SAR 19#7

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SAR</strong> STAFF<br />

PUBLISHER<br />

Chipotle Publishing, LLC<br />

18<br />

GENERAL MANAGER<br />

Deborah Shea<br />

STAFF ARCHIVIST<br />

Donald Thomas<br />

<strong>SAR</strong> Vol. 19, No. 7 SEPT. 2015<br />

6<br />

DIRECTOR OF OPERATIONS<br />

Megan Shea<br />

EDITOR-IN-CHIEF<br />

TECHNICAL EDITOR<br />

Dan Shea<br />

SENIOR EDITOR<br />

Robert G. Segel<br />

PRODUCTION DIRECTOR<br />

John M. Robledo<br />

ART DIRECTOR<br />

Gracie Wingert<br />

GRAPHICS ASSISTANT<br />

Pouya Behdadnia<br />

EDITORIAL COORDINATOR<br />

Jayne Wynes<br />

DISTRIBUTION<br />

Ana Gonzalez<br />

ADVERTISING<br />

John M. Robledo<br />

Megan Shea<br />

702.565.0746<br />

adv@smallarmsreview.com<br />

SMALL ARMSREVIEW.COM<br />

ADMINISTRATOR<br />

Ross Herman<br />

NEW PRODUCTS EDITOR<br />

Chris A. Choat<br />

CARTOONIST<br />

Scott Novzen<br />

CROSSWORD<br />

Caroline Schloss<br />

MILITARY AFFAIRS<br />

Robert Bruce<br />

Rob Krott<br />

TECHNICAL ADVISERS<br />

Dr. Philip Dater<br />

Dolf Goldsmith<br />

Dr. J. David Truby<br />

CONTRIBUTING WRITERS<br />

“The Usual Suspects”<br />

David Albert<br />

Felix A. Alejos Cutuli<br />

Christopher R. Bartocci<br />

Charles Brown<br />

John Brown<br />

Todd Burgreen<br />

Bob Campbell<br />

Chris A. Choat<br />

Will Dabbs, MD<br />

Leszek Erenfeicht<br />

Teresa G. Ficaretta, Esq.<br />

Robert Hausman<br />

Michael Heidler<br />

Jean Huon<br />

Frank Iannamico<br />

N.R. Jenzen-Jones<br />

Richard Jones<br />

George E. Kontis PE<br />

Jean-Francois Legendre<br />

Julio Montes<br />

Ronaldo Olive<br />

Paolo Ortenzi A.A.I.<br />

David Pazdera<br />

Maxim Popenker<br />

Johanna Reeves, Esq.<br />

Dean Roxby<br />

Jim Schatz<br />

Robert G. Segel<br />

Dan Shea<br />

Gabriele Tansella<br />

Joseph Trevithick<br />

Anthony Wicks<br />

Anthony G. Williams<br />

Jason Wong<br />

Small Arms Review (ISSN:1094-995x)<br />

is published monthly except for Jan./Feb. and July/Aug. in print<br />

and weekly online by:<br />

Chipotle Publishing LLC<br />

631 N. Stephanie St. #282, Henderson, NV 89014.<br />

Telephone: 702.565.0746. Fax: 702.567.2425.<br />

E-mail: office@smallarmsreview.com.<br />

Periodical Postage is paid at Henderson, NV 89014 and<br />

additional mail offices. Copyright@2015. All material contained in<br />

Small Arms Review is copyrighted, and no portion may be reproduced<br />

in any way without the written permission of the publisher.<br />

US subscriptions are available for $39.95 for 1 year (10<br />

issues) with weekly online and 1 year Foreign Surface $74.95<br />

with weekly online. (All US Funds Only). Subscription prices may<br />

change without notice.<br />

Small Arms Review is not responsible for the misuse of any<br />

information contained in this publication. We do not endorse any<br />

item or practice offered in any ad or article in this publication. The<br />

opinions expressed are those of the individual writers. Small Arms<br />

Review will not accept any ad for any firearm, device, or combination<br />

of parts that would fall under the authority of the Bureau<br />

of Alcohol, Tobacco, and Firearms unless legal and registered,<br />

when necessary. It is up to each individual and dealer to comply<br />

with NFA act rules and all Federal and local laws, and Small Arms<br />

Review accepts no responsibility. For advertising information,<br />

writers guidelines, and bulk sales information call Chipotle Publishing,<br />

LLC at 702.565.0746. Publisher assumes all North American<br />

Rights upon acceptance and payment of all manuscripts. We<br />

are not responsible for lost or damaged manuscripts. POSTMAS-<br />

TER: Send change of address to Chipotle Publishing, LLC 631 N.<br />

Stephanie St. #282, Henderson, NV 89014.<br />

38

CONTENTS<br />

COLUMNS<br />

8 NEW REVIEW<br />

By Chris A. Choat<br />

14 LEGALLY ARMED<br />

By Teresa G. Ficaretta, Esq. & Johanna Reeves, Esq.<br />

17 OUR WORLD<br />

By Scott Novzen & Robert G. Segel<br />

93 CROSSWORD: <strong>SAR</strong>OUND Selection<br />

By Caroline Schloss<br />

97 MG MEMORABILIA<br />

By Robert G. Segel<br />

FEATURES<br />

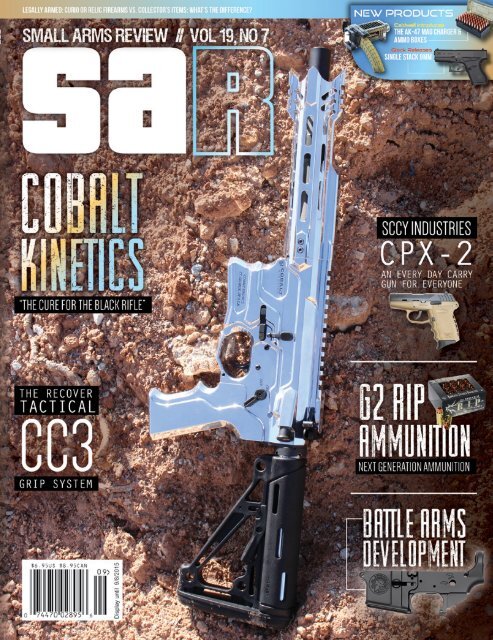

18 Cobalt Kinetics<br />

By David Lake<br />

26 CC3 Grip System<br />

By JM Ramos<br />

32 Lage Manufacturing LLC<br />

Upper Receivers for the M11/Nine<br />

By Frank Iannamico<br />

46<br />

38 Battle Arms Development<br />

By David Lake<br />

46 CPX-2:<br />

An Every Day Carry Gun for Everyone<br />

By Chris A. Choat<br />

52 The G2 RIP Ammunition<br />

Next Generation Ammunition<br />

By Christopher R. Bartocci<br />

60 Japanese Taishō Type 11<br />

By Robert G. Segel<br />

72 Japanese Type 11 Light Machine Gun<br />

Maintenance Wallet<br />

By Robert G. Segel<br />

76 Battle Rifle Company BR4 ODIN Rifle<br />

By Chris A. Choat<br />

83 Rock Island Arsenal Museum<br />

By Peter Suciu<br />

CONTENTS<br />

7<br />

On the Cover:<br />

Cobalt Arms<br />

Photo by David Lake<br />

<strong>SAR</strong> Vol. 19, No. 7

Glock Releases<br />

Single Stack 9mm<br />

NEW PRODUCTS<br />

by Chris A. Choat<br />

Glock, Inc. has just announced the<br />

release of the new Glock single stack<br />

slimline 9mm pistol, the Glock 43. The<br />

G43 is the most highly desired and anticipated<br />

pistol release in Glock’s history.<br />

Designed to be the answer to everyday<br />

concealed carry needs, the G43 is ultra-concealable,<br />

accurate, and comfortable<br />

for all shooters regardless of hand<br />

size. The G43 sets a new standard for<br />

concealed carry pistols. A true slimline<br />

pistol, the frame width of the G43 is<br />

just over one inch and the slide width<br />

measures only 0.87 inch. The overall<br />

length is 6.26 inches. For those who<br />

have smaller hands, the trigger distance<br />

is only 2.6 inches, making it ideal for<br />

functionality. The single stack magazine<br />

holds 6 rounds and is the perfect concealed<br />

carry pistol for both duty and civilian<br />

use. The G43 is engineered to the<br />

same superior standards as all Glock<br />

pistols and the reliability instills confidence<br />

for all lifestyles. For more information<br />

please go to www.Glock.us.<br />

Caldwell Introduces<br />

the AK-47 Mag Charger<br />

and Ammo Boxes<br />

<strong>SAR</strong> Vol. 19, No. 7 SEPT. 2015<br />

8<br />

Caldwell now brings the same revolutionizing<br />

ammo loading process of the AR-15 Mag Charger to<br />

the AK platform by introducing the new AK (7.62x39)<br />

Mag Charger that is designed to hold 50-rounds from<br />

any common 50-round ammo box. Simply align the<br />

bullet tips with holes in the Mag Charger and dump<br />

them in. Specially designed indexing tabs align all<br />

the rounds in the loader at the same time. No need<br />

to handle each round. Then insert your AK magazine<br />

into Mag Charger, operate the plunger back and<br />

forth and with each stroke 5 rounds are loaded until<br />

the magazine is full. Now you can load 50 rounds<br />

into two AK magazines in less than 15 seconds. Made<br />

from a highly durable polycarbonate, the loader is<br />

compatible with all 7.62x39 ammo. The loader allows<br />

the user to load AK magazines in just seconds and

HIVIZ Announces New<br />

LITEWAVE Series Sights for Ruger10/22<br />

HIVIZ Shooting Systems is excited to introduce another<br />

addition to their new fiber optic LITEWAVE rifle sight line —<br />

now for the Ruger 10/22. Like all HI-VIZ LITEWAVE sights,<br />

the new Ruger 10/22 front sight features a state of the art<br />

exoskeleton frame made of carbon steel allowing an unprecedented<br />

amount of light to enter their uniquely interchangeable<br />

LitePipes. All LITEWAVE designs not only offer an even brighter<br />

sight picture giving shooters faster target acquisition in a<br />

variety of light conditions whether on the range or out on the<br />

field, but also provide even more extreme durability than prior<br />

HIVIZ sights with a streamlined design for easy target acquisition<br />

of your favorite #1 plinker rifle. LITEWAVE for the Ruger<br />

10/22 also offers the unique versatility of the interchangeable<br />

LitePipe system for the front and rear sight, giving shooters a<br />

variety of color choices for all shooting conditions. The unique<br />

design and patented locking feature of the LitePipe system effectively<br />

secures any color or size of sight in place providing<br />

shooters the ultimate combination of durability and visual lighting<br />

flexibility for their rifle. For the rear foldable sight, the HIVIZ<br />

10/22 features simple elevation adjustments with the ability to<br />

interchange the color of the LitePipe as well like all LITEWAVE<br />

designs. The new LITEWAVE sight for the Ruger 10/22 and<br />

many others are available today at HIVIZ retailers or check<br />

them out at www.HIVIZSights.com. Retail price is just $48.95.<br />

is compatible with all AK platform mags.<br />

The loader loads 5 rounds per “stroke”<br />

with an auto advance feature. Caldwell<br />

also introduces their new Mag Charger<br />

Ammo Boxes. The Mag Charger Ammo<br />

Box is optimized to drop ammo into<br />

the AR-15 and AK-47 Mag Chargers.<br />

The AR ammo box will hold 50 rounds<br />

of .223, 5.56 and .204. The AK ammo<br />

box will hold 50 rounds of 7.62x39. The<br />

durable polymer design is proven to be<br />

extremely tough and great for long term<br />

storage. The lid can easily be removed<br />

for use when loading. They are available<br />

in 5 Pack. For more information go to<br />

www.BTIbrands.com.<br />

9NEW REVIEW<br />

<strong>SAR</strong> Vol. 19, No. 7

Luth-AR Introduces<br />

Their New MBA-1 Modular<br />

Buttstock Assembly<br />

Luth-AR has just introduced their new<br />

MBA-1 Modular Buttstock Assembly. The new<br />

buttstock is fully adjustable for cheek rest<br />

height and length of pull adding up to one inch<br />

of cheek rest height and 1 and 1/16th inch<br />

length of pull. The cheek can also be adjusted<br />

forward or rearward. The MBA-1 is approximately<br />

half the weight of competitor’s adjustable<br />

stocks weighing in at just 1.26 pounds.<br />

The new stock is easy to replace and quick to<br />

install fitting all .223 and most .308 AR style<br />

stocks. Made from super strong glass-filled<br />

nylon, the stock is almost indestructible. All<br />

adjustments are made by loosening metal<br />

thumbscrews with no parts to lose or tools<br />

needed. The stock also has a non-slip rubber<br />

buttpad for positive shoulder positioning.<br />

The stock features sling swivel sockets and<br />

Grovetec heavy duty push button sling swivels<br />

are available as an option. The stock is<br />

perfect for your SASS rifle. For more information<br />

on the web go to www.luth-ar.com.<br />

Breakthrough<br />

IntroducesNew<br />

Revolutionary<br />

Cleaning Products<br />

<strong>SAR</strong> Vol. 19, No. 7 SEPT. 2015<br />

10<br />

Breakthrough Clean is proud to announce<br />

its two new products: Battle Born Oil and<br />

Battle Born Grease. Along with its revolutionary,<br />

made in the USA Breakthrough Military-Grade<br />

Solvent, Breakthrough Clean is<br />

ushering in a new era of technology, where<br />

cleaning your firearm is now faster and safer<br />

than ever. Breakthrough’s state-of-the-art<br />

distillation process provides superior firearm<br />

cleaning products that are environmentally<br />

friendly, non-toxic and virtually odorless. Currently<br />

Breakthrough is approved, qualified,<br />

and utilized daily by the largest user of firearm<br />

cleaning technology in the USA – The U.S.<br />

Department of Defense. Now, it’s available<br />

to you. Breakthrough Military-Grade Solvent<br />

is a non-water based distilled petroleum solvent<br />

that through their proprietary distillation<br />

process has had all carcinogens and hazardous<br />

waste materials virtually wiped out of the<br />

formula. Breakthrough Military-Grade Solvent<br />

has no odor, is non-staining, removes all fouling,<br />

while completely evaporating, leaving<br />

absolutely no residue behind. It’s truly pH

American Built Arms Introduces<br />

Mission Critical Kit<br />

American Built Arms Company (A*B Arms), a veteran-owned, Type<br />

07 U.S. manufacturer of firearms and firearms parts and accessories to<br />

the civilian, law enforcement and defense industry, has launched the A*B<br />

Arms Mission Critical Kit (MCK). The A*B Arms Mission Critical Kit is a<br />

collection of critical replacement parts for you and your AR-15/M4 that<br />

are there to serve you in your time of need. The MCK is manufactured<br />

for military and law enforcement, as well as civilian firearms enthusiasts.<br />

The MCK will make sure you have what you need, when you need it. The<br />

Mission Critical Kit includes the following items:<br />

1) One A*B Arms Complete Nickel Boron Coated Bolt Assembly<br />

2) One A*B Arms Firing Pin<br />

3) One Firing Pin Retaining Pin<br />

4) One A*B Arms Extractor<br />

5) One Extractor Axle<br />

6) Six Gas Rings<br />

7) One Bolt Assembly Instruction Card<br />

8) Two UV Resistant Black Gear Bands<br />

9) One A*B Arms Latex Barrel Cover<br />

10) One 5.56 Broken Shell Extractor<br />

11) Two vials of 3ml Breakthrough Battle Born High-Purity Oil<br />

12) Two Latex-Free Adhesive Bandages and Alcohol Prep Pad – Great for<br />

those annoying cuts when you’re out in the thick of it.<br />

13) One Tactical Black, Ballistic Nylon Case with Multiple Gear Pockets:<br />

This 5x3.5x1-inch compact zippered pouch is an EDC style kit that’s small<br />

enough to fit into your pocket or gun bag.<br />

For more information or to order go to www.abarms.com.<br />

neutral, which means it’s safe on your firearm’s wood,<br />

plastics, polymers, Cerakote and/or hydro-printing.<br />

Unlike traditional firearm cleaning solvents, Breakthrough<br />

Military-Grade Solvent has a flashpoint of<br />

150° F and is therefore considered non-flammable.<br />

Breakthrough Military-Grade Solvent cleans efficiently,<br />

dramatically reducing the duration of cleaning while<br />

using less product. Battle Born Oil is a blend of the<br />

finest synthetic oils available and treated with the<br />

most effective extreme pressure, corrosion inhibitors,<br />

anti-oxidant, anti-foam, and anti-wear additives. This<br />

unique combination provides maximum firearm lubrication<br />

and protection in extreme environmental conditions<br />

and is a bio-degradable multi-service lubricant<br />

and protectant for extended service under high and<br />

low temperatures conditions (from -90°F to 417°F).<br />

Battle Born Grease represents some of the most advanced<br />

lubricant technology. It is a versatile, premium<br />

quality, synthetic grease fortified with Sub-Micron size<br />

PTFE blended completely with pure synthetic base<br />

oils, additives, and shear stable thickeners to provide<br />

maximum firearm protection in extremely high and low<br />

temperatures (from -75°F to 510°F). Learn more at:<br />

www.breakthroughclean.com.<br />

NEW REVIEW<br />

11<br />

<strong>SAR</strong> Vol. 19, No. 7

<strong>SAR</strong> Vol. 19, No. 7 SEPT. 2015<br />

12

13<br />

<strong>SAR</strong> Vol. 19, No. 7<br />

NEW REVIEW

y Teresa G. Ficaretta, Esq.<br />

& Johanna Reeves, Esq.<br />

Legal News from the Nation’s Capital<br />

<strong>SAR</strong> Vol. 19, No. 7 SEPT. 2015<br />

14<br />

Curio or Relic Firearms vs. Collector’s<br />

Items: What’s the Difference?<br />

Classifications of firearms as curios<br />

or relics and/or collector’s items have legal<br />

significance that affects importation,<br />

transfer, interstate movement, and the<br />

ability of firearms enthusiasts to acquire<br />

such firearms. This article will explain<br />

the two terms, the significance of classifications<br />

by the Bureau of Alcohol, Tobacco,<br />

Firearms and Explosives (ATF),<br />

and will provide tips on submitting requests<br />

for classification to ATF.<br />

I. Curio or Relic Firearms<br />

A. What is a Curio or Relic?<br />

The term “curio or relic” is not defined<br />

in the Gun Control Act (GCA), 18<br />

U.S.C. Chapter 44. It is referenced in<br />

several provisions of the GCA, including<br />

the definition of “collector” in 18<br />

U.S.C. § 921(a)(13), and in the import<br />

provisions of the GCA in 18 U.S.C. §<br />

925(d) and (e).<br />

ATF regulations implementing the<br />

GCA in 27 C.F.R. Part 478 define the<br />

term “curios or relics.” The regulatory<br />

definition in 27 C.F.R. § 478.11 provides<br />

as follows:<br />

Curios or relics. Firearms which are<br />

of special interest to collectors by reason<br />

of some quality other than is associated<br />

with firearms intended for sporting<br />

use or as offensive or defensive weapons.<br />

To be recognized as curios or relics,<br />

firearms must fall within one of the<br />

following categories:<br />

(a) Firearms which were manufactured<br />

at least 50 years prior to<br />

the current date, but not including<br />

replicas thereof;<br />

(b) Firearms which are certified<br />

by the curator of a municipal, State,<br />

or Federal museum which exhibits<br />

firearms to be curios or relics of<br />

museum interest; and<br />

(c) Any other firearms which derive a<br />

substantial part of their monetary value<br />

from the fact that they are novel, rare,<br />

bizarre, or because of their association<br />

with some historical figure, period, or<br />

event. Proof of qualification of a particular<br />

firearm under this category may<br />

be established by evidence of present<br />

value and evidence that like firearms<br />

are not available except as collector’s<br />

items, or that the value of like firearms<br />

in ordinary commercial channels is<br />

substantially less.<br />

An appropriations restriction has<br />

been included in ATF’s annual appropriations<br />

since 1994 prohibiting the agency<br />

from amending the above regulatory<br />

definition. The restriction also prohibits<br />

the removal of any firearm from the<br />

Firearms Curios or Relics List if the firearm<br />

was on the list on January 1, 1994.<br />

Until this restriction is lifted, ATF cannot<br />

change the regulatory definition of<br />

“curio or relic.”<br />

ATF publishes a list of firearms classified<br />

as “curios or relics” on its website,<br />

www.atf.gov. The current list, ATF Publication<br />

5300.1, was revised in December<br />

2007. ATF has published updates to the<br />

list through June 2010.<br />

ATF regulations in 27 C.F.R. § 478.26<br />

set forth the method for obtaining a determination<br />

whether a particular firearms<br />

is a curio or relic. The regulation<br />

requires submission of a written request,<br />

in duplicate, for a ruling to the Director.<br />

ATF has delegated C&R determinations<br />

to the Firearms and Ammunition<br />

Technology Division, and the authors

ecommend submitting the request to the<br />

division Chief. The regulations require<br />

requests for classification be executed<br />

under penalties of perjury and contain<br />

a complete and accurate description of<br />

the firearm and photographs, diagrams,<br />

or drawings as may be necessary to assist<br />

with the determination. Finally, the<br />

regulations provide that a sample of the<br />

firearm may be required for examination<br />

and evaluation.<br />

Based on the regulatory definition of<br />

“curios or relics,” there are three ways<br />

a firearm may be classified as C&R.<br />

The first is that it be at least 50 years<br />

old. ATF has stated that firearms automatically<br />

attain C&R status when they<br />

are 50 years old, and it is not necessary<br />

for such firearms to be listed in the<br />

Firearms Curios or Relics List to be so<br />

classified. Assuming no problems in<br />

verifying the age of a particular firearm,<br />

this is the easiest way for a firearm to<br />

attain C&R status.<br />

The second way for firearms to be<br />

classified as C&R is for a curator of a<br />

government-owned museum to certify<br />

that the firearms are of “museum<br />

interest.” A number of firearms classified<br />

as C&R made their way onto the<br />

list through the museum curator certification<br />

process. This requires that an<br />

applicant send a letter to the Chief,<br />

Firearms and Ammunition Technology<br />

Division, requesting classification of the<br />

particular firearm as a curio or relic. The<br />

application must include a letter from a<br />

curator of a Federal, State, or municipal<br />

museum certifying that the firearms are<br />

of museum interest.<br />

Applicants who seek classification<br />

under the museum curator certification<br />

process should be forewarned that<br />

ATF requires a great deal of specificity<br />

in the certification. The agency is likely<br />

to require a list of all serial numbers<br />

for firearms sought to be classified as<br />

C&R; specific information as to why the<br />

firearms are of museum interest (e.g.,<br />

associated with particular military conflicts,<br />

military operations, or other historical<br />

events), and evidence supporting<br />

the museum curator’s conclusions. The<br />

applicant may also be asked to provide<br />

evidence that the curator is associated<br />

with a government-owned museum, as<br />

opposed to a private museum.<br />

The third way for firearms to be classified<br />

as C&R is to request ATF make<br />

a determination under paragraph (c)<br />

of the regulatory definition. Such a request<br />

should be submitted in writing to<br />

the Chief, Firearms and Ammunition<br />

Technology Division and address all the<br />

requirements of the regulations, including<br />

(1) monetary value; (2) rarity and/or<br />

novelty; and (3) association with a specific<br />

historical figure, period, or event.<br />

The information provided should be<br />

specific and detailed. ATF may request<br />

a sample of the firearm sought for C&R<br />

classification for its examination.<br />

ATF takes the position that curio<br />

or relic firearms must be in their original<br />

condition to be classified as a C&R<br />

firearm. However, information on ATF’s<br />

website indicates that minor changes to<br />

firearms, such as the addition of scope<br />

mounts, non-original sights, or sling<br />

swivels would not affect a firearm’s classification<br />

as C&R. ATF has also determined<br />

that replacing particular firearms<br />

parts with new parts manufactured in<br />

the original design would also be acceptable.<br />

An example of an acceptable<br />

repair would be replacing a cracked M1<br />

Garand stock with a new wooden stock<br />

of the same design, while ATF advises<br />

that replacing it with a plastic stock<br />

would change the rifle’s classification as<br />

C&R. In addition, although frames and<br />

receivers are included in the definition<br />

of “firearm,” ATF takes the position that<br />

frames and receivers cannot be classified<br />

as C&R firearms.<br />

LEGALLY ARMED<br />

15<br />

<strong>SAR</strong> Vol. 19, No. 7

B. What Is the Significance of a Curio<br />

or Relic Classification?<br />

1. Licensed Collectors<br />

The definition of “collector” in 18<br />

U.S.C. § 921(a)(13), combined with other<br />

provisions of the GCA, makes it clear<br />

that licensed collectors may lawfully<br />

acquire firearms classified as curios or<br />

relics in interstate commerce. Persons<br />

who do not hold a collector’s license<br />

are generally prohibited from obtaining<br />

firearms (including curios or relics) in<br />

interstate commerce from any person<br />

other than a Federal firearms licensee.<br />

Licensed collectors may obtain curio<br />

or relic firearms from other licensees<br />

without completing an ATF Form 4473,<br />

and the transferring licensee is not required<br />

to comply with the background<br />

check provisions of the Brady Law, 18<br />

U.S.C. § 922(t). For persons interested<br />

in firearms of historical significance, obtaining<br />

a collector’s license is of tremendous<br />

benefit. It allows the license holder<br />

to obtain firearms from other licensed<br />

collectors and other licensees without<br />

going through a licensee in their state<br />

of residence.<br />

It should be noted, however, that a<br />

collector’s license conveys no benefits<br />

as to firearms that are not C&R. As to<br />

non-C&R firearms, a licensed collector<br />

is like any other unlicensed individual<br />

and must generally go through a Federal<br />

firearms licensee in his or her state of<br />

residence to lawfully obtain firearms.<br />

Licensed collectors are also cautioned<br />

that a collector’s license does not<br />

authorize the holder to engage in a firearms<br />

business, even if that business is<br />

limited to curio or relic firearms. Any person<br />

who is devoting time, attention, and<br />

labor to engaging in business in curio or<br />

relic firearms with the principal objective<br />

of livelihood and profit must obtain a<br />

dealer’s license to lawfully do so. ATF’s<br />

Firearms Curios or Relics List, ATF Publication<br />

5300.1, page 2, provides the following<br />

guidance on this topic:<br />

For example, if a collector acquires<br />

Curios or Relics for the purpose of sale<br />

rather than to enhance a collection, the<br />

collector would have to be licensed as a<br />

dealer in firearms under the GCA. The<br />

sole intent and purpose of the collector’s<br />

license is to enable a firearms<br />

collector to obtain curio or relic firearms<br />

from outside his or her State of<br />

residence. (Emphasis in original).<br />

The determining factor for whether<br />

a dealer’s license is needed is whether<br />

the person is acquiring curio or relic<br />

firearms for a personal collection or<br />

for resale. Collectors may swap or sell<br />

firearms from their collection and do so<br />

at a profit. However, the motive must<br />

always be to enhance a personal collection,<br />

rather than to make money selling<br />

firearms. Collectors who are unsure<br />

whether their activities may be lawfully<br />

conducted with a collector’s license<br />

should discuss with qualified counsel<br />

whether it would be advisable to obtain<br />

a dealer’s license.<br />

2. Importation of C&R Firearms<br />

Import provisions of the GCA generally<br />

prohibit the importation of surplus<br />

military firearms, firearms subject to the<br />

National Firearms Act, and those that<br />

are “nonsporting.” 18 U.S.C. § 925(d)<br />

(3). However, a provision of the GCA<br />

added to the statute in 1984 provides as<br />

follows (18 U.S.C. § 925(e)):<br />

Notwithstanding any other provision<br />

of this title, the Attorney General shall<br />

authorize the importation of, by any licensed<br />

importer, the following:<br />

(1) All rifles and shotguns listed as<br />

curios or relics by the Attorney General<br />

pursuant to section 921(a)(13), and<br />

(2) All handguns, listed as curios or<br />

relics by the Attorney General pursuant<br />

to section 921(a)(13), provided that such<br />

handguns are generally recognized as<br />

particularly suitable for or readily adaptable<br />

to sporting purposes.<br />

Section 925(e) allows surplus military<br />

firearms to be imported by a licensed<br />

importer if they are classified as<br />

C&R. Handguns must also be “sporting”<br />

by meeting ATF’s Factoring Criteria as<br />

set forth on ATF Form 4590. This provision<br />

of the GCA is very significant, as<br />

it allows otherwise non-importable surplus<br />

military firearms to be imported if<br />

they are 50 years old or are classified<br />

as C&R under one of the other regulatory<br />

definitions. Surplus military rifles,<br />

shotguns, and handguns have been imported<br />

by licensed importers under this<br />

provision of the statute.<br />

II. Collector’s Items<br />

A. What is a Collector’s Item?<br />

The National Firearms Act (NFA),<br />

26 U.S.C. Chapter 53, imposes registration,<br />

transfer, tax, and other requirements<br />

on certain specified “firearms.”<br />

The term “firearm” is defined to include<br />

machine guns, short barrel shotguns,<br />

short barrel rifles, silencers, destructive<br />

devices, and other concealable<br />

weapons. 26 U.S.C. § 5845(a). This<br />

provision of the NFA also provides that<br />

the term “firearm” shall not include any<br />

device (other than a machine gun or<br />

destructive device) which, although designed<br />

as a weapon, ATF finds by reason<br />

of the date of its manufacture, value,<br />

design, and other characteristics is<br />

primarily a collector’s item and not likely<br />

to be used as a weapon.<br />

Implementing regulations in 27<br />

C.F.R. § 479.25 set forth the process for<br />

obtaining a classification of a particular<br />

firearm as a collector’s item. The regulation<br />

provides that requests for such<br />

classification should be submitted in<br />

writing in triplicate, to the Director. As<br />

with curio or relic classifications, the<br />

authority to make collector’s item classifications<br />

has been delegated to the<br />

Chief, Firearms and Ammunition Technology<br />

Division. Accordingly, requests<br />

for such classification should be sent<br />

to this Division. The regulations require<br />

that classification requests be executed<br />

under penalties of perjury and contain<br />

a complete and accurate description of<br />

the device, the name and address of the<br />

manufacturer or importer, the purpose<br />

of and use for which it is intended, and<br />

photographs, diagrams, or drawings of<br />

the device. ATF may request a sample<br />

of the device for examination.<br />

It should be noted that the statute<br />

specifically excludes machine guns<br />

and destructive devices from the removal<br />

authorization. Removal requests<br />

submitted for these two categories<br />

of NFA firearms will be returned by<br />

ATF without action.<br />

The most important information that<br />

must be included in a request for classification<br />

as a collector’s item is information<br />

on the date of manufacture,<br />

value, design, and other characteristics<br />

indicating that the firearm is primarily<br />

a collector’s item and not likely to be<br />

used as a weapon. This information<br />

must be very specific, particularly the<br />

information about value. Information<br />

indicating the firearm is not likely to be<br />

used as a weapon must also be specific<br />

and compelling.<br />

B. Significance of Classification as a<br />

Collector’s Item.<br />

Firearms removed from the NFA as a<br />

collector’s item are no longer subject to<br />

any provisions of the NFA. This means<br />

such firearms are not required to be registered,<br />

no advance approval is required<br />

for the transfer of the firearms, and none<br />

of the other provisions of the NFA apply.<br />

Significantly, a firearm removed from the<br />

NFA as a collector’s item will not be subject<br />

to the stringent import provisions of<br />

the NFA. Import provisions of the NFA in<br />

26 U.S.C. § 5844 generally limit importation<br />

of NFA firearms to those brought in<br />

<strong>SAR</strong> Vol. 19, No. 7 16 SEPT. 2015

OUR WORLD<br />

by Scott Novzen and Robert Segel<br />

“Jennifer has been shooting my Thompson<br />

ever since she was a little girl . She always<br />

wins a lot of prizes at these fairs . ”<br />

for the official use of government agencies.<br />

Classification as a collector’s item<br />

removes this obstacle, and if the firearm<br />

is sporting or fits within the other import<br />

criteria of the GCA, the firearm may be<br />

lawfully imported into the United States.<br />

Importation is often one of the primary<br />

reasons removal requests are filed<br />

under the NFA.<br />

Because the removal of a firearm<br />

from the NFA results in significantly less<br />

Federal regulation, ATF carefully and<br />

thoroughly considers removal applications.<br />

Only specific and compelling information<br />

about a particular firearm is likely<br />

to result in granting a removal request.<br />

There are also certain types of firearms<br />

ATF generally denies for removal.<br />

These include pistol grip shotgun-type<br />

weapons, due to their concealability<br />

and configuration similar to sawed-off<br />

shotguns, which are commonly used in<br />

crime. ATF has also consistently denied<br />

applications to remove certain firearms<br />

classified as an “any other weapon” because<br />

of the narrow category of weapons<br />

described in the statutory language.<br />

ATF denies such requests on the basis<br />

that removal would render the statutory<br />

language meaningless.<br />

Even though a firearm is removed<br />

as a collector’s item, it will likely still<br />

be a “firearm” subject to all provisions<br />

of the GCA. This is true even if the<br />

weapon is classified as a “curio or relic”<br />

firearm under the GCA. Marking<br />

requirements, interstate movement, record<br />

keeping requirements applicable<br />

to Federal firearms licensees, and all<br />

other requirements of the GCA would<br />

continue to apply.<br />

III. Conclusion<br />

Classifications of firearms as curios<br />

or relics and/or collector’s items result<br />

in less Federal regulation and may allow<br />

otherwise non-importable firearms<br />

to lawfully enter the United States. Persons<br />

who submit curio or relic or collector’s<br />

item classification requests should<br />

ensure their submissions are accurate,<br />

specific, and complete to avoid delays<br />

in obtaining a response from ATF.<br />

(The information in this article is<br />

for informational purposes only and is<br />

not intended to be construed or used<br />

as legal advice.)<br />

About the authors –<br />

Johanna Reeves is the founding partner<br />

of the law firm Reeves & Dola, LLP in<br />

Washington, DC (www.reevesdola.com).<br />

For more than ten years she has dedicated<br />

her practice to advising and representing<br />

U.S. companies on compliance<br />

matters arising under the federal firearms<br />

laws and U.S. export controls.<br />

Teresa Ficaretta is one of the country’s<br />

foremost experts on ATF regulations<br />

under the Gun Control Act, the National<br />

Firearms Act, the Arms Export Control Act<br />

and Federal explosives laws. Before joining<br />

Reeves & Dola in 2013, Teresa served<br />

as legal counsel to ATF for 26 years,<br />

followed by two years as Deputy Assistant<br />

Director in Enforcement Programs<br />

and Services. They can be reached<br />

at (202) 683-4200.<br />

LEGALLY ARMED<br />

17<br />

<strong>SAR</strong> Vol. 19, No. 7

Cobalt Kinetics<br />

“THE CURE FOR THE BLACK RIFLE”<br />

BY DAVID LAKE<br />

Here is the unlikely success story about a new small arms<br />

manufacturer from the desert of Southern Utah. Cobalt Kinetics<br />

came from nothing; that is, the founder and partners involved in<br />

the inception of the company knew little to nothing about guns<br />

or how to make them, or how to sell them. All they really had<br />

was vision and motivation; usually enough to ensure success in<br />

anything. Cobalt began unencumbered by the financial burden<br />

that makes growing a new business difficult; the infrastructure<br />

to make this business venture possible came about at the snap<br />

of a finger. Free from the mundane struggles and growing pains<br />

of starting a new business, the men and women of Cobalt Kinetics<br />

were able to move forward at the speed of thought in pursuit<br />

of their endeavor. The company’s success was not without cost<br />

however. There was much hard work involved, to be sure. The<br />

people of Cobalt Kinetics will regale you with stories of 20 hour<br />

workdays and 7 day workweeks to get the thing started. Their<br />

greatest challenge, and highest achievement, and ultimately<br />

the key to their success was the cohesive working relationship<br />

among the staff. The machine operators, the executives, and<br />

everyone in between shared a common goal. Cobalt’s goal and<br />

vision was not to simply package another AR-15 but to create<br />

a better AR-15. Sure, the current staple of the Cobalt brand is<br />

indeed an AR-15 at its heart. But Small Arms Review was made<br />

to understand (and shown, unofficially) that Cobalt’s interpretation<br />

of the AR-15 is just a first step. Cobalt Kinetics is scheming<br />

to change the industry and they intend to make some waves.<br />

<strong>SAR</strong> Vol. 19, No. 7 18 SEPT. 2015

The BAMF SBR and EDGE in the<br />

very sought-after mirror polish. Contact<br />

Cobalt for details.<br />

WWW.SMALLARMSREVIEW.COM 19 <strong>SAR</strong> Vol. 19, No. 7

At first look, Cobalt’s flagship rifle,<br />

the BAMF (Billet Aluminum Modern Firearm)<br />

comes across as an abstract modern<br />

art masterpiece. It’s as if Alexander<br />

Calder and his contemporaries conspired<br />

to craft a rifle. Maybe the BAMF<br />

is where gothic architecture meets science<br />

fiction space film. This rifle’s shape<br />

is more art than engineering. During<br />

conception and design, the artist behind<br />

the gun was left to draIw and design as<br />

he wished (Cobalt really does employ<br />

an artist who in fact knows precious little<br />

about guns). Cobalt’s engineering team<br />

just had to fine tune the artwork until a<br />

gun could fit inside. Whatever the cause<br />

or effect of its marked appearance,<br />

believe that the BAMF is all business.<br />

Small Arms Review became aware of<br />

Cobalt’s plans in October of 2014. Cobalt<br />

expressed some very optimistic<br />

plans and goals for the future and direction<br />

of the company. They had nothing<br />

but a lower receiver and some drawings<br />

and, in no more than 10 weeks, Cobalt<br />

Kinetics managed to create a full line of<br />

rifles and unique features and amazing<br />

possibilities. SHOT Show 2015 was the<br />

official unveiling of Cobalt and its BAMF.<br />

During its growth, the team at Cobalt<br />

never lost sight of the plan to produce<br />

a supreme quality AR-15. The internals<br />

and all working components are either<br />

sourced from top-shelf industry firms<br />

or created in-house at Cobalt Kinetics.<br />

The BAMF makes neither compromise<br />

nor concession for economy’s sake. No<br />

expense is spared, as long as that expense<br />

directly enhances the rifle’s performance<br />

or aesthetic. There are many<br />

practical rifles available to the consumer.<br />

There are many accurate rifles available<br />

to the competitor. There are many<br />

hard-working rifles available to the<br />

professional. There are beautiful rifles<br />

available to the collector. The BAMF is<br />

all of these; and available to everyone.<br />

The BAMF straddles the thin line that<br />

separates form from function. Nay, it<br />

erases that line and expresses plainly<br />

that form and function can coexist. The<br />

trend in small arms development today<br />

demands modularity and durability and<br />

the tastes of upcoming consumers demand<br />

style and exclusivity. Anyone with<br />

a background in mechanics or engineering<br />

will scoff at the allusion that you can<br />

have it all. For example, a Maserati is<br />

a work of art – it’s exquisitely sculpted<br />

by old-world craftsmen, but it can never<br />

run as long or be as reliable as a<br />

Toyota, which is built with gross robotic<br />

precision. And be sure that Toyota will<br />

never make anything as beautiful as the<br />

Maserati. So, maybe it’s true, in cars at<br />

least- you cannot have it all. But if you’re<br />

seeking an AR-15 rifle that is visually<br />

pleasing, and functionally superior, you<br />

are now in luck. As with all things art, everyone<br />

has their taste. If the BAMF does<br />

not please your eye, sorry, you should<br />

move on. There are plenty of boring, ordinary<br />

AR clones on the market.<br />

When looking over the Cobalt BAMF,<br />

it’s easy to miss the mechanical genius<br />

inside and the beauty is in the details.<br />

The BAMF has a totally new and unique<br />

operating feature coined the “DD” (double<br />

“d”) and it is an ambidextrous forward<br />

assist and simultaneous bolt release<br />

integrated and incorporated into<br />

the upper receiver. The conventional<br />

forward assist is mirrored on both sides<br />

of the upper. The forward assist buttons<br />

have been linked through a secret<br />

mechanism in the upper receiver, so<br />

each button actuates the other. And this<br />

symmetrical forward assist has been<br />

linked to the bolt catch in the lower receiver.<br />

There are no major changes to<br />

the basic function of the AR-15. The<br />

system does not require a special bolt<br />

group or any modification to any component.<br />

It’s a big step forward, without<br />

the usual step back. The Double-D offers<br />

the user fast (and safe) actuation of<br />

the bolt catch after the bolt has locked to<br />

the rear on an empty magazine. Once a<br />

full mag has been seated into the rifle,<br />

<strong>SAR</strong> Vol. 19, No. 7 20 SEPT. 2015

the thumb of the strong hand just bumps<br />

one of the forward assist buttons to<br />

send the bolt home. The result is equal<br />

to the extended levers that snake down<br />

through the trigger guard with claims to<br />

speed up the operation of a rifle. But<br />

these devices come with their own kinds<br />

of potential problems. Some shooters<br />

have been observed to discharge a rifle<br />

while attempting to actuate the control<br />

lever in the trigger guard. It is the belief,<br />

in fact, of every gun-handling professional<br />

that the finger should only ever<br />

enter the trigger guard with immediate<br />

intent to fire the gun. The placement of<br />

other optional control surfaces proximal<br />

to the bang switch is just a bad idea. The<br />

Double-D mechanism serves the same<br />

purpose, without exposing the shooter<br />

to the possibility of an accident. Also, the<br />

forward assist is a familiar part on the<br />

AR-15 and a standard part of the AR’s<br />

manual of arms, so there’s no need to<br />

re-learn or familiarize one’s self with the<br />

placement of a new control surface to<br />

operate the rifle.<br />

Cobalt Kinetics would not rest on<br />

their laurels when it comes to proving<br />

the rifle. Good looks will only get you<br />

so far today so they employed a team<br />

of men whose daily job requirement was<br />

to wear out and destroy the BAMF. For<br />

weeks this team loaded magazines and<br />

emptied those magazines as efficiently<br />

as possible; by pulling the trigger on<br />

a rifle. Cobalt burned off over 80,000<br />

rounds of 5.56 NATO through 4 rifles<br />

in the name of learning, by way of abusive<br />

testing. Two of these rifles have<br />

cycled over 30,000 rounds each. Failures<br />

happened, sure, but not like one<br />

would expect. A gas tube burst as it approached<br />

a temperature so high all tensile<br />

strength had been lost. One barrel<br />

cooked off its ceramic coating. Another<br />

barrel changed color turning from bright<br />

stainless to purple and brown. Extractor<br />

and ejector springs flattened out after<br />

taking a set and losing tension from extreme<br />

heat exposure. One buffer’s urethane<br />

bumper shattered from fatigue.<br />

Smoke escaped from all the cracks and<br />

gaps as oil and lock-tite were boiled off.<br />

The pair of 30,000 round rifles, however,<br />

kept the same bolt groups and trigger<br />

mechanisms throughout testing. The<br />

structural members; the receivers, forearms,<br />

stocks and buffer tubes all lasted<br />

the duration with no demonstrable wear,<br />

failure or other deficiency (the barrels<br />

lasted through the entire test, but with<br />

little remaining accuracy potential). This<br />

month long exercise showed a wanton<br />

indifference to the ammunition shortage<br />

we’re experiencing today. But what was<br />

learned from it is the important part.<br />

Cobalt<br />

WWW.SMALLARMSREVIEW.COM 21 <strong>SAR</strong> Vol. 19, No. 7

Cobalt<br />

Cobalt can authoritatively say what<br />

works and what doesn’t. You can wholeheartedly<br />

believe that the Cobalt BAMF<br />

is built to perform based on that.<br />

The lessons learned in the testing<br />

phase have been applied to the production<br />

rifle. Cobalt’s rifles are held to a<br />

standard of perfection. The receiver’s internal<br />

tolerances and surface finish are<br />

tightly controlled to a far greater degree<br />

than Mil-Spec demands. The receivers<br />

are tracked and recorded through every<br />

step of the manufacturing process;<br />

from the delivery of the bar stock to the<br />

final assembly of a complete rifle. The<br />

receivers are inspected for tolerance,<br />

function and appearance at multiple<br />

stages throughout the process. Upper to<br />

lower fit are held at between zero and<br />

two thousandths of an inch. The magazine<br />

wells are cut by the slowest, but<br />

most precise means – wire EDM. The<br />

final assembly process is taken on with<br />

the solemnity of a religious rite. One<br />

technician is tasked with hand selecting<br />

components for a rifle, based on individual<br />

fit. The receiver sets are assembled<br />

and a finger is passed over the mating<br />

edges to ensure perfect fit. The buffer<br />

tubes and receiver extensions are<br />

honed and polished inside. The buffer<br />

springs are polished as well. Safety selector<br />

barrels and takedown and pivot<br />

pins are sourced from the best firms in<br />

the industry, but are still checked with a<br />

micrometer before assembly to ensure it<br />

fits ideally in the prescribed hole, which<br />

has also been checked with a precision<br />

pin gauge just before the moment of<br />

assembly. Every screw is torqued to a<br />

prescribed load. One technician carries<br />

one rifle through the process from parts<br />

selection to test fire and ultimately packaging<br />

for shipment. His name and contact<br />

information accompany the rifle to<br />

the end user. He and he alone has built<br />

your rifle. It’s a matter of personal pride<br />

and absolute quality assurance.<br />

The componentry selected for the<br />

BAMF rifles is all top shelf- again, from<br />

the lessons learned in destructive testing.<br />

The bolt groups are the best avail-<br />

<strong>SAR</strong> Vol. 19, No. 7 22 SEPT. 2015

Top Left, Top Right, Left: The EDGE in slate gray.<br />

Top Center: The DD system from the shooter’s perspective.<br />

WWW.SMALLARMSREVIEW.COM 23 <strong>SAR</strong> Vol. 19, No. 7

Cobalt<br />

able; made by Toolcraft and are then<br />

treated with a high performance Nickel<br />

Boron Coating. This coating reduces the<br />

need for regular lubrication in the upper<br />

receiver. These enhanced bolt groups<br />

also add a great deal of functionality to<br />

the gun. The coating is so smooth that<br />

fouling and particulate contaminants<br />

find it difficult to adhere to the bolt group,<br />

where they might retard function. When<br />

the bolt group looks dirty and needs a<br />

cleaning, a wipe down with rag and light<br />

oil does the trick. The trigger supplied<br />

with the BAMF is from KE Arms. A unitized<br />

drop-in assembly, it is adjustable<br />

for pull weight and let-off by one screw.<br />

KE Arms’ triggers feature a titanium nitride<br />

PVD surface treatment on all the<br />

working bits. Titanium nitride is totally<br />

corrosion resistant and very hard, which<br />

results in a smooth trigger feel. The barrels<br />

are manufactured by a seasoned<br />

expert in barrel making to the standards<br />

and specifics established by Cobalt engineers.<br />

The safety selector and magazine<br />

latch and changing handle are all<br />

premium ambidextrous components. All<br />

BAMF models come standard with an<br />

adjustable gas block that features audible<br />

clicks in the adjustment valve.<br />

Cobalt offers these rifles in two trims;<br />

the basic BAMF and the BAMF EDGE.<br />

The visible difference is the butt-stock<br />

assembly. The EDGE utilizes Cobalt’s<br />

proprietary billet stock. It’s a fixed rifle<br />

length stock that completes the aesthetic<br />

appeal of the rifle. It’s also a very comfortable<br />

and practical place to rest your<br />

cheek while shooting your BAMF. Yes,<br />

it’s heavy, but the little extra weight in<br />

the rear end of the rifle does wonders for<br />

balance and handling. The basic BAMF<br />

features a Hogue collapsible over-molded<br />

unit, attached to a Mil-Spec receiver<br />

extension tube. The two rifles utilize<br />

different barrels. The BAMF includes a<br />

14.5-inch service weight, chrome-lined<br />

CM steel barrel permanently affixed to<br />

Cobalt’s own flash hider. The EDGE<br />

model gives buyers an option for a 16-<br />

inch chrome lined or 18-inch matchgrade<br />

stainless steel barrel. All barrels<br />

are chambered in .223 Wylde. All BAMF<br />

rifles feature the signature forearm, notable<br />

by the spikes at the business end.<br />

These are indeed Picatinny bases at<br />

12 and 6 o’clock to attach iron sights<br />

or other accessories. The forearm is<br />

also part of the statement Cobalt wishes<br />

to make about the current shape of<br />

the AR-15 that everything need not be<br />

low profile and boring to be of practical<br />

use. The forearm is also M-LOK compatible<br />

for the addition of lights, grips,<br />

bipods or additional optical equipment.<br />

Another signature feature of the BAMF<br />

forearm is the hump at the receiver end<br />

that makes room for the gas tube. Absent<br />

is the continuous “tunnel” along<br />

the inside dorsal surface of the forearm.<br />

The unique arrangement allows for the<br />

forearm to clear the gas tube where required,<br />

and at the same time, keep the<br />

forearm round, and of a smaller diameter<br />

than most free-float tubes on the<br />

market. The last standard option is the<br />

color of the rifle. The BAMF and EDGE<br />

can be ordered in 3 finishes; OD green,<br />

slate gray, and brazed (a tan/straw).<br />

The BAMF and EDGE rifles are in<br />

production and shipping and are available<br />

at a few discerning gun dealers<br />

around the country who signed up early.<br />

These rifles may be on the backorder list<br />

from time to time, but be assured that<br />

Cobalt has no intention of keeping their<br />

wares exclusive. The company is constantly<br />

expanding and has just moved<br />

production into a larger facility, and installed<br />

more 5 axis CNC machines and<br />

another wire EDM to keep up with production<br />

demand. Upcoming additions to<br />

the BAMF lineup includes a PRO model;<br />

a rifle that has been designed taking input<br />

and direction from a few of America’s<br />

top multi-gun competitors. It has all the<br />

<strong>SAR</strong> Vol. 19, No. 7 24 SEPT. 2015

ideal features and capabilities required<br />

for top performance on the range. The<br />

stock and forearm have been optimized<br />

and streamlined and the trigger has<br />

been upgraded to a fully adjustable unit.<br />

The barrel is lighter and more accurate<br />

and longer wearing. The bolt group is<br />

from Cryptic and features a CVD coating<br />

that is arguably the best AR bolt group<br />

ever made. The BAMF PRO is as good<br />

as a rifle can get.<br />

“Kinetic” in the company name at<br />

first seemed out of place as this refers<br />

to something in motion. A rifle is a solid-state<br />

machine for the most part; there<br />

is only a reciprocating bolt and occasionally<br />

a projectile headed downrange.<br />

And its motion is repetitive and cyclic.<br />

After touring Cobalt’s Utah facility, and<br />

fielding the rifles and spending time with<br />

this visionary group, we became aware<br />

that “Kinetic” refers to the company and<br />

the ideas and the people who make it<br />

run. It’s moving forward - sometimes<br />

too fast. As mentioned before, <strong>SAR</strong> was<br />

made aware of some next generation<br />

concept rifles and projects. Some of<br />

these concepts are waiting for manufacturing<br />

capability to evolve enough to<br />

make them possible. That is boldness at<br />

its best; to outrun one’s own abilities. It<br />

has been said by wise men that “fortune<br />

favors the bold.” Many a tactical shoulder<br />

patch, ball cap or challenge coin<br />

touts this theme, as a reminder to us. It<br />

would seem that this great concept has<br />

been lost on too many gun companies,<br />

who continue to make rubber stamp<br />

“M-forgeries” and are content to remain<br />

static. Cobalt Kinetics is going to cure<br />

the black rifle.<br />

Cobalt Kinetics<br />

1478 South 270 East, Suite #1<br />

Saint George, UT 84790<br />

(435) 656-0599<br />

www.cobaltkinetics.com<br />

www.facebook.com/cobaltkinetics27<br />

WWW.SMALLARMSREVIEW.COM 25 <strong>SAR</strong> Vol. 19, No. 7

THE RECOVER TACTICAL<br />

CC3<br />

GRIP SYSTEM<br />

A REVOLUTIONARY UPGRADE<br />

FOR AN OLD WARHORSE<br />

by JM Ramos<br />

Over the years since its initial adoption<br />

as the official U.S. military sidearm<br />

in 1911, the legendary Colt .45 automatic<br />

has seen countless upgrading that<br />

includes mechanical redesigns such as<br />

double action conversions, high capacity<br />

magazine enhancement, cosmetic<br />

improvements and the introduction of<br />

many recoil reduction devices that were<br />

made popular by the action shooting<br />

circuits of the 80s and the 90s. In the<br />

aesthetic department, it was the custom<br />

grip that never ran out of style.<br />

The market is continually flooded with<br />

stylish 1911 pistol grips that are made<br />

from so many different materials; from<br />

aluminium, titanium, ivory, stag, exotic<br />

woods and the popular G-10 fiberglass<br />

composite just to name a few. This line<br />

of custom grips comes in different patterns<br />

and checkering cuts to maximize<br />

purchase and overall appeal. Despite all<br />

the differences in materials, color and<br />

styling, they all share the same commonality<br />

– plain and slab sided. That<br />

old tradition in 1911 grip innovation is<br />

about to change with the introduction of<br />

the revolutionary Recover Tactical CC3<br />

grip system. The CC3 is truly a superb<br />

21st century upgrade for the veteran<br />

service handgun. The unique design<br />

and styling of the CC3 can be attributed<br />

to the exceptional talent of Tamir Porat,<br />

a world renowned Israeli weapon engineer,<br />

also responsible for the creation of<br />

the Tavor combat rifle recently adopted<br />

Left: The two piece Recover Tactical CC3<br />

grip system will fit virtually any brand of<br />

1911 type pistol almost seamlessly except<br />

the Taurus PT-1911 and Caspian Arms<br />

first generation frame kit of 1980 manufacture<br />

(center). This is due to dimensional<br />

difference in the radius of the grip’s fore<br />

strap having a corner and not a full contour<br />

like a Colt frame.<br />

<strong>SAR</strong> Vol. 19, No. 7 26 SEPT. 2015

Above: Comparison between Para-Ordnance<br />

Todd Jarrett custom railed .45 ACP hi-capacity<br />

1911 (left) and custom Colt with Para 16-40<br />

Limited top end in .40 caliber (right) with black<br />

Recover Tactical CC3 grip. Note the lower position<br />

of the rail on the CC3 compared to the Para’s<br />

built-in receiver rail. The lower rail section<br />

of the CC3 grip prevents slide installation when<br />

using the Fab Defence USM scope mount.<br />

by the Israeli Defence Forces. With his<br />

impressive firearm design background,<br />

it’s not surprising that Mr. Porat was able<br />

to accomplish a remarkable feat when<br />

creating his CC3 grip system. It has truly<br />

benefited the 1911 aficionado on a tight<br />

budget by instantly transforming this<br />

century old warhorse to an ultra-modern<br />

pistol equalizer capable of accepting<br />

tactical wares such as weapon light,<br />

laser and even vertical grip (where allowed<br />

by law) for maximum control with<br />

a large pistol caliber.<br />

The CC3 grip system consists of two<br />

halves that virtually cover the receiver<br />

(frame) of the pistol except the back<br />

side where the main spring housing and<br />

grip safety is located. It is made of highgrade<br />

polymer – the same material used<br />

on the Tavor rifle. The CC3 is tailored to<br />

be a universal fit to a standard 1911 type<br />

WWW.SMALLARMSREVIEW.COM 27 <strong>SAR</strong> Vol. 19, No. 7

the versatility of a railed 1911 pistol at<br />

a fraction of the price all without the<br />

added weight and bulk.<br />

Installation of the CC3 to the pistol<br />

is quite straightforward and takes<br />

about three minutes to complete. Simply<br />

remove the original grip of the gun<br />

and substitute the Recover. The only<br />

added work is the installation of the two<br />

small screws (comes with the kit with<br />

a hardware) that tightens the front end<br />

of the part. The halves are surprisingly<br />

snug when mated to the frame with no<br />

looseness whatsoever once all screws<br />

are tightened. The cut out for the magazine<br />

catch is very well thought out providing<br />

easy access, while the opposite<br />

side has an identical profile that gives<br />

the trigger finger excellent clearance<br />

for trigger reach and pull. In addition,<br />

the CC3 thumb safety clearance is also<br />

commendable focusing primarily on the<br />

shooter’s comfort and ergonomics. The<br />

profile on this area is also the same on<br />

both sides, truly ambidextrous and very<br />

nicely done. The CC3 fully encloses the<br />

pistols. While most 1911 pistols produced<br />

by various gun manufacturers are<br />

designed to Colt specifications, there<br />

are some makes that differ in certain<br />

areas – primarily in the grip fore-strap<br />

contour for raised checkering purposes<br />

and the dust cover being beefed up a bit<br />

for strength and added weight as an aid<br />

to muzzle flip reduction without the aid<br />

of a muzzle device. To check out the fit<br />

of the CC3 with various 1911s, the grip<br />

was installed to the Series-70 Colt; then<br />

to the Caspian Arms, utilizing an early<br />

manufacture frame kit. The fit to the<br />

Colt Series 70 frame is near seamless<br />

with just a tiny line appearing below the<br />

trigger guard. On the Series-80 gun, the<br />

CC3 grip fit perfectly and seamlessly.<br />

The Caspian frame kit on the other hand<br />

had a very prominent .042 inch wide gap<br />

at the front of the grip. This could be the<br />

result of the added material from the<br />

raised checkering as well as the overall<br />

contour and dimension of the front<br />

strap radius. Another production brand<br />

1911 pistol that has the same issue in<br />

this area is the Taurus PT 1911. Both<br />

1911 frames have a noticeable square<br />

edge at the rim of the front strap (not a<br />

full radius like Colt) precluding a seamless<br />

fit. The large ribbings on all sides<br />

of the CC3 afford excellent purchase<br />

and the portion of the grip that covers<br />

the front strap improves the ergonomics.<br />

The CC3 appears to have better feel<br />

and ergonomics than any 1911 grip this<br />

author has tried before (wood or plastic).<br />

The styling is great, the material is<br />

light and strong but most of all, it offers<br />

Above Left: The CC3 grip drastically improve both the aesthetics and ergonomics<br />

of the single stack 1911 in any variations including a compensated model (left) or an<br />

Officer’s ACP models with a mini-comp for carry. The added rail system is definitely<br />

a welcome addition in modernizing the old warhorse allowing the installation of tactical<br />

gadgetries such as light, laser, SIG Sauer bridge mount for optics as well as a<br />

forward grip for licenced individuals.<br />

Above: Two Colt pistols without accessories installed showing the detail of the CC3<br />

rail and the two small hex screws that secures the front end of the part. Fit of the<br />

CC3 grip to both pistols is excellent.<br />

<strong>SAR</strong> Vol. 19, No. 7 28 SEPT. 2015

CC3 GRIP SYSTEM<br />

A TLR-1 weapon light is installed on the compensated pistol (right) while the gun on the left has the SIG mini-laser. Fab Defence<br />

folding grips are seen beside the guns as alternate accessories. These vintage and classic custom guns never looked<br />

this good with CC3 grip system.<br />

dust shield of the frame and extend just<br />

a bit to increase the length of the rail and<br />

was perfect for the TLR weapon light,<br />

SIG-Arms mini-laser and Fab Defence<br />

folding front grip (made for a Glock pistol)<br />

for PDW conversion. Naturally, it is<br />

even more exciting to dress up a vintage<br />

1911 carbine utilizing a detachable<br />

shoulder stock to a more sophisticated<br />

modernized PDW conversion complete<br />

with a folding front grip. In Canada this<br />

setup is perfectly legal for restricted<br />

firearms license holders. In the USA,<br />

stocked handguns or a handgun with a<br />

forward grip falls under a different class<br />

of weaponry and is subject to NFA rules<br />

and regulations. Having a forward grip<br />

on a railed stocked handgun makes a<br />

lot of difference in weapon control and<br />

comfort. It provided the handling characteristic<br />

of shooting a short barrelled rifle.<br />

The stock and grip in the carbine set-up<br />

really does make a lot of difference and<br />

it’s quite pleasurable to shoot specially<br />

WWW.SMALLARMSREVIEW.COM 29 <strong>SAR</strong> Vol. 19, No. 7

CC3 GRIP SYSTEM<br />

Above: The CC3 came without inlet for an ambidextrous<br />

safety. This must be an added feature of the system<br />

to eliminate the extra work to fit the extended part<br />

of the safety. You need a Dremel tool to do it. Note the<br />

exquisitely cut slot of the main spring housing to allow<br />

installation of the Browning HP shoulder stock.<br />

Below Right: The upgraded stocked 1911 is a perfect<br />

companion to any modern tactical long arm be it AK,<br />

AR or an FS-556 with superlative Mission First Tactical<br />

attire seen with the gun.<br />

with a compensated top end or a long<br />

slide with a match barrel. This can only<br />

be accomplished with a railed frame and<br />

the CC3 system made this all possible<br />

almost instantly without all the extra<br />

work or expense.<br />

Although the overall design characteristics<br />

of the CC3 is quite impressive,<br />

there is still a little bit more room<br />

for improvement to further enhance its<br />

ergonomic and user friendliness. One<br />

desirable feature that can be incorporated<br />

with the system is an elevated<br />

serrated thumb rest to be positioned<br />

just forward of the slide stop and behind<br />

the CC3 marking on the dust cover. This<br />

would be a perfect location for locking<br />

the thumb of the non- shooting hand in<br />

a two hand hold position to attain maximum<br />

control of the gun as well as comfort.<br />

The built-in thumb rest can be made<br />

ambidextrous for all shooters and ideally<br />

the same height and profile as the slide<br />

stop serrated section. The right half of<br />

the grip of the CC3 first production batch<br />

has no cut for an ambidextrous safety.<br />

The ambidextrous cut is now incorporated<br />

on the latest production grips. A<br />

square bottom type grip for Smith & Alexander<br />

type mag-wells for those who<br />

prefer to use this popular accessory as<br />

an aid for speed reloading would also<br />

be a welcome addition to the series. A<br />

very useful tactical accessory for the<br />

CC3 that can be put to a good use is<br />

an optional one-piece scope mount that<br />

can be slid and secured directly to the<br />

rail of the grip. The mount will shroud<br />

the top of the slide just forward of the<br />

ejection port to allow unobstructed ejection<br />

of empty shell during firing. The top<br />

of the mount that covers the portion of<br />

the slide would have a built-in rail similar<br />

to that one already incorporated in<br />

the CC3 for mounting a small red dot or<br />

reflex type optic. The scope mount can<br />

be tailored to have a clearance underneath<br />

the shroud for aiming with an iron<br />

sight without removing the mount in the<br />

event the optic becomes unserviceable.<br />

If the overall dimension of the bridge<br />

module that encloses the slide can be<br />

kept streamlined and flat, it can be a<br />

phenomenal outfit for defense, competition<br />

or hunting purposes. A very versatile<br />

hi-quality optical mounting system is<br />

currently available for this tactical set up.<br />

It is called the handgun Universal Scope<br />

Mount (USM) by Fab Defence, one<br />

of Israel’s leading weapon accessory<br />

<strong>SAR</strong> Vol. 19, No. 7 30 SEPT. 2015

producers. This accessory is made from<br />

CNC machined 6061 T-6 aluminum and<br />

beautifully anodized to match any handgun<br />

finish. The USM features a top and<br />

bottom rail system allowing the mounting<br />

of an optic at the top and the bottom<br />

for a folding forward grip such as the<br />

Tactical Folding Fore-grips (FGG-S and<br />

FGGK-S for Glock pistols) also made by<br />

Fab Defence. Unfortunately, the USM is<br />

not compatible for use with the CC3 due<br />

to the low position of the rail in comparison<br />

to rails cut directly to the frame of<br />

the pistol. The good news is there is an<br />

alternative mount to the USM that can<br />

be used with the CC3 and is available<br />

from SIG Sauer called bridge mount.<br />

This accessory is made of high strength<br />

polymer and a bit bulkier than the USM<br />

but lighter. The bridge-mount features<br />

top rail (for miniature reflex type optic)<br />

and bottom rail (for weapon light, laser<br />

or forward grip). Just recently, Recover<br />

Tactical expanded their grip system series<br />

with the introduction of the new BC2<br />

grip system for the Beretta 92F pistol.<br />

Sources<br />

www.recovertactical.com<br />

www.fabdefence.com<br />

www.missionfirsttactical.com<br />

www.sig-sauer.com<br />

WWW.SMALLARMSREVIEW.COM 31 <strong>SAR</strong> Vol. 19, No. 7

Lage Manufacturing LLC<br />

Upper Receivers for the<br />

M11/Nine<br />

By Frank Iannamico<br />

Both organized and informal machine<br />

gun shoots have been around for<br />

many years. The firing lines at these<br />

events are usually dominated by the<br />

belt-fed guns, often leaving subgun<br />

owners feeling somewhat left out. Before<br />

long, the subgun crowd decided<br />

they would organize their own special<br />

event for subguns only. The contests<br />

were won by successfully engaging<br />

the most targets in the fastest time. Before<br />

long, new challenges were added<br />

that included the jungle walk, the fun<br />

house and others.<br />

The first documented submachine<br />

gun contests, like those now held<br />

semi-annually at the Knob Creek Range<br />

in Kentucky, started in the late 1970s.<br />

Early contests were largely dominated<br />

by those wielding Thompsons, which<br />

soon gave way when HK94 to MP5<br />

submachine conversions became available<br />

becoming the submachine gun of<br />

choice for serious competitors. One disadvantage<br />

to the MP5 was they were/<br />

are expensive. Subgun contests have<br />

substantially evolved and refined since<br />

those early days. Today the playing field<br />

has evened out with the introduction of<br />

specific categories for the old classics,<br />

as well as modern, open class, openbolt,<br />

closed-bolt, rapid-fire weapons<br />

(like MACs) and a special class for the<br />

growing number of female competitors.<br />

With the proliferation of rails and modern<br />

optics, a few more categories were<br />

added for weapons so equipped.<br />

Like many endeavors, those with the<br />

best (read expensive) equipment usually<br />

prevail. However, Americans like an<br />

underdog, which what the MAC-type<br />

series of guns would certainly qualify<br />

as when attempting to compete with<br />

MP5 or M16/9mm submachine guns in<br />

a contest environment. This is probably<br />

the mindset that began the evolution of<br />

MAC-type guns to be competitive. The<br />

first known transformation into a competition<br />

weapon was of an SWD M11/<br />

Nine by individuals from the Triad Action<br />

Shooter’s Klub or TASK. Their earliest<br />

modifications included a wooden buttstock,<br />

a muzzle brake and an inexpensive<br />

red-dot sight. The cyclic rate was<br />

reduced by using 9mm cartridges with a<br />

reduced powder charge.<br />

The original TASK M11/Nine design<br />