National Gypsum Construction Guide - 12th Edition

National Gypsum Construction Guide - 12th Edition National Gypsum Construction Guide - 12th Edition

Wood Frame Walls and Ceilings/Double Layer Construction DESCRIPTION The Gold Bond double layer system consists of a face layer of gypsum board joblaminated to a base layer of gypsum board, or gypsum sound deadening board applied with power driven screws or staples, or nailed to the framing in the conventional manner. DETAILS CEILING DETAIL STUD PLATE JOIST RECOMMENDATIONS DOUBLE LAYER GYPSUM BOARD 1. Base layer The first layer may be specified the same as single layer application except that fasteners shall be driven flush with the board surface and joints will not be treated. Base layer must not be secured to framing with clips. 2. Adhesive Application of Face Layer, General a. All joints shall fall at least 10" from parallel joints in the base layer. Adhesive shall be: (select one) b. ProForm all-purpose ready mix joint compound or Sta-Smooth setting type compound applied with a notched spreader to the back side of the finish layer. c. Adhesive is applied with a caulking gun. Align board edges. Reference ASTM C 840, section 9. OUTSIDE CORNER PLATE 104 NATIONAL GYPSUM BOARD PRODUCTS CORNERBEAD PLATE INSIDE CORNER 3. Adhesive Application, Regular Gypsum Board The finish layer shall be positioned on the wall or ceiling within 10 minutes (unless otherwise specified above) and held in place with sufficient temporary (nails) (Type G Drywall Screws) (bracing) to ensure adequate contact and alignment of the gypsum boards. When the bond has developed (usually 24 hours) the temporary (fasteners) (bracing) shall be removed. Resulting holes shall be filled flush to the surface with Joint Compound and the joints shall be finished. Cornerbead shall be applied at all exterior angles. 4. Adhesive Application, Prefinished Gypsum Board a. Pre-bow board by storing overnight in such a position that the ends of each board curve away from the base layer when put in vertical mounting position. b. Apply ready-mix or Sta- Smooth joint compound in nominal 5" ribbons of four 1/4" x 1/4" beads located around the perimeter and center of the boards (approximate coverage for ready-mix is 9-10 gal./1000 sq.ft and Sta-Smooth is 50- 60 lbs./1000 sq.ft.). An alternative is 2" diameter daubs 1 /2" thick, 16" o.c. (approximate coverage for ready-mix is 5 1/2"-6 gal./1000 sq.ft. and Sta- Smooth is 30 - 35 lbs./1000 sq.ft.). c. Temporarily brace, as required, to ensure proper contact and edge alignment of boards. 5. Mechanical Application of Face Layer Mechanical attachment of face layer for fire or sound rated constructions shall be made in accordance with the specifications for the system selected. For non-rated construction, nails used in wood framing to supplement adhesive shall be type GWB, of a length to provide 7/8" minimum penetration into framing and shall be spaced 16" o.c. max. Screws used in wood framing shall be Type W, of a length to provide minimum 5/8" penetration into the framing and shall be spaced 24" o.c. max. If no adhesive is used, standard fastener spacings shall prevail. SPECIFICATIONS See CSI 3-Part format Generic/Proprietary Specifications on page 120. INSTALLATION Cut gypsum board to allow for a 1/8" to 1/4" gap between gypsum board and floor to prevent potential wicking. In double layer construction use any of the following appropriate laminating adhesives: (1) Sta-Smooth Compound or Sta-Smooth Lite for fast hardening; (2) All-Purpose Joint Compound for spreading on the back surface of the finish layer boards: (3) drywall adhesive meeting ASTM C 557. Base layer is applied on ceilings, then sidewalls, secured with 1 1/4" Type W Screws 12" o.c. on ceilings, 16" o.c. on walls; nails located 7" o.c. on ceilings; 8" o.c. on sidewalls; staples 5" o.c. on ceilings and 6" o.c. on sidewalls. Finish layer is temporarily nailed or braced until adhesive dries. On walls, prefinished boards, applied vertically, can be prebowed, nailed just top and bottom. RECOMMENDATIONS 1. Double layer gypsum board application over wood framing is recommended for the ultimate in wall surfacing and in areas where increased fire protection and better sound insulation are desired between rooms. (For test results see pages 13-14 of this guide.) Custom built homes, commercial buildings and party walls between apartments would be considered appropriate areas for double layer application.

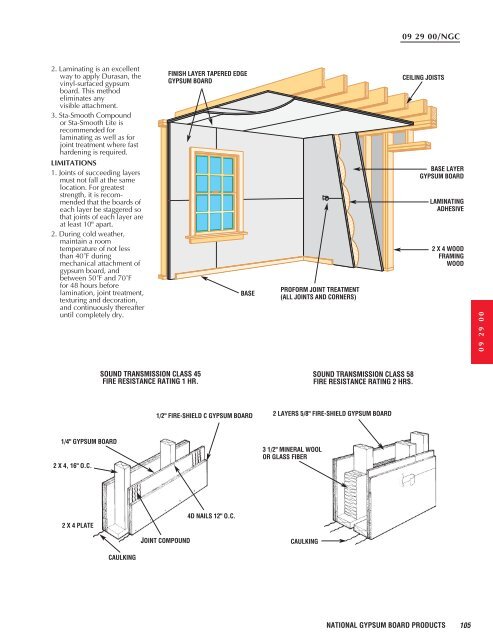

2. Laminating is an excellent way to apply Durasan, the vinyl-surfaced gypsum board. This method eliminates any visible attachment. 3. Sta-Smooth Compound or Sta-Smooth Lite is recommended for laminating as well as for joint treatment where fast hardening is required. LIMITATIONS 1. Joints of succeeding layers must not fall at the same location. For greatest strength, it is recommended that the boards of each layer be staggered so that joints of each layer are at least 10" apart. 2. During cold weather, maintain a room temperature of not less than 40˚F during mechanical attachment of gypsum board, and between 50˚F and 70˚F for 48 hours before lamination, joint treatment, texturing and decoration, and continuously thereafter until completely dry. 1/4" GYPSUM BOARD 2 X 4, 16" O.C. 2 X 4 PLATE SOUND TRANSMISSION CLASS 45 FIRE RESISTANCE RATING 1 HR. CAULKING JOINT COMPOUND FINISH LAYER TAPERED EDGE GYPSUM BOARD BASE 1/2" FIRE-SHIELD C GYPSUM BOARD 4D NAILS 12" O.C. PROFORM JOINT TREATMENT (ALL JOINTS AND CORNERS) 2 LAYERS 5/8" FIRE-SHIELD GYPSUM BOARD 3 1/2" MINERAL WOOL OR GLASS FIBER CAULKING SOUND TRANSMISSION CLASS 58 FIRE RESISTANCE RATING 2 HRS. 09 29 00/NGC CEILING JOISTS BASE LAYER GYPSUM BOARD NATIONAL GYPSUM BOARD PRODUCTS LAMINATING ADHESIVE 2 X 4 WOOD FRAMING WOOD 105 09 29 00

- Page 55 and 56: Veneer plaster walls are particular

- Page 57 and 58: KAL-MESH INSTALLATION 1" X 4" BRIDG

- Page 59 and 60: 12 TH EDITION Gypsum Board Systems

- Page 61 and 62: STA-SMOOTH ® STA-SMOOTH ® STA-SMO

- Page 63 and 64: HIGH STRENGTH BRAND HIGH STRENGTH

- Page 65 and 66: METRIC CAPABILITIES The Federal Gov

- Page 67 and 68: Gold Bond ® BRAND Gypsum Board DES

- Page 69 and 70: Gold Bond ® BRAND Sta-Smooth ® Gy

- Page 71 and 72: INSTALLATION Application And Fasten

- Page 73 and 74: Gold Bond ® BRAND Exterior Soffit

- Page 75 and 76: Gold Bond ® BRAND 1" Fire-Shield

- Page 77 and 78: Gold Bond ® BRAND High Flex ® Gyp

- Page 79 and 80: Gold Bond ® BRAND High Strength Ce

- Page 81 and 82: SURFACE BURNING CHARACTERISTICS AST

- Page 83 and 84: Gold Bond ® BRAND Hi-Impact XP ®

- Page 85 and 86: Exposure to excessive or continuous

- Page 87 and 88: RECOMMENDATIONS Installation of Sou

- Page 89 and 90: PACKAGING 2' x 2' - 4 pcs./bundle,

- Page 91 and 92: Gold Bond ® BRAND Foil Back Gypsum

- Page 93 and 94: Table 1 25 GAUGE STUDS/PARTITION LI

- Page 95 and 96: Drywall Metal Framing* 25 & 20 GAUG

- Page 97 and 98: DETAILS STUD SPLICE 16" LENGTH OF T

- Page 99 and 100: RECOMMENDATIONS 1. FRAMING Align fl

- Page 101 and 102: Steel Frame Ceilings/Furring Channe

- Page 103 and 104: Wood Frame Walls and Ceilings/Singl

- Page 105: TECHNICAL DATA 09 29 00/NGC FASTENE

- Page 109 and 110: INSTALLATION SPLICE ON JOIST 1 1/4"

- Page 111 and 112: RECOMMENDATIONS Z FURRING 1. Begin

- Page 113 and 114: STEEL JAMB 1" FIRE-SHIELD SHAFTLINE

- Page 115 and 116: ProForm BRAND Taping Joint Compound

- Page 117 and 118: ProForm ® BRAND Texture Products D

- Page 119 and 120: RECOMMENDATIONS A. For specific rec

- Page 121 and 122: LEVEL 5 All joints and interior ang

- Page 123 and 124: D.Fire-Resistant Mold-Resistant Gyp

- Page 125 and 126: 12 TH EDITION Cavity Shaftwa l Syst

- Page 127 and 128: VIEW A-A U498 2 HOUR STAIRWELL CONS

- Page 129 and 130: CORNERBEAD J TRACK DETAILS PAN HEAD

- Page 131 and 132: 20 GA. 3" LEG J TRACK SHAFTWALL J T

- Page 133 and 134: CANTS SCREWED TO SHAFTWALL STUDS 75

- Page 135 and 136: TOGGLE BOLT SHAFTWALL STUD 6" x 23

- Page 137 and 138: Note: Maintain 24" module Shaftwall

- Page 139 and 140: Horizontal Shaftwall Duct and Ceili

- Page 141 and 142: 12 TH EDITION H-Stud Area Separatio

- Page 143 and 144: AREA SEPARATION WALL LIMITING HEIGH

- Page 145 and 146: 1" FIRE-SHIELD SHAFTLINER 3/4" AIR

- Page 147 and 148: 12 TH EDITION PermaBase ® BRAND Ce

- Page 149 and 150: WARRANTY � 30-year limited warran

- Page 151 and 152: FLOOR UNDERLAYMENT COUNTERTOP JOINT

- Page 153 and 154: WATER-MANAGED, HIGH-IMPACT RESISTAN

- Page 155 and 156: PERMABASE ® BRAND CEMENT BOARD TEC

2. Laminating is an excellent<br />

way to apply Durasan, the<br />

vinyl-surfaced gypsum<br />

board. This method<br />

eliminates any<br />

visible attachment.<br />

3. Sta-Smooth Compound<br />

or Sta-Smooth Lite is<br />

recommended for<br />

laminating as well as for<br />

joint treatment where fast<br />

hardening is required.<br />

LIMITATIONS<br />

1. Joints of succeeding layers<br />

must not fall at the same<br />

location. For greatest<br />

strength, it is recommended<br />

that the boards of<br />

each layer be staggered so<br />

that joints of each layer are<br />

at least 10" apart.<br />

2. During cold weather,<br />

maintain a room<br />

temperature of not less<br />

than 40˚F during<br />

mechanical attachment of<br />

gypsum board, and<br />

between 50˚F and 70˚F<br />

for 48 hours before<br />

lamination, joint treatment,<br />

texturing and decoration,<br />

and continuously thereafter<br />

until completely dry.<br />

1/4" GYPSUM BOARD<br />

2 X 4, 16" O.C.<br />

2 X 4 PLATE<br />

SOUND TRANSMISSION CLASS 45<br />

FIRE RESISTANCE RATING 1 HR.<br />

CAULKING<br />

JOINT COMPOUND<br />

FINISH LAYER TAPERED EDGE<br />

GYPSUM BOARD<br />

BASE<br />

1/2" FIRE-SHIELD C GYPSUM BOARD<br />

4D NAILS 12" O.C.<br />

PROFORM JOINT TREATMENT<br />

(ALL JOINTS AND CORNERS)<br />

2 LAYERS 5/8" FIRE-SHIELD GYPSUM BOARD<br />

3 1/2" MINERAL WOOL<br />

OR GLASS FIBER<br />

CAULKING<br />

SOUND TRANSMISSION CLASS 58<br />

FIRE RESISTANCE RATING 2 HRS.<br />

09 29 00/NGC<br />

CEILING JOISTS<br />

BASE LAYER<br />

GYPSUM BOARD<br />

NATIONAL GYPSUM BOARD PRODUCTS<br />

LAMINATING<br />

ADHESIVE<br />

2 X 4 WOOD<br />

FRAMING<br />

WOOD<br />

105<br />

09 29 00