve and r esource<br />

estimates are planned to be completed<br />

on an annual basis, with the next drilling cut-of<br />

date June 30, 2012. <strong>The</strong> exploration team r emains<br />

confident, given CGA ’s demonstrated<br />

commitment to incr ease exploration activity,<br />

that the ability to further gr ow the reserve and<br />

resource base of the project is strong.<br />

CGA achieved record monthly production of<br />

20,007 ounces of gold in May , eclipsing the<br />

previous record of 18,318 ounces in December<br />

2010. <strong>The</strong> record came from processing<br />

a record of 642,816 tonnes, with the previous<br />

record being 605,330 tonnes in May 2011, at<br />

1.15 grams/tonne gold head grade and an<br />

average hourly throughput rate of 919 tonnes.<br />

Since the SAG mill was br ought back into<br />

production in late December 2011,<br />

throughput has averaged 802 tonnes/hour<br />

with an availability of 93%.<br />

A gold pour at CGA Mining’s Masbate Gold Project. <strong>The</strong> project achieved record monthly production of 20,007<br />

ounces during May.<br />

Broker says Medusa is ‘golden’ opportunity<br />

a strong cash and gold balance and relatively<br />

well set gold production growth from here. It<br />

is consistently mining and pr ocessing high<br />

grade gold material from the Co-O gold mine,<br />

which is highly cash generative and its expansion<br />

to an annual 200,000 ounces is largely<br />

compete. We view the current market as a<br />

‘golden’ opportunity to buy into Medusa Mining<br />

stock as gold production rates improve.”<br />

Medusa says that it is on a growth path to<br />

annual production of 400,000 ounces by the<br />

end of 2015 or early 2016.<br />

July/August 2012 | <strong>ASIA</strong> <strong>Miner</strong> | 11

Philippines<br />

Policy review provides hope for Tampakan<br />

INDOPHIL Resources believes a systematic<br />

review of mining policy by the Philippine Government<br />

provides some light at the end of<br />

the tunnel for the T ampakan Copper-Gold<br />

Project. <strong>The</strong> project is owned by Sagittarius<br />

Mines, a joint venture company with Xstrata<br />

Copper and Indophil as major shareholders.<br />

Development at the project that is estimated<br />

to contain 15 million tonnes of copper and almost<br />

18 million ounces of gold, was hampered<br />

by a provincial government ban on open pit mining<br />

in South Cotabato, the province in which<br />

Tampakan is located, that took ef fect in October<br />

2010. As well as impacting the companies<br />

involved, the ban has had an adverse<br />

effect on investor confidence in the Philippines.<br />

Indophil’s chairman Gavan Collery says the<br />

company was comforted at the time the mining<br />

ban was announced by assurances from<br />

the Philippine Government that such a ban<br />

was illegal - that it was contrary to national<br />

law - but it is still in place. “To add further uncertainty,<br />

in early 2012 the Of fice of the Secretary<br />

of the Department of Envir onment<br />

and Natural Resour ces (DENR) r eturned<br />

Tampakan’s application for appr oval of the<br />

Environmental Impact Statement for the mine<br />

area. This approval, known locally as an Environmental<br />

Compliance Certificate or an<br />

ECC, was conditionally denied and made<br />

subject to resolution of the open pit ban.”<br />

An appeal by Xstrata to reconsider the ECC<br />

has recently been tur ned down with the<br />

DENR re-stating that the matter is dependent<br />

on the resolution of the conflict between national<br />

mining policy and the envir onmental<br />

code in South Cotabato.<br />

Gavan Collery says the framework of the<br />

Gold Fields boosts Far South East interest<br />

GOLD Fields intends to incr ease its interest<br />

in the Far South East Gold Project on Luzon<br />

to up to 60% as part of a strategy to diversify<br />

risk away fr om South Africa. An initial r esource<br />

estimate for the pr oject is expected<br />

during the second half of this year at which<br />

time a pre-feasibility study will be started. An<br />

indicative timeline shows that a mine could<br />

be constructed during 2015-16.<br />

Gold Fields has a strategy to have 5 million<br />

ounces of gold either in pr oduction or under<br />

12 | <strong>ASIA</strong> <strong>Miner</strong> |July/August 2012<br />

<strong>The</strong> Tampakan project of Sagittarius Mines is in southern Mindanao. Major Sagittarius stakeholders are Xstrata<br />

Copper and Indophil Resources.<br />

mining policy review is understood to be contained<br />

within six points, covering sustainable<br />

development; best practice and governance;<br />

protection of the environment; primacy of national<br />

law; sharing of benefits; and sound mining<br />

sector management.<br />

“This framework – save for implying ‘restoration<br />

of investor confidence’ – is the basis<br />

for the type of responsible practice that one<br />

would care to see applied in any jurisdiction<br />

in the world. <strong>The</strong> framework is one that we<br />

support, and one that we will continue to advocate<br />

within the industry and within all levels<br />

of government. Hopefully, its carriage and adoption<br />

will see the mining industry in the Philippines<br />

contributing to a sound economic<br />

future; a future that can in part be underpinned<br />

by development of Tampakan.<br />

“While being understandably cautious<br />

development by 2015, with South Africa making<br />

up 40% of that, contributing 2 million ounces.<br />

It plans to have 1 million ounces fr om<br />

each of the three regions in which it operates<br />

- West Africa, South America and Australasia.<br />

<strong>The</strong> company is buying up to 60% of the<br />

Far South East pr oject from the existing<br />

owners for a total payment of $340 million. In<br />

September 2010 it reached an agreement to<br />

buy the stake from Lepanto Consolidated Mining,<br />

the 60% owner of Far South East, and<br />

based on past experiences, it appears that<br />

mining policy in the Philippines is coming of<br />

age, and will be based on sound process and<br />

system. A robust and invigorated national mining<br />

policy will deliver nation-building benefit<br />

to the people of the Philippines and r eward<br />

those who embark on the considerable risk<br />

of minerals exploration and development.”<br />

He says, “Re-affirmation and enforcement of<br />

the issue of primacy of national laws over local<br />

government ordinances, such as the ban on<br />

open pit mining in South Cotabato, is critical to<br />

any decision to proceed with the near-$6 billion<br />

development of Tampakan. <strong>The</strong> mor e than<br />

US$400 million already invested on the Tampakan<br />

study programs, legislated government<br />

payments, community development and related<br />

project expenditure is a clear demonstration<br />

of the joint venturers’ commitment.”<br />

Liberty Express Assets, the 40% holder . In<br />

March this year, Gold Fields brought forward<br />

a payment of $110 million to raise its stake to<br />

40% in the project. <strong>The</strong> early exercise of the<br />

option to buy the Liberty stake does not afect<br />

the option to buy a further 20% stake for $110<br />

million from Lepanto, which will r emain Gold<br />

Fields’ partner in the project.<br />

Gold Fields plans to mine an unexploited<br />

ore body below a mine that is near the end<br />

of its life.

St Augustine starts King-king permitting process<br />

ST AUGUSTINE Gold & Copper has started<br />

the process of permitting of the King-king<br />

Copper-Gold Project in the southeast of the<br />

island of Mindanao by completing and submitting<br />

the Declaration of Mine Project Feasibility<br />

(DMPF). King-king is one of the largest undeveloped<br />

copper-gold deposits in the world<br />

with a measur ed and indicated mineral r esource<br />

of 5.4 billion pounds of contained copper<br />

and 10.3 million ounces of contained gold.<br />

<strong>The</strong> project, which is listed as one of the top<br />

priority projects by the Philippine Mines and<br />

Geosciences Bureau, also has an inferred resource<br />

of 188.8 million tonnes @ 0.215%<br />

total copper, 0.048% soluble copper and<br />

0.265 grams/tonne gold. It is 35km east of<br />

Davao City, 13km from the coast, has a low<br />

strip ratio (0.8:1) and is at an advanced stage<br />

with 95,651 metres of drilling composed of<br />

291 core and reverse circulation holes, including<br />

6052 metres of new drilling composed<br />

of 14 core holes (and 1 RC) in 2011.<br />

<strong>The</strong> company’s Philippines partner, Nation-<br />

INITIAL drilling as well as the extensive and<br />

intense skarn alteration that extends for more<br />

than 700 metres along strike have pr ovided<br />

Mining Group with further indications that the<br />

Tagpura/Bayag Bayag prospects at its Comval<br />

Copper-Gold Project have the potential to<br />

host a significant copper ore body. Assay results<br />

from the first of eight holes into Bayag<br />

Bayag target have provided results that support<br />

extensive drilling.<br />

<strong>The</strong> initial hole inter cepted more than 100<br />

metres of variably skarn altered limestone consisting<br />

of massive gar net, pyroxene, epidote<br />

pyrrhotite and visible copper mineralization as<br />

chalcopyrite. <strong>The</strong> assays include 44 metres @<br />

0.64% copper from 39 metres, including 28<br />

metres @ 0.88% copper from 55 metres.<br />

Three holes have been drilled at Bayag<br />

Bayag with another thr ee being drilled. <strong>The</strong><br />

company has a total of eight holes planned in<br />

the initial drilling program at Bayag Bayag in<br />

order to test the overall width and strike extent<br />

of this mineralization. This will be done in conjunction<br />

with ground magnetic surveyingl.<br />

<strong>The</strong> onsite exploration team has mapped<br />

surface mineralization consisting of skarn al-<br />

wide Development Corporation (NADECOR),<br />

as party to the <strong>Miner</strong>al Pr oduction Sharing<br />

Agreement with the Philippine Gover nment,<br />

has submitted the DMPF to the Department<br />

of Environment and Natural Resources and<br />

the Mines and Geosciences Bur eau for review<br />

and approval.<br />

<strong>The</strong> DMPF is a r egulatory requirement that<br />

includes 20 plans, certifications and other documents<br />

required to obtain approval from the<br />

Philippine government to develop King-king.<br />

This submittal begins the permitting pr ocess<br />

and represents an important milestone. NADE-<br />

COR’s and St Augustine’s mutual commitment<br />

to development of the project in a manner that<br />

is protective of health, safety and the environment<br />

was incorporated into the DMPF.<br />

NADECOR is in the process of resolving internal<br />

issues within its boar d of directors, however<br />

these issues did not impact submission<br />

of the DMPF. Also, while some delay in the issuance<br />

of deliverables due to St Augustine by<br />

NADECOR has occurred as a result, the com-<br />

pany understands that NADECOR’ s board<br />

members and key shar eholders are working<br />

toward resolution of these issues. Company<br />

management is communicating constantly<br />

with its partner to ensur e the interests of the<br />

company and the project are protected.<br />

St Augustine’s CEO Andrew J Russell says,<br />

“<strong>The</strong> company has invested mor e than $70<br />

million in the project and the DMPF to date.<br />

<strong>The</strong> next steps are the completion of a pr efeasibility<br />

study and following that, a bankable<br />

feasibility study (BFS). <strong>The</strong> BFS is targeted for<br />

completion later this year to coincide with anticipated<br />

receipt of approved permits.<br />

On June 1 St Augustine Services Inc, a<br />

subsidiary of St Augustine, signed a Memorandum<br />

of Agr eement with the T echnical<br />

Education and Skills Development Authority<br />

(TESDA) of the Philippines, the first such<br />

agreement for a mining company. TESDA will<br />

facilitate and participate in the conduct of<br />

workforce training for the King-king pr oject<br />

through construction and operation.<br />

Promising indications from Comval project<br />

teration and gossans, with this potentially mineralized<br />

zone being identified over 700 metres<br />

of strike length. <strong>The</strong> nature and extent of<br />

the alteration mineral assemblage indicates<br />

that the mineralizing system is large and par-<br />

<strong>The</strong> pit and workings at Mining Group’s Tagpura prospect on the Comval project.<br />

allels can be drawn with many skarn/copper<br />

porphyry systems around the world. Skar n<br />

alteration is a common tool for exploration of<br />

larger porphyry mineralizing systems.<br />

Mining Group’s managing director Andrew<br />

Maurice says, “<strong>The</strong> initial assay r esults from<br />

Bayag Bayag ar e encouraging, especially<br />

Philippines<br />

when combined with the assay r esults we<br />

previously announced from the Tagpura and<br />

Maangob targets. All of our targets are in relatively<br />

close pr oximity, with Bayag Bayag<br />

only 700 metres south of T agpura, further<br />

supporting the potential economic viability of<br />

the Comval copper/gold project.<br />

“Perhaps the most significant featur e of<br />

what we see at Bayag Bayag is evidence of<br />

a widespread and intensive zoned alteration<br />

system commonly associated with large copper/gold<br />

porphyry systems.<br />

July/August 2012 | <strong>ASIA</strong> <strong>Miner</strong> | 13

Philippines<br />

Taysan PFS delivers positive results<br />

A POSITIVE pre-feasibility study (PFS) for the<br />

Taysan Copper-Gold Project supports the<br />

proposal of Crazy Horse Resour ces to pursue<br />

a trade sale or a joint ventur e of the<br />

Luzon Island project. <strong>The</strong> PFS forecasts average<br />

annual payable production of 76 million<br />

pounds of copper, 30,000 ounces of gold,<br />

93,000 ounces of silver and 476,000 tonnes<br />

of magnetite over the 24 year mine life.<br />

Average operating costs for the project are<br />

estimated at US$1.68 per pound of copper<br />

equivalent over the life of the mine and<br />

US$1.18 per pound of copper equivalent during<br />

the first five years of production. Initial capital<br />

costs are estimated at US$502 million.<br />

<strong>The</strong> PFS also determines that the project has<br />

an estimated net present value at a 10% discount<br />

rate of US$503 million and an inter nal<br />

rate of return of 49.2%, both calculated on<br />

after tax, post-financing cash flow including<br />

metal by-products.<br />

Since the release of the PFS Crazy Horse<br />

has engaged the services of Regent Advisors<br />

to advise the company as it seeks a potential<br />

buyer or joint venture partner for the project.<br />

Crazy Horse’s chairman and CEO Mitch Alland<br />

says, “We are excited about the attractiveness<br />

and the financial r obustness of<br />

Taysan. <strong>The</strong> large measured and indicated resource<br />

of 1.2 million tonnes of contained<br />

copper will provide the basis for the stage 1<br />

MARTINA <strong>Miner</strong>als has signed a binding Letter<br />

of Intent with BlueCreek Mining, a Filipinoowned<br />

company, to acquire a 40% interest in<br />

two groups of gold pr ospective property<br />

known as Boston and San Miguel in Eastern<br />

Mindanao. Martina is a Canadian-listed company<br />

focused on minerals exploration and<br />

was formed from the merger of Compostela<br />

Mining with Manor Global.<br />

Boston is to the east of Mt Diwalwal, one of<br />

the largest gold deposits in the Philippines,<br />

which is itself immediately to the east of Martina’s<br />

TRIMA 1 property. <strong>The</strong> San Miguel property<br />

is about 130km to the north of Boston.<br />

<strong>The</strong> properties are along the well-known and<br />

highly mineralized East Mindanao fault.<br />

<strong>The</strong> Boston exploration area is held in an<br />

Ancestral Domain Title of the Boston Man-<br />

14 | <strong>ASIA</strong> <strong>Miner</strong> |July/August 2012<br />

project of a 15 million tonnes per annum operation<br />

for 24 years which can then be followed<br />

by the stage 2 expansion to either<br />

double the throughput rate or extend mine life<br />

to up to 40 years.”<br />

Drilling on Crazy Horse Resources’ Taysan Copper-Gold Project in Southern Luzon.<br />

Martina acquires additional gold prospects<br />

daya-Manobo Indigenous Peoples. <strong>The</strong> Boston<br />

properties comprise 19,151 hectar es.<br />

<strong>The</strong> Indigenous Peoples will also r eceive 1<br />

million common shares and warrants of Martina<br />

and a cash payment of US$150,000. <strong>The</strong><br />

San Miguel property is also within an Ancestral<br />

Domain T itle and r epresented by the<br />

Upper San Miguel Manobo Sectoral Council<br />

of Elders and Leaders. <strong>The</strong> Indigenous<br />

Peoples will r eceive a cash payment of<br />

US$50,000. <strong>The</strong> San Miguel pr operty comprises<br />

about 18,000 hectares.<br />

As part of the transaction BlueCreek will retain<br />

a 30% ownership in each of the properties<br />

and the local Indigenous Peoples will hold the<br />

balance of the properties. Martina can, at its<br />

option, acquire BlueCreek’s 30% economic interest<br />

in the properties based on the following:<br />

Located in Southern Luzon, Taysan is accessible<br />

from Manila by 106km of expr essway<br />

followed by 7km on sealed pr ovincial<br />

roads. It is 20km fr om the provincial capital<br />

on sealed provincial roads.<br />

Discovery of 500,000 ounces of gold or its<br />

equivalent to NI 43-101 resource standard for<br />

2.5 million common shares; discovery of 1 million<br />

ounces of gold or its equivalent to NI 43-<br />

101 resource standard for 5 million common<br />

shares; and 1 million common shares per additional<br />

1 million ounces or its equivalent to NI<br />

43-101 resource standard.<br />

Since this acquisition Martina has also acquired<br />

up to a 68% interest in privately held exploration<br />

land in northeast Mindanao. <strong>The</strong><br />

company has signed an MOU with Consolidated<br />

Ores Philippines, a Filipino company owned<br />

by the Adviento Group, to acquire an initial 40%<br />

interest in its property known as Umalag.<br />

Consolidated Ores holds a <strong>Miner</strong>al Production<br />

Sharing Agreement for Umalag, which is<br />

in the Province of Surigao del Sur.

INTERNATIONAL diversified resource company<br />

Astra Resources, through its joint venture<br />

in Cagayan River Construction and<br />

Development Corporation (CRCDC), will<br />

begin dredging its iron sands project later this<br />

year. <strong>The</strong> Babuyan Channel Ir on Sand Lode<br />

in the province of Cagayan, northeast Luzon,<br />

is estimated to contain more than 31.3 billion<br />

tonnes in the <strong>Miner</strong>al Pr oduction Sharing<br />

Agreement areas (MPSA), which is only a<br />

fraction of the lode.<br />

Through its subsidiary Astra Philippines Pty<br />

Ltd, Astra beneficially owns 90% of the joint<br />

venture company CRCDC, a Philippine registered<br />

company. <strong>The</strong> ultimate goal of<br />

CRCDC is of f-shore mining of magnetite<br />

sand with a top monthly pr oduction of<br />

300,000 tonnes on a floating plant.<br />

Astra’s CEO Dr Jaydeep Biswas says commencement<br />

of the project is pursuant to a Memorandum<br />

of Agr eement by and between<br />

BEZANT Resources has signed an option<br />

agreement with Gold Fields Netherlands Services<br />

for the potential disposal of its Philippines<br />

subsidiary Asean Copper Investments<br />

Limited which has the Mankayan Copper -<br />

Gold Project on Luzon. In light of Gold Fields<br />

recent further part exercise of their options<br />

with Lepanto Consolidated Mining and Liberty<br />

Express Assets to acquire up to 60%<br />

of the adjacent Far South East pr oject, Bezant<br />

believes there is a good probability that<br />

the option will be exercised.<br />

Under the terms of the agr eement, Gold<br />

Fields paid a non-r efundable upfront cash<br />

payment of US$7 million to Bezant, with a<br />

further cash sum of US$63 million becoming<br />

payable, should the option be exercised prior<br />

to its scheduled expiry on January 31, 2013.<br />

Bezant’s chairman Gerry Nealon says, “In<br />

the event that the option is exercised and the<br />

sale and transfer of the issued shar es in<br />

Asean is completed, the company anticipates<br />

that approximately 50% of the gross sale proceeds<br />

will potentially be available for distribution<br />

to shareholders. Of the 50% of funds<br />

retained, all taxes will be paid out of this sum<br />

with the remainder being retained to progress<br />

the company’s copper/gold exploration portfolio,<br />

particularly in Argentina.”<br />

Iron sands dredging by the end of 2012<br />

CRCDC and the Provincial Government of Cagayan,<br />

which was ratified by the Pr ovincial<br />

Board on May 4, 2012. “This grants CRDCD<br />

the authority to dr edge, extract and utilize<br />

‘quarry resources’, sand particles and other<br />

materials of commercial value such as magnetite<br />

iron sands from the Cagayan River Delta.”<br />

<strong>The</strong> authority to dredge the assigned area, a<br />

200 metre by 12km strip along the mouth of<br />

the Cagayan River, located in Aparri, was stipulated<br />

to be for a period of 25 years, with production<br />

expected to reach annual gross sales<br />

of about 1 million tonnes by 2014. <strong>The</strong> initial<br />

estimated resource is 135 million tonnes.<br />

Astra’s managing director Silvana De Cianni<br />

says Astra is in the process of acquiring additional<br />

mining areas alongside MPSA 1, 2, 3<br />

and 4 to add to the joint ventur e. “This site,<br />

to be secured from the Department of Environment<br />

and Natural Resources, has inferred<br />

resources of 13 billion tonnes.”<br />

It is expected that this business partner -<br />

ship will significantly enhance the Economic<br />

Development Program, particularly in the<br />

mining industry sector, in the Philippines.<br />

Astra, through its joint ventur e interest in<br />

CRCDC, has successfully arranged all r equirements<br />

to start full operation by the end<br />

of 2012. Top level discussions will be held<br />

in Manila for a corporate review of the requirements<br />

before full implementation.<br />

Astra Resources’ global portfolio includes<br />

gold interests in South East Asia, coal in<br />

Africa, iron ore in India, Norway and the Philippines,<br />

carbon efficient and commodity businesses,<br />

the pr oduction of high-str ength<br />

T-Steel technology in Hungary , clean coal<br />

technology and the provision of mining services<br />

housing in Rockhampton, Queensland,<br />

and a large agricultural focus on creating Australia<br />

as the food bowl for the Asian r egion<br />

through Astra Agricultural Resources.<br />

Bezant signs option on Mankayan project<br />

<strong>The</strong> Guinaoang porphyry copper/gold deposit,<br />

or Mankayan pr oject, is in the Mankayan-Lepanto<br />

mining district, an ar ea of<br />

porphyry copper belts in the Philippines. It is<br />

240km north of the capital and 6km east of<br />

the copper/gold mine owned and operated<br />

by Lepanto Consolidated, and is accessible<br />

by both road and air.<br />

<strong>The</strong> Mankayan project of Bezant Resources is in a mineral-rich area of northwest Luzon.<br />

Philippines<br />

July/August 2012 | <strong>ASIA</strong> <strong>Miner</strong> | 15

China<br />

Drilling extends main zone at Beiya<br />

DRILLING by Asia Now Resour ces at the<br />

main zone of the Beiya pr oject has extended<br />

the gold-silver and base metal zone to<br />

2480 metres by 180 to 700 metres with the<br />

zone remaining open to the northwest and<br />

east. <strong>The</strong> main zone is adjacent to the<br />

open-pit Beiya Gold Mine that pr oduces<br />

200,000 ounces of gold annually but which<br />

is not part of Asia Now’s property.<br />

<strong>The</strong> drilling r eturned a number of higher<br />

grade intersections: 5.8 metr es @ 1.0<br />

grams/tonne gold, 121.6 grams/tonne silver<br />

and 9.9% lead and zinc, including 1.5 metres<br />

Asia Now Resources’ Beiya and Habo projects are in Yunnan province.<br />

钻探作业扩展了北衙北区块的主区域<br />

亚洲现代资源公司在其位于云南省的北衙项<br />

目实施的钻探作业使北衙北区块的金-银和<br />

基础金属区域长度延伸至2480米,宽度<br />

介于180-700米,并保持向西北和东方向延<br />

伸。该主区域临近露天开采的北衙金矿,北<br />

衙金矿年产黄金20万盎司,并不属于亚洲<br />

现代公司。<br />

此次钻探作业得到许多较高品位的矿段:<br />

5.8米矿段金品位1.0克/吨,银品位121.6<br />

克/吨,铅锌品位9.9%,其中,1.5米金品位<br />

2.1克 /吨,银品位169克 /吨,铅锌品位<br />

14.4%;10.5米矿段金品位1.0克/吨,银品<br />

位48克/吨,铅锌品位4.8%。<br />

其他显著的矿段包括:1.3米矿段金品位<br />

16 | <strong>ASIA</strong> <strong>Miner</strong> | July/August 2012<br />

@ 2.1 grams/tonne gold, 169 grams/tonne<br />

silver and 14.4% lead and zinc; and 10.5 metres<br />

@ 1.0 grams/tonne gold, 48<br />

grams/tonne silver and 4.8% lead and zinc.<br />

Other notable intersections are: 1.3 metres<br />

@ 0.35 grams/tonne gold, 375<br />

grams/tonne silver and 26.1% lead and<br />

zinc; 10.5 metres @ 0.22 grams/tonne gold,<br />

89.1 grams/tonne silver, 0.3% copper and<br />

3.9% lead and zinc, including 1.5 metres @<br />

1.0 grams/tonne gold, 308 grams/tonne silver,<br />

1.68% copper and 6.1% lead and zinc;<br />

1.5 metres @ 4.0 grams/tonne gold and 14<br />

0.35克 /吨,银品位375克 /吨,铅锌品位<br />

26.1%;10.5米金品位0.22克/吨,银品位<br />

89.1克/吨,铜品位0.3%,铅锌品位3.9%,<br />

其中,1.5米矿段金品位1.0克/吨,银品位<br />

308克/吨,铜品位1.68%,铅锌品位6.1%;<br />

1.5米矿段金品位4.0克/吨,银品位14克/<br />

吨;1.7米矿段金品位2.18克/吨,银品位21<br />

克/吨;4.5米金品位0.22克/吨,银品位58克<br />

/吨,铅锌品位4.7%,其中1.5米金品位0.36<br />

克/吨,银品位148克/吨,铅锌品位10%。<br />

公司技术总监Noel White博士表示,“非常<br />

高兴在公司刚刚完成NI43-101报告后,我们<br />

又扩大了主矿带范围。北衙工作不断取得的<br />

成果是我们尽快开展预可行性研究的主要推<br />

动力。为了进一步完善预可行性研究的准备<br />

grams/tonne silver; 1.7 metr es @ 2.18<br />

grams/tonne gold and 21 grams/tonne silver;<br />

and 4.5 metr es @ 0.22 grams/tonne<br />

gold, 58 grams/tonne silver and 4.7% lead<br />

and zinc, including 1.5 metr es @ 0.36<br />

grams/tonne gold, 148 grams/tonne silver<br />

and 10% lead and zinc.<br />

Chief technical advisor to the company, Dr<br />

Noel White, says, “We are very pleased that<br />

not long after completing an initial NI43-101<br />

resource estimate late last year, we have already<br />

expanded the main zone at Beiya.<br />

<strong>The</strong> continuing growth at Beiya is encouraging<br />

us to commence a pre-feasibility study<br />

as soon as possible. In addition to finalizing<br />

our preparations for the study we will continue<br />

to drill several new highly pr ospective<br />

copper-gold targets in the Beiya area.”<br />

Asia Now has earned 72% with the option<br />

of increasing to 90% its interest in the Beiya<br />

North property. Beiya North is part of the<br />

Beiya project that involves two joint ventur e<br />

companies. Beiya North is part of the JV with<br />

Yunnan Non-Ferrous Geology and <strong>Miner</strong>al<br />

Resources Company. <strong>The</strong> company is ear -<br />

ning 70% with the possibility of earning up to<br />

88% interest in another JV with Yunnan Geology<br />

and <strong>Miner</strong>al Resources Company.<br />

Asia Now has appointed Har old Shipes as<br />

president and chief executive officer, replacing<br />

Kaihui Yang who served in these r oles since<br />

May 1, 2006, under the terms of a management<br />

services consulting agreement. Harold<br />

Shipes has 30 years of mining experience in<br />

senior positions in base and pr ecious metals<br />

production, engineering and project development<br />

management around the world.<br />

工作,我们将继续在北衙地区几处潜力较大<br />

的铜金靶区增加钻孔。”<br />

亚洲现代已经获得北衙北区块72%的股<br />

份,并有权提高至90%。北衙北是北衙项目<br />

的一部分,涉及两个合资企业。北衙北项目<br />

是与云南有色金属地质矿业资源公司合资项<br />

目的一部分。该公司正在获得与云南地质矿<br />

业资源公司的一个合作项目70%的股份,并<br />

有可能增至88%。<br />

亚洲现代已经任命Harold Shipes先生为公<br />

司总裁兼首席执行官,接替了依据管理服务<br />

咨询协议、自2006年5月1日开始任职的杨<br />

开辉先生。Harold Shipes先生在世界范围内<br />

的基础金属和贵金属生产、工程和项目开发<br />

管理领域拥有30年的高管层经验。

China<br />

Follow-up exploration in Yejiaba area<br />

MINCO Gold has started an exploration<br />

program at the Longnan pr oject in Gansu<br />

province aimed at following up multiple drill<br />

targets defined in its 2010 and 2011 pr ograms.<br />

<strong>The</strong> new program is focusing primarily<br />

on the Shajinba and Baimashi sub-areas<br />

within the Yejiaba area, and includes surface<br />

trenching, sampling, drilling and tunnelling.<br />

<strong>The</strong> company has planned about 3000<br />

metres of diamond drilling in eight holes and<br />

about 3000 metres of underground tunnelling<br />

designed to follow-up the drill targets.<br />

<strong>The</strong> surface trenching and sampling is being<br />

conducted to determine the overall footprint<br />

of the multiple gold zones identified in the<br />

Yejiaba metallogenic trend.<br />

<strong>The</strong> initial parts of the pr ogram include<br />

mobilization of geological teams, initiation of<br />

surface work, and the delivery and set up of<br />

a drill rig at the Baimashi gold zone. Testing<br />

of Baimashi Zones 1 and 2, along with the<br />

corresponding induced polarization anomalies<br />

previously defined at the depth will be<br />

conducted to pr ovide data for initial r esource<br />

definition and program extensions.<br />

Canadian-based Minco Gold has successfully<br />

maintained 12 exploration permits<br />

in the south of Gansu province, collectively<br />

referred to as the Longnan project. As well<br />

as the exploration follow-up, the company<br />

has initiated construction of an access road<br />

18 | <strong>ASIA</strong> <strong>Miner</strong> | July/August 2012<br />

to the Yejiaba area facilitating the tunnelling<br />

and drilling. Minco Gold owns an exploration<br />