SAIPEM offshore

SAIPEM OFFSHORE - Progressivemediagroup

SAIPEM OFFSHORE - Progressivemediagroup

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

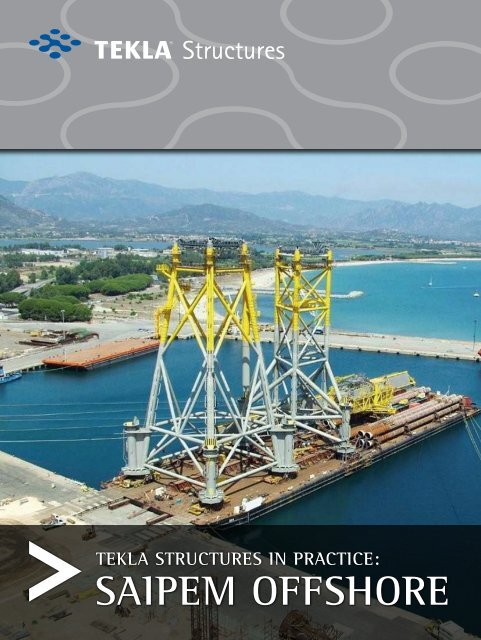

Tekla Structures in practice:<br />

<strong>SAIPEM</strong> <strong>offshore</strong>

At work with<br />

SAipem<br />

<strong>offshore</strong><br />

a In 2002 Saipem and Tekla joined on<br />

a technical project to get Saipem’s Offshore<br />

division started in using the Tekla Structures<br />

software. The technical team at Harpaceas<br />

(Tekla’s reseller in Italy) first worked with<br />

Saipem’s design teams in San Donato Milanese<br />

to determine the relevant technical issues<br />

in this critical design sector. They then<br />

cooperated directly with Tekla’s development<br />

teams to develop a customized application<br />

and also used their own development<br />

resources based in Italy. This process<br />

achieved defined results in a relatively short<br />

time, and today, the configuration of Tekla<br />

Structures used by Saipem includes a series<br />

of additional features created specifically to<br />

allow management of <strong>offshore</strong> design project.<br />

With Tekla’s open solution, Saipem was able<br />

to generate added value by exploiting its own<br />

design organization.

The Halfdan<br />

platform<br />

s Halfdan BB is an unmanned<br />

platform situated in the North<br />

Sea at a location where the<br />

depth reaches 50 m. The<br />

platform’s substructure consists<br />

of traditional tubular cable<br />

profiles which are welded together to form a tower lattice<br />

with three arms joined below to the foundation pylons.<br />

The deck is supported by the jacket’s three pillars which<br />

are spaced apart at a distance of 18 m. All of the technical<br />

equipment is situated on the deck along with the platform’s<br />

auxiliary services. The platform also supports a bridge to the<br />

other two platforms installed in the same area.<br />

The design of the deck structure was done with Tekla<br />

Structures right from the early stages of the project.<br />

Modeling began with the main steel structure as soon as<br />

the calculations were completed on the computer. The<br />

model encompassed all of the reinforcements and minor<br />

elements such as the connecting joints welded between the<br />

main beams. As soon as information about the equipment<br />

was available, the designers moved on successively to the<br />

secondary structures with all of the required detailing.<br />

The Tekla Structures model was used successfully for various<br />

purposes:<br />

- Continuous monitoring of the weight of the structure<br />

and the position of the deck structure’s center of gravity<br />

during the design phase<br />

- Output of 2D drawings to present to the end client and<br />

the relevant authorities for certification purposes<br />

- Output of lists of materials to obtain the necessary<br />

materials<br />

- Updating of the structure using the 3D model to identify<br />

and correct any conflicts with the equipment, piping,<br />

cables, access routes, etc.<br />

- Output of 2D drawings for developing the workshop<br />

designs used on the construction site

a “We believe that in the future, Tekla Structures<br />

will contribute to further boosting the efficiency<br />

of our work processes as well as the quality of<br />

the results that can be derived from the model.“<br />

– Giuseppe Frigerio, Engineer at Saipem<br />

The Awa-Paloukou<br />

platform<br />

s The Awa platform is a structure used to extract fuel oil<br />

with 12 slots. It is installed <strong>offshore</strong> from Congo at a depth<br />

of about 76 m. The jacket consists of a frame structure<br />

with four arms which are positioned over four preinstalled<br />

foundation pylons and securely attached to them. The deck<br />

is supported on the four arms of the jacket. Its total weight<br />

during operating conditions is about 3000 t. On the western<br />

side of the deck, a cantilever flare extends over about 60<br />

m. Tekla Structures was used to model the entire structure<br />

including the jacket, deck and flare. The 3D model of the<br />

entire platform was also used to characterize all of the other<br />

structural components, provide lists of needed materials,<br />

monitor the weight and the position of the center of gravity,<br />

and prepare the project plans and workshop detailing.

Why Saipem chose Tekla<br />

Structures<br />

Saipem’s Offshore division has now used Tekla Structures<br />

to design its platforms for two years. “Clearly, the most<br />

significant benefit is the availability of a single structural<br />

model from which we can extract project plans and<br />

detailing, lists of materials, weights and centers of gravity.<br />

The software also allows direct interfacing to the piping<br />

model in PDS,” noted engineer Giuseppe Frigerio, Engineer<br />

at Saipem.<br />

“The program was customized to handle our needs related<br />

to material management, construction phase management<br />

and integration with corporate standards (standard joint<br />

macros and customized user attributesand material lists).<br />

Another useful function provided by Tekla Structures is<br />

simultaneous access by multiple users to the same model.”<br />

“Modeling the design of an entire platform with small<br />

dimensions, such as Maamoura, required a single designer<br />

for the deck and another designer for the<br />

jacket. Without Tekla Structures, we would<br />

have definitely needed one more designer.”<br />

“However, the greatest benefit of using Tekla Structures<br />

lies in the ability to oversee the whole project since all of<br />

the information is encompassed in the model. This is also<br />

true of the execution of feasibility studies and initial steps,<br />

assessment and evaluation of weights and centers of gravity<br />

and the speed of verification of project variations over the<br />

course of the work.”<br />

“We believe that in the future, Tekla Structures will<br />

contribute to further boosting the efficiency of our work<br />

processes as well as the quality of the results that can be<br />

derived from the model,” concluded Frigerio.<br />

Saipem<br />

Crossing ocean and sea, Saipem’s <strong>offshore</strong><br />

activities division has built a global reputation<br />

as one of the true innovators in its field. Since<br />

the late 1950s, the company has continually<br />

updated and advanced its capabilities to<br />

anticipate the ever greater demands of the<br />

market. Saipem’s pioneering work in pipeline<br />

installation is matched by its experience<br />

installing <strong>offshore</strong> platforms around the world,<br />

mastering both the heavy lift and the floatover<br />

techniques.<br />

Over the last ten years, Saipem has<br />

completed some 120 <strong>offshore</strong> construction<br />

projects – including modular deck drilling<br />

and production platforms, integrated deck<br />

platforms, wellhead platforms, accommodation<br />

platforms, FPSOs – often, and increasingly<br />

so, in an integrated contractor role. Current<br />

potential of Saipem fabrication facilities<br />

exceeds an aggregate of 130,000 t per annum.

tekla structures –<br />

intelligent 3d modeling<br />

Tekla<br />

Tekla’s model-based software products make customers’ core<br />

processes more effective in building and construction and<br />

infrastructure management. Tekla Corporation has area offices<br />

and partner organizations worldwide. International operations<br />

account for nearly 85% of net sales. Founded in 1966, Tekla is<br />

one of the longest operating software companies in Finland.<br />

Tekla structures<br />

Tekla’s technology creates new business opportunities for the<br />

construction industry. The most advanced building information<br />

modeling (BIM) solution on the market includes an accurate,<br />

dynamic and data-rich 3-dimensional environment.<br />

The highly detailed ‘as-built’ digital structural models generated<br />

with Tekla Structures software enable effective visualization<br />

and management of the project. Effectively integrating model<br />

and non-model-based software solutions allows using the<br />

building information model in collaborative workflows. Tekla<br />

Structures users can streamline the design, fabrication, and<br />

construction processes, ultimately ensuring the highest level of<br />

constructability in project delivery.<br />

Tekla Structures encompasses specialized configurations for<br />

structural engineers, steel detailers and fabricators, concrete<br />

detailers and manufacturers, and construction companies.<br />

Find your local TEKLA contact at<br />

CONTACT:<br />

Tekla Corporation (HQ)<br />

Metsänpojankuja 1, P.O. Box 1<br />

FI-02131 Espoo, FINLAND<br />

Tel. +358 30 661 10<br />

Fax +358 30 661 1500<br />

Tekla is either a registered trademark or a trademark of Tekla Corporation in the United States and other countries.