TBA400 ecoline - Heinrich Georg GmbH Maschinenfabrik

TBA400 ecoline - Heinrich Georg GmbH Maschinenfabrik

TBA400 ecoline - Heinrich Georg GmbH Maschinenfabrik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fast Rate of<br />

Return of Investment<br />

GEORG transformer division<br />

Equipment uses the very latest leading technology.<br />

Transformer companies worldwide recognize that GEORG offers the combination of well designed high quality long lasting machines<br />

together with superb long term support. Our customers trust in GEORG!<br />

GEORG trafo range of equipment for transformer division Customer focus drives our performance<br />

> Transformer lamination core cutting lines (TBA)<br />

> Toroidal reactor core cutting lines (TRKA)<br />

> Wound core cutting lines (SWA)<br />

> Cutting lines for amorphous material (AMC)<br />

> Core stacking and core assembly tables (KLT/KMT)<br />

> Slitting Lines for electrical steel (TKS)<br />

> Corrugated tank wall production lines for transformer tanks (TKWA)<br />

> Production lines for cooling radiators (RAD)<br />

<strong>Heinrich</strong> <strong>Georg</strong> <strong>GmbH</strong><br />

<strong>Maschinenfabrik</strong><br />

Siegener Straße 73–83<br />

57223 Kreuztal, Germany<br />

Forward thinking and in co-operative partnership,<br />

we create advanced technology. Because we make a<br />

point of knowing what our customers need, we ensure<br />

optimal results – for many future years to come.<br />

Phone +49 2732 779-0<br />

Fax +49 2732 779-340<br />

trafo@georg.com<br />

georg.com<br />

NEW<br />

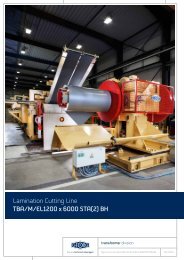

<strong>TBA400</strong> <strong>ecoline</strong> / TBA600 <strong>ecoline</strong><br />

State of the art technology. Best value for money.<br />

transformer division<br />

<strong>TBA400</strong> <strong>ecoline</strong> / TBA600 <strong>ecoline</strong><br />

06/2012

<strong>TBA400</strong> <strong>ecoline</strong> and TBA600 <strong>ecoline</strong> are made to a<br />

standard specification ensuring a very competitive<br />

investment and economic production of transformer<br />

laminations. They are 100 % produced in Germany.<br />

Economic technology for transformer cores<br />

GEORG lamination step-lap cutting lines are very reliable and produce<br />

high quality low loss transformer cores consistently day in day out.<br />

<strong>TBA400</strong> <strong>ecoline</strong> has an average power consumption of only 8 kW.<br />

Plug & Run<br />

<strong>TBA400</strong> <strong>ecoline</strong> and TBA600 <strong>ecoline</strong> do not require any special foundation<br />

or loop pit. The line can be installed efficiently and production<br />

starting with minimum delay.<br />

World-wide support and service<br />

GEORG provides fast world-wide technical support from<br />

Germany online and phone in conjunction with our network<br />

of agents and subsidiary companies. You can rely on long<br />

term spare parts support from GEORG.<br />

Technical specification<br />

GEORG transformer division<br />

Phone +49 2732 779-294<br />

Fax +49 2732 779-180<br />

trafo@georg.com<br />

georg.com<br />

<strong>TBA400</strong> <strong>ecoline</strong><br />

> Strip width 40 to 440 mm<br />

> Double decoiler<br />

> 1 Hole punch<br />

> 1 V-Notch<br />

> 2 fixed shears (1 x 45°, 1 x 45°/90°)<br />

> Option of 2 stacking systems for simple sheet<br />

stacking (RS or HS/T)<br />

> Max. speed 240 m/min<br />

> Run line full speed 24/7<br />

> No special foundation and no loop pit necessary<br />

‘The added value for our<br />

customer? The future.<br />

It comes as standard in<br />

all our systems.’<br />

Bernd Peter Schmidt<br />

Managing Director, transformer division<br />

Please visit georg.com/<br />

tba-<strong>ecoline</strong> to see videos<br />

and more information.<br />

TBA600 <strong>ecoline</strong><br />

Technical specification<br />

> Strip width 50 to 640 mm<br />

> Double head decoiler<br />

> 1 Hole punch (2 nd hole punch optional)<br />

> 1 V Notch<br />

> 2 fixed shears (1 x 45°, 1 x 45°/90°)<br />

> Option of two stacking systems for sheet stacking (HS/T or PB/T)<br />

> Max. speed 240 m/min<br />

> Run line full speed 24/7<br />

> No special foundation and no loop pit necessary<br />

transformer division<br />

<strong>TBA400</strong> <strong>ecoline</strong> / TBA600 <strong>ecoline</strong><br />

NEW<br />

06/2012