Interview With A Tyre Leader_PK Mohamed_Apollo Tyres

Mohamed is a soft-spoken and an accomplished tyre technologist with 5 decades of experience in the field of Tyre Technology and Manufacturing. When you read this passionate interview of his journey from a college lecturer to a well-known tyre technologist, you will observe struggles, challenges, achievements, dedication and loyalty; and importance of continuous education - a complete package of learning and leadership wisdom for new generation of aspiring professionals in tyre industry. Mohamed is a soft-spoken and an accomplished tyre technologist with 5 decades of experience in the field of Tyre Technology and Manufacturing. When you read this passionate interview of his journey from a college lecturer to a well-known tyre technologist, you will observe struggles, challenges, achievements, dedication and loyalty; and importance of continuous education - a complete package of learning and leadership wisdom for new generation of aspiring professionals in tyre industry.

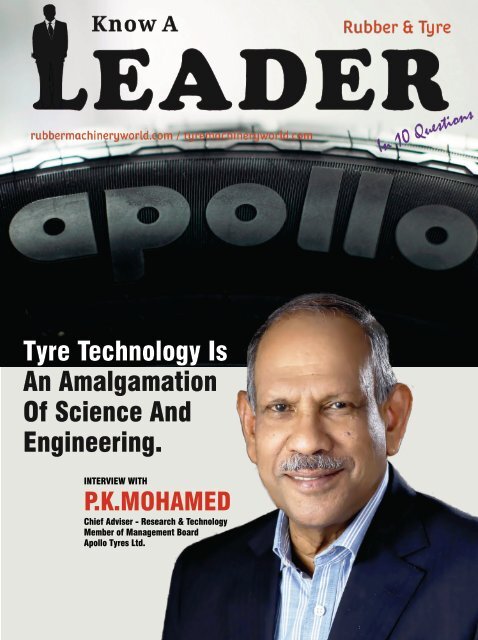

Tyre Technology Is An Amalgamation Of Science And Engineering. INTERVIEW WITH P.K.MOHAMED Chief Adviser - Research & Technology Member of Management Board Apollo Tyres Ltd.

- Page 3 and 4: | Interviewer’s Note | “A leade

- Page 5 and 6: | LEADER - INTERVIEW | Tyre Technol

- Page 10 and 11: | LEADER - INTERVIEW | Quality repu

- Page 12: | LEADER - INTERVIEW | 12 (Image So

- Page 17 and 18: | LEADER - INTERVIEW | “Hercules

- Page 19: | LEADER - INTERVIEW | PW: Today, p

- Page 23 and 24: | LEADER - INTERVIEW | “Changes d

- Page 25: | LEADER - INTERVIEW | tyre buildin

- Page 29 and 30: | LEADER - INTERVIEW | recent mater

- Page 31: | LEADER - INTERVIEW | designs to m

- Page 35 and 36: | LEADER - INTERVIEW | testing. For

- Page 38: KELACHANDRA MACHINES (MFRS. OF RUBB

<strong>Tyre</strong> Technology Is<br />

An Amalgamation<br />

Of Science And<br />

Engineering.<br />

INTERVIEW WITH<br />

P.K.MOHAMED<br />

Chief Adviser - Research & Technology<br />

Member of Management Board<br />

<strong>Apollo</strong> <strong>Tyre</strong>s Ltd.

| <strong>Interview</strong>er’s Note |<br />

“A leader is someone who<br />

demonstrates, what’s possible”<br />

- Mark Yarnell<br />

P.K. <strong>Mohamed</strong> is a soft-spoken and an accomplished tyre<br />

technologist. I consider it a privilege to know him and<br />

present his leadership wisdom to you in this special edition.<br />

The above quote aptly summarizes <strong>Mohamed</strong>. You will<br />

agree with me when you read this passionate interview of<br />

his journey from a college lecturer to a well-known tyre<br />

technologist. There are struggles, challenges, achievements,<br />

lessons on loyalty and continuous education for us to imbibe<br />

in his more than 49 years' of experience in the field of <strong>Tyre</strong><br />

Technology and Manufacturing.<br />

<strong>Mohamed</strong>’s exceptional knowledge, clarity, relevance and<br />

insight on the various aspects is awe-inspiring. I have said<br />

earlier that true leaders are few and when we find one, we<br />

look towards them as mentor and guide.<br />

<strong>Mohamed</strong> is a Fellow Member of the Rubber and Plastic<br />

Institute London, Member in the Management Board of<br />

<strong>Apollo</strong> <strong>Tyre</strong>s Ltd, Industrial Advisory board of Centre for<br />

<strong>Tyre</strong> Research, USA, IRCO and Area Director of American<br />

Chemical Society Rubber Division. <strong>Mohamed</strong> is also the<br />

Chairman of Indian <strong>Tyre</strong> Technical Advisory Committee<br />

(ITTAC), Technology Environment Safety and Standard<br />

(TESS) group of ATMA and past chairman of IRI. He has<br />

several international publications to his credit.<br />

As always, I welcome your feedback on<br />

rubbermachineryworld@gmail.com.<br />

Best Regards<br />

Prasanth Warrier<br />

There are struggles,<br />

challenges, success<br />

lessons on loyalty<br />

and continuous<br />

education for us to<br />

imbibe in his more<br />

than 49 years of<br />

experience.<br />

rubbermachineri<br />

rubbermachineryworld<br />

+Rubbermachineryworld1<br />

grp/home?gid=8252803<br />

rubbermachineri<br />

3<br />

(Disclaimer: All the pictures and statements in this special supplement are sourced from web or shared by respective companies.<br />

All copyrights belong to actual owner. Rubber Machinery World does not independently verify them nor will vouch for their<br />

genuineness, hence will not be liable for any misrepresented data. The images are used for representation purpose only.)<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

4<br />

“Most of my learning in rubber<br />

technology and compounding<br />

has happened during my career.”<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016<br />

(Image Source: <strong>Apollo</strong> <strong>Tyre</strong>s Website.)

| LEADER - INTERVIEW |<br />

<strong>Tyre</strong> Technology is an Amalgamation<br />

of Science and Engineering<br />

<strong>Interview</strong> <strong>With</strong> P.K.<strong>Mohamed</strong>,<br />

Chief Adviser - Research & Technology. Member of Management Board, <strong>Apollo</strong> <strong>Tyre</strong>s<br />

PRASANTH WARRIER (PW):<br />

Hello <strong>Mohamed</strong>. First of all thank<br />

you for accepting an interview with<br />

Rubber Machinery World (RMW) and<br />

sharing your thoughts. From a Junior<br />

Lecturer at Calicut Farook College<br />

(Kerala) to being recognized as ‘Best<br />

<strong>Tyre</strong> Technologist’ and a Member of<br />

Management Board of <strong>Apollo</strong> <strong>Tyre</strong>s<br />

is a remarkable journey. So let me<br />

start with a personal question - What<br />

would you say was key to your success<br />

and how you reached the very top<br />

spot? What are the take away for the<br />

next generation of leaders in your<br />

inspiring story?<br />

P.K. MOHAMED (<strong>PK</strong>M):<br />

It is a fact that I started my career as<br />

a Junior Lecturer in the year 1965<br />

immediately after passing out from college<br />

with Chemistry major. But it was not long<br />

before I realized that the challenges in the<br />

position as a junior lecturer was<br />

inadequate to meet my desires. And my<br />

mind was prompting me to look for a job in<br />

the industry to meet my aspirations and<br />

challenges. So I tried for a job in rubber and<br />

fertilizer industries and was fortunate to<br />

receive positive responses from both. My<br />

decision was to join rubber industry for the<br />

more lucrative remuneration then offered<br />

by the industry.<br />

I joined as a Supervisor in the Quality<br />

Department in Premier <strong>Tyre</strong>s under J.D.<br />

Kamath. Kamath was a good teacher and<br />

guide. At that time the technical department<br />

was headed by G.K.Pillai, a well known <strong>Tyre</strong><br />

Technologist trained in the USA under the<br />

collaboration agreement with General <strong>Tyre</strong>.<br />

The compounding department was headed<br />

by Dr. A.S. Nair, a doctorate holder from IIT<br />

Kharagpur and a well known person in the<br />

field of rubber compounding and material<br />

science. I was fortunate to be a protégé<br />

of these eminent personalities. They<br />

provided me with excellent training that<br />

enabled me to perform better and better in<br />

future. It is worth to mention that when I<br />

joined the Rubber Industry, my knowledge<br />

about Rubber technology and rubber<br />

compounding was very limited. During my<br />

academic time, I only learnt that there was<br />

a molecule called ‘isoprene’ which was the<br />

monomer of natural rubber.<br />

Most of my learning in rubber technology<br />

and compounding has happened during my<br />

5<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

6<br />

career. This reinforced my belief in the<br />

benefits of continuing education in the<br />

fieldof one’s interest, through reading,<br />

interaction, active participation in the<br />

technical discussion, experimentation of<br />

one’s ideas and analysis of their outcome.<br />

Linking these observations with the<br />

theories, is an important element of<br />

learning which is essential for one’s<br />

professional growth.<br />

It is also important to acquire<br />

qualification in the respective<br />

professional field for better recognition.<br />

The successful stint in Premier saw me<br />

elevated to the position of the Manager -<br />

Compounding & Laboratory Chemist.<br />

It was time in 1976, when <strong>Apollo</strong> <strong>Tyre</strong>s<br />

was looking for a rubber technologist<br />

with a qualification of LPRI (London) and<br />

with compounding background to be<br />

trained under their collaborator, General<br />

Tire International Company (GTIC) in the<br />

USA. A change seemed just right for me at<br />

that stage to further my career growth<br />

and also to support the financial needs of<br />

my family which was particularly more<br />

felt after my marriage.<br />

I applied for the position on offer and got<br />

selected. People around me and well<br />

wishers like Dr. A.S.Nair, G.K.Pillai,<br />

M.Jayashankar, I.Venugopal, and Dr. John<br />

Jacob congratulated me because then<br />

<strong>Apollo</strong> <strong>Tyre</strong>s was considered to be a rising<br />

star in the industry circles. And more for<br />

the fact that it was managed by the<br />

dynamic entrepreneur, Raunaq Singh.<br />

“The products offered by our<br />

collaborator were not meeting<br />

the customer and market<br />

requirements and hence tyres<br />

started failing miserably.”<br />

I joined <strong>Apollo</strong> with a lot of hope and went<br />

to General Tires for extensive training in<br />

the areas of rubber compounding, fabric<br />

dipping, calendaring, and heat engineering.<br />

I returned to India and started working<br />

under William Stebins, a General <strong>Tyre</strong><br />

Compounding Specialist.<br />

The Technology was then headed by Ceaser<br />

Pereira. Even though every individual<br />

department put in their best efforts, heart<br />

and soul for the growth of the company, the<br />

products offered by our collaborator were<br />

not meeting the customer and market<br />

requirements. Hence tyres started failing<br />

miserably.<br />

<strong>Apollo</strong> reached a situation where in all the<br />

raw material suppliers refused to make<br />

anymore supply of their products,<br />

collaborator refused to provide further<br />

technology and dealers stopped lifting our<br />

tyres. During that time Raunaq Singh<br />

installed a new management team under the<br />

leadership of Onkar Singh Kanwar, the<br />

present Chairman and Managing Director.<br />

When he took over the company, there was<br />

no credible management team and whoever<br />

was available, was having a very low<br />

morale.<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

Quality reputation was extremely poor,<br />

financial and labour situation were<br />

miserable. But he managed the situation<br />

with his management skill, positive<br />

attitude, optimistic and aggressive<br />

approach.<br />

10<br />

During that time the technical<br />

department was totally vacant and there<br />

was no chance for an external person<br />

with good background joining the<br />

company. So they identified me to steer<br />

the technical department by promoting<br />

me as a Senior manager.<br />

It was then D.V. Kohli and Kanwar gave<br />

the assignment for the development of a<br />

tyre for over-load market and get the<br />

share of this market from the Modi N-416,<br />

(then market leader in that segment with<br />

60 per cent market share). This was an<br />

herculean task to achieve with the<br />

available expertise and man power.<br />

Despite that, I along with R.N. Krishnan,<br />

Sondh, T.R. Gopalakrishnan, Tom Thomas<br />

and Cyriac Mattam, decided to put our<br />

heart and soul; determined to achieve the<br />

goal set by our beloved chairman. We<br />

identified the weaknesses of N-416 tyres<br />

and developed a tyre with the new design<br />

concept, carcass platform, process and<br />

material technology.<br />

The project was a great success. Our<br />

company’s sales of this particular brand<br />

of tyres moved from 3,000 tyres to over<br />

400,000 tyres per annum.<br />

“These developments changed<br />

the overall reputation and<br />

financial status of <strong>Apollo</strong>.”<br />

This success encouraged the whole team and<br />

boosted their morale multi-fold. The<br />

increased vigour further paved the way for<br />

the development of XT-7, Amar and passenger<br />

radial tyre technology using available<br />

equipment and market a brand of tyres<br />

called Polyglass.<br />

These developments changed the overall<br />

reputation and financial status of <strong>Apollo</strong>,<br />

which lead to the expansion of company’s<br />

Perambra plant capacity from 56 MT to 106<br />

MT per day.<br />

As the demand for our tyres further<br />

increased, the management decided to set up<br />

a plant in Gujarat with a capacity of 76 MT<br />

and the same got expanded to 350 MT with in<br />

a short time.<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

(Image Source: Autocarpro.in)<br />

“Our company continued to<br />

grow from strength to strength<br />

and prospered.”<br />

Our company continued to grow from<br />

strength to strength and prospered under<br />

the leadership of Onkar Kanwar and Neeraj<br />

Kanwar. New technology products like PCR,<br />

TBR, OTR and Agricultural products were<br />

introduced successfully, which helped to<br />

expand the company from 56 MT to reach a<br />

capacity of 1600 MT day in the year 2014.<br />

<strong>Apollo</strong> <strong>Tyre</strong>s also acquired plants in thr<br />

Netherlands, South Africa and India<br />

(Premier <strong>Tyre</strong>s).<br />

During this journey of growth, the<br />

technology department, under my<br />

leadership developed products, processes,<br />

systems etc., to maintain the market<br />

leadership. This was recognized by the<br />

management and suitable rewards were<br />

<strong>Apollo</strong> <strong>Tyre</strong>s Display at IMME2014<br />

given to all people who have worked in the<br />

technology department including myself.<br />

I consider myself as one of the luckiest<br />

person in the company because I always<br />

received full support from Onkar Kanwar<br />

and Neeraj Kanwar. And they played a vital<br />

role in developing me as one of the wellrecognized<br />

technologists in the field of tyre<br />

technology. I am greatly indebted to them.<br />

My journey in <strong>Apollo</strong> <strong>Tyre</strong>s was fascinating<br />

one, full of challenges which I cherished<br />

throughout my career in the company. I<br />

taught myself, several new lessons in the<br />

company and wish to share a few of them<br />

with the readers:<br />

1. I am a strong believer of Abraham<br />

Lincoln’s words "failure is not a dead end<br />

11<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

12<br />

(Image Source: Web)<br />

Onkar S. Kanwar<br />

Chairman & Managing Director<br />

Neeraj Kanwar<br />

Vice-Chairman & Managing Director<br />

P.K. <strong>Mohamed</strong><br />

“I always received full support from<br />

Onkar Kanwar and Neeraj Kanwar.<br />

And they played a vital role in<br />

developing me as one of the wellrecognized<br />

tyre technologists. I am<br />

greatly indebted to them.”<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

but it is a detour. Enthusiasm, passion,<br />

commitment, proper analytical<br />

capability, dedication, positive mind and<br />

of course expertise building through<br />

continuous upgradation of knowledge<br />

will make you an expert.<br />

PW: As one of the first few employees,<br />

your contribution at various levels has<br />

been significant in <strong>Apollo</strong>’s rise to today’s<br />

leadership position in tyre industry.<br />

Which is the position that you enjoyed<br />

the most? Why?<br />

2. Please do not believe in one-time<br />

education, the success will be depended<br />

upon continuing the education throughout<br />

your career.<br />

3. Challenges always, look insurmountable<br />

and difficult to achieve but the same can<br />

easily be achieved if you commit<br />

yourself to face them with all your<br />

beliefs and passion.<br />

<strong>PK</strong>M: When I scan my memory of<br />

achievements in <strong>Apollo</strong> <strong>Tyre</strong>s, several<br />

incidences are flashing across in my mind. It<br />

is difficult for me to list all of these items<br />

here, but would like to provide a few of them<br />

for the information of the readers of this<br />

interview. I enjoyed my job in every position<br />

held, that started as the Deputy Manager,<br />

Compounding to Chief Advisor, Technology,<br />

in the span of 38 years in the company.<br />

16<br />

4. Individual can achieve very little but a<br />

team can achieve a lot. Team work is<br />

very critical for success.<br />

“Challenges can be<br />

achieved if you commit<br />

yourself to face them<br />

with all your beliefs<br />

and passion.”<br />

I have already mentioned some of the<br />

interesting developments that took place in<br />

the company but wish to highlight a few<br />

major happenings that I cherish, for better<br />

understanding for the readers.<br />

Image from advertisement of<br />

<strong>Apollo</strong> Alnac 4G Winter <strong>Tyre</strong><br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016<br />

(Image Source: <strong>Tyre</strong>press.com.)

| LEADER - INTERVIEW |<br />

“Hercules Loadstar changed the<br />

fortune of the company. Initial<br />

production was only 3000 tyres<br />

per annum and the same had<br />

increased to 400, 000 and earned<br />

market share of more than 40%<br />

with quality leadership. The<br />

positive attitude of my team<br />

members and my belief in me<br />

and my people had paved the<br />

way to develop the tyre,<br />

perfect the same, and establish<br />

leadership position.”<br />

P.K. <strong>Mohamed</strong><br />

1. First incident comes in mind is the task<br />

given by Onkar Kanwar and D.V. Kohli in<br />

the year 1981. Kanwar was inducted into<br />

the company when the company was<br />

continuously making losses, morale of<br />

the employees were at the bottom and<br />

quality reputation of the product was<br />

poor. Then Sales Director, Kohli<br />

convinced Kanwar that the quality<br />

reputation of the company can only be<br />

revived if technology can develop a<br />

product for heavy load market and<br />

create a stiff competition to Modi N-416,<br />

the then market leader in that segment<br />

with 60% market share. I was asked to<br />

develop a tyre for heavy load market<br />

using existing man power and facilities.<br />

Even though it was an herculean task at<br />

that time, the positive attitude of my<br />

team members and my belief in me and<br />

my people had paved the way to develop<br />

the tyre, perfect the same, and establish<br />

leadership position in the market. This<br />

tyre was known in the market as<br />

Hercules Loadstar. Initial production was<br />

only 3000 tyres per annum and the same<br />

had increased to 400, 000 and earned<br />

market share of more than 40% with<br />

quality leadership. This changed the<br />

fortune of the company.<br />

2. Second task was given to me by my best<br />

friend, colleague, the then Technical<br />

Service Head, U.S. Oberoi. This happened<br />

in the year 1986. During that time<br />

Goodyear introduced a tyre called CT-169,<br />

and claimed as a mileage leader in the<br />

market place. Oberoi advised me to<br />

develop a tyre to compete with the<br />

Goodyear product and to take major<br />

market share in the load and mileage<br />

segment. We developed a tyre with<br />

innovative tread and compounding<br />

technology and embedded on Hercules<br />

17<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

(Image Source: Cardekho.com)<br />

<strong>Apollo</strong> Chennai Plant<br />

18<br />

platform. Even though, initially we had<br />

many problems with the performance of<br />

the tyres, we as a team solved them one by<br />

one. And ultimately the tyre became the<br />

volume, quality and price leader in the<br />

Indian market. Production of this tyre<br />

increased from initial 6000 tyres to over<br />

500,000 per annum.<br />

3. Third task was given to me by our young,<br />

dynamic leader Neeraj Kanwar in the year<br />

2006. This was the development of TBR<br />

tyres with excellent durability, to establish<br />

the same in the market place, and earn<br />

brand leadership similar to the global<br />

competitors. During that time all<br />

companies, except JK, were struggling hard<br />

to establish their TBR tyres in the market<br />

place. JK’s TBR tyre, JDH was very well<br />

known in the load segment and our<br />

challenge was to create a product credibly<br />

competing with JDH in the Indian market.<br />

<strong>Apollo</strong> was well known for the production<br />

of high quality bias tyres then but our<br />

knowledge and experience in truck radial<br />

“On the strength of great<br />

belief on our capabilities, and<br />

technological knowhow,<br />

Neeraj Kanwar decided to set<br />

up a new plant with the<br />

capacity of 2 million tyres per<br />

annum in Chennai.”<br />

tyre technology were not tested at all. On<br />

the strength of great belief on our<br />

capabilities, and technological knowhow,<br />

Neeraj Kanwar decided to set up a new<br />

plant with the capacity of 2 million tyres<br />

per annum in Chennai. After taking this<br />

decision, he gave the responsibility of<br />

setting up plant and selection of<br />

equipment to K. Prabhakar and process<br />

and product development to myself. We<br />

had sleepless nights because we did not<br />

have a proven product, process technology<br />

and an established market. But myself and<br />

K. Prabhakar worked like a single soul,<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

PW: Today, profitability for tire<br />

producers is from falling raw material<br />

prices, which may not be a true<br />

reflection for the future. Strategically,<br />

where do you see opportunities for tire<br />

producers like <strong>Apollo</strong> to build sustaining<br />

profitability while creating more value<br />

to your customers?<br />

<strong>PK</strong>M: We are fully aware of this aspect and<br />

our Chairman and Vice Chairman are<br />

always emphasizing on this, the way you<br />

mentioned. Product cost of a tyre is highly<br />

influenced by raw material input cost. The<br />

value addition on raw material cost is very<br />

low in the developing countries like India.<br />

But at the same time it is good in developed<br />

countries. In developing countries, the<br />

value addition on raw material cost may<br />

vary between 40 to 70% but at the same<br />

time this may way vary more than 100%<br />

in developed countries. <strong>Tyre</strong> Industry is a<br />

special industry where the R&D,<br />

marketing and sale expenses are relatively<br />

high. So it is necessary to create better<br />

value addition on raw material cost<br />

through improvement in product<br />

performance, brand building and marketing<br />

your products in the markets and segments<br />

where the value addition is high. It is also<br />

essential to contain the cost of raw material<br />

through innovation in tyre design,<br />

manufacturing, and usage of alternate and<br />

recycled materials, wherever the same is<br />

possible through value engineering. Other<br />

conversion cost such as labour, energy,<br />

repair and maintenance have to be<br />

controlled and wastage of material have to<br />

be minimised with the support of every team<br />

member involved in the process.<br />

“It is necessary to create better<br />

value-addition on raw material<br />

cost through improvement in<br />

product performance, brand<br />

building and marketing your<br />

products in the markets and<br />

segments where the valueaddition<br />

is high.”<br />

19<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

22<br />

provided the right leadership to our next<br />

line leaders like T.R.Gopalakrishnan<br />

(Technology & Process Development) and<br />

C. Krishnakumar (Projects & Equipment).<br />

We commissioned this plant, developed<br />

process technology and products suitable<br />

for Indian market, and established the<br />

same in the market place. We are now<br />

doubling Chennai Plant from 2 million to<br />

4.1 million tyres per annum. We are one<br />

of the well-known players in truck radial<br />

tyres in Indian market. My satisfaction is<br />

that, after starting and establishing the<br />

development of bias tyres at <strong>Apollo</strong>, I also<br />

had an opportunity to manage the<br />

transition from bias to radial tyre<br />

technology and establish TBR tyres.<br />

4. Another small challenge I remember was<br />

given by Neeraj Kanwar. Kanwar after<br />

visiting a few international plants came<br />

and advised us to enhance the mixing<br />

capacity to be in line with international<br />

plants. This was required to expand our<br />

bias tyre capacity without any fresh<br />

investment in the mixing area. During<br />

that time our mixing cycle to produce<br />

one batch from master to final, was more<br />

than 300 seconds. We as a team used all<br />

our knowledge, experience, expertise<br />

and worked in the areas of productive<br />

and non productive time and reduced<br />

the mixing cycle from 300 seconds to 180<br />

second for a batch from master to final.<br />

This helped to make huge saving on<br />

investment in man power, equipment,<br />

building and utility.<br />

I hope that I have provided enough example<br />

of challenges given by my leaders, Onkar<br />

Knwar and Neeraj Kanwar, which has<br />

helped me to keep motivated and perform<br />

beyond my expectation.<br />

“We as a team used all our knowledge,<br />

experience, expertise and worked in<br />

the areas of productive and non<br />

productive time and reduced the<br />

mixing cycle from 300 seconds to<br />

180 second for a batch from master<br />

to final.”<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

“Changes demanded newer<br />

raw materials and significant<br />

alterations in compound design<br />

mixing, extrusion and curing<br />

technology.”<br />

Extrusion Inside <strong>Apollo</strong> Chennai Plant<br />

23<br />

PW: Would you say that rubber<br />

compounding has undergone change in<br />

the last decades that you have been with<br />

rubber industry? What were the drivers<br />

for this change? What role has<br />

machinery played in this change?<br />

<strong>PK</strong>M: In general, all industries are<br />

influenced by the changes happening in the<br />

environment, regulations, standards and of<br />

course the developments happening in the<br />

industries around the same business. We<br />

have witnessed major changes in the<br />

automobile industries, particularly in the<br />

environmental and legal requirements. The<br />

adoption of ABS breaking system by the<br />

automobile industries demanded higher<br />

wet and dry traction for tread compounds<br />

used for the tyres. The introduction of tyre<br />

labeling system in Europe, and in a few<br />

more countries, forced the tyre<br />

manufacturers to design their tyres with<br />

better traction, rolling resistance and<br />

reduced noise level. In truck categories of<br />

tyres, customers are demanding better<br />

mileage, durability and retreading<br />

capabilities. All these changes demanded<br />

newer raw materials and significant<br />

alterations in compound design, mixing,<br />

extrusion and curing technology. Key<br />

equipment manufacturers have responded<br />

very well to the requirement of the tyre<br />

industries and some of them developed new<br />

equipment and others modified their<br />

existing equipment to process these<br />

materials, compounds and components in<br />

the desired way.<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

24<br />

PW: How do you envision tyre building<br />

shaping up in the next 10 years? As a<br />

technologist, what are your expectations<br />

from a machinery manufacturer/supplier<br />

to achieve this vision?<br />

<strong>PK</strong>M: As we all know, the tyre building<br />

machine is one piece of equipment which is<br />

used by the tyre engineer to convert tyre<br />

layout into actual green tyre. This is a very<br />

critical process. The tyre technologist<br />

expects that this process to happen with<br />

bare minimum movements of components<br />

placed in the respective position of tyres. If<br />

changes happen as against his expectation,<br />

the performance of the tyre will have a<br />

very adverse impact. Even though tyre<br />

building equipment manufacturers have<br />

done enough development in the areas<br />

of cycle time reduction, application of<br />

component, its accuracy and<br />

repeatability, there are several areas<br />

which need attention to improve the<br />

uniformity, cycle time and accuracy of<br />

component placement. The cycle time of<br />

carcass drum is 80 to 90% more than<br />

shaping and B&T drums which<br />

determines the overall productivity of<br />

“There are several areas (in<br />

<strong>Tyre</strong> Building Machinery)<br />

which need attention to<br />

improve the uniformity,<br />

cycle time and accuracy of<br />

component placement.”<br />

Inside <strong>Apollo</strong> Chennai Plant<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

tyre building machine. Automation can<br />

be enhanced in the machine in the areas<br />

like ply zipping operation etc, to improve<br />

the cycle time. In order to minimize tyre<br />

failures in the areas of tread splice and<br />

turn up, possibilities of application of<br />

strip tread can be explored to avoid<br />

splices related failures and bead<br />

clamping device and its holding pressure<br />

can be modified to improve the<br />

performance in the bead area. All the<br />

above have to be done to realize the<br />

“Automation can be<br />

enhanced in the machine in<br />

the areas like ply zipping<br />

operation etc., to improve<br />

the cycle time.”<br />

Inside <strong>Apollo</strong> Chennai Plant<br />

vision of the tyre technologist of creating<br />

the best product in his mind.<br />

PW: What new ideas are energizing the<br />

tire industry globally? How much of<br />

these ideas is facilitated by<br />

developments or improvements in<br />

machinery?<br />

<strong>PK</strong>M: I am witnessing several changes in the<br />

tyre manufacturing process to meet the<br />

challenges of tyre technology and to meet<br />

such changes, equipment manufacturers are<br />

working in tandem. Many of these changes<br />

are happening to meet the rules set by<br />

regulatory authorities, enhancement in<br />

performance requirements of replacement<br />

customers and OEMs and in processing of<br />

new material.<br />

25<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

I am witnessing a sea change in the area of<br />

mixing. The introduction of Silica filler, in<br />

combination with solution SBR and Silane<br />

coupling agent, revolutionised mixing,<br />

extrusion, building and curing technology<br />

and their equipment configuration. Earlier<br />

mixing process was known as a physical<br />

processes and today the same is known as<br />

a chemical process.<br />

The equipment manufacturers have<br />

developed tandem mixing, for mixing<br />

silica compounds to enhance its<br />

consistency and productivity.<br />

28<br />

Tangential mixer manufacturers have<br />

improved their rotors design with better<br />

cooling capabilities. The configuration of<br />

rotor wings are changed to enhance<br />

distributive and disperse mixing. Special<br />

coating were given to rotors, ram bottom<br />

and walls to take care of wear and tear.<br />

Image: Tandem Mixer<br />

Image: L&T-Kobelco Make Internal Mixer<br />

“Mixing processes are changing<br />

from several steps of mixing to<br />

single-step; single RPM mixing<br />

to variable RPM and also to<br />

RPM down mixing.”<br />

Mixing processes are changing from several steps of<br />

mixing to single step, single RPM mixing to variable<br />

RPM and also to RPM down mixing. As the tyre<br />

technology is changing from optimised performance<br />

of each components of a tyre, the placement of such<br />

components accurately in a tyre has become a<br />

challenge. Thankfully the design technology is<br />

improved considerably in extrusion equipment. And<br />

today we have extruders which can assemble 4 to 6<br />

components in a tread and extrude as single piece. In<br />

order to avoid excessive shrinkage and distortion due<br />

to poor green strength of recent materials, the<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

recent materials, the handling method of<br />

extruded treads are improved. Similar<br />

changes are taking places in <strong>Tyre</strong> Building<br />

and Curing Equipment. Curing is moving<br />

from high temperature cures to low<br />

temperature cures to enhance performance,<br />

and mould venting system and lubrication<br />

system is making dramatic changes to<br />

enhance the much needed tyre appearance.<br />

Image: L&T Make Optima Curing Press<br />

29<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

30<br />

PW: <strong>Tyre</strong> design is a fascinating topic<br />

though few people really understand<br />

the differences in design between<br />

brands. How has the design of tyres<br />

really changed during as you witnessed<br />

it? What were the key factors driving this<br />

change?<br />

<strong>PK</strong>M: <strong>Tyre</strong> technology is an amalgamation<br />

of science and engineering. It is dominated<br />

by physics, chemistry, mechanical and<br />

chemical engineering. <strong>Tyre</strong> is a product<br />

which is a unique combination of steel and<br />

rubber. Steel is responsible to withstand all<br />

stresses experienced by the tyre and rubber<br />

is responsible for taking care of its strain.<br />

Such an intelligent sharing of stresses and<br />

strain is rarely seen in any other product<br />

other than a tyre. So it is a challenge for<br />

the tyre engineer to design a carcass of a<br />

tyre with minimal strain on material when<br />

the same is stressed by inflation, vehicle<br />

load or traction loads. This challenge<br />

further increases when it comes to the tread<br />

design. Tread is responsible not only for<br />

providing adequate traction, mileage, and<br />

water drainage but also need to cater to<br />

other performance requirement of rolling<br />

resistance and noise. It is noticed that,<br />

several new concepts such as Natural<br />

Inflated Profile (NIP) and Tension Controlled<br />

Optimized Theory (TCOT), have been tried<br />

by several companies but the tyre<br />

technologist is yet not very successful in<br />

creating a carcass which can withstand<br />

under inflated condition and provide the<br />

same performance. This still remains as a<br />

challenge. In the case of tread, several<br />

developments have taken place to enhance<br />

water drainage & traction improvement,<br />

reduction in foot print pressure & noise and<br />

improvement in aesthetics and aggressive<br />

looks. While the pattern design methodology<br />

followed by many companies generally<br />

follow same guidelines, significant<br />

deviations are seen recently to meet the new<br />

found challenges in meeting label values in<br />

RR, traction and noise. In depth<br />

understanding is required to make<br />

significant alterations in tried and tested<br />

“<strong>Tyre</strong> technology is an<br />

amalgamation of science and<br />

engineering. It is dominated by<br />

physics, chemistry, mechanical<br />

and chemical engineering. <strong>Tyre</strong><br />

is a product which is a unique<br />

combination of steel and<br />

rubber.”<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

designs to meet ever increasing performance<br />

requirements and advanced design<br />

simulation tools are of great use for the tyre<br />

designers in this process. <strong>With</strong> the usage of<br />

new materials and improvements in<br />

compound properties, tyre technologists are<br />

now trying to tune the behavior of new<br />

compounds in different designs for optimal<br />

performance in a given operating condition.<br />

“The automation in tyre<br />

industry, especially in India, is<br />

deployed selectively because<br />

the cost of automation is very<br />

high and the expertise<br />

required to make it work<br />

smoothly is also high.”<br />

PW: <strong>With</strong> automation being extensively<br />

deployed in every step of tyre production<br />

today, what are the key trends happening<br />

in tire testing aspect?<br />

<strong>PK</strong>M: In my opinion, the automation in tyre<br />

industry, especially in India, is deployed<br />

selectively because the cost of automation<br />

is very high and the expertise required to<br />

make it work smoothly is also high. It is<br />

possible to manage tyre manufacturing<br />

with the above principle. The countries<br />

where the cost of capital is very high, the<br />

value addition on manufacturing cost and<br />

labour cost is low. This principle can be<br />

employed effectively to produce good<br />

quality products with accuracy and<br />

repeatability. Several developments are<br />

taking place in the internal and external<br />

31<br />

Image: Quality Check Inside <strong>Apollo</strong> Plant<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

AMCL MACHINERY LIMITED<br />

SERVICE TO THE NATION FOR FOUR DECADES<br />

Product Range<br />

• Rubber Mixer – 76" liter and 270 liter.<br />

• Mixing Mills – 16", 22", 26" and special sizes<br />

• Hot feed extruders – 6" and 8"<br />

• Rubber Calenders – 2/3 rolls.<br />

• Bias <strong>Tyre</strong> Building machine – RB1/RB3<br />

• Automatic LCV <strong>Tyre</strong> Building Machine – RB1619<br />

• Automatic Truck <strong>Tyre</strong> Building Machine-RB2022<br />

• Mechanical <strong>Tyre</strong> Curing Presses – Scooter to Truck size<br />

• Bladder Curing Presses<br />

• Tube Splicers<br />

For all your enquiries please contact:<br />

AMCL MACHINERY LIMITED<br />

Works: Plot No.A1/1, MIDC, Butirobi-441122, Nagpur<br />

Mumbai office: 202, Ackruti Centre Point, MIDC Central Road, Andheri (East), Mumbai-400 093.<br />

Contact person: Mr. S.H. Mehta<br />

Mobile No. +91-9004697430. Email: shmehta@amcl.in Website: www.amcl.in

| LEADER - INTERVIEW |<br />

testing. Forensic analysis methods have<br />

improved considerably and reached a<br />

stage where we can pin point the failure<br />

more accurately. Reverse engineering<br />

capabilities have enhanced in terms of<br />

equipment and expertise which provides<br />

accurate information to reconstruct a<br />

formulation and also identification of<br />

material.<br />

Microscopic technique capabilities have<br />

enhanced considerably to understand the<br />

physical and chemical nature of the material<br />

and its final form. Even though all these<br />

improvements are available in India, the<br />

gap is evident very much in external testing<br />

capabilities. Developing necessary facility<br />

for external testing is highly essential for the<br />

development of tyre, provide accurate<br />

information to OEM for their development<br />

and improvement of tyre performance in<br />

the areas of handling, traction characteristic<br />

and noise level. Also these types of testing<br />

are extremely essential to generate the<br />

necessary and sufficient validation results<br />

for developing simulation methods, which<br />

will soon take a significant place in testing.<br />

PW: Manufacturers find it difficult to<br />

carry hand-in-hand “superior<br />

technology” and “low-cost” expectations<br />

in rubber and tire machinery/<br />

equipment? As a tyre producer (i.e<br />

consumer of machinery), what are your<br />

views to this dilemma?<br />

<strong>PK</strong>M: In my opinion, the tyre manufacturer<br />

is looking for high value for their<br />

investment. They are very cautious in<br />

selecting a machines because its<br />

“There is an urgent need for the<br />

tyre equipment manufacturers<br />

to work very closely with the<br />

tyre manufacturer for the<br />

development of equipment<br />

which can meet all the above<br />

requirement at a reasonable<br />

cost.”<br />

repeatability, accuracy, break down,<br />

productive & non productive time, machine<br />

mounting space, ease of maintenance and of<br />

course the price, are the critical factors<br />

which are considered prior to selecting a<br />

machine. Even though some of the<br />

manufacturers are attractive on price, they<br />

are failing in several areas I mentioned<br />

above, which may make the equipments<br />

costlier. Engineering companies are capable<br />

of designing equipment with all features<br />

needed by the tyre industry but at the same<br />

time they are lacking process knowledge<br />

which are needed for establishing the<br />

processes to produce high quality products<br />

with accuracy and repeatability. So there is<br />

an urgent need for the tyre equipment<br />

manufacturers to work very closely with<br />

the tyre manufacturer for the development<br />

of equipment which can meet all the above<br />

requirement at a reasonable cost. This may<br />

help to resolve issue raised by you. If you<br />

take any productive equipment, you may<br />

notice that the total time for the production<br />

of unit is a combination of machine and<br />

man time. There is enough scope of reducing<br />

both components of time, if adequate<br />

attention is provided. The implementation<br />

of this concept may revolutionise the<br />

process which may make both sides<br />

happier.<br />

35<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016

| LEADER - INTERVIEW |<br />

“<strong>Tyre</strong> manufacturing processes are<br />

designed by the tyre, material and<br />

process technologists and hence the<br />

equipment and process conditions<br />

used for producing the tyre should<br />

match the process requirement of<br />

its compound, and components.”<br />

PW: Great! And one last question. What advice<br />

on “machinery selection” would you give to<br />

buyers in rubber and tyre industry?<br />

36<br />

<strong>PK</strong>M: I have expressed my views on this aspect,<br />

while answering the previous question. To<br />

elaborate a little more I wish to inform the readers<br />

of this interview that tyre manufacturing processes<br />

are designed by the tyre, material and process<br />

technologists and hence the equipment and process<br />

conditions used for producing the tyre should match<br />

the process requirement of its compound, and<br />

components. It is also essential that the same should<br />

meet the threshold limits of temperature, pressure<br />

accuracy, stresses and strain. This can only be<br />

achieved through proper understanding of process<br />

requirement.<br />

RMW<br />

P.K. <strong>Mohamed</strong>

KELACHANDRA MACHINES<br />

(MFRS. OF RUBBER INDUSTRIAL MACHINERY)<br />

Chingavanam - 686 531, Kottayam, Kerala. India.<br />

Phone Off: +91- 481-2430325. Fax: +91- 481-2430596<br />

e-mail: km1912@gmail.com

KELACHANDRA MACHINES<br />

(MFRS. OF RUBBER INDUSTRIAL MACHINERY)<br />

Chingavanam - 686 531, Kottayam, Kerala. India.<br />

Phone Off: +91- 481-2430325. Fax: +91- 481-2430596<br />

e-mail: km1912@gmail.com