Centrifugal Pumps Design and Application 2nd ed - Val S. Lobanoff, Robert R. Ross (Butterworth-Heinemann, 1992)

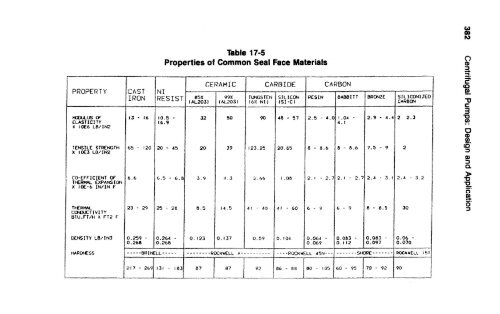

Mechanical Seals 381 Table 17-4 Temperature Limitations for Common Secondary and Static Seals An additional consideration in the selection of the primary and mating rings is their PV limitations. As discussed in the section on seal wear, a PV value can be determined for each application and compared to those given in Table 17-2. A value of less than the value given in the table will result in a seal life greater than two years. Also shown in Table 17-5 are the physical properties of common seal face materials. Mating Ring Designs A complete seal installation consists of the seal head assembly and a mating ring assembly. The mating ring assembly consists of the mating ring and a static seal. There are five common mating ring types; a) groove O-ring, b) square section, c) cup mounted, d) floating, and e) clamped in (Figure 17-20). Other designs may exist but they are all variations of these common types. The purpose of a mating ring is to provide a hard surface for the softer member of the seal face to run against. Because wear will occur at the seal faces, the mating ring must be designed as a replaceable part in the seal installation. This is accomplished through the use of a static seal, as shown. The material of construction of the static seal will determine the temperature limit of the assembly.

Table 17-5 Properties of Common Seal Face Materials PROPERTY CAST IRON NI RESIST 85% (AL203) CERAMIC 99% JAL203) TUNGSTEN !6% N!) CARBIDE SILICON ISI-C! RESIN CARBON BABBITT BRONZE SIL ICONIZED CARBON MODULUS OF ELASTICITY X IOE6 LB/IN2 f3 - 16 10.5 - 16.9 32 50 90 48 - 57 2.5 - 4.0 1.04 - 4. ! 2.9 - 4.4 2 2.3 TENSILE STRENGTH X IOE3 LB/IN2 65 - 120 20 - 45 20 39 123.25 20.65 8 - 8.6 8 - 8.6 7.5 - 9 2 CO-EFFICIENT OF THERMAL EXPANSION X IOE-6 IN/IN F 6.6 6.5 - 6.8 3.9 4.3 2.66 1 .06 2. 1 - 2.7 2. ! - 2.7 2.4 - 3, 1 2.4 - 3.2 THERMAL CONDUCTIVITY BlU.FT/H X FT2 F 23 - 29 25 - 26 8.5 14.5 4 ! - 4S 41-60 6-9 6-9 8 - g.5 30 DENSITY L8/IN3 0.259 - 0.268 0.264 - 0.268 0, 123 0.13? 0.59 0.104 0.064 - 0.069 0.0ft3 - 0. 1 12 0.083 - 0.097 0.06 - 0.070 HARDNESS BRINELL-"-- ROCKWELL A- ----ROCKWELL 45N--- - — --SHORE ROCKWEtL IS! ^!7 - 269 !31 - 183 »? 8? 93 66 - 88 80-105 60-95 70 -

- Page 346 and 347: Part3 Mechanical Design

- Page 348 and 349: 16 Shaft Design and Axial Thrust Sh

- Page 350 and 351: Shaft Design and Axial Thrust 335 S

- Page 352 and 353: Shaft Design and Axial Thrust 337 W

- Page 354 and 355: Shaft Design and Axial Thrust 339 T

- Page 356 and 357: Shaft Design and Axial Thrust 341 b

- Page 358 and 359: Shaft Design and Axial Thrust 343 K

- Page 360 and 361: Double-Suction Single-Stage Pumps S

- Page 362 and 363: Shaft Design and Axial Thrust 347 F

- Page 364 and 365: Shaft Design and Axial Thrust 349 F

- Page 366 and 367: Shaft Design and Axial Thrust 351 F

- Page 368 and 369: D (with subscript) P D P s T T (wit

- Page 370 and 371: Mechanical Seals 355 Figure 17-1. M

- Page 372 and 373: Mechanical Seats 357 Figure 17-2B.

- Page 374 and 375: Mechanical Seals 359 Figure 17-2D.

- Page 376 and 377: Mechanical Seals 361 Figure 17-4. H

- Page 378 and 379: Mechanical Seals 363 Pressure-Veloc

- Page 380 and 381: Mechanical Seals 365 The temperatur

- Page 382 and 383: Mechanical Seals 367 Figure 17-7. B

- Page 384 and 385: Mechanical Seals 369 Figure 17-9. P

- Page 386 and 387: Mechanical Seals 371 where C 3 = 53

- Page 388 and 389: Mechanical Seals 373 Classification

- Page 390 and 391: Mechanical Seals 375 Double seals m

- Page 392 and 393: Mechanical Seals 377 less than 100,

- Page 394 and 395: Mechanical Seals 379 Figure 17-19.

- Page 398 and 399: Mechanical Seals 383 Figure 17-20.

- Page 400 and 401: Mechanical Seats 385 steam, is to p

- Page 402 and 403: Mechanical Seats 38? rather than a

- Page 404 and 405: Mechanical Seals 389 Mechanical Sea

- Page 406 and 407: Mechanical Seals 391 seal to work i

- Page 408 and 409: Mechanical Seals 393 Figure 17-29.

- Page 410 and 411: Mechanical Seals 395 The measured l

- Page 412 and 413: Mechanical Seals 39? Figure 17-34.

- Page 414 and 415: Mechanical Seals 399 Figure 17-36.

- Page 416 and 417: Mechanical Seals 401 This design is

- Page 418 and 419: Mechanical Seals 403 alignment, par

- Page 420 and 421: Mechanical Seals 405 Figure 17-42.

- Page 422 and 423: Mechanical Seals 407 Figure 17-43.

- Page 424 and 425: Mechanical Seals 409 Figure 17-46.

- Page 426 and 427: Mechanical Seals 411 Figure 17-47.

- Page 428 and 429: Mechanical Seals 413 Figure 17-51.

- Page 430 and 431: Mechanical Seals 415 Figure 17-53.

- Page 432 and 433: Mechanical Seals 417 Figure 17-55.

- Page 434 and 435: Mechanical Seats 419 Figure 17-58.

- Page 436 and 437: Vibration and Noise in Pumps 421 Re

- Page 438 and 439: Vibration and Noise in Pumps 423 me

- Page 440 and 441: Vibration and Noise in Pumps 425 in

- Page 442 and 443: Vibration and Noise in Pumps 427 pr

- Page 444 and 445: Vibration and Noise in Pumps 429 ot

Table 17-5<br />

Properties of Common Seal Face Materials<br />

PROPERTY<br />

CAST<br />

IRON<br />

NI<br />

RESIST<br />

85%<br />

(AL203)<br />

CERAMIC<br />

99%<br />

JAL203)<br />

TUNGSTEN<br />

!6% N!)<br />

CARBIDE<br />

SILICON<br />

ISI-C!<br />

RESIN<br />

CARBON<br />

BABBITT<br />

BRONZE<br />

SIL ICONIZED<br />

CARBON<br />

MODULUS OF<br />

ELASTICITY<br />

X IOE6 LB/IN2<br />

f3 - 16<br />

10.5 -<br />

16.9<br />

32<br />

50<br />

90<br />

48 - 57<br />

2.5 - 4.0<br />

1.04 -<br />

4. !<br />

2.9 - 4.4<br />

2 2.3<br />

TENSILE STRENGTH<br />

X IOE3 LB/IN2<br />

65 - 120<br />

20 - 45<br />

20<br />

39<br />

123.25<br />

20.65<br />

8 - 8.6<br />

8 - 8.6<br />

7.5 - 9<br />

2<br />

CO-EFFICIENT OF<br />

THERMAL EXPANSION<br />

X IOE-6 IN/IN F<br />

6.6<br />

6.5 - 6.8<br />

3.9<br />

4.3<br />

2.66<br />

1 .06<br />

2. 1 - 2.7 2. ! - 2.7 2.4 - 3, 1<br />

2.4 - 3.2<br />

THERMAL<br />

CONDUCTIVITY<br />

BlU.FT/H X FT2 F<br />

23 - 29<br />

25 - 26<br />

8.5<br />

14.5<br />

4 ! - 4S<br />

41-60<br />

6-9<br />

6-9<br />

8 - g.5<br />

30<br />

DENSITY L8/IN3<br />

0.259 -<br />

0.268<br />

0.264 -<br />

0.268<br />

0, 123<br />

0.13?<br />

0.59<br />

0.104<br />

0.064 -<br />

0.069<br />

0.0ft3 -<br />

0. 1 12<br />

0.083 -<br />

0.097<br />

0.06 -<br />

0.070<br />

HARDNESS<br />

BRINELL-"--<br />

ROCKWELL A-<br />

----ROCKWELL 45N---<br />

- — --SHORE<br />

ROCKWEtL IS!<br />

^!7 - 269 !31 - 183<br />

»? 8? 93<br />

66 - 88 80-105<br />

60-95 70 -