You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

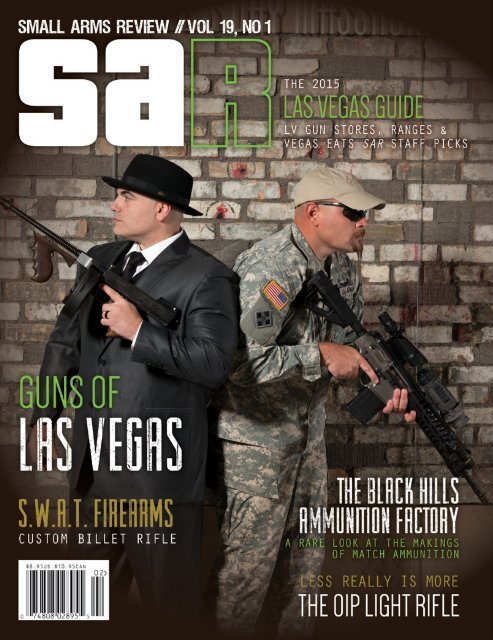

sa<br />

WWW.SMALLARMSREVIEW.COM 1 <strong>SAR</strong> Vol. 19, No. 1

EVOLUTION<br />

Today’s Operator (Below),<br />

JOSH HOLZER:<br />

Today’s operator has a massive technical<br />

arsenal available to him for his close<br />

quarter battle and unusual needs. Gear from<br />

Operation: Iraqi Freedom and Enduring<br />

Freedom. Sunglasses; WileyX. Hat; Voodoo<br />

Tactical. Machine Gun; POF USA P308-FA<br />

piston-driven select fire 7.62x51mm rifle<br />

with 16.5” barrel and Magpul P-Mag 20<br />

round magazine. This system is augmented<br />

with a Trijicon TA11 optic with the 7.62 reticle<br />

and an ATN Mini-Thor Thermal weapon<br />

site. The Mini-Thor can be quickly installed<br />

or left off for straight daylight mission use.<br />

On the right side forward, the Vingtech VarioRay<br />

with visible laser aperture, non-visible<br />

IR laser aperture, non-visible IR illuminator<br />

and a powerful LED flashlight with strobe<br />

capabilities. The Trijicon RMR sight mounted<br />

on the VarioRay allows for a very, very<br />

fast target acquisition by simply rolling the<br />

rifle into the cheek and clearing the opto-electronics<br />

out of the way. All of this leads<br />

up to a whole lot of options for the modern<br />

operator to use at his choice.<br />

SITUATION REPORT<br />

The G-Man<br />

Photographer: Michael Balasko<br />

Art Director: Gracie Wingert<br />

Makeup: None. Our manly cover models<br />

refused even Chapstick.<br />

Hair: None, but Josh combed his goatee.<br />

&<br />

THE OPERATOR<br />

Location: The Mob Museum, Las Vegas,<br />

www.themobmuseum.org (special thanks to<br />

Brenda Hengel).<br />

Background: St. Valentine’s Day Massacre<br />

wall at The Mob Museum in Las Vegas.<br />

FBI G-Man (Above), ROCCO LOISI:<br />

Suit; Mastroianni Fashions Las Vegas, www.<br />

mastroiannifashions.com. Hat; The Doctor in<br />

Black, Goorin Bros. at The Linq, Las Vegas, www.<br />

goorin.com (special thanks to Yeisenn DelToro).<br />

Machine Gun; original Colt 1921AC Thompson<br />

Submachine Gun in .45ACP, with 50 round New<br />

York “L-Drum,” from Zangaro Ltd. He’s removed<br />

the buttstock to keep it compact and sports a<br />

Colt 1911A1 in .38 Super caliber (hidden on his<br />

belt) for shooting through bad guys’ cars.

<strong>SAR</strong> realizes that one of the optics on the Operator’s<br />

machine gun needs to be raised. We apologize, the<br />

part we needed did not arrive in time for our photo<br />

shoot and we were out of duct tape.<br />

Trijicon TA11 optic with the 7.62<br />

reticle and an ATN Mini-Thor<br />

Thermal weapon site<br />

Trijicon RMR sight<br />

Vingtech VarioRay with visible laser<br />

aperture, non-visible IR laser aperture,<br />

non-visible IR illuminator and a powerful<br />

LED flashlight with strobe capabilities<br />

On the<br />

Original Colt 1921AC Thompson<br />

Submachine Gun in .45ACP, with<br />

50 round New York “L-Drum,”<br />

from Zangaro Ltd.

The Mob Museum<br />

The Mob Museum is a world-class destination in downtown<br />

Las Vegas dedicated to the story of organized crime and law<br />

enforcement. True stories of Mob history are brought to life<br />

through interactive, high-tech exhibits and over 600 artifacts,<br />

the largest collection of Mob and law enforcement memorabilia<br />

under one roof.<br />

Museum hours are Sundays through Thursdays from 10 a.m.<br />

to 7 p.m.; Fridays and Saturdays 10 a.m. until 8 p.m. For more<br />

information, call (702) 229-2734 or visit www.themobmuseum.<br />

org. Connect on Facebook: www.Facebook.com/themobmuseum<br />

and on Twitter: @TheMobMuseum.<br />

The Museum has acquired some of the most iconic artifacts<br />

in Mob history including the barber chair Albert Anastasia was<br />

sitting in when murdered in New York City, and the brick wall<br />

from the St. Valentine’s Day Massacre in Chicago in 1929. The<br />

Museum opened on Valentine’s Day 2012, the 83rd anniversary<br />

of the Massacre where seven men affiliated with Bugs Moran’s<br />

gang were lined up along the wall, shot and killed by Al Capone’s<br />

South Side Italian gang.<br />

Artifacts integrated throughout the Museum’s interactive exhibits<br />

provide an insider’s look into many of organized crime’s<br />

biggest names, including, Al Capone, Dion O’Bannion, George<br />

Moran, Charlie “Lucky” Luciano, Meyer Lansky, Ben Siegel,<br />

Sam Giancana, Joe Bonanno, Frank Rosenthal, Mickey Cohen,<br />

Tony Cornero, Whitey Bulger and John Gotti to name just a few.<br />

The Museum is located in what many consider the ultimate artifact,<br />

the former federal courthouse and United States Post Office.<br />

Completed in 1933 and listed on the Nevada and National<br />

Registers of Historic Places, it houses the courtroom where in<br />

1950 one of 14 national Kefauver hearings was held to expose<br />

organized crime in America. Meticulously rehabilitated for The<br />

Mob Museum, the building is significant not only for its neo-classical<br />

architecture reminiscent of the period in which it was built,<br />

but also for the historic events that unfolded inside of it.<br />

In addition, items and artifacts relating to law enforcement’s<br />

role in helping to eradicate and control the Mob, such as weapons,<br />

wiretapping tools and tactics and crime scene photos, are<br />

also shown.<br />

The Museum has accumulated numerous accolades since<br />

opening in 2012, including being named one of “10 World Landmarks<br />

You Haven’t Seen – Yet” by NBC News, “20 Places Every<br />

American Should See” by Fox News and Budget Travel magazine,<br />

“Las Vegas’ Best New Attractions for 2012” by Travel<br />

+ Leisure magazine, “9 Reasons to Visit Las Vegas” by CNNgo,<br />

a finalist for the “Best Wider World Project Award,” by the<br />

British Guild of Travel Writers and “Best Museum” by Nevada<br />

Magazine and the Las Vegas Review-Journal.<br />

The St. Valentine’s Day Massacre Wall<br />

The Mob Museum has acquired some of the most iconic artifacts<br />

in Mob history including the brick wall from the St. Valentine’s<br />

Day Massacre in 1929 in Chicago. Seven men affiliated<br />

with Bugs Moran’s gang were lined up against the wall and shot<br />

to death by Al Capone’s gang.<br />

In 1967, the wall was torn down, and a Vancouver businessman<br />

bought the bricks which were still full of bullet holes from<br />

the massacre. Over the next 42 years, the bricks were featured<br />

in a traveling exhibit, housed in a short-lived crime museum and<br />

displayed in a nightclub restroom. They finally found a permanent<br />

home at The Mob Museum.<br />

From their first sale in 1967 the bricks were lettered and<br />

numbered, allowing The Mob Museum to assemble and display<br />

the wall in a manner very close to the original. At some point,<br />

some of the bullet holes in the bricks were enhanced by red<br />

paint. (No, it’s not blood!)<br />

Repeal Day celebration at<br />

The Mob Museum<br />

Party Like It’s 1933<br />

Party like it’s 1933 at the 3rd Annual Repeal<br />

Day Celebration from 6 p.m. to midnight<br />

as The Mob Museum marks the anniversary<br />

of the end of Prohibition (December 5, 1933).<br />

Highlight of the evening will be the Boss<br />

of the Bars Competition. Guests also will be<br />

able to enjoy signature drinks, VIP Party, casino<br />

table games, Costume Contest, cabaret<br />

dancers and jazz swing band.<br />

Toast Repeal Day with former Mayor Oscar<br />

Goodman<br />

7 p.m. on the steps of The Mob Museum<br />

$60 VIP Party 6-midnight<br />

The Mob Museum’s Speakeasy Party will<br />

be a soiree for classy dames and stand-up<br />

fellas. Speakeasy tickets grant you entry to<br />

the VIP Party beginning at 6 p.m. Activities<br />

include 1920s Dance Lessons, Special Music<br />

from the age of crooners, a Commemorative<br />

Repeal Day Flask and two free drink tickets.<br />

VIP guests also will enjoy all the events of the<br />

Repeal Day celebration including the Boss<br />

of the Bars Competition, signature drinks, cigars,<br />

casino table games, Costume Contest,<br />

cabaret dancers and a jazz swing band.<br />

$40 Repeal Day Celebration 7-midnight<br />

Admission includes Museum access,<br />

Boss of the Bars Competition, signature<br />

drinks, cigars, casino table games, Costume<br />

Contest, cabaret dancers and a jazz swing<br />

band. Roaring 20s costumes are encouraged<br />

and prizes will be awarded.<br />

WWW.SMALLARMSREVIEW.COM 7 <strong>SAR</strong> Vol. 19, No. 1

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015<br />

8<br />

<strong>SAR</strong> STAFF<br />

PUBLISHER<br />

Chipotle Publishing, LLC<br />

GENERAL MANAGER<br />

Deborah Shea<br />

DIRECTOR OF OPERATIONS<br />

Megan Shea<br />

EDITOR-IN-CHIEF<br />

TECHNICAL EDITOR<br />

Dan Shea<br />

SENIOR EDITOR<br />

Robert G. Segel<br />

PRODUCTION DIRECTOR<br />

John M. Robledo<br />

ART DIRECTOR<br />

Gracie Wingert<br />

GRAPHICS ASSISTANT<br />

Pouya Behdadnia<br />

EDITORIAL COORDINATOR<br />

Chantanese Nicole<br />

DISTRIBUTION<br />

Ana Gonzalez<br />

ADVERTISING<br />

John M. Robledo<br />

Megan Shea<br />

702.565.0746<br />

adv@smallarmsreview.com<br />

SMALL ARMSREVIEW.COM<br />

ADMINISTRATOR<br />

Ross Herman<br />

NEW PRODUCTS EDITOR<br />

Chris A. Choat<br />

INDUSTRY NEWS<br />

Robert Hausman<br />

CARTOONIST<br />

Scott Novzen<br />

CROSSWORD<br />

Caroline Schloss<br />

STAFF ARCHIVIST<br />

Donald Thomas<br />

MILITARY AFFAIRS<br />

Robert Bruce<br />

Rob Krott<br />

TECHNICAL ADVISERS<br />

Dr. Philip Dater<br />

Dolf Goldsmith<br />

Dr. J. David Truby<br />

CONTRIBUTING WRITERS<br />

”The Usual Suspects”<br />

David Albert<br />

Felix A. Alejos Cutuli<br />

Chris R. Bartocci<br />

Charles Brown<br />

John Brown<br />

Todd Burgreen<br />

Bob Campbell<br />

Chris A. Choat<br />

Will Dabbs, MD<br />

Leszek Erenfeicht<br />

Teresa G. Ficaretta, Esq.<br />

Robert Hausman<br />

Michael Heidler<br />

Jean Huon<br />

Frank Iannamico<br />

N.R. Jenzen-Jones<br />

Richard Jones<br />

George E. Kontis PE<br />

Jean-Francois Legendre<br />

Julio Montes<br />

Ronaldo Olive<br />

Paolo Ortenzi A.A.I.<br />

David Pazdera<br />

Maxim Popenker<br />

Johanna Reeves, Esq.<br />

Dean Roxby<br />

Jim Schatz<br />

Robert G. Segel<br />

Dan Shea<br />

Gabriele Tansella<br />

Joseph Trevithick<br />

Anthony Wicks<br />

Anthony G. Williams<br />

Jason Wong<br />

Small Arms Review (ISSN:1094-995x)<br />

is published 10x per year in print and weekly online by:<br />

Chipotle Publishing LLC<br />

631 N. Stephanie St. #282, Henderson, NV 89014.<br />

Telephone: 702.565.0746. Fax: 702.567.2425.<br />

E-mail: office@smallarmsreview.com.<br />

Periodical Postage is paid at Henderson, NV 89014 and<br />

additional mail offices. Copyright@2015. All material contained in<br />

Small Arms Review is copyrighted, and no portion may be reproduced<br />

in any way without the written permission of the publisher.<br />

US subscriptions are available for $39.95 for 1 year (10<br />

issues) with weekly online and 1 year Foreign Surface $74.95<br />

with weekly online. (All US Funds Only). Subscription prices may<br />

change without notice.<br />

Small Arms Review is not responsible for the misuse of any<br />

information contained in this publication. We do not endorse any<br />

item or practice offered in any ad or article in this publication. The<br />

opinions expressed are those of the individual writers. Small Arms<br />

Review will not accept any ad for any firearm, device, or combination<br />

of parts that would fall under the authority of the Bureau<br />

of Alcohol, Tobacco, and Firearms unless legal and registered,<br />

when necessary. It is up to each individual and dealer to comply<br />

with NFA act rules and all Federal and local laws, and Small Arms<br />

Review accepts no responsibility. For advertising information,<br />

writers guidelines, and bulk sales information call Chipotle Publishing,<br />

LLC at 702.565.0746. Publisher assumes all North American<br />

Rights upon acceptance and payment of all manuscripts. We<br />

are not responsible for lost or damaged manuscripts. POSTMAS-<br />

TER: Send change of address to Chipotle Publishing, LLC 631 N.<br />

Stephanie St. #282, Henderson, NV 89014.<br />

CONTENTS<br />

COLUMNS<br />

10 NEW REVIEW<br />

By Chris A. Choat<br />

16 LEGALLY ARMED<br />

By Teresa G. Ficaretta, Esq. & Johanna Reeves, Esq.<br />

19 OUR WORLD<br />

By Scott Novzen & Robert G. Segel<br />

126 INDUSTRY NEWS<br />

By Robert M. Hausman<br />

130 NFATCA<br />

By John Brown<br />

131 CROSSWORD: <strong>SAR</strong>OUND Selection<br />

By Caroline Schloss<br />

133 MG MEMORABILIA<br />

By Robert G. Segel<br />

FEATURES<br />

14 Bushnell Rangefinder<br />

By David Lake<br />

22 Guns of Las Vegas<br />

By Tom Murphy<br />

35 The 2015 Las Vegas Guide<br />

By <strong>SAR</strong> Staff<br />

42 Adams Arms Mid Evo Ultra Lite AR<br />

Piston Driven Performer<br />

By Todd Burgreen<br />

50 Her Majesty’s Tools of Diplomacy<br />

By Miles Vining<br />

56 S.W.A.T. Firearms Custom Billet Rifle<br />

By Chris A. Choat<br />

62 The Black Hills Ammunition Factory<br />

By Christopher R. Bartocci<br />

72 The Type 1 Stamped Receiver AK Rifle<br />

By Frank Iannamico<br />

78 Operationally Testing Uselton Arms’<br />

Explosively Bonded Model 1911 .45 ACP<br />

By Paul Evancoe<br />

86 The Man Who Designed the<br />

World’s Fastest Gun<br />

By George E. Kontis PE<br />

96 Argentina’s “World Standard”<br />

Maxim Machine Gun<br />

By Robert G. Segel<br />

104 It’s an M16 Thing<br />

By David Lake<br />

110 Glock 41<br />

Latest Addition to the Glock Family<br />

By Todd Burgreen<br />

119 Less Really is More<br />

By Andrew Thomas

NEW PRODUCTS<br />

by Chris A. Choat<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015<br />

10<br />

Faxon Firearms, manufacturer of<br />

the ARAK-21 Upper Receiver, is proud<br />

to announce the new ARAK-21 XRS<br />

Complete Rifle. The ARAK-21 XRS<br />

was designed to greatly improve the<br />

operator’s ability to accomplish multiple<br />

missions and features a monolithic<br />

upper receiver with an integral<br />

full-length Picatinny rail, a dual forward<br />

recoil spring system, a folding<br />

ambidextrous forward charging handle<br />

with spring return and a longstroke<br />

gas piston with variable settings.<br />

The ARAK-21 XRS also comes<br />

with interchangeable barrels that can<br />

be changed in less than 2 minutes<br />

from 5.56 to .300 blackout; making it<br />

the perfect rifle for any shooter. This is<br />

a completely redesigned modular rifle<br />

system based on the best from both

Kahr introduces their newest fullframe<br />

value-priced firearm; the 9mm<br />

CT9. Earlier this year Kahr introduced<br />

the CT40 and CT45, and with the addition<br />

of the CT9, it completes their value-priced<br />

CT Series. For decades, Kahr<br />

has offered gun enthusiasts the option<br />

of both compact and full-frame firearms.<br />

Their popular TP9, TP40 and TP45 have<br />

become legendary, but as the economy<br />

continues to take a hit, the demand for<br />

more affordable firearms has become a<br />

call to duty. Kahr took the best features<br />

of their TP-series and with ingenuity and<br />

their meticulous dedication to detail and<br />

quality, they developed the CT Series.<br />

The CT9 features a full-size polymer<br />

frame with a matte stainless steel slide<br />

and drift-adjustable white bar-dot sight<br />

configuration. Features of the CT9093<br />

include a 3.95-inch conventional rifling<br />

barrel length, overall length of 6.5 inches,<br />

height of 5.08 inches and a slide<br />

width of .90 inches. It weighs just 20.6<br />

ounces with the magazine, making it<br />

very slim, lightweight and perfect for concealed<br />

carry. The pistol comes standard<br />

with one 8-rounds magazine, but, if you<br />

purchase now you can also qualify for<br />

one free magazine. The downloadable<br />

free magazine coupon can be obtained<br />

by visiting the Kahr website.<br />

The MSRP on the CT9093<br />

is being offered at the introductory<br />

rate of $369 but only<br />

for a limited time. For more<br />

information on the CT Series,<br />

or any of their other firearms<br />

visit them at www.kahr.com.<br />

Steyr Arms has announced the arrival<br />

of the .40 S&W version of its full-size<br />

L-A1 service pistol on American shores.<br />

Following last year’s introduction of<br />

the L9-A1, the L40-A1 pistol features a<br />

full-length slide, 4.5-inch cold-hammerforged<br />

barrel and 12-round magazine<br />

capacity for .40 S&W. The Steyr L40-A1<br />

was designed to serve the dual role of<br />

a duty and sporting handgun. The new<br />

L40-A1 is nearly identical in form and<br />

function to the L9-A1 and other handguns<br />

in the Steyr line, which combine<br />

unparalleled ergonomics, a low bore<br />

axis, remarkable safety features, extreme<br />

reliability and amazing accuracy<br />

– thanks to a consistently crisp trigger<br />

break and short, distinct reset. The L40-<br />

A1’s full-size polymer frame offers a high<br />

grip that places the barrel axis lower in<br />

the hand to mitigate muzzle rise, while<br />

creating a perfect grip angle and a very<br />

natural point of aim. The drift-adjustable<br />

sights are in the Steyr’s intuitive trapezoidal<br />

configuration, and a Picatinny rail<br />

on the frame’s dust cover provides a<br />

mounting position for illumination and laser-aiming<br />

devices. The integrated trigger<br />

safety within the recently redesigned<br />

Reset Action System trigger requires<br />

positive finger pressure to operate<br />

Steyr’s remarkable double-action-only<br />

mechanism. This striker-fired pistol also<br />

incorporates a keyed safety lock. The<br />

barrel is cold-hammer forged with conventional<br />

rifling, and the chamber is fully<br />

supported. The suggested retail price<br />

of the Steyr L40-A1 pistol is $560. See<br />

more at www.steyrarms.com.<br />

the AR-15 and the AK-47 weapon systems.<br />

With the ability to be configured<br />

with a variety of barrels, calibers and<br />

stocks the ARAK-21 XRS can fit most<br />

any mission profile. The ARAK-21 XRS<br />

Complete Rifle MSRP is $1,899 (one<br />

barrel) and $2,159 (with 5.56 and .300<br />

blackout options). For more information<br />

on Faxon Firearms visit them online at<br />

www.faxonfirearms.com.<br />

NEW REVIEW<br />

11<br />

11<br />

<strong>SAR</strong> <strong>SAR</strong> Vol. Vol. 19, 19, No. No. 1 1

Vero Vellini, the acknowledged<br />

leader in comfortable, handcrafted gun<br />

slings, introduced its new Two-Point Adjustable<br />

Sling at the 2014 SHOT Show<br />

in January. The company now has the<br />

new Two-Point Adjustable Sling in stock<br />

and is shipping to dealers. Like all Vero<br />

Vellini slings, the new Vero Tactical Two-<br />

Point Sling is extremely functional and is<br />

constructed of the highest quality textile<br />

webbing on the market for long-lasting<br />

durability. The Two-Point Sling features<br />

proprietary closed-cell padding<br />

with a backing surface that slides only<br />

when you need it to. All sling components<br />

are synthetic and the buckles are<br />

constructed of reinforced nylon, so there<br />

is no possibility of corrosion. The Vero<br />

Tactical Two-Point Sling allows users to<br />

quickly, quietly and easily transition from<br />

a comfortable inverted high-chest-carry<br />

position to any shooting position simply<br />

by pulling out on the tethered-loop-release<br />

buckle. This releases the tension<br />

on the sling and allows the user to move<br />

the firearm into a shooting position. The<br />

Two-Point Sling can be attached on either<br />

end to a 1-inch sling swivel, or it can<br />

be wrapped around a standard collapsible<br />

AR-style stock. It allows more than<br />

24 inches of adjustment for wearing<br />

the firearm over anything from a T-shirt<br />

to body armor plus several layers of<br />

clothing. The Vero Tactical Two-Point<br />

Sling fits all platforms from ultra-short<br />

bullpup rifles through the full-length<br />

AR-10 semiautomatic rifles, as well<br />

as most bolt-action rifles. A wrapstyle<br />

sling keeper retains the excess<br />

webbing on shorter rifles. The Vero<br />

Tactical Two-Point Sling is available<br />

at high-end shooting retailers nationwide<br />

in solid black or black with an<br />

olive-green padding cover. The suggested<br />

retail price of either version<br />

is $64.99. This new Vero Vellini sling<br />

can also be purchased conveniently<br />

online at www.gunslingdirect.com.<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015<br />

12<br />

Night Optics USA introduces their new Krystal 950 Clip-on Night Vision Sight. The new<br />

Krystal 950 clip-on brings superior low-light performance to daytime riflescopes with no<br />

loss of zero. The sleek new housing design provides improved light transference to the<br />

image intensifier tube, while new multi-coated HD optics boost contrast and clarity by<br />

more than 25% over the original D-930 clip-on sight. Available with two rear aperture options<br />

(standard – 24 mm and large – 34 mm), users can expect magnification capability as<br />

high as 25x when paired with high quality day optics. A built-in manual gain control allows<br />

for on-the-fly image brightness adjustments. The Krystal 950 can be mounted directly to<br />

the front objective of the daytime riflescope with a custom Night Optics throw-lever adapter<br />

or to the Picatinny rail with the included rail mount adapter. The Krystal 950 is available with<br />

large or standard rear aperture sizes, generation 2+ Black and White and Generation 3 Gated<br />

with manual gain. The entire package includes the Krystal 950 Clip-on sight, Picatinny rail mount<br />

or optional throw-lever adapter, padded soft pouch or optional hard case, lens cover, lens cloth<br />

and operator manual. Suggested retail pricing starts at just $4,449.99. For more information you can<br />

contract them at www.nightoptics.com.

Crimson Trace, America’s recognized<br />

leader in laser sighting systems and tactical<br />

lights for firearms, has begun shipping<br />

two new products designed exclusively for<br />

Glock’s popular compact semiautomatic<br />

pistols. The two new laser sight models<br />

are in Crimson Trace’s expanding Lasergrips<br />

series and are the LG-639 with a<br />

red diode and the LG-639G featuring a<br />

green diode. These products are reaching<br />

dealers and gun stores now, and join the<br />

recently released Crimson Trace Laserguard<br />

LG-443 that fits onto Glock’s compact<br />

Model 42 pistol. The new LG-639 and<br />

LG-639G feature Crimson Trace’s patented<br />

Instinctive Activation on the rear of the<br />

grip and includes a master on/off switch to<br />

give shooters the option to use their pistols<br />

with-or without-engaging the laser. Each<br />

unit is also easily adjusted for windage and<br />

elevation and can be installed without the<br />

use of special gunsmithing tools. These<br />

products are specifically designed to fit securely<br />

onto Glock Third Generation pistol<br />

models 19, 23, 25, 32 and 38. Those compact<br />

Glock handgun models are favored<br />

by many persons for concealed carry. The<br />

MSRP for the LG 639G with the green diode<br />

is $329 and $249 for the LG-639 with<br />

red diode. More information can be found<br />

online at www.crimsontrace.com.<br />

13<br />

<strong>SAR</strong> Vol. 19, No. 1<br />

NEW REVIEW

Rangefinders can be hard to shop<br />

for. There are top brands that promise<br />

good value; there are value brands that<br />

promise good performance, and there<br />

are some premium brands that cross<br />

well into the 4 figure price column that<br />

almost promise world domination. Now,<br />

the decision has been made for you.<br />

The Bushnell Elite Tactical 1 Mile ARC<br />

laser rangefinder is as good as a rangefinder<br />

gets. The unit asks $599 at retail,<br />

half that of other brands offering similar<br />

performance. Its capabilities were well<br />

proven in our field tests. Bushnell claims<br />

this rangefinder will read up to 1 mile<br />

on a hard target. That’s 1,760 yards.<br />

We were able to get a read at 1,759<br />

yards. So we took one big step forward,<br />

and got a read of 1,758 yards. Amazing<br />

enough by any standard. We tried<br />

this rangefinder on trees, cars, brush,<br />

rocks and livestock at the maximum<br />

ranges claimed by Bushnell. It passed our<br />

tests, upheld the claims, and exceeded<br />

our expectations.<br />

The Bushnell 1 Mile ARC rangefinder<br />

replaces the 1600ARC line and includes<br />

Bushnell’s latest technology suite, called<br />

“ESP2” ranging technology. This system<br />

uses Bushnell’s second generation laser<br />

and receiver tech to send and analyze<br />

multiple measurements from every<br />

“shot” and then employs a logic filter to<br />

display the best result. This ranging tech<br />

actually analyzes air conditions to detect<br />

and compensate for dust, rain, or snow<br />

that could diffuse the infra-red laser and<br />

skew readings. This new unit features a<br />

high contrast “Vivid Display” that shows<br />

the reticle and information display in<br />

bright red figures. The display is adjustable<br />

for brightness. The 1 Mile ARC<br />

offers 3 ranging modes; a target mode<br />

for ranging easy fixed objects, a brush<br />

mode which ignores vegetation, and a<br />

constant scan mode to follow moving<br />

targets. The ranged results can be displayed<br />

in yards or meters to the target<br />

along the line-of-sight or actual horizontal<br />

distance to the target, which compensates<br />

for incline. This unit goes a step<br />

further by including a bullet drop mode<br />

so you don’t ever have to know distance<br />

to the target; it just tells you where to<br />

hold to make a hit. This “rifle mode”<br />

includes 10 ballistic groups that cover<br />

the average downrange performance<br />

of over 2,000 caliber and load combinations.<br />

Bushnell suggests that these<br />

average trajectories are close enough<br />

to make a hit on a medium game animal.<br />

The display can show holdover in<br />

inches, centimeters or MOA values at<br />

the target’s distance. So it’s not just a<br />

rangefinder--it’s a firing solution.<br />

The 1 Mile ARC features rubber armored<br />

construction, a fast adjust eye<br />

cup, and an ocular focus to adjust for an<br />

individual’s eyesight. There are only 2<br />

buttons, one to “fire” and one to access<br />

the menu. Bushnell has kept the menu<br />

options well organized so it’s easy to<br />

navigate. The battery cover unscrews<br />

without the need for a coin as they<br />

have in the past. There’s a flip-open tab<br />

on the cover that makes battery install<br />

quick and easy. The only complaint we<br />

had is that the battery cover is not tethered<br />

to the unit and thus could get lost.<br />

A tripod can be attached to the threaded<br />

boss on the bottom surface. The belt<br />

pouch has done away with plastic snaps<br />

and Velcro for a closure. Instead it uses<br />

magnets within the pouch’s flap. It’s fast,<br />

secure, and quiet. Bushnell continues to<br />

impress with an outstanding product at a<br />

winning price.<br />

Bushnell Outdoor Products<br />

20 Constitution Blvd. South<br />

Shelton, CT 06484<br />

(866) 255-8406<br />

ShopBushnell.com<br />

<strong>SAR</strong> Vol. 19, No. 1 14 JANUARY / FEBRUARY 2015

FLIR ONE is the first personal thermal<br />

imaging camera for the iPhone 5 and 5s,<br />

enabling outdoor enthusiasts to see invisible<br />

heat and to measure minute variances<br />

in temperature right on the iPhone screen.<br />

Thermal imaging through FLIR ONE enables<br />

a host of outdoor solutions such as<br />

observing wildlife in the dark, ensuring a<br />

campfire is extinguished, or hiking / exploring<br />

at night. With the free FLIR ONE app<br />

available through the App store, users can<br />

take and send thermal videos and photos<br />

via text, email or social media. The device<br />

also includes its own battery that lasts for<br />

four hours of continuous use in the wild.<br />

Find out more at www.flir.com/flirone.

y Teresa G. Ficaretta, Esq.<br />

& Johanna Reeves, Esq.<br />

Legal News from the Nation’s Capital<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015<br />

16<br />

ATF Ruling 2014-1 Impacts Manufacture<br />

and Import of Machine guns<br />

On September 4, 2014, the Bureau<br />

of Alcohol, Tobacco, Firearms and Explosives<br />

(ATF) released Ruling 2014-1,<br />

addressing the transfer and possession<br />

of machine guns by qualified manufacturers<br />

and importers. The ruling reviews<br />

the restrictions of Section 922(o) of the<br />

Gun Control Act (GCA) (Title 18 United<br />

States Code, § 922(o)), and sets forth<br />

rules for qualified manufacturers and<br />

importers to lawfully transfer machine<br />

guns for further manufacturing or for repair.<br />

The complete text of the ruling can<br />

be found on ATF’s website at http://www.<br />

atf.gov/sites/default/files/assets/Library/<br />

Rulings/Firearms/atf_ruling_2014_-_<br />

manufacturing-inventory_of_machine<br />

guns_for_le_and_military_2.pdf.<br />

Background<br />

Section 922(o) of the GCA makes it<br />

unlawful for any person to transfer or<br />

possess a machine gun. The only exemption<br />

to this prohibition is a transfer<br />

to or by, or possession by or under the<br />

authority of a Federal, State, or local<br />

government agency. ATF regulations<br />

implementing Section 922(o) provide<br />

that qualified manufacturers may manufacture<br />

machine guns for sale or distribution<br />

to a Federal, State, or local<br />

government agency so long as they are<br />

registered in the National Firearms Registration<br />

and Transfer Record, and their<br />

transfer is restricted to the distribution<br />

for official use of Federal, State, or local<br />

government agencies. The regulations<br />

also authorize the manufacture of machine<br />

guns for purposes of exportation<br />

in compliance with regulations of the<br />

Department of State issued under the<br />

Arms Export Control Act.<br />

ATF has consistently interpreted<br />

Section 922(o) to allow qualified<br />

manufacturers to stockpile machine<br />

guns they manufacture for sale to Federal,<br />

State, and local government agencies<br />

or for export. These positions are<br />

outlined in ATF’s National Firearms<br />

Act Handbook (the “NFA Handbook”),<br />

E-Publication 5320.8, Section 7.5, also<br />

available on ATF’s website.<br />

Prior to issuance of Rul. 2014-1, ATF<br />

allowed qualified manufacturers and<br />

importers to transfer machine guns to<br />

other qualified licensees for purposes of<br />

further manufacture, repair, alteration, or<br />

integration into another defense article.<br />

In fact, Section 7.6.1 of the NFA Handbook<br />

states that qualified NFA manufacturers<br />

may contract with other qualified<br />

manufacturers to produce machine<br />

guns for sale to Federal, State, or local<br />

government agencies or for dealer sales<br />

samples. This section of the NFA Handbook<br />

goes on to state that a variance<br />

is required for these types of transfers,<br />

as the regulations in 27 C.F.R. 479.105<br />

limit the number of machine guns that<br />

may be transferred. Accordingly, section<br />

7.6.1 indicates that both manufacturers<br />

who participate in the production of the<br />

machine guns must obtain a variance<br />

authorizing the transfer from one manufacturer<br />

to the other pursuant to 27<br />

C.F.R. 479.26.<br />

Historically, a number of manufacturers<br />

have received variances from<br />

ATF authorizing the transfer of unlimited<br />

quantities of machine guns between licensed<br />

manufacturers during the manufacturing<br />

process pursuant to the provisions<br />

outlined in the NFA Handbook.<br />

However, beginning in 2012, ATF officials<br />

made statements at industry trade<br />

shows concerning the legality of such<br />

transfers under Section 922(o). At the<br />

Sporting, Hunting, and Outdoor Trade<br />

Show (SHOT Show) held in Las Vegas,<br />

Nevada, in January, 2012, ATF officials<br />

announced the agency’s position that<br />

allowing licensed manufacturers to

transfer machine guns to a second<br />

qualified manufacturer for additional<br />

manufacturing processes is inconsistent<br />

with the plain meaning of Section<br />

922(o). These officials announced that<br />

the agency would be providing written<br />

clarification at some point in the<br />

future. ATF Rul. 2014-1 appears to be<br />

this clarification.<br />

Holdings of ATF Rul. 2014-1<br />

The ruling has three separate holdings,<br />

outlined below:<br />

1. Stockpiling of machine guns for future<br />

sale. The first holding states that<br />

licensed manufacturers who are properly<br />

qualified under the National Firearms<br />

Act (NFA) may manufacture and stockpile<br />

machine guns for future sale to Federal,<br />

State, or local government agencies<br />

without first obtaining a specific<br />

contract or order from such government<br />

agency, provided the machine guns are<br />

properly registered under the NFA and<br />

are only distributed for the official use of<br />

such government agencies.<br />

2. Delivery of machine guns to a second<br />

manufacturer-maintaining constructive<br />

possession. The ruling states that qualified<br />

manufacturers may deliver machine<br />

guns (including frames or receivers) to<br />

another qualified manufacturer but may<br />

not transfer such firearms to the second<br />

manufacturer without violating Section<br />

922(o). However, the ruling states<br />

that the delivery to a second manufacturer<br />

will not violate Section 922(o) if<br />

the first manufacturer maintains continuous<br />

dominion or control over the<br />

machine guns.<br />

3. Transfers of machine guns between<br />

manufacturers when the second manufacturer<br />

has a government contract<br />

or “official written request” from a government<br />

agency. The last holding in<br />

ATF Rul. 2014-1 states that a manufacturer<br />

may transfer machine guns it<br />

has manufactured to another qualified<br />

manufacturer if the first manufacturer<br />

has a government contract or official<br />

written request that meets the<br />

following requirements:<br />

• The document is from a Federal,<br />

State, or local government agency<br />

and is on official letterhead;<br />

• The document states that the first<br />

manufacturer is an agent of the<br />

government agency authorizing the<br />

transfer of the machine guns to the<br />

second manufacturer;<br />

• The document is signed and dated<br />

by an authorized government official<br />

and includes the official’s title<br />

and position;<br />

• The document states that the firearms<br />

to be transferred are machine<br />

guns as defined by Federal law.<br />

• The document states that the machine<br />

guns to be transferred are<br />

particularly suitable for official use<br />

by the requesting Federal, State, or<br />

local government agency; and<br />

• The document includes a statement<br />

that the Federal, State, or<br />

local government agency requests<br />

and authorizes the manufacturer<br />

to transfer the machine guns<br />

to and/or from other licensed<br />

manufacturers for assembly, repair,<br />

development, testing, other<br />

manufacturing processes, or storage,<br />

as the case may be, for that<br />

government agency.<br />

The ruling states that manufacturers<br />

who wish to transfer machine guns under<br />

the third holding, as outlined above,<br />

must attach a copy of the government<br />

contract or other official written request<br />

to the transfer application submitted to<br />

ATF’s NFA Branch.<br />

CAUTION! ATF Rul. 2014-1 Modifies<br />

ATF Rul. 2004-2<br />

The last paragraph of ATF Rul. 2014-<br />

1 states that ATF Rul. 2004-2 is “clarified”<br />

with respect to the documentation<br />

required under the GCA for qualified importers<br />

to transfer an imported machine<br />

gun to another qualified licensee for<br />

inspection, testing, calibration, repair,<br />

reconditioning, further manufacture,<br />

or incorporation into another defense<br />

article. This “clarification” will significantly<br />

affect the ability of U.S. companies<br />

to service the repair needs of their<br />

foreign customers.<br />

In Rul. 2004-2, ATF used its variance<br />

authority under the GCA and NFA to establish<br />

a procedure for qualified importers<br />

to bring exported machine guns and<br />

other NFA firearms into the U.S. temporarily<br />

for purposes of inspection, testing,<br />

calibration, repair, or incorporation into<br />

another defense article. The ruling recognized<br />

the fact that many manufacturers<br />

have a legitimate need to import machine<br />

guns they exported to foreign law<br />

enforcement agencies for purposes of<br />

repairs under warranty, recalibration, or<br />

incorporation into another defense article,<br />

and that such importations are necessary<br />

for national defense. The ruling<br />

further indicated ATF was aware most of<br />

these temporary importations take place<br />

pursuant to the Department of State’s<br />

International Traffic in Arms Regulations<br />

at 22 C.F.R. Part 120-130. However,<br />

ATF expressed concern in the ruling that<br />

importers utilizing such regulations were<br />

not complying with the registration provisions<br />

of the NFA, which help ensure<br />

the security and accountability of the<br />

firearms while within the U.S. Accordingly,<br />

ATF Rul. 2004-2 required importers<br />

temporarily importing NFA firearms<br />

under State Department requirements<br />

to also register the firearms on<br />

ATF Form 2.<br />

ATF Rul. 2004-2 also addressed<br />

transfers of machine guns following<br />

their temporary importation. The ruling<br />

stated that conveyance of temporarily<br />

imported NFA firearms does not amount<br />

to a “transfer” as that term is used in the<br />

NFA. Accordingly, the ruling stated that<br />

no transfer application must be submitted<br />

to ATF to lawfully accomplish such<br />

conveyances. The ruling did not specifically<br />

address the requirements of Section<br />

922(o). However, the ruling clearly<br />

authorized the conveyance of imported<br />

machine guns to a properly qualified<br />

manufacturer for repair, remanufacture,<br />

or any of the other purposes outlined in<br />

the ruling.<br />

LEGALLY ARMED<br />

17<br />

<strong>SAR</strong> Vol. 19, No. 1

It is important to highlight that the<br />

“clarification” of ATF Rul. 2004-2 by ATF<br />

Rul. 2014-1 effectively OVERRULES<br />

the transfer/conveyance language in<br />

the 2004 ruling. According to the 2014<br />

ruling, ATF considers a qualified importer’s<br />

delivery of an imported machine<br />

gun to another FFL to be a transfer that<br />

violates Section 922(o), absent a government<br />

contract or other document<br />

specifically authorizing the transfer of<br />

the imported machine gun to a manufacturer.<br />

Because the machine guns<br />

will be the property of foreign governments,<br />

obtaining a written authorization<br />

from a Federal, State, or local government<br />

agency may be difficult. Accordingly,<br />

it will be challenging for importers<br />

to utilize the procedure authorized<br />

in ATF Rul. 2014-1 to lawfully transfer<br />

temporarily imported machine guns to<br />

another manufacturer.<br />

CAUTION! Prior Inconsistent<br />

Rulings Modified<br />

ATF Rul. 2014-1 also modifies any<br />

prior letter rulings or marking variances<br />

that are inconsistent with the positions<br />

outlined in the ruling. Consequently,<br />

businesses that operate under privately<br />

issued variances that authorize machine<br />

gun transfers between qualified<br />

manufacturers may no longer rely upon<br />

such variances.<br />

Impact of ATF Rul. 2014-1 on Federal<br />

Firearms Licensees<br />

The practical impact of ATF Rul.<br />

2014-1 on the operations of Federal firearms<br />

licensees is summarized below.<br />

1. Manufacture and stockpiling of<br />

machine guns. Qualified manufacturers<br />

may continue to manufacture<br />

and stockpile machine guns for future<br />

sale to Federal, State, and local<br />

government agencies.<br />

2. Transfers of machine guns to a<br />

second manufacturer. ATF marking variances<br />

or private letter rulings specifically<br />

authorizing the transfer of machine<br />

guns from one qualified manufacturer<br />

to another qualified manufacturer are<br />

no longer valid. Licensees who utilize<br />

the services of another qualified manufacturer<br />

to manufacture machine guns<br />

must have an employee accompany<br />

the registered machine guns to the<br />

premises of the second manufacturer<br />

and maintain continuous dominion and<br />

control over the machine guns while the<br />

manufacturing operations are conducted.<br />

Alternatively, the first manufacturer<br />

may obtain a government contract or<br />

other document specifically authorizing<br />

the transfer to the second manufacturer.<br />

Such a document must meet all requirements<br />

of ATF Rul. 2014-1 as set forth<br />

above and must be submitted to the ATF<br />

National Firearms Act Branch with the<br />

Form 3 transfer application.<br />

In the case of machine guns manufactured<br />

for export, transfers to another<br />

qualified manufacturer must meet<br />

all the requirements outlined above. It<br />

may be difficult to obtain a contract or<br />

other written authorization from a Federal,<br />

State, or local government agency<br />

specifically authorizing the transfer to a<br />

second manufacturer when the machine<br />

guns are being made for export to a<br />

foreign customer. The only alternative<br />

to this requirement is for the first manufacturer<br />

to maintain continuous dominion<br />

and control over the machine guns<br />

while they are on the premises of the<br />

second manufacturer.<br />

3. Transfers of machine guns temporarily<br />

imported under Department of<br />

State requirements. Importers who are<br />

properly qualified under the GCA and<br />

NFA may continue to temporarily import<br />

machine guns exported to foreign governments<br />

for purposes of repair, recalibration,<br />

and incorporation into another<br />

defense article. These temporary imports<br />

must comply with ITAR regulations<br />

in 22 C.F.R. Parts 120-130 and be registered<br />

on ATF Form 2 within 15 days of release<br />

from Customs custody. However,<br />

these machine guns may not be transferred<br />

to another qualified manufacturer<br />

absent a contract with a Federal, State,<br />

or local government agency specifically<br />

authorizing the transfer to the qualified<br />

manufacturer OR a written authorization<br />

that meets all the requirements set forth<br />

in ATF Rul. 2014-1. As with transfers of<br />

machine guns manufactured for export<br />

to foreign customers, it may be difficult<br />

to obtain such an authorization from a<br />

domestic government agency when the<br />

machine guns are owned by a foreign<br />

customer. Alternatively, manufacturers<br />

or importers who have a need for another<br />

qualified manufacturer to perform<br />

repair or manufacturing operations on<br />

temporarily imported machine guns<br />

must maintain continuous dominion<br />

and control over the weapons while on<br />

the premises of the qualified manufacturer<br />

to avoid both licensees violating<br />

Section 922(o).<br />

4. Impact of ATF Rul. 2014-1 on Repair<br />

of Machine Guns. ATF’s National<br />

Firearms Act Handbook, section 9.5.1,<br />

“Repair of Firearms,” states that ATF<br />

does not consider the temporary conveyance<br />

of an NFA firearm to an FFL for<br />

repair to be a “transfer” under the NFA.<br />

Accordingly, this section states that a<br />

transfer application is not required to<br />

convey the firearm for repair or to return<br />

the repaired firearm to its owner/<br />

possessor. The issuance of ATF Rul.<br />

2014-1 raises questions as to the continued<br />

application of this position as to<br />

machine guns subject to control under<br />

Section 922(o). ATF advises that the<br />

ruling changes ATF’s position on repairs<br />

of machine guns in certain situations.<br />

These situations are outlined below.<br />

Temporary Imports. As stated above,<br />

machine guns temporarily imported under<br />

State Department regulations may<br />

not be delivered to another FFL for repair<br />

absent a written authorization from<br />

a Federal, State, or local government<br />

agency expressly authorizing the transfer<br />

to the second FFL. ATF views such<br />

deliveries as a “transfer” as that term<br />

is used in Section 922(o) and the NFA,<br />

and they must be accomplished with a<br />

Form 3 transfer application with the written<br />

authorization attached. Given the<br />

difficulties in obtaining such an authorization,<br />

the best option for facilitating<br />

repair of temporarily imported machine<br />

guns will be for an employee of the importer<br />

to retain continuous dominion and<br />

control over the weapons while on the<br />

premises of the repairing FFL to avoid<br />

violating the law.<br />

Manufacturers Discontinuing Business.<br />

The ruling will affect the repair<br />

of machine guns acquired by a qualified<br />

FFL pursuant to the provisions<br />

of 27 C.F.R. 479.105(f). This section<br />

of the regulations requires a qualified<br />

manufacturer, importer, or dealer, prior<br />

to discontinuing licensed business, to<br />

transfer, in accordance with the NFA,<br />

machine guns to a Federal, State, or<br />

local government agency or to another<br />

qualified manufacturer or importer. Alternatively,<br />

the FFL going out of business<br />

may transfer the registered machine<br />

guns (in limited quantities) to a qualified<br />

dealer as sales samples pursuant<br />

to 27 C.F.R. 479.105(d). Machine guns<br />

acquired by a qualified FFL pursuant to<br />

section 479.105(f) will not be transferred<br />

pursuant to a contract or letter from a<br />

Federal, State, or local government<br />

agency authorizing possession by the<br />

acquiring FFL. Accordingly, the delivery<br />

of such machine guns to another licensee<br />

for repair would be a transfer that<br />

would violate Section 922(o). The only<br />

option for facilitating repair in this situation<br />

will be for the registrant to maintain<br />

continuous custody and control over the<br />

machine guns during the repair process.<br />

Machine guns Acquired as Sales<br />

Samples. Machine guns may be lawfully<br />

acquired as dealer sales samples<br />

<strong>SAR</strong> Vol. 19, No. 1 18 JANUARY / FEBRUARY 2015

OUR WORLD<br />

by Scott Novzen and Robert Segel<br />

North Africa ’42? No, just another<br />

Arizona machine gun shoot.<br />

pursuant to regulations in 27 C.F.R.<br />

479.105(d). This regulation requires<br />

FFLs to obtain a letter from a Federal,<br />

State, or local government agency expressing<br />

a need for a particular model<br />

or interest in seeing a demonstration of<br />

a particular weapon (a “law letter”). ATF<br />

advises that the law letter authorizes the<br />

FFL-registrant to deliver the machine<br />

gun to another qualified FFL for repair<br />

and that such delivery is a “conveyance”<br />

rather than a “transfer.” As noted in the<br />

NFA Handbook, section 9.5.1, a transfer<br />

application is not required to convey<br />

a machine gun for repair or to return<br />

the repaired machine gun to the registrant.<br />

However, in order to avoid any<br />

appearance that a transfer has taken<br />

place, ATF recommends that a Form 5<br />

application be submitted for approval<br />

prior to conveying the machine gun for<br />

repair. It is also recommended that the<br />

FFL making repairs obtain an approved<br />

Form 5 to return a repaired machine<br />

gun. If Form 5’s are not used, the parties<br />

should maintain documentation showing<br />

that the conveyance was for the<br />

purpose of repair. For dealer sales<br />

samples requiring repair, ATF Rul. 2014-<br />

1 did not change this procedure.<br />

Delivery of Machine Guns for Repair<br />

by One FFL to a Second FFL. Assuming<br />

the delivery of machine guns to a qualified<br />

manufacturer for repair is lawful, the<br />

next question is whether the manufacturer<br />

may lawfully deliver the machine<br />

guns to a second manufacturer. It may<br />

be necessary, for example, for the first<br />

manufacturer to obtain the services of<br />

a second manufacturer for purposes of<br />

refinishing or heat treating the machine<br />

gun. ATF advises that such deliveries<br />

amount to “transfers” and are lawful<br />

only if there is a specific contract or other<br />

written authorization from a Federal,<br />

State, or local government agency that<br />

authorize the delivery to the secondary<br />

manufacturer. Such transfers must be<br />

accomplished on ATF Form 3 with the<br />

written authorization attached. For repair<br />

of dealer sales samples, ATF advises<br />

that a delivery/conveyance to the first<br />

qualified FFL for repair is permissible,<br />

but the FFL may not convey the machine<br />

guns to a second qualified FFL without<br />

violating Section 922(o). ATF further<br />

advises that machine guns in the hands<br />

of law enforcement agencies that require<br />

repair may continue to be conveyed to a<br />

qualified FFL for repair without a transfer<br />

occurring, but delivery to a second FFL<br />

would amount to a “transfer” that also<br />

requires a transfer application supported<br />

by a specific written authorization.<br />

Conclusion<br />

ATF Rul. 2014-1 significantly changes<br />

the way importers and manufacturers<br />

of machine guns should conduct business,<br />

both as to machine guns distributed<br />

domestically and those that are<br />

exported. As violations of the GCA and<br />

NFA may result in significant civil and<br />

criminal penalties, licensees should take<br />

care to avoid unintentional violations of<br />

the law.<br />

(The information in this article is for<br />

informational purposes only and is not<br />

intended to be construed or used as<br />

legal advice).<br />

LEGALLY ARMED<br />

19<br />

<strong>SAR</strong> Vol. 19, No. 1

Guns of<br />

1855 - 1899<br />

Las Vegas<br />

The Early Years<br />

By Tom Murphy<br />

Nevada Territory became our 36th state<br />

on October 31, 1864. Las Vegas is generally<br />

thought to have begun in 1905 when the Union<br />

Pacific Railroad began stopping at a site where<br />

there was water from a spring and an area for<br />

passengers to rest.<br />

The sight was named Las Vegas (The Meadows)<br />

Springs for the three springs that ran into<br />

two pools of water. It’s said that American adventurers<br />

John C. Fremont and Kit Carson<br />

camped at the springs in 1844. By 1924 so<br />

much water had been used that the water table<br />

had dropped below the surface and the Las<br />

Vegas Land and Water Company drilled Well<br />

#1 in 1923.<br />

The Mormons out of Salt Lake City established<br />

the first non-native American settlement<br />

near the springs in 1855. Due to hardship, high<br />

temperatures and problems with the local Paiute<br />

inhabitants, the 30 Mormon missionaries<br />

petitioned leader Brigham Young in Salt Lake<br />

City to be allowed to abandon the settlement<br />

and a fort that was under construction. They<br />

departed in 1857 and the settlement was<br />

left unattended.<br />

During this time, prospectors had found their<br />

way to a remote canyon south of Las Vegas,<br />

near the route of current-day Hwy 95, where<br />

Spaniards had discovered silver back in 1775.<br />

The early Spanish miners built a small settlement<br />

at the canyon mouth where it drained into<br />

the Colorado River. They named it Eldorado (El<br />

Hombre Dorado - literally “The Man Golden”, or<br />

The Gold Man). Unfortunately for the Spaniard<br />

prospectors, they mined the silver, but completely<br />

missed the gold just under the ground.<br />

The new miners began by sluicing the<br />

streams feeding into the Colorado River. Then<br />

the gold was found in the hills and times became<br />

interesting in Eldorado Canyon. They<br />

managed to keep the gold secret more or less,<br />

due to the remoteness of the discovery. However,<br />

this all changed in 1858 when paddle wheel<br />

steamboats made their way up to the remote<br />

encampment from Yuma, Arizona. Gold fever<br />

struck and in short order miners began to arrive<br />

and stake out claims on any available, or sometimes<br />

un-available, piece of dirt that looked like<br />

gold might be below.<br />

By 1862 miners had discovered a vertical<br />

seam of gold and named it the Techatticup - a<br />

Paiute word for starving. Next up was the nearby<br />

Nelson District, where the Gettysburg, Duncan,<br />

Solar, Rand, and other mines were sunk.<br />

22<br />

22<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015

ABOVE: Around since the 1820s, John Dixon and Son of Edinburgh, Scotland<br />

built this .577 sharpshooter rifle. Southern blockade runners brought these<br />

into South Carolina as the South had little or no gun making facilities and relied<br />

heavily on gunmakers in Great Britain for their weapons.<br />

The area was to become the earliest<br />

and richest mining district in Nevada.<br />

Many of the area’s inhabitants<br />

were deserters from the Civil War,<br />

gamblers, men on the run from serious<br />

crimes and other ne’er-do-wells.<br />

Their skill at extracting wealth from the<br />

ground wasn’t quite as good as their<br />

ability to extract wealth from people.<br />

Disputes grew into gunfights rapidly.<br />

Greed reared its ugly head. Claim<br />

jumping was commonplace, and vigilante<br />

justice was the only justice in this<br />

very remote area.<br />

Mine ownership came to question.<br />

The Techatticup Mine was a case in<br />

point. At one time part of it was owned<br />

by Senator George Hearst, father of<br />

William Randolph Hearst of publishing<br />

fame. So much dispute, labor problems<br />

and bad management overshadowed<br />

the mine that it grew a dangerous<br />

reputation.<br />

The killings in Eldorado Canyon,<br />

by that time with a population of nearly<br />

500 people, became almost a daily<br />

matter. Regular law enforcement refused<br />

to patrol the canyon for fear of<br />

getting murdered.<br />

The weapons the residents used<br />

to dispatch each other with great frequency<br />

ranged from whatever was<br />

close at hand, be it a pick, or some<br />

blunt object, to well-worn-but-serviceable<br />

black powder weapons for the<br />

most part. Commonly used firearms<br />

would include Civil War rifles like the<br />

Sharps New Model 1859 rifle as carried<br />

by Col. Hiram Berdan’s 1st and<br />

2nd Regiments of U.S. Sharpshooters.<br />

Some guns came from the British<br />

Isles via Confederate deserters like<br />

the John Dixon and Son of Edinburgh,<br />

Scotland .577 sharpshooter rifle.<br />

Southern blockade runners brought<br />

these into South Carolina. The South<br />

had little or no gun making facilities<br />

and relied heavily on gunmakers in<br />

Great Britain for their weapons. Like<br />

other British gun makers, Dixon had<br />

been around since the 1820s and<br />

turned out shotguns and rifles.<br />

Handguns would vary from pocket<br />

pistols like the Remington-Beals<br />

1st Model Pocket Revolver built<br />

1857-1858 to a Colt 2nd Model Dragoon<br />

Revolver manufactured around<br />

1850-1851.<br />

Prospectors weren’t the only killers.<br />

Eldorado Canyon had two of Nevada’s<br />

nastiest murderers who were Native<br />

Americans - Ahvote and his stepbrother<br />

Queho. Ahvote is said to have been<br />

responsible for five victims. Queho<br />

was a bit more active and is believed<br />

to have sent over 20 souls to the happy<br />

hunting ground; with the last being<br />

Maude Douglas whom he dispatched<br />

in 1919. Adding insult to injury, he then<br />

proceeded to successfully avoid all efforts<br />

of capture by various posses. His<br />

bones were located inside a cave near<br />

the Colorado River in 1940 by prospectors.<br />

They are now interred at Cathedral<br />

Canyon, NV, 40 miles Southwest<br />

of Las Vegas. Ahvote’s outcome?<br />

Hunted down by Queho and slain for<br />

the murder of some local residents.<br />

BELOW: Sharps New Model 1859 Rifle was a .52 caliber, percussion, breech-loader manufactured by Sharps Rifle<br />

Manufacturing Co, Hartford, Connecticut. It was used during the Civil War and many miners, some who were deserters,<br />

brought this weapon with them to the goldfields near Las Vegas. Some of them were converted after the war by the U.S.<br />

Government to fire .52-70 rimfire metallic cartridges, or .50-70 centerfire.<br />

WWW.SMALLARMSREVIEW.COM 23 <strong>SAR</strong> Vol. 19, No. 1

1875<br />

Kiel Kyle Ranch Killings<br />

ABVOVE: The Remington Model 1875 Single Action Improved<br />

Army was made from 1875-1889. This particular gun is from the<br />

Kyle Ranch, and is on display at the Clark County Museum.<br />

Running a ranch in the Las Vegas<br />

area back in the late 1800s was a<br />

back-breaking, thankless, arid job. Water<br />

was scarce, the alkaline soil wasn’t<br />

suitable for many crops, and feeding<br />

livestock on scrub brush made for very<br />

skinny cows and sheep.<br />

The Kyle Ranch was established by<br />

Conrad Kiel in 1875 near the corner of<br />

Losee St. and Carey Ave. in North Las<br />

Vegas. It had a well-earned reputation<br />

as a hideaway and shelter for some serious<br />

badmen like Jack Longstreet – a<br />

particularly nasty fellow. In his youth, he<br />

had an ear removed, probably not gently,<br />

for stealing a neighbor’s cattle. He<br />

hired on with the Tonopah Stage as a<br />

gunman - not as a stage guard. Thusly<br />

employed, he proceeded to kill his<br />

brother-in-law. Both his temper and his<br />

guns were deadly quick. He died from an<br />

accidental self-inflicted gunshot wound<br />

at 94 years of age.<br />

Then there was the killing of Archie<br />

Stewart at the Kyle Ranch in 1884. Archie<br />

owned the Las Vegas Ranch a few<br />

miles south of the Kyle Ranch. His wife,<br />

Helen, was in charge while Archie was<br />

down in Eldorado Canyon delivering<br />

produce and meat to hungry miners.<br />

While he was bouncing over rocks in his<br />

freight wagon many miles from home,<br />

one of his ranch hands, Schyler Henry,<br />

announced in fairly foul terms that<br />

he was quitting and wanted his wages.<br />

Helen Stewart said he’d have to wait for<br />

Archie to return. He replied threateningly<br />

in what she said was a “black-hearted<br />

slanderer’s tongue.”<br />

Archie was tired from many hours in<br />

a stiffly sprung wagon, but after a short<br />

meal and a long drink, he saddled a<br />

horse and loaded his rifle (said to be a<br />

Winchester 30-30, a very popular gun<br />

for ranchers) and headed out to find Mr.<br />

Henry at the Kyle ranch.<br />

He arrived at the Kyle ranch house<br />

and proceeded to the back of the house,<br />

gun in hand. All the windows and doors<br />

were open. He was spotted and shot first<br />

– and missed. Shots rang out from the<br />

ranch house. He fell dead with bullets to<br />

his chest and head. Schyler Henry had<br />

two minor flesh wounds. Conrad Kiel<br />

and Schyler Henry were hauled before a<br />

grand jury for killing Archie Stewart. The<br />

jury elected not to indict. Though as an<br />

example of the gentle nature of the early<br />

ranchers, before the gunsmoke had<br />

cleared, Conrad Kiel dispatched a rider<br />

to Helen Stewart with a note saying,<br />

“Mrs. Sturd (sic) send a team and take<br />

Mr. Sturd (sic) away he is dead. C. Kiel.”<br />

OPPOSITE PAGE TOP LEFT: Jack Longstreet was called a criminal by some and a hero by others. He worked as a hired gunman<br />

for the Tonopah Stage. While employed, he managed to kill his brother-in-law, and was acquitted of the crime. He was nicknamed<br />

“One-eared Longstreet after a rancher cut off one of his ears when he was young when he was caught rustling cattle.<br />

OPPOSITE PAGE TOP RIGHT: After 140 years of various owners, the interior of the Kyle Ranch house is much the worse for wear.<br />

The building is not open to the general public.<br />

OPPOSITE PAGE BOTTOM: The Kyle Ranch, built in 1875 by Conrad Kiel, sits on the corner of Losee St and Carey Way. It was<br />

the scene of a shootout between Archie Stewart of the Las Vegas Ranch and Schyler Henry in 1884. The ranch is the oldest<br />

standing building in Las Vegas.<br />

24<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015

Guns of LV<br />

WWW.SMALLARMSREVIEW.COM 25 <strong>SAR</strong> Vol. 19, No. 1<br />

WWW.SMALLARMSREVIEW.COM 25 <strong>SAR</strong> Vol. 19, No. 1

Jack Longstreet lived in this cabin in the Ash Meadows<br />

National Wildlife Refuge 30 miles northwest of the town<br />

of Pahrump, Nevada. It is said that he had a hidden room<br />

built so he could hide if the law showed up.<br />

The stamping “41 WCF” (Winchester Center Fire)<br />

identify Frank Wait’s Colt as a very rare caliber.<br />

26<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015

Guns of LV<br />

This hideout revolver has no markings whatsoever. It’s similar to a Fordham<br />

& Wadsworth D.A. .32, but in .45 caliber. It’s from the early 20th<br />

Century and was used in Las Vegas.<br />

This .41 WCF Colt Single Action belonged to<br />

Frank Wait who served as undersheriff various<br />

times during the 1920s and 1930s. He was<br />

said to be somewhat of a throwback to frontier<br />

lawman like Sam Gay.<br />

WWW.SMALLARMSREVIEW.COM 27 <strong>SAR</strong> Vol. 19, No. 1

1900 - 1949<br />

The First Half Century<br />

Sam Gay was the second sheriff of Clark County. He<br />

served from 1911 to 1931 except for a short period<br />

around 1917. In 1911, while still sheriff, he was appointed<br />

Police Chief of Las Vegas.<br />

The Census of 1900 showed Las Vegas to have 30 inhabitants.<br />

In 1904 the San Pedro, Los Angeles and Salt<br />

Lake Railroad Co. ran a line connecting Las Vegas to the<br />

rest of the world. Along with a depot, the station had a cafe<br />

and the town’s first casino. Prior to the coming of the railroad,<br />

travel was limited to wagons on a dirt road. The Las<br />

Vegas area actually had fewer people than Searchlight, a<br />

mining town 60 miles to the south.<br />

Montana Senator William Clark saw the possibilities of<br />

the Las Vegas Springs area as a stopping and watering<br />

spot on the Salt Lake City - Los Angeles rail line and he<br />

bought a large parcel of land near the Springs. He then sold<br />

600 lots to the tune of $265,000 in 1905 and the city was<br />

born. Then, if the heat and the dust weren’t enough to keep<br />

visitors away in hordes, Nevada banned all gambling in<br />

1909. However, railroad workers kept moving to Las Vegas,<br />

and Las Vegas was incorporated as a city March 16, 1911.<br />

Over the next 20 years small ranches began to appear<br />

28<br />

<strong>SAR</strong> Vol. 19, No. 1 JANUARY / FEBRUARY 2015

Guns of LV<br />

Sam Gay is said to be the large man in the center<br />

of the photo in the white hat. He liked to get drunk<br />

and shoot out street lights on Fremont Street. The<br />

subsequent arrest caused him to swear off alcohol<br />

as long as he was a sheriff.<br />

both in and around the new city. Some<br />

of them didn’t do so much farming, but<br />

were only thinly disguised brothels.<br />

Soon the town became a draw for Californian<br />

residents, especially from the<br />

Los Angeles basin. Then Hollywood<br />

discovered Las Vegas. Both actors and<br />

people in the rapidly growing entertainment<br />

business were drawn mainly to the<br />

gambling, which even though outlawed<br />

continued to flourish, the climate, and<br />

Nevada’s liberal divorce laws. Future<br />

divorcees had to live in Nevada for only<br />

six weeks before obtaining a decree.<br />

Life in Las Vegas during the formative<br />

years was a bit on the wild and wooly<br />

side and law enforcement became a<br />

top priority in Clark County beginning<br />

around 1909. (Clark County, named after<br />

William Clark, was spun off from Lincoln<br />

County Feb. 5, 1909.) The county<br />

needed a sheriff’s department and the<br />

Clark County Sheriff’s Office was established.<br />

The first sheriff appointed was<br />

Charles C. Corkhill, owner and editor of<br />

The Las Vegas Age newspaper. He had<br />

no law enforcement background and<br />

only held the position for 18 months.<br />

Replacing him was “Big Sam Gay.”<br />

Six foot tall and 260 pounds, he came<br />

by his nickname honestly. Born March<br />

1, 1860 on Prince Edward Island, Canada,<br />

Sam came to Las Vegas in 1905 and<br />

became Charles Corkhill’s deputy.<br />

Now, Sam had a slightly slanted outlook<br />

on crime and criminals. He firmly<br />

believed that all the miners and freight<br />

haulers had every right to raise hell,<br />

get drunk and generally lose money<br />

at the gambling halls. He just wanted<br />

to keep them from doing serious harm<br />

to each other, or killing their drinking<br />

companions. Big Sam came by this<br />

attitude honestly, as he was known to<br />

enjoy the taste of good whiskey and<br />

he claimed to having been instructed in<br />

the manly art of fisticuffs by none other<br />

than John L. Sullivan, the heavyweight<br />

boxing champion.<br />

Gay was noted to prefer to settle a<br />

drunken brawl by banging the participant’s<br />

heads together. Should that not<br />

stifle the festivities, he would drag the<br />

drunks out to the bar’s hitching post, tie<br />

WWW.SMALLARMSREVIEW.COM 29 <strong>SAR</strong> Vol. 19, No. 1

Guns of LV<br />

A lever action rifle similar to this Marlin<br />

30-30 would have been in the gun room<br />

of the Clark County Sheriff’s office when<br />

gambling was legalized in 1931. The Model<br />

1893 was made from 1893 to 1936.<br />

them there and apply a liberal application<br />

of cold water from a hose. He could<br />

settle most problems without resorting<br />

to a gun. As a matter of fact, he said<br />

many times that he preferred not to carry<br />

a gun… except for one well known situation,<br />

that is. The incident was reported<br />

in The Las Vegas Age as “Bloodless<br />

Scrap; Adam Kramer and Sam Gay Talk<br />

Politics with Rock and Gun.”<br />

It seems as though Big Sam and a<br />

local barber, Adam Kramer, were having<br />

a somewhat heated discussion<br />

based around politics. Sam invited<br />

Kramer to step behind his barber shop<br />

and continue the discussion. Kramer<br />

opined that Sam might be amenable to<br />

changing his mind if persuaded by an<br />

outside source - like a large rock upside<br />

Sam’s head. Sam rightfully determined<br />

that he really didn’t wish to be a recipient<br />

of such largess and elected<br />

to settle the argument by a display<br />

of one of Mr. Colt’s .44 caliber<br />

revolvers. Kramer wisely decided to<br />

return said rock to its resting place<br />

in the dirt.<br />

Though seldom wielding his firearm<br />

in the course of his work, it must be<br />

said that Sam did enjoy taking a large<br />

dose of his favorite drink, and then proceeding<br />

to shoot out street lights. One<br />

seriously drunken night Sam managed<br />

to lower the population of overhead<br />

lights on downtown Fremont Street by<br />

quite a respectable number. This show<br />

of, shall we say, “unadvised” behavior<br />

earned him a visit to the District Attorney.<br />

He did not plead, but informed the<br />

DA that “so long as I am sheriff of Clark<br />

County, I will no longer take a drink of<br />

intoxicating liquor. If I do, I will hand in<br />

my resignation.”<br />

He stuck it out as far as is known.<br />

However, in later years he said that Prohibition,<br />

made law in 1919, helped him<br />

out. “I quit drinking it after they started<br />

making it out of old shoes,” he said. Sam<br />

Gay lived until 1932 when a massive<br />

heart attack hit him and he died in Las<br />

Vegas Hospital.<br />

1930s<br />

And then came 1931 and Nevada<br />