Valspar Ultra Exterior Semi-Gloss Paint No 19910 – White

19910 Series Valspar Ultra Exterior SG Paint

19910 Series Valspar Ultra Exterior SG Paint

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

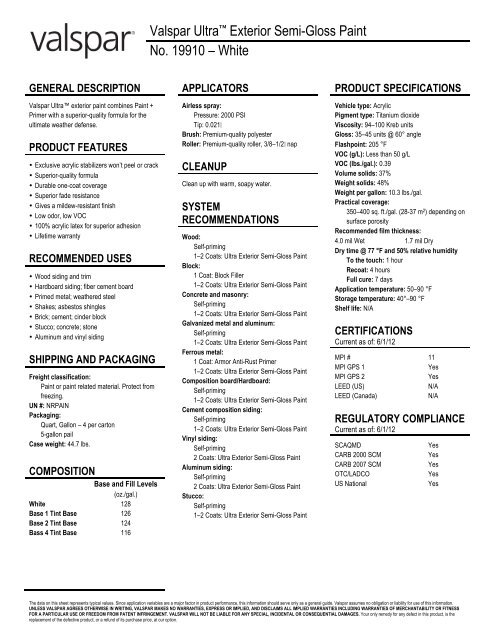

<strong>Valspar</strong> <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

<strong>No</strong>. <strong>19910</strong> <strong>–</strong> <strong>White</strong><br />

GENERAL DESCRIPTION<br />

<strong>Valspar</strong> <strong>Ultra</strong> exterior paint combines <strong>Paint</strong> +<br />

Primer with a superior-quality formula for the<br />

ultimate weather defense.<br />

PRODUCT FEATURES<br />

• Exclusive acrylic stabilizers won’t peel or crack<br />

• Superior-quality formula<br />

• Durable one-coat coverage<br />

• Superior fade resistance<br />

• Gives a mildew-resistant finish<br />

• Low odor, low VOC<br />

• 100% acrylic latex for superior adhesion<br />

• Lifetime warranty<br />

RECOMMENDED USES<br />

• Wood siding and trim<br />

• Hardboard siding; fiber cement board<br />

• Primed metal; weathered steel<br />

• Shakes; asbestos shingles<br />

• Brick; cement; cinder block<br />

• Stucco; concrete; stone<br />

• Aluminum and vinyl siding<br />

SHIPPING AND PACKAGING<br />

Freight classification:<br />

<strong>Paint</strong> or paint related material. Protect from<br />

freezing.<br />

UN #: NRPAIN<br />

Packaging:<br />

Quart, Gallon <strong>–</strong> 4 per carton<br />

5-gallon pail<br />

Case weight: 44.7 lbs.<br />

COMPOSITION<br />

Base and Fill Levels<br />

(oz./gal.)<br />

<strong>White</strong> 128<br />

Base 1 Tint Base 126<br />

Base 2 Tint Base 124<br />

Bass 4 Tint Base 116<br />

APPLICATORS<br />

Airless spray:<br />

Pressure: 2000 PSI<br />

Tip: 0.021<br />

Brush: Premium-quality polyester<br />

Roller: Premium-quality roller, 3/8<strong>–</strong>1/2 nap<br />

CLEANUP<br />

Clean up with warm, soapy water.<br />

SYSTEM<br />

RECOMMENDATIONS<br />

Wood:<br />

Self-priming<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Block:<br />

1 Coat: Block Filler<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Concrete and masonry:<br />

Self-priming<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Galvanized metal and aluminum:<br />

Self-priming<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Ferrous metal:<br />

1 Coat: Armor Anti-Rust Primer<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Composition board/Hardboard:<br />

Self-priming<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Cement composition siding:<br />

Self-priming<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Vinyl siding:<br />

Self-priming<br />

2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Aluminum siding:<br />

Self-priming<br />

2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

Stucco:<br />

Self-priming<br />

1<strong>–</strong>2 Coats: <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

PRODUCT SPECIFICATIONS<br />

Vehicle type: Acrylic<br />

Pigment type: Titanium dioxide<br />

Viscosity: 94<strong>–</strong>100 Kreb units<br />

<strong>Gloss</strong>: 35<strong>–</strong>45 units @ 60° angle<br />

Flashpoint: 205 °F<br />

VOC (g/L): Less than 50 g/L<br />

VOC (lbs./gal.): 0.39<br />

Volume solids: 37%<br />

Weight solids: 48%<br />

Weight per gallon: 10.3 lbs./gal.<br />

Practical coverage:<br />

350<strong>–</strong>400 sq. ft./gal. (28-37 m 2 ) depending on<br />

surface porosity<br />

Recommended film thickness:<br />

4.0 mil Wet 1.7 mil Dry<br />

Dry time @ 77 °F and 50% relative humidity<br />

To the touch: 1 hour<br />

Recoat: 4 hours<br />

Full cure: 7 days<br />

Application temperature: 50<strong>–</strong>90 °F<br />

Storage temperature: 40°<strong>–</strong>90 °F<br />

Shelf life: N/A<br />

CERTIFICATIONS<br />

Current as of: 6/1/12<br />

MPI # 11<br />

MPI GPS 1<br />

Yes<br />

MPI GPS 2<br />

Yes<br />

LEED (US)<br />

N/A<br />

LEED (Canada)<br />

N/A<br />

REGULATORY COMPLIANCE<br />

Current as of: 6/1/12<br />

SCAQMD<br />

CARB 2000 SCM<br />

CARB 2007 SCM<br />

OTC/LADCO<br />

US National<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

The data on this sheet represents typical values. Since application variables are a major factor in product performance, this information should serve only as a general guide. <strong>Valspar</strong> assumes no obligation or liability for use of this information.<br />

UNLESS VALSPAR AGREES OTHERWISE IN WRITING, VALSPAR MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND DISCLAIMS ALL IMPLIED WARRANTIES INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS<br />

FOR A PARTICULAR USE OR FREEDOM FROM PATENT INFRINGEMENT. VALSPAR WILL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. Your only remedy for any defect in this product, is the<br />

replacement of the defective product, or a refund of its purchase price, at our option.

<strong>Valspar</strong> <strong>Ultra</strong> <strong>Exterior</strong> <strong>Semi</strong>-<strong>Gloss</strong> <strong>Paint</strong><br />

<strong>No</strong>. <strong>19910</strong> <strong>–</strong> <strong>White</strong><br />

SURFACE PREPARATION<br />

Wood:<br />

Spot prime pine knots with bonding primer or<br />

exterior oil primer. Countersink nails and prime<br />

entire wood surface with exterior latex primer.<br />

Slight discoloration over cedar and redwood is<br />

typical. Apply a second coat of primer if<br />

discoloration is extreme. Caulk with acrylic caulk<br />

before top coating.<br />

Block:<br />

New masonry surfaces and mortar should be<br />

fully cured, usually 30 days. Remove any loose<br />

material or dust. Fill concrete block with acrylic<br />

block filler and allow to dry. Aged block should be<br />

powerwashed or scrubbed to remove loose<br />

concrete, laitance, efflorescence, mildew, dirt and<br />

dust. Allow surface to dry thoroughly.<br />

Concrete and masonry:<br />

New surfaces should be cured, usually 30 days.<br />

Remove all form release or curing agents.<br />

Surfaces should be free of loose material and<br />

dust.<br />

Mildew:<br />

Remove mildew or suspected mildew by<br />

scrubbing with a commercial mildew remover or<br />

a solution of 1 part liquid chlorine bleach to 3<br />

parts water. Allow solution to remain on surface<br />

for 10 minutes. Rinse thoroughly with water and<br />

allow surface to dry completely. Take precautions<br />

to avoid contact with skin or eyes.<br />

Galvanized metal and aluminum:<br />

Allow new galvanized metal to age 6 months or<br />

clean with mild muriatic solution. Metal should be<br />

free of oils and other contaminants.<br />

Ferrous metal (steel and iron):<br />

Hand or power-tool clean surfaces to remove oils<br />

and other contaminants, mill scale and rust.<br />

Prime with Armor Anti-Rust Primer.<br />

Composition board/Hardboard:<br />

Surface should be dry and free of dust,<br />

contaminants and wax bleed through. Prime<br />

entire surface and edges with exterior oil primer.<br />

Caulk with an acrylic caulk before top coating.<br />

SURFACE PREPARATION<br />

Cement composition siding:<br />

Surface should be dry and free of dust and<br />

contaminants. Prime entire surface and edges<br />

with exterior latex primer. Caulk with an acrylic<br />

caulk before top coating.<br />

Vinyl siding/Aluminum siding:<br />

Surface should be clean, dry and free of<br />

contaminants. Powerwash to remove chalk and<br />

mildew.<br />

Stucco:<br />

Powerwash or scrub surface, with appropriate<br />

cleaners, to remove loose material,<br />

efflorescence, chalk and mildew. New stucco<br />

should be allowed to cure and pH should be<br />

below 10.<br />

APPLICATION<br />

<strong>Paint</strong> only when air or surface temperatures are<br />

between 50 °F<strong>–</strong>90°F. Do not paint if<br />

temperatures are expected to be below 50 °F<br />

within 48 hours after application or when heavy<br />

dew or precipitation is expected in the next 12<br />

hours. Stir paint well and intermix containers of<br />

the same color. Start at the highest point of the<br />

house and work across. Always paint back into<br />

freshly painted areas and end up at a door,<br />

window or outer edge. Move windows after 1<br />

hour to prevent sticking.<br />

LEAD WARNING<br />

WARNING! If you scrape, sand or remove old<br />

paint, you may release lead dust. LEAD IS<br />

TOXIC. EXPOSURE TO LEAD DUST CAN<br />

CAUSE SERIOUS ILLNESS, SUCH AS BRAIN<br />

DAMAGE, ESPECIALLY IN CHILDREN.<br />

PREGNANT WOMEN SHOULD ALSO AVOID<br />

EXPOSURE. Wear a NIOSH-approved respirator<br />

to control lead exposure. Clean up carefully with<br />

a HEPA vacuum and a wet mop. Before you<br />

start, find out how to protect yourself and your<br />

family by contacting the National Lead<br />

Information Hotline at 1-800-424-LEAD or log on<br />

to www.epa.gov/lead.<br />

CAUTIONS<br />

WARNING! Contains Crystalline Silica. KEEP OUT<br />

OF THE REACH OF CHILDREN. May cause eye<br />

and skin irritation. USE ONLY WITH ADEQUATE<br />

VENTILATION. Avoid breathing vapors, spray mist<br />

or sanding dust. If painting indoors, open windows<br />

and doors or use other means to ensure fresh air<br />

entry during application and drying. If you<br />

experience eye watering, headache or dizziness, or<br />

if air monitoring demonstrates vapor/mist levels are<br />

above applicable limits, wear an appropriate,<br />

properly fitted respirator (NIOSH approved) during<br />

and after application. Follow respirator<br />

manufacturer’s directions for respirator use. When<br />

sanding, wear a dust mask. AVOID CONTACT<br />

WITH THE EYES AND SKIN. Wash thoroughly after<br />

use. Close container after each use. DO NOT TAKE<br />

INTERNALLY. Delayed effect from long-term<br />

exposure: Cancer Hazard. Contains crystalline<br />

silica, which can cause cancer. Risk depends upon<br />

duration and level of exposure to dust generated<br />

from sanding surfaces or spray mist. WARNING:<br />

This product contains a chemical known to the State<br />

of California to cause cancer. FIRST AID: EYE<br />

CONTACT: Flush thoroughly with water for at least<br />

15 minutes. If irritation persists, get medical<br />

attention.* IF INHALED: If affected by vapor or spray<br />

mist, move to fresh air. If breathing difficulty<br />

continues, get medical attention.* IF SWALLOWED:<br />

Drink 2 glasses of water. Get medical attention<br />

immediately.*<br />

*Call poison control center, hospital emergency<br />

room or physician immediately.<br />

CL 3.3<br />

For additional safety and chronic health hazard<br />

information, refer to the Material Safety Data<br />

Sheet for this product.<br />

EMERGENCY MEDICAL TELEPHONE:<br />

1-888-345-5732<br />

This product contains less than 50 g/L VOC<br />

1191 Wheeling Road, Wheeling, IL 60090<br />

1.888.313.5569<br />

valsparpaint.com<br />

Revised: 6/1/12<br />

Version: <strong>19910</strong>G<br />

The data on this sheet represents typical values. Since application variables are a major factor in product performance, this information should serve only as a general guide. <strong>Valspar</strong> assumes no obligation or liability for use of this information.<br />

UNLESS VALSPAR AGREES OTHERWISE IN WRITING, VALSPAR MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND DISCLAIMS ALL IMPLIED WARRANTIES INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS<br />

FOR A PARTICULAR USE OR FREEDOM FROM PATENT INFRINGEMENT. VALSPAR WILL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. Your only remedy for any defect in this product, is the<br />

replacement of the defective product, or a refund of its purchase price, at our option.