MINICAP DAILY AND WEEKLY MAINTENANCE FOR HEMOGLOBIN(E) ASSAY

minicap daily and weekly maintenance for hemoglobin(e) assay

minicap daily and weekly maintenance for hemoglobin(e) assay

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

MCP09<br />

<strong>MINICAP</strong> <strong>DAILY</strong> <strong>AND</strong> <strong>WEEKLY</strong> <strong>MAINTENANCE</strong><br />

<strong>FOR</strong> <strong>HEMOGLOBIN</strong>(E) <strong>ASSAY</strong><br />

Version 7.4.1 and above<br />

<strong>DAILY</strong> <strong>MAINTENANCE</strong><br />

<strong>MINICAP</strong> daily maintenance consists of replenishing reagents, loading reagent cups, and<br />

emptying waste as needed. Please refer to quick reference guide entitled “<strong>MINICAP</strong> Start<br />

Up and Shut Down Procedure for Hemoglobin(e) Buffer” for step by step instructions.<br />

<strong>WEEKLY</strong> <strong>MAINTENANCE</strong><br />

CLEAN CAPILLARIES <strong>AND</strong> PROBE WITH CAPICLEAN SOLUTION<br />

To perform CAPICLEAN procedure, the following reagents and supplies are required:<br />

1. Distilled or deionized water<br />

2. CAPICLEAN (purchase from Sebia, PN 2058) and specific barcode label<br />

3. 12 x 75mm or similar tube (to be used as a holder tube) that fits the <strong>MINICAP</strong><br />

carousel<br />

4. Pipette and tips capable to dispense 500µL<br />

IMPORTANT: To improve workflow and conserve reagents, it is recommended to perform<br />

the CAPICLEAN procedure just before instrument shut down.<br />

1. Attach the CAPICLEAN-specific barcode (there are 12 barcode labels in reagent<br />

container box) onto an external (holder) tube. BARCODE LABEL IS REQUIRED IN<br />

ORDER TO RUN CAPICLEAN CYCLE.<br />

2. Slowly add 500µl CAPICLEAN to the tube avoiding the formation of foam.<br />

3. Slowly add 500µl deionized water to the same tube avoiding formation of foam.<br />

4. AFTER THE LAST PATIENT SAMPLE ON THE CAROUSEL HAS BEEN<br />

PROCESSED BY THE SYSTEM, place the CAPICLEAN tube into the next available<br />

position on the carousel.<br />

5. Shut the <strong>MINICAP</strong> door.<br />

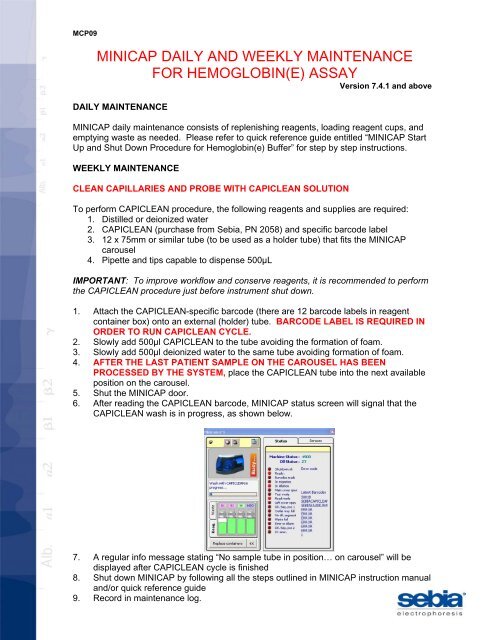

6. After reading the CAPICLEAN barcode, <strong>MINICAP</strong> status screen will signal that the<br />

CAPICLEAN wash is in progress, as shown below.<br />

7. A regular info message stating “No sample tube in position… on carousel” will be<br />

displayed after CAPICLEAN cycle is finished<br />

8. Shut down <strong>MINICAP</strong> by following all the steps outlined in <strong>MINICAP</strong> instruction manual<br />

and/or quick reference guide<br />

9. Record in maintenance log.

2<br />

PROBE DECONTAMINATION USING BLEACH SOLUTION<br />

To perform probe decontamination, the following reagents and supplies are required:<br />

1. distilled or deionized water<br />

2. any commercially available bleach solution (purchase in any general store)<br />

3. SODIUM HYPOCHLORITE-specific barcode (included in CAPICLEAN package, PN<br />

2058)<br />

4. 12 x 75mm or similar tube that fits the <strong>MINICAP</strong> carousel<br />

5. pipette and tips capable to dispense 500µL<br />

IMPORTANT: To improve workflow and conserve reagents, it is recommended to perform<br />

the probe decontamination procedure just before instrument shut down.<br />

1. Prepare a 2% bleach solution.<br />

2. Attach the SODIUM HYPOCHLORITE SOLUTION-specific barcode from the<br />

CAPICLEAN, PN 2051, reagent box (there are 4 barcode labels per box) onto the<br />

tube with bleach solution. BARCODE LABEL IS REQUIRED IN ORDER TO RUN<br />

PROBE DECONTAMINATION.<br />

3. Pipette 500µL of bleach solution into the tube.<br />

4. WHEN THE LAST PATIENT SAMPLE ON THE CAROUSEL HAS BEEN<br />

PROCESSED BY THE SYSTEM, place the barcoded tube containing bleach into<br />

the next available position on the carousel.<br />

5. Shut <strong>MINICAP</strong> door to launch the PROBE<br />

WASH program<br />

a. In the status window, SODIUM<br />

HYPOCHLORITE barcode will be<br />

displayed as SEBIAEAUDEJAVI<br />

b. The reagent status screen will<br />

display message “Cleaning of the<br />

sample probe in progress...” during<br />

the cycle, as shown on the right.<br />

6. When cycle is finished, shut down<br />

<strong>MINICAP</strong> by following all the steps<br />

outlined in <strong>MINICAP</strong> instruction manual<br />

and/or quick reference guide<br />

7. Record in maintenance log.<br />

NOTE: If desired, probe decontamination procedure with bleach can be performed<br />

immediately after CAPICLEAN procedure.<br />

To proceed, place the SODIUM HYPOCHLORITE SOLUTION tube in the next available<br />

carousel position after the CAPICLEAN-containing tube.<br />

• Both CAPICLEAN and sodium hypochlorite tubes can be placed on the carousel at the<br />

same time, i.e., after patient sample processing is finished.<br />

• In this case, probe decontamination with bleach will start as soon as CAPICLEAN<br />

cycle is finished.

3<br />

CLEAN REAGENT BAY <strong>AND</strong> SAMPLER<br />

1. Prepare 10% bleach solution<br />

2. Wipe the reagent bay area with a 10% bleach solution<br />

a. Do not use bleach solution more than necessary (i.e., do not spray or flood<br />

the bay); bleach is corrosive!<br />

3. Wipe the rotating sampler with a 10% bleach solution<br />

4. Record the activity in the maintenance log<br />

MONTHLY <strong>MAINTENANCE</strong><br />

BACK UP THE DATABASE<br />

Please follow step by step instructions on QRG entitled Advanced Backup Quick<br />

Reference Guide for use with CDRs (request QRG number PH02 if you do not<br />

have one).<br />

Rev. 12.19.2008