Gear Cutting Tools

Hobs - Torion

Hobs - Torion

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

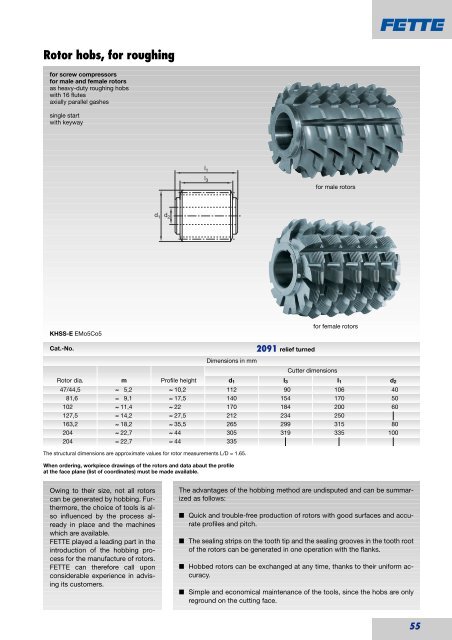

Rotor hobs, for roughing<br />

for screw compressors<br />

for male and female rotors<br />

as heavy-duty roughing hobs<br />

with 16 flutes<br />

axially parallel gashes<br />

single start<br />

with keyway<br />

l 1<br />

l 3<br />

for male rotors<br />

d 1 d 2<br />

KHSS-E EMo5Co5<br />

Cat.-No.<br />

2091 relief turned<br />

for female rotors<br />

Dimensions in mm<br />

Cutter dimensions<br />

Rotor dia. m Profile height d 1 I 3 I 1 d 2<br />

47/44,5 ≈ 5,2 ≈ 10,2 112 90 106 40<br />

81,6 ≈ 9,1 ≈ 17,5 140 154 170 50<br />

102 ≈ 11,4 ≈ 22 170 184 200 60<br />

127,5 ≈ 14,2 ≈ 27,5 212 234 250<br />

163,2 ≈ 18,2 ≈ 35,5 265 299 315 80<br />

204 ≈ 22,7 ≈ 44 305 319 335 100<br />

204 ≈ 22,7 ≈ 44 335<br />

The structural dimensions are approximate values for rotor measurements L/D = 1.65.<br />

When ordering, workpiece drawings of the rotors and data abaut the profile<br />

at the face plane (list of coordinates) must be made available.<br />

Owing to their size, not all rotors<br />

can be generated by hobbing. Furthermore,<br />

the choice of tools is also<br />

influenced by the process already<br />

in place and the machines<br />

which are available.<br />

FETTE played a leading part in the<br />

introduction of the hobbing process<br />

for the manufacture of rotors.<br />

FETTE can therefore call upon<br />

considerable experience in advising<br />

its customers.<br />

The advantages of the hobbing method are undisputed and can be summarized<br />

as follows:<br />

■ Quick and trouble-free production of rotors with good surfaces and accurate<br />

profiles and pitch.<br />

■ The sealing strips on the tooth tip and the sealing grooves in the tooth root<br />

of the rotors can be generated in one operation with the flanks.<br />

■ Hobbed rotors can be exchanged at any time, thanks to their uniform accuracy.<br />

■ Simple and economical maintenance of the tools, since the hobs are only<br />

reground on the cutting face.<br />

55